Numerical methods were developed long before the advent of computers and were intended to solve problems in mechanics. Initially, calculations were carried out manually; the algorithms of the methods were well debugged and optimized. Further steps towards automation of modeling were associated with the development of computer-aided design (CAD) systems and computer experiment automation systems - application software packages. Standard calculations and presentation of experimental results were subject to automation. These systems were created for a specific subject area, primarily in high-tech industries (space, aviation). To create most application packages for numerical calculations, the Fortran language was used, which is well suited for these purposes. When using a computer-aided modeling system, the researcher formulates a mathematical model of the system under study in a formal input modeling language. The following factors can be noted that contribute to the implementation of automated modeling systems: 1. the complexity of obtaining a mathematical model of complex technical objects; 2. it is necessary to have several models for one object, differing in complexity; 3. the ability to quickly make changes to the model, which is easiest based on the use of graphic languages for specifying the initial information. ____ Modern professional CAMs have the following distinctive features: support for hierarchical design, both top-down and bottom-up, through the implementation of multi-level modeling and the method of local detailing of the model; component modeling based on the use of libraries containing a large number of graphic and functional descriptions of components, and these libraries are open to adding new descriptions to them that the user himself can make; graphical user interface, automatic generation of a model of the entire circuit according to its structural description; availability of an interactive design work environment; the presence of modeling postprocessors in modern CAD and CAM systems, which allows not only viewing modeling results in a convenient form, but also processing these results; the presence of built-in tools for numerical simulation of the workflow in real time or in model time scaling mode; operability with other packages of similar purpose; the possibility of interactive intervention in the course of modeling; possibility of using 2D and 3D animation.

2. Architecture of automated modeling programs. Graphical interface. GUI tasks.

Existing automated modeling tools may belong to different subject areas and differ significantly in their capabilities, but their modular structures differ little from each other. A graphical interface is now a standard component of modern CAM. It creates an interface between the user and the program and makes it possible to operate with graphic images instead of analytical expressions. This makes working in CAM easier and reduces the likelihood of errors when entering information about the system.

The form of graphical representation of information about the simulated system can be; operator-structural diagrams adopted at TAU; functional and schematic diagrams of various physical devices; kinematic diagrams of mechanisms; signal graphs; connection graphs; flowcharts of algorithms and other graphical models. The tasks of the graphical interface are: monitoring compliance with certain rules in the process of creating a graphic image on the monitor screen; converting information about the circuit into commands for the modeling program (simulator); control over the modeling process, visualization of modeling results.

Software tools for automation of design, modeling and design

1. CAD application packages

2. SCADA systems

3. Genie Data Acquisition and Control Application Development Environment

1. CAD application packages

CAD is a recognized field of application of computer technology. The computer can provide designers and technologists with a full range of CAD capabilities and, freeing them from routine work, give them the opportunity to engage in creativity, which dramatically increases productivity.

Bringing CAD closer to the designer has made it possible to dramatically increase the productivity of CAD systems themselves, the spread of which was hampered by the difficulty of algorithmizing design tasks. Indeed, it is impossible to “assign” a programmer to each designer. This contradiction can be eliminated only by the widespread use of application software that “communicates” with the designer in a “natural” language. It should be noted that this is not only true for computer graphics. Almost all modern software focuses on the user, communicating with him in a friendly way that he understands and giving him complete freedom of action. Such “communication” between a person and a computer is possible only in an interactive (dialogue) mode, when the user immediately sees the result of his actions on the screen. CAD systems are also focused on working in an interactive mode, providing the designer with quick access to graphic information, a simple and effective language for controlling its processing with almost unlimited possibilities for controlling the results. First of all, this applies to graphic dialogue, since it is graphics (drawings, diagrams, diagrams, etc.), as the most effective way of presenting information, that occupies a privileged position in CAD. Thus, it is possible to automate the most labor-intensive part of the work - according to specialists from design bureaus, in the process of traditional design, the development and execution of drawings accounts for about 70% of the total labor costs of design work (15% for organizing and maintaining archives, and 15% for the actual design, including design development, calculations, coordination with related areas, etc.).

Many modern software systems focused on the design of industrial products have a fairly large arsenal of interactive graphics capabilities, providing the ability to create and edit two-dimensional images consisting of product projections, shading, dimensions, etc., as well as the formation of realistic three-dimensional images of designed products, constructed from the original drawing data with the removal of invisible lines, taking into account various lighting methods, setting surface structure parameters, etc. At the same time, CAD systems provide previously unattainable capabilities. In fact, the designer finds himself in a new environment - the environment of computer graphics. And the quality of a CAD package is almost primarily determined by how difficult it is for a designer to transition to a new technology when using a particular package.

Currently, there is a huge number of CAD systems of varying complexity and purpose. Obviously, the user will select a system by balancing the need for graphics capabilities with the cost of the system and hardware that has the required capabilities. For example, the cost of an Apollo workstation or SAN, which has all the capabilities imaginable today, is significantly higher than the cost of any conventional PC - it’s just a different class of machines. Most drafting and design work requires more modest, but still quite broad capabilities, and a number of systems can satisfy them.

Among small and medium-class systems in the world, the most popular is the AutoCad system from AutoDesk, as well as the Pcad, OrCAD systems (development and modeling of electronic devices, mainly printed circuit boards), ArchiCAD (architecture), Basis, Compass, SolidWorks "(mechanics), each of which has its own advantages and disadvantages and preferred area of application.

AutoDesk is one of the recognized leaders in the field of CAD development, and the AutoCad package it created is one of the best. This is a complex and branched system in its structure, which at the same time is easily controlled using simple and clear commands. This system gives the PC user capabilities previously available only on large and expensive computing systems. AutoCad has an effective system of dialogue with the user using several menus. The use of layers also provides additional convenience for the designer, allowing, when overlaying layers with images of individual parts drawn on them, to control their compatibility in the overall layout, as well as to keep “in reserve” any number of different parts options and, by turning layers on or off, selectively enter them into general layout. Completed drawings can be stored as a set of slides with the ability to automatically view them, and the availability of a large number of colors makes working with such a system aesthetically pleasing.

AutoCad is a universal graphics package designed for any specialist working with technical graphics. AutoDesk, focusing on the widest range of users, has included in the package rich adaptation capabilities to any subject area. That is why AutoCad has gained wide popularity and continues to maintain its position in the global market.

In addition to automating the actual drawing and graphic work, AutoCad with its extensions (AutoShade, AutoFlix, 3D-STUDIO, etc.) provides the following capabilities:

* graphical modeling, i.e. using a computer in CAD as a powerful computing tool that allows you to work with complex spatial models without special programming skills;

* creation and maintenance of an information database (archive) of drawings;

* creating a library of standard drawing elements related to a certain subject area in order to build new drawings from previously created elements;

* parameterization of drawings - construction of parts and drawings with new dimensions based on a once-drawn drawing (model);

* creation of demonstration illustrations and cartoons.

AutoDesk has been improving its system for several years - currently there are several versions that differ in their functionality. All of them are compatible from the bottom up, i.e. drawings created in earlier versions are processed in later versions. The most widely used versions now are from 10 to 14. Latest version of AutoCAD 2000.

KOMPAS 5 is a modern software product running under the Windows 95/98/NT operating system.

The system has a customizable window interface that complies with Windows standards and is controlled using text menu commands, button panels, and context-sensitive (dynamic) menus. The screen design, the composition of the button panels and any system parameters can be configured directly during the work session. The user can create his own button panels, including connecting functions of application libraries as commands.

Simultaneous work with several documents is supported, as well as displaying each document in several windows. Various backup modes for downloaded documents have been implemented.

Printing of developed documents can be performed on any devices (printers or plotters) supported by Windows. Realistic image of documents in preview mode allows you to arrange several documents on the output field and print simultaneously. Flexible configuration of all printing parameters is provided. The system includes a utility for developing your own drivers for pen output devices (plotters).

KOMPAS 5 supports OLE technology, which allows you to insert KOMPAS documents into any document that is an OLE container (for example, into a MS Word document). The OLE object created in this way can later be viewed using KOMPAS-Viewer or edited using KOMPAS. If the connection to the source is preserved when inserting an OLE object, then all changes made to the source will be reflected in the container document.

The main components of KOMPAS 5 are KOMPAS-GRAFIC - a design documentation editor and KOMPAS-3D - a three-dimensional solid modeling system.

The graphic editor allows you to develop and produce various documents - sketches, drawings, diagrams, posters, etc. The system provides two types of graphic documents - drawings and fragments. The drawing has a frame and a main inscription; in it you can create up to 255 views (projections, sections, sections) with different image scales. Specifications, technical requirements, and a sign of unspecified roughness can be placed on the drawing sheet. The fragment contains a full-size image without design elements (frames, technical requirements, etc.).

Any drawing view or fragment can contain up to 255 layers, each of which can be made current or uneditable or invisible.

Fig.1. COMPASS screen form.

KOMPAS-GRAPHIC allows you to work with all types of graphic primitives necessary to perform any construction. These include points, straight lines, segments, circles, ellipses, arcs of circles and ellipses, polygons, polylines, NURBS curves (including Bezier curves). Various methods and modes for constructing these primitives (for example, commands for creating chamfers, fillets, equidistant lines, constructing segments and circles, tangents to objects, etc.) relieve the user of the need to make complex auxiliary constructions. To speed up construction, you can use local coordinate systems, a multi-scale grid, and an object snap mechanism.

Lecture 7. Automated modeling systems

The complexity of modern objects, containing hundreds of thousands and sometimes millions of components, makes their design using traditional (manual) methods with the obligatory production of a model almost impossible.

It is for this reason that the interest of electronic equipment developers in computer-aided design systems and the modeling subsystems included in them has sharply increased.

This can be judged by the amount of funds invested in their development, which, according to foreign estimates, exceeds the annual turnover of such a monster as Intel.

In recent years, even the most conservative hardware developers have been forced to reconsider their attitude towards CAD as large and expensive “toys”, having discovered very powerful and effective tools in them. Particularly attractive is the opportunity to finally replace the current layout with a simulation model, and full-scale experiments with model ones. Previously, they were stopped by the lack of reliability of simulation experiments, but now everything seems to be in order.

CAD and its integral part AFM can now do a lot. They allow you to check not only the correct operation of the designed device, but also to find out its main characteristics, starting from the very first steps, when only the architectural solutions of the future project are being worked out.

Modern AFM electronic equipment allows:

§ check the correct operation of the designed device;

§ find out its time delays and monitor compliance with the required timing relationships in the circuit;

§ carry out modeling taking into account permissible loads on output contacts;

§ check the permissible power dissipation on each component;

In other words, modern SMs make it possible to take into account such “little things” in a project, because of which the “correct” scheme for some reason refuses to work in real conditions and in a real environment.

Modern professional management systems have the following distinctive features:

§ graphical user interface that allows you to “draw” the designed circuit and timing diagrams at its inputs on the monitor screen;

§ interactive working design environment - a control shell, that is, a special program from which you can run all or most of the other programs in the package without resorting to the services of a standard operating system (for example, PCADSHL.EXE in the PCAD package);

§ modern management systems support hierarchical design both top-down and bottom-up;

§ multi-level modeling and the method of local detailing of the project, inextricably linked with hierarchical design;

§ multi-bit contacts and buses, allowing the upper levels of the hierarchy to very succinctly describe the project and immediately determine its functionality;

§ the presence of simulation postprocessors in modern CAD and AFM allows not only viewing simulation results in a user-friendly form, but also processing these results, searching for the necessary events or states in the circuit, measuring time intervals, and monitoring compliance with timing relationships in the circuit;

§ modern management systems support the library design method, that is, they contain a huge number of graphic and functional descriptions of components; Moreover, these libraries are open to adding new descriptions to them, which the user himself can do;

§ in modern SM, an event mechanism for advancing model time is implemented, based on the dz principle; this means that model time advances based on the nearest event, and not on the next tick;

§ modeling is performed taking into account real time delays associated with the propagation of signals inside components; in this case, not only average delays can be taken into account, but also their maximum values, as well as the worst case with their spread;

§ automatic generation of a model of the entire circuit based on its structural description;

For this purpose, a structural model of the object is constructed as a combination of behavioral models of the structural primitives that make up the object. An attractive aspect of the library design method is that structural primitives can belong to different hierarchical levels. This significantly improves the efficiency of modeling.

It is clear that behavioral models must very accurately reflect the temporal parameters of the primitive. Modern SMs allow the construction of such models. This explains the great attention paid to the most promising CAD and MS systems, such as PCAD, PSPICE (DesignLab), OrCAD, Active HDL and the modeling languages PML, VERILOG and VHDL.

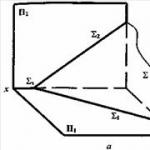

The typical composition of a professional modeling system (Fig. 3) includes graphic or text object description language (NOO), with the help of which the user enters a simulated circuit into the system. For event modeling, the description of an object is usually presented in tabular form or automatically converted into it from the original graphical representation (into the so-called linked list).

The design of the circuit is carried out using basic structural primitives, the graphic and functional descriptions of which are contained in the corresponding libraries.

Translator of nuclear weapons (in PCAD, for example, this is the PC-NODES program) converts the original description of the project into a format suitable for modeling. The simulation is performed by a special program called simulation control program or briefly modeler (in PCAD such a program is called PC-LOGS). The following functions are usually assigned to the modeler:

§ initial initialization of the simulated circuit;

§ setting timing diagrams at the inputs of the circuit (note that this function is sometimes performed by another program called the input signal editor.);

§ promotion of model time according to the Dt or dz principle, and when modeling mixed (analog-digital) circuits, both principles are used simultaneously (Lecture 6);

§ automatic or step-by-step implementation of model experiments planned by the user;

§ maintaining a dialogue with the user (queries, diagnostic messages, errors);

§ accumulation and recording of simulation results and their presentation in the desired form (usually in the form of time diagrams or tables).

To set the timing diagrams of input signals, the SM usually has a special program that allows you to draw or edit input test sets in graphical or text form. It is called the input signal editor, for example in the DesignLab package it is the Stimulus Editor - a stimulus editor that allows you to draw diagrams of external influences with the mouse.

To output, monitor and process simulation results, another program is used, called a simulation postprocessor (in PCAD it is called POSTSIM). Often additional programs are combined under a common name: modeling tools . This may include some other programs, such as a hierarchy manager, a project manager, an electrical circuit control program, a librarian, behavioral model debuggers, automatic macromodel generation programs, software logic analyzers, etc.

Modern industrial management systems also have tools for designing behavioral models, including logic modeling languages (YALM) and corresponding YALM compilers .

Information about the project is stored in MS databases, which are divided into reference and working. The SM control shell makes calls to the necessary programs and makes working with the system convenient for the user.

Thus, it can be stated that AFM combines the means for:

§ interactive input of the structural diagram of the object being designed or studied;

§ automatic construction (generation) of its model;

§ interactive input of timing diagrams of input signals, including directly in graphical form;

§ automatically conducting simulation experiments with the constructed model;

§ automated or interactive processing of modeling results.

One of the weakest aspects of modeling is the inability to simulate the operation of an object in real time, that is, to maintain the pace at which processes occur in the simulated object. The above applies, first of all, to computing systems with their crazy operating speeds. For example, to simulate the functioning of the MP8086 microprocessor on a time interval of 100 ns, one second of computer processor time with a speed of 1 MIPS is required.

The ratio of the named times is called modeling efficiency and for this example the value is:

The low efficiency of modeling is largely due to the inability to adequately simulate parallel processes on single-processor computer systems. Such processes have to be modeled quasi-parallel (Lecture 6), processing simultaneous events one after another while the model time is stopped (frozen).

This time remains fixed until all simultaneous (multiple) events tied to the current point in time are processed. After this, model time comes to life again and begins to move further in steps of equal length (the Dt principle - clockwise simulation ) or jumping in uneven leaps from the current event to the near future (dz principle - event modeling ).

To increase the efficiency of modeling, the following methods are used:

n high-level modeling;

n multiprocessor computers;

n event mechanism for advancing model time;

n multilevel modeling;

n method of local detailing of the project;

n network modeling;

n compilative modeling method (instead of interpretive);

n hardware simulation accelerators.

The methods listed above for increasing the efficiency of modeling indicate that AFM can be not only a software, but also a hardware-software complex. In the latter case, in addition to the software package, it also includes specialized equipment, in particular, multiprocessor computing installations and/or hardware simulation accelerators.

Such accelerators are also used in other tasks, for example, graphics accelerators are installed on video cards or specialized arithmetic coprocessors, which until recently were mounted on PC motherboards to speed up floating point operations.

Brief overview of modern CAD and AFM

In this review we will not touch on CAD and AFM, aimed at “large machines”. Let's consider only systems installed on personal computers.

It is no coincidence that we are starting our review with this package. PCAD is one of the first (if not the first) end-to-end computer-aided design systems to appear on the CAD systems market. The word “end-to-end” means that such a system allows you to automate all stages of hardware design, from creating and checking the correctness of the developed circuit to laying out the printed circuit board and creating control information for the executive equipment.

The package inherited its name Personal Computer Aided Design (PCAD for short) from the name of the company that developed it - Personal CAD Systems. For a long time, PCAD remained a leader in the class of similar software products, and if it were not for the frequent change of owner, then perhaps even now it would not have lost its leading position.

But fate decided otherwise. The first versions of this product 1.0, 2.0 and 3.0, created by the named company in 1985 - 1987, did not receive noticeable attention in our country.

In 1988, the rights to PCAD were acquired by the CADAM Company, which released version PCAD 4.5, which then gained great popularity in the Soviet Union. It was Russified, extensive libraries of graphic descriptions of domestic components were created for it, and, most importantly, the problems of access to domestic technological equipment - photo plotters and automatic drilling machines - were solved for it.

Thanks to these achievements, PCAD 4.5 is still used in Russian electronics industry enterprises.

In 1992, PCAD changed its owner again, now it was owned by ALTIUM, which decided on serious innovations. It released PCAD 6.0, which introduced floating point arithmetic. Thanks to this, the resolution of graphic editors increased by two orders of magnitude, and many problems associated with the layout of printed circuit boards were eliminated.

ALTIUM made a difficult decision. She decided to change the formats of graphics libraries and moved from 16- to 32-bit data description formats. In order not to lose all the libraries of graphic descriptions created for earlier versions, the company developed a special program that converts old libraries into the new format.

However, neither this nor the subsequent DOS versions of PCAD (PCAD 7.0, PCAD 8.0, PCAD 8.5) won much love from domestic hardware developers. The old love for PCAD 4.5 turned out to be stronger than the new features.

It is necessary to mention one more feature of later versions of PCAD. The modeling subsystem was removed from them, and the package ceased to be an end-to-end CAD system.

In recent years (more precisely, since 1995), the owner of the PCAD package is ACCEL Technologies, which stopped the rather boring line of DOS versions of this product and switched to the Windows application platform.

Her latest brainchild ACCEL EDA 14.0, even in the name itself, does not reflect the connection with the former PCAD. However, the new product retains the ideology of earlier versions of PCAD, so that hardware developers do not have to relearn.

ACCEL Technologies has made another attempt to regain its so absurdly lost position as a leader in the field of CAD systems for personal computers. In any case, having created a hot connection with the Dr. modeling system. Spice 2000 A/D 8.2 from Deutsch Research has restored ACCEL EDA 14.0 to its former status as an end-to-end design system.

It must be said that ACCEL Technologies has made the use of “foreign” programs a strategic line of its behavior. Likewise, she connected Cadence's SPECCTRA 7.1 auto-placement and auto-routing software to her system. This is one of the most powerful and efficient programs using the latest meshless PCB routing algorithms.

PSpice (Design Center, DesignLab)

The abbreviation PSpice stands for: Simulation Program with Integrated Circuit Emphasis (simulation program with an emphasis on integrated circuits).

Unlike PCAD, this CAD system remained faithful to its owner. It all started with development in the late 1970s at the University of California

(Berkeley) circuit modeling program SPICE 2. Its input circuit description language turned out to be so successful that it determined the unofficial standard for describing electronic equipment for many years to come.

The formats and models adopted in it are now used in many programs for similar purposes, and circuit netlists in SPICE format are used in many modern packages, for example, Micro-Cap, Dr. Spice, OrCAD, ACCEL EDA, ViewLogic and many others.

The abbreviation PSpice stands for: Simulation Program with Integrated Circuit Emphasis.

The first version of the PSpice program on the PC platform was created in 1984 by MicroSim Corporation. This and subsequent versions use the same algorithms as SPICE, the same format for representing input and output data. Note that the first version of PSpice simulated only analog circuits.

In 1989, PSpice 4.0 was released, allowing the simulation of mixed analog-digital circuits. The following year, the fifth version of this program appeared. It, unlike all previous versions, allowed you to enter a diagram not only in text, but also in graphical form. In addition, MicroSim has released a version that runs in Windows.

Since 1994, based on the developed modeling programs, MicroSim began to produce CAD Design Center (versions 6.0, 6.1, 6.2, 6.3), which additionally included technical design programs, in particular, the SPECCTRA autorouter already known to us.

In 1996, there was another change in the name of the system. The new version 7.1 is called DesignLab. In 1997, the latest version appeared under this name, DesignLab 8. We say “last” because after its release, MicroSim Corporation merged with another monster in the field of CAD product development - OrCAD. The merged company was named OrCAD, but the MicroSim trademark was retained. The established company has already announced the development of a new CAD system - OrCAD 9.0.

Let us immediately note that VHDL is not CAD or AFM, but a hardware description language, which is currently supported by many modeling systems, such as GMVHDL, Active HDL, Accolade Peak VHDL, OrCAD, etc. The history of the appearance and development of this language in many relations is indicative.

The VHDL language did not appear out of nowhere. You can give a fairly long list of languages for describing and modeling digital devices, for example FOROS, OSS-2, DDL, HSL, etc., which seemed to be intended for the same purposes. However, they all suffered from one drawback - while modeling the function of an object, they did not have developed means for describing and controlling timing relationships in digital equipment (DA).

This was especially acute during the development of ultra-high-speed integrated circuits (VHSIC - Very High Speed Integrated Circuits). The circuit operates correctly at moderate frequencies. But at high synchronization frequencies, failures appear and the performance of the control center is impaired. It was not possible to detect these limiting frequencies for the equipment by modeling in the languages that still exist.

The US Military Department, which financed the VHSIC program for the development of ultra-high-speed ICs, decided to sponsor the development of such a language in 1983. It was called VHDL (Vhsic Hardware Description Language) - a hardware description language based on ultra-high-speed integrated circuits.

The development of VHDL was supported by the Institute of Electrical and Electronics Engineers (IEEE), and in late 1987 the language was adopted as a standard (IEEE Standard 1076).

The final edition of the VHDL language (1993) included proposals and recommendations from many well-known specialists in the field of computer technology and leading companies involved in the development of CAD electronic equipment. Therefore, VHDL can be said to reflect a general consensus about what characteristics an effective standard hardware description language should have.

The VHDL language has a developed general algorithmic base, borrowed from the PASCAL programming language. It contains carefully developed constructs for behavioral (functional) and structural representation, as well as tools for documenting designs.

High-level descriptions can be combined with low-level circuit diagrams. In other words, it is a multi-level language that supports hierarchical design.

The language has tools for describing processes occurring over time and for specifying time delays on elements. With its help, you can describe the timing diagrams at the inputs of the simulated circuit and the interactions between individual devices via the system bus.

The US Department of Defense has obliged its IC suppliers to provide VHDL models and VHDL vectors testing them as part of the documentation for new products.

Interest in the VHDL language is enormous. The VHDL Users Group has been created in the USA, and the VHDL FORUM group has been created in Europe, which are involved in the implementation of this language. A similar association also existed in the former USSR.

With the introduction of VHDL, hardware designers can “experiment” digital hardware design ideas at the architectural level on their computers and immediately see the results of their experiments.

They no longer have to wait until their designs are detailed down to the logic gate level to be able to evaluate their ideas in practice. They will no longer have to wait until it is too late to go back to make fundamental changes to the overall project architecture without a huge loss of time and money. Now introducing even major changes to the project will have a small impact on its cost and production preparation time.

Unlike other hardware description and modeling languages, VHDL does not impose a specific design method on the developer. He is free to choose any design method using both behavioral and structural representations of components, either bottom-up or top-down design, or a combination of them.

The VHDL language allows you to first create an abstract description of functions, and then (as the project progresses) to carry out their detailing, up to the moment when structural solutions for them become clear. Other languages cannot boast such wide capabilities.

Simulation systems that support VHDL typically include a VHDL compiler, a source code debugger, and an interactive digital simulation engine. Some ACMs additionally include a circuit editor or are integrated with other CAD systems that have such an editor. For example, you can create a circuit diagram in the OrCAD package and a special program converts the graphic description into VHDL code.

One of the most modern modeling systems in the VHDL language, developed by ALDEC Corporation, is called Active HDL 3.6. For an initial acquaintance with the VHDL language, we can recommend the “toy” AFM created by Green Mountain Computing Systems. It's called GMVHDL, runs under DOS and takes up only about 1Mb of disk memory.

Box 1

A modeling system is a set of language and software tools that includes... (see System modeling technology, p. 332).

Occurred to happen, to happen

To connect a new graphic library (symbol library) to the circuit editor, activate the command Options -> Editor Configuration

To connect libraries with mathematical (functional) models to the control shell (circuit editor), activate the Analysis -> Library and Include Files command

1. CAD application packages

2. SCADA systems

3. Genie Data Acquisition and Control Application Development Environment

1. CAD application packages

CAD is a recognized field of application of computer technology. The computer can provide designers and technologists with a full range of CAD capabilities and, freeing them from routine work, give them the opportunity to engage in creativity, which dramatically increases productivity.

Bringing CAD closer to the designer has made it possible to dramatically increase the productivity of CAD systems themselves, the spread of which was hampered by the difficulty of algorithmizing design tasks. Indeed, it is impossible to “assign” a programmer to each designer. This contradiction can be eliminated only by the widespread use of application software that “communicates” with the designer in a “natural” language. It should be noted that this is not only true for computer graphics. Almost all modern software focuses on the user, communicating with him in a friendly way that he understands and giving him complete freedom of action. Such “communication” between a person and a computer is possible only in an interactive (dialogue) mode, when the user immediately sees the result of his actions on the screen. CAD systems are also focused on working in an interactive mode, providing the designer with quick access to graphic information, a simple and effective language for controlling its processing with almost unlimited possibilities for controlling the results. First of all, this applies to graphic dialogue, since it is graphics (drawings, diagrams, diagrams, etc.), as the most effective way of presenting information, that occupies a privileged position in CAD. Thus, it is possible to automate the most labor-intensive part of the work - according to specialists from design bureaus, in the process of traditional design, the development and execution of drawings accounts for about 70% of the total labor costs of design work (15% for organizing and maintaining archives, and 15% for the actual design, including design development, calculations, coordination with related areas, etc.).

Many modern software systems focused on the design of industrial products have a fairly large arsenal of interactive graphics capabilities, providing the ability to create and edit two-dimensional images consisting of product projections, shading, dimensions, etc., as well as the formation of realistic three-dimensional images of designed products, constructed from the original drawing data with the removal of invisible lines, taking into account various lighting methods, setting surface structure parameters, etc. At the same time, CAD systems provide previously unattainable capabilities. In fact, the designer finds himself in a new environment - the environment of computer graphics. And the quality of a CAD package is almost primarily determined by how difficult it is for a designer to transition to a new technology when using a particular package.

Currently, there is a huge number of CAD systems of varying complexity and purpose. Obviously, the user will select a system by balancing the need for graphics capabilities with the cost of the system and hardware that has the required capabilities. For example, the cost of an Apollo workstation or SAN, which has all the capabilities imaginable today, is significantly higher than the cost of any conventional PC - it’s just a different class of machines. Most drafting and design work requires more modest, but still quite broad capabilities, and a number of systems can satisfy them.

Among small and medium-class systems in the world, the most popular is the AutoCad system from AutoDesk, as well as the Pcad, OrCAD systems (development and modeling of electronic devices, mainly printed circuit boards), ArchiCAD (architecture), Basis, Compass, SolidWorks "(mechanics), each of which has its own advantages and disadvantages and preferred area of application.

AutoDesk is one of the recognized leaders in the field of CAD development, and the AutoCad package it created is one of the best. This is a complex and branched system in its structure, which at the same time is easily controlled using simple and clear commands. This system gives the PC user capabilities previously available only on large and expensive computing systems. AutoCad has an effective system of dialogue with the user using several menus. The use of layers also provides additional convenience for the designer, allowing, when overlaying layers with images of individual parts drawn on them, to control their compatibility in the overall layout, as well as to keep “in reserve” any number of different parts options and, by turning layers on or off, selectively enter them into general layout. Completed drawings can be stored as a set of slides with the ability to automatically view them, and the availability of a large number of colors makes working with such a system aesthetically pleasing.

AutoCad is a universal graphics package designed for any specialist working with technical graphics. AutoDesk, focusing on the widest range of users, has included in the package rich adaptation capabilities to any subject area. That is why AutoCad has gained wide popularity and continues to maintain its position in the global market.

In addition to automating the actual drawing and graphic work, AutoCad with its extensions (AutoShade, AutoFlix, 3D-STUDIO, etc.) provides the following capabilities:

graphical modeling, i.e. using a computer in CAD as a powerful computing tool that allows you to work with complex spatial models without special programming skills;

creation and maintenance of an information database (archive) of drawings;

creating a library of standard drawing elements related to a certain subject area in order to build new drawings from previously created elements;

parameterization of drawings - construction of parts and drawings with new dimensions based on a once-drawn drawing (model);

creation of demonstration illustrations and cartoons.

AutoDesk has been improving its system for several years - currently there are several versions that differ in their functionality. All of them are compatible from the bottom up, i.e. drawings created in earlier versions are processed in later versions. The most widely used versions now are from 10 to 14. Latest version of AutoCAD 2000.

KOMPAS 5 is a modern software product running under the Windows 95/98/NT operating system.

The system has a customizable window interface that complies with Windows standards and is controlled using text menu commands, button panels, and context-sensitive (dynamic) menus. The screen design, the composition of the button panels and any system parameters can be configured directly during the work session. The user can create his own button panels, including connecting functions of application libraries as commands.

Simultaneous work with several documents is supported, as well as displaying each document in several windows. Various backup modes for downloaded documents have been implemented.

Printing of developed documents can be performed on any devices (printers or plotters) supported by Windows. Realistic image of documents in preview mode allows you to arrange several documents on the output field and print simultaneously. Flexible configuration of all printing parameters is provided. The system includes a utility for developing your own drivers for pen output devices (plotters).

KOMPAS 5 supports OLE technology, which allows you to insert KOMPAS documents into any document that is an OLE container (for example, into a MS Word document). The OLE object created in this way can later be viewed using KOMPAS-Viewer or edited using KOMPAS. If the connection to the source is preserved when inserting an OLE object, then all changes made to the source will be reflected in the container document.

The main components of KOMPAS 5 are KOMPAS-GRAFIC - a design documentation editor and KOMPAS-3D - a three-dimensional solid modeling system.

The graphic editor allows you to develop and produce various documents - sketches, drawings, diagrams, posters, etc. The system provides two types of graphic documents - drawings and fragments. The drawing has a frame and a main inscription; in it you can create up to 255 views (projections, sections, sections) with different image scales. Specifications, technical requirements, and a sign of unspecified roughness can be placed on the drawing sheet. The fragment contains a full-size image without design elements (frames, technical requirements, etc.).

Any drawing view or fragment can contain up to 255 layers, each of which can be made current or uneditable or invisible.

Fig.1. COMPASS screen form.

KOMPAS-GRAPHIC allows you to work with all types of graphic primitives necessary to perform any construction. These include points, straight lines, segments, circles, ellipses, arcs of circles and ellipses, polygons, polylines, NURBS curves (including Bezier curves). Various methods and modes for constructing these primitives (for example, commands for creating chamfers, fillets, equidistant lines, constructing segments and circles, tangents to objects, etc.) relieve the user of the need to make complex auxiliary constructions. To speed up construction, you can use local coordinate systems, a multi-scale grid, and an object snap mechanism.

One of the greatest strengths of KOMPAS-GRAFIC is still its full support for ESKD. Standard (corresponding to ESKD) and custom line and hatch styles are supported. All types of linear, angular, radial and diametrical dimensions are implemented (including inclined dimensions, height dimensions and arc dimensions). Tolerances are set automatically and qualifications are selected based on specified maximum deviations. Design objects include all types of roughness, leader lines, base designations, tolerances of shape and location of surfaces, cutting and section lines, viewing direction arrows, hatching, texts, tables.

A raster image in BMP, PCX, DCX, JPEG, TIFF formats can be inserted into the KOMPAS-GRAPHIC graphic document. When inserting a raster object, you can set its scale and rotation angle.

The KOMPAS-GRAPHIC text editor allows you to produce various text documents - calculation and explanatory notes, technical specifications, instructions, etc. A text document is a separate type of KOMPAS document.

The KOMPAS-GRAFIC specifications design module allows you to produce a variety of specifications, statements and other spreadsheet documents. The specification is a separate type of KOMPAS-GRAPHIC document.

Many of the functionality of the KOMPAS-GRAFIC specifications development module are borrowed from the logic and technology of developing “paper” specifications.

When filling out a document on the screen, the user sees a standard specification table and can enter data into its columns.

KOMPAS applications: KOMPAS-MASTER application development tools, mechanical engineering library, integrated design systems for bodies of rotation KOMPAS-SHAFT Plus and cylindrical springs KOMPAS-SPRING, libraries of elements of hydraulic and pneumatic circuits, machine tools, electrical and kinematic diagrams, architectural and construction library, toolkits means of conducting standard projects, a system for designing metal structures, library packages “Elements of engineering communications”, “Elements of chemical production”, “Power supply”, “Automation of technological processes”, “Switching devices”, library of pipeline fittings, library “Building structures. Profiles", directory of structural materials, electronic directory on rolling bearings.

2. SCADA systems

In most cases, automated process control systems are organizational and technical systems, which means the presence of functions performed by a person (operator, dispatcher).

Several decades ago, these functions consisted mainly of monitoring instrumentation and direct manual control of the process.

After computerization reached the manufacturing sector, computers began to appear on operator desktops, where the interaction between the operator and the process is carried out using software, collectively called SCADA.

“SCADA-system” (Supervisory Control And Data Acquisition System) - a system for data collection and operational dispatch control. The name contains two main functions assigned to the SCADA system:

collection of data on the controlled technological process;

technological process control, implemented by responsible persons on the basis of collected data and rules (criteria), the implementation of which ensures the greatest efficiency and safety of the technological process.

If we try to briefly characterize the main functions, we can say that the SCADA system collects information about the technological process, provides an interface with the operator, saves the process history and automatically controls the process to the extent necessary and possible.

It is necessary to distinguish between SCADA software operating as part of the automated process control system of a specific facility and a set of software tools intended for the development of such software.

SCADA systems can significantly speed up the process of creating upper-level software for automated process control systems, without requiring the developer to have knowledge of modern general-purpose procedural programming languages. It is no secret that only a technologist or other representative of the technological staff, who, as a rule, does not have programming skills, understands the intricacies of an automated technological process. The SCADA system must be accessible not only to the developer, but also to the end user of the automated process control system being created, since the appearance of the system is determined and can be changed by both the developer and the user.

In addition to accessibility, the SCADA system should be characterized by maximum openness - the presence of universal and generally accepted mechanisms for exchanging data with input-output equipment.

Reasonable price and efficient use of invested funds - the cost of the system, development costs and the cost of work on the creation, maintenance and development of automated process control systems should be minimal. All other things being equal, this requirement is the most significant when choosing a SCADA system.

3. Genie Data Acquisition and Control Application Development Environment

Genie is an application development environment for collecting, processing and graphically representing data and control, which contains many built-in functional blocks and graphical display elements that can significantly reduce the cost of software development for industrial automation systems. Application development consists of selecting the appropriate functional blocks, establishing logical connections between them, creating a graphical operator interface and customizing report forms.

Developed by Advantech, a company specializing in the production of industrial computers and other automation and data collection equipment. With the development of this system, the company has “closed” the cycle, that is, it supplies both the hardware and software necessary for the creation of industrial information management systems. As an example, we consider the educational version - Genie for Windows v3.04.

The requirements for the hardware and software platform are very moderate.

Functionality: open architecture data center; programming in a scripting language compatible with Visual Basic for Applications (VBA); use of multitasking when implementing data collection and control algorithms; object-oriented graphics; standard user interface adopted in Windows; application development using function blocks; customizable report editor; display, control and processing of data in real time; plotting graphs of controlled parameters in real time; managing access to system information and controls; event/alarm processing; communication with other Windows applications via the DDE mechanism; application programming interface via OLE Automation; dynamic link libraries created by the user; possibility of organizing network interaction; support for DeviceNet and CANOpen protocols.

Main areas of application: data acquisition and supervisory control systems; automation of production areas; creation of technologist workstations; automation of laboratory measurements; measuring systems; test automation systems and complexes.

The package has a built-in script development environment compatible with Microsoft VB and VBA, providing the system developer with a powerful set of tools called the Script Designer. The script editor contains many VBA functions, as well as data collection and processing methods that allow you to implement applied algorithms of almost any level of complexity. VBA has implemented and is constantly expanding support for many Windows OS functions: dynamic data exchange (DDE) and object linking and embedding (OLE Automation) mechanisms; Open Database Interoperability (ODBC) features.

The openness of the Genie architecture guarantees the user the ability to integrate the package with a corporate system implemented or being implemented in the enterprise.

To reduce software development time while maintaining fit-for-purpose software and making it easy to maintain and upgrade, Genie offers graphical design and presentation tools called Task Designer and Display Designer. Examples of screen forms of these editors are shown in Fig. 1. and 2. The task editor uses an information-flow programming model, which is much more convenient for perception and algorithmic interpretation than the traditional linear architecture of text-based programming languages. When developing an application, the user creates a flowchart of the strategy without focusing on the various logical and syntactic conventions characteristic of standard programming. Objects (icons of functional blocks) are selected from the task editor toolbar (Fig. 3) and connected to each other to transfer data from one block to another. If it is necessary to create a graphical operator interface, the display form editor provides the ability to develop easy-to-read screen display forms in the shortest possible time using the standard display elements included in the package (Fig. 4 and 5). In addition, the specified graphical operator interface can be enhanced with special drawing tools and user-defined display elements. Libraries of built-in function blocks and display elements include the most commonly used functions in industrial automation for collecting, processing and graphically representing data. An example of the result of developing an operator interface for monitoring the conveyor load and accounting for the amount of bulk materials is shown in Fig. 6.

The Genie Task Editor allows you to edit multiple tasks at once. Each task is displayed in its own window and has its own parameters: scanning period, start/stop methods, etc. Genie 3.04 supports up to 8 tasks.

Fig.2. Genie Task Editor

Fig.3. Genie display form editor.

Fig.4. Genie Task Editor Toolbar.

Fig.5. Forms panel

Fig.6. Genie Display Operator Interface Form Element Menu

Fig. 7 An example of a conveyor line in Genie.

Genie's Report Designer provides a configurable development environment in which users can define the required report content, presenting the required data at specific points in time and then automatically printing at a specified time. The interfaces provided by the report editor can also be used to manually select and print reports.

The Report Editor provides five main functions: data collection, report format configuration, report scheduling, event report generation, and alarm report generation.

The event recording subsystem of the Genie package allows for continuous monitoring of the state of the technological process and data acquisition system, as well as early warning of possible deviations in the course of the technological process and the functioning of the system hardware and software. Flexible options for configuring threshold and limit parameter values allow you to implement multiple conditions by which emergency and pre-emergency situations are identified. Alarm values can be displayed, logged, archived with a time stamp, and confirmed by the operator in real time. In addition, the emergency event protocol can be displayed on a monitor screen or printed on a printing device to obtain a hard copy.

Currently, Advantech has developed a more advanced version of GenieDAQ 4.11.

Literature

Stekhin A.P. Fundamentals of design, modeling and design of production process control systems: Textbook. allowance. – Donetsk: DonGAU, 2008.

Lucas V.A. Fundamentals of the theory of automatic control. -M.: “Nedra”, 1977.

Fundamentals of optimal control theory: Textbook. Allowance for economics universities/ V.F. Krotov, B.A. Lagosha, S.M. Lobanov, etc.; Under the editorship of V.F. Krotov. - M.: Higher. School, 2008.

Ivanilov Yu.P., Lotov A.V. Mathematical models in economics. - M.: “Science”, 2007

Similar abstracts:

Characteristics of modern computer use. Modem computer telecommunications. Types and characteristics of communication organization. Modem telecommunications software. The concept and principle of operation of fax-modem telecommunications.

Analysis of combinational circuit implementation options for various types of programmable logic integrated circuits (FPGAs). Capabilities of Decomposer and WebPACK ISE software packages. Description of the adder in VHDL, its synthesis using the Decomposer package.

Automated information technologies of electronic document management systems and types of their support. Management information technology. Office automation. Automated information technologies in the office. Microsoft Office XP. Word.

Review of instrumental developments. Analysis of the market situation. Since its inception, the market for software development tools has probably never experienced a crisis - and is unlikely to experience one in the future. But this does not mean that working in this market is easy. The rapidly changing situation...

Design of modern electronic means and characteristics of existing methods of their design. State standards for the preparation of design documentation, their recording and storage in the technical documentation bureau. Types of storage media.

Methods and stages of designing electronic equipment. The role of programming language in computer-aided design systems. Brief description of computers used in solving problems of automation of electronic equipment design.

System software functions. Programming systems are software tools that provide automation of program development and debugging. Composition and purpose of the operating system (OS). Service programs, expanding OS capabilities.

The procedure for the development and production of technical products and electrical equipment, determined by the State Standards of the Russian Federation. Classification groups of standards in the ESKD. List of graphic and text design documents.

Software tools for the design of radio engineering devices. Basic technical capabilities of Microsoft Word. Comparative characteristics of programs for mathematical calculations. Programs for modeling processes in radio-electronic circuits.

Principles of designing a complex of technical means of automated control systems. Requirements for specialized devices and the costs of their implementation. Graphic information encoding devices. Plotters and scoreboards.

Optimization of management in various spheres of human activity. Classification of automated information management systems. Design methods and development stages. Block diagram, memory capacity, information output and display equipment.

Design automation software

CAD software

CAD software consists of mathematical models of design objects, methods and algorithms for performing design operations and procedures.

In CAD software we can distinguish special part, which largely reflects the specifics of the design object, the physical and informational features of its functioning and is closely tied to specific hierarchical levels (this part covers mathematical models, methods and algorithms for their production, methods and algorithms for single-variant analysis, as well as most of the synthesis algorithms used), And invariant part, which includes methods and algorithms that are loosely related to the features of mathematical models and are used at many hierarchical levels (these are methods and algorithms for multivariate analysis and parametric optimization).

Requirements for mathematical software

The properties of software (MS) have a significant and sometimes decisive impact on the capabilities and performance of CAD systems.

When selecting and developing models, methods and algorithms, it is necessary to take into account the requirements for modeling in CAD. Let's consider the main ones.

Versatility

Under universality of MO its applicability to a wide class of designed objects is understood. One of the differences between calculation methods in CAD and manual calculation methods is a high degree of versatility. For example, in the circuit design subsystem of CAD IET, mathematical models of the transistor are used that are valid for any area of operation (active, saturation, cutoff, inverse active), and methods for obtaining and analyzing models are applicable to any analog or switching circuit on elements from the allowed list; in the structural design subsystem of CAD computers, models and algorithms are used that make it possible to study stationary and non-stationary processes of information processing under arbitrary servicing laws in computer systems and with arbitrary input flows.

A high degree of ML universality is necessary for CAD to be applicable to any or most objects designed at the enterprise.

Algorithmic reliability

Methods and algorithms that do not have a strict justification are called heuristic. The lack of clearly formulated conditions of applicability leads to the fact that heuristic methods can be used incorrectly. As a result, either a solution will not be obtained at all (for example, due to lack of convergence), or it will be far from the true one. The main problem is that the engineer may not have the data at his disposal to determine whether the results obtained are correct or incorrect. Consequently, a situation is possible when an incorrect solution will be used in the future as a correct one.

The property of a MO component to produce correct results when used under these conditions is called algorithmic reliability. The degree of universality is characterized by pre-specified restrictions, and algorithmic reliability is characterized by restrictions that are not identified in advance and, therefore, not specified.

A quantitative assessment of algorithmic reliability is the probability of obtaining correct results while observing the specified restrictions on the use of the method. If this probability is equal to or close to one, then the method is said to be algorithmically reliable.

The use of algorithmic nature of unreliable methods in CAD is undesirable, although it is acceptable in cases where incorrect results are easily recognized.

Closely related to the problem of algorithmic reliability is the problem conditionality of mathematical models and tasks. Poor conditionality is spoken of in cases where small errors in the initial data lead to large errors in the results. Each stage of calculations has its own intermediate initial data and results, and its own sources of errors. With poor conditioning, errors can increase sharply, which can lead to both a decrease in accuracy and an increase in computer time costs.

Accuracy

For most ML components, an important property is accuracy, determined by the degree of agreement between the calculated and true results. Algorithmically robust methods may produce varying accuracies. And only in those cases when the accuracy turns out to be worse than the maximum permissible values or a solution cannot be obtained at all, one speaks not of accuracy, but of algorithmic reliability.

In most cases, the solution to design problems is characterized by:

joint use of many MO components, which makes it difficult to determine the contribution to the overall error of each of the components;

the vector nature of the results (for example, during analysis, the vector of output parameters is found, during optimization, the coordinates of the extreme point are found), i.e. The result of the solution is not the value of a single parameter, but of many parameters.

In this regard, the accuracy is assessed using special computational experiments. These experiments use special tasks called tests. A quantitative assessment of the error in the result of solving a test problem is one of the norms of the vector of relative errors: m-norm or l-norm, where l is the relative error in determining the j-th element of the result vector; m is the dimension of this vector.

Computer time consumption

Universal models and methods are characterized by a relatively large amount of calculations, which increases with the size of the problems. Therefore, when solving most problems in CAD, the cost of computer time T m is significant. Usually it is T m that are the main limiting factor when trying to increase the complexity of objects designed on a computer and the thoroughness of their research. Therefore, the requirement for efficiency in T m is one of the main requirements for MO CAD.

When using multiprocessor computers in CAD systems, the calculation time can be reduced using parallel computing. In this regard, one of the indicators of the efficiency of MO is its adaptability to parallelization of the computing process.

In CAD, it is advisable to have libraries with sets of models and methods that cover the needs of all CAD users.

Memory used

Memory costs are the second indicator of machine learning efficiency after computer time costs. They are determined by the length of the program and the size of the data arrays used. Despite the significant increase in RAM capacity in modern computers, the requirement for efficiency in memory costs remains relevant. This is due to the fact that in the multiprogram mode of computer operation, a task with a request for a large amount of memory receives a lower priority and, as a result, its residence time in the system increases.

You can improve the efficiency of RAM costs by using external memory. However, frequent data exchanges between RAM and external memory can lead to an unacceptable increase in T m. Therefore, for large volumes of programs and arrays of processed information, it is advisable to use MO that allows the construction of overlay program structures and implements the principles of diakoptic information processing.

Mathematical modeling of objects and automation devices in CAD

Requirements for mathematical models

Mathematical models (MM) are used to describe the properties of objects in AM procedures. If a design procedure includes creating a MM and operating it in order to obtain useful information about an object, then the procedure is said to be performed on the basis of mathematical modeling.

Mathematical models are subject to the requirements of universality, adequacy, accuracy and efficiency.

Degree of versatility MM characterizes the completeness of the representation of the properties of a real object in the model. A mathematical model reflects only some of the properties of an object.

The accuracy of the MM is assessed by the degree of agreement between the values of the parameters of a real object and the values of the same parameters calculated using the estimated MM. Let the properties reflected in the MM be estimated by the vector of output parameters Y = (y 1, y 2, ..., y m). Then, denoting the true and calculated using MM values of the j-th parameter as y jist and y jm, respectively, we determine the relative error E j of calculating the parameter Y j as

E j = (y jm - y jist)/y jist (2.1)

The vector estimate E = (E 1 , E 2 , ..., E m) is obtained. If it is necessary to reduce this estimate to a scalar one, use some norm of the vector E, for example

E m = ||E|| = maxE j .

Adequacy of MM is the ability to reflect the specified properties of an object with an error no higher than the specified one. Since the output parameters are functions of the vectors of the external Q and internal X parameters, the error E j depends on the values of Q and X.

Typically, the values of the internal parameters of the MM are determined from the condition of minimizing the error E m at some point Q in the nom space of external variables, and a model with a calculated vector for various values of Q is used. In this case, as a rule, the adequacy of the model occurs only in a limited range of changes in external variables - area of adequacy (AO) of the mathematical model:

OA = (Q|E m , d),

where d is a given constant equal to the maximum permissible error of the model.

Cost-effectiveness of MM characterized by the cost of computing resources. The smaller they are, the more economical the model is.

Classification of mathematical models

Let's consider the main features, classifications and types of MM used in CAD.

Based on the nature of the displayed properties of an object, MMs are divided into structural and functional.

Structural MMs are designed to display the structural properties of an object. Structural MMs are distinguished between topological and geometric.

IN topological MM the composition and relationships of elements are displayed. They are most often used to describe objects consisting of a large number of elements, when solving problems of linking structural elements to certain spatial positions (for example, problems of equipment layout, placement of parts, routing connections) or to relative points in time (for example, when developing schedules, technological processes). Topological models can take the form of graphs, tables (matrices), lists, etc.

IN geometric MM properties of objects are displayed; in addition to information about the relative position of elements, they contain information about the shape of parts. Geometric MMs can be expressed by a set of equations of lines and surfaces; a set of algebraic relations that describe the areas that make up the body of an object; graphs and lists displaying structures from standard structural elements, etc. Geometric MMs are used in solving design problems in mechanical engineering, instrument making, radio electronics, for drawing up design documentation, and when specifying initial data for the development of technological processes for manufacturing parts. Several types of geometric MMs are used.

Functional MM are intended to display physical or information processes occurring in an object during its operation or manufacture. Typically, functional MMs are systems of equations connecting phase variables, internal, external and output parameters.

According to the level of detail of the description, complete MM and macromodels are distinguished within each hierarchical level.

A complete model is a model in which phase variables appear that characterize the states of all existing inter-element connections (i.e., the state of all elements of the designed object).

Macromodel - MM, which displays the states of a significantly smaller number of interelement connections, which corresponds to the description of the object with an enlarged selection of elements.

According to the method of representing the properties of an object, functional MMs are divided into analytical and algorithmic.

Analytical MM are explicit expressions of output parameters as functions of input and internal parameters.

Algorithmic MM express connections between output parameters and internal and external parameters in the form of an algorithm.

A simulation MM is an algorithmic model that reflects the behavior of the object under study over time when external influences on the object are specified.

Mathematical models at micro, macro and meta levels

Descriptions of technical objects must be consistent in complexity with the capabilities of human perception and with the capabilities of a computer to operate with descriptions of models in the process of their transformation during design. However, it is possible to fulfill this requirement within the framework of a certain unified description, without dividing it into separate components, only for simple products. As a rule, the structuring of descriptions and the corresponding division of ideas about the designed objects into hierarchical levels and aspects are required. This allows you to distribute work on the design of complex objects between departments of the design organization, which contributes to the efficiency and productivity of designers.

Using the principles of a block-hierarchical approach to designing the structures of mathematical models of designed objects allows us to formalize the process of writing them. The number of hierarchical levels in modeling is determined by the complexity of the objects being designed and the capabilities of the design tools. However, the hierarchical levels of most subject areas can be classified into one of three general levels, hereafter referred to as micro-, macro- and meta-levels.

Depending on their place in the hierarchy of description, mathematical models are divided into MMs related to micro-, macro- and meta-levels.

A feature of MM at the micro level is the reflection of physical processes occurring in continuous space and time. Typical MMs at the micro level are partial differential equations (PDEs). In them, the independent variables are spatial coordinates and time. Using these equations, fields of mechanical stresses and strains, electrical potentials and stresses, pressures and temperatures, etc. are calculated. The possibilities of using MM in PDE are limited to individual parts; attempts to use them to analyze processes in multicomponent environments, assembly units, and electronic circuits cannot be successful due to the excessive increase in the cost of computer time and memory.

At the macro level, an enlarged discretization of space according to a functional criterion is used, which leads to the representation of MM at this level in the form of systems of ordinary differential equations (ODE). In these equations, the independent variable is time t, and the vector of dependent variables consists of phase variables that characterize the state of the enlarged elements of the discretized space. Such variables are forces and speeds in mechanical systems, voltages and currents in electrical systems, pressures and flow rates of liquids and gases in hydraulic and pneumatic systems, etc. ODE systems are universal models at the macro level, suitable for analyzing both dynamic and steady states of objects. Models for steady-state conditions can also be represented as systems of algebraic equations. The order of the system of equations depends on the number of selected elements of the object. If the order of the system approaches 10,000, then operating the model becomes difficult and therefore it is necessary to move on to representations at the meta level.

At the meta level, fairly complex sets of parts are taken as elements. The meta-level is characterized by a wide variety of types of MMs used. For many objects, MMs at the meta level are still represented by ODE systems. However, since the models do not describe internal phase variable elements, but only phase variables related to the mutual connections of elements appear, an enlarged representation of elements at the meta level means obtaining MM of an acceptable dimension for significantly more complex objects than the MM dimension at the macro level.

In a number of subject areas, it is possible to use specific features of the functioning of objects to simplify MM. An example is electronic digital automation devices, in which it is possible to use a discrete representation of phase variables such as voltages and currents. As a result, the MM becomes a system of logical equations that describe signal conversion processes. Such logical models are significantly more economical than electrical models that describe changes in voltages and currents as continuous functions of time.

The use of tensor concepts of design objects makes it possible to use diakoptic methods to obtain the MM of complex technical systems.

Studying complex systems piece by piece implemented in diakoptic research methods. The difference between the diakoptic design approach and the block-hierarchical one is that diakoptics is based on the use of the structural features of the analyzed circuits and the matrices expressing them, and not on the adoption of any simplifying assumptions. In diakoptic methods, mathematical models are divided into parts that can be studied independently.

Dividing mathematical models into parts makes it possible to streamline and minimize the number of information exchanges between RAM and external memory when analyzing complex systems, as well as to select the most advantageous analysis modes for studying each part. These circumstances make diakoptic methods economical in terms of computer time and RAM.

Macromodeling underlies the direction associated with the rational choice of mathematical models of elements when constructing a mathematical model of a system. Macromodeling makes it possible to use several models when analyzing the same object, differing in complexity, accuracy and completeness of displaying the properties of the object, the complexity of the required calculations, etc.

When macromodeling, the following conditions must be met:

adequacy of the model (fulfillment of this condition requires the engineer to take into account the goals of solving each specific problem and the degree of influence of the parameters of the selected elements on the results of solving this problem);

greater efficiency in creating macromodels of elements and their further use compared to solving a problem based on a full mathematical model (usually this condition is met when using macromodels for elements that are typical or, at least, frequently encountered in a given system);

Eventfulness of analysis lies in the fact that when simulating processes occurring in the object under study, at each moment of model time, calculations are carried out only for a small part of the mathematical model of the object. This part includes those elements whose state may change at the next time step. The use of the event principle significantly increases the cost-effectiveness of analysis at the functional-logical and system levels of design.

Rational use of human heuristic abilities in interactive procedures allows the engineer to intervene in the course of calculations and select the most promising continuations based on heuristic assessments. This is beneficial in all those design procedures in which following only formal criteria for selecting further actions is associated with excessive costs of computer time. When studying complex elements and automation devices, multivariate analysis methods and sensitivity theory are often used.

The main types of multivariate analysis in design problems are sensitivity and statistical analyses.

Purpose of sensitivity analysis- determination of sensitivity coefficients, also called influence coefficients:

a ji = δY i /δx i ; b ji = a ji x inom /Y inom (2.1)