In the kitchen there is a tool necessary for cutting various products - a cutting board. Initially it was stone, then iron, bronze, and only then became wooden). Although plastic analogues have recently appeared, wooden boards are still popular. I recently managed to get into a workshop where cutting boards are made, but what I saw did not go with my ideas about such a simple utilitarian kitchen item on which vegetables, meat and other food are cut.

Today, we will find out how the most expensive cutting boards are made in Russia.

Just as a theater begins with a hanger, so a workshop where wooden products are made begins with a warehouse where the wood is stored. It arrives to our master, whose work will be discussed today, in finished form, dried at a certain temperature for several years. Fresh wood cannot be used to produce boards, as the finished product will deform over time due to shrinkage.

Here, the warehouse maintains a certain temperature and air humidity, which prevent the wood from drying out too much and becoming too wet. This table, which hangs on the wall of the workshop, shows the optimal percentage of humidity at different temperatures.

There is also a hygrometer hanging here showing the degree of humidity in the room. True, the master said that his readings were incorrect).

To produce some boards with particularly complex patterns, a CNC (computer numerical control) machine is used. The machine is small, just connect a laptop with a preset program to it.

The drawing of the board that the mill is currently working on is inspired by Maurits Escher's famous work "Reptiles".

If desired, the cutter will work wonders).

This is what the board looks like after the machine is running. If you look closely, you will see that this future board is glued together from pieces. We will find out why this was done later.

If the base of the board is made of walnut, then the inserts are cut from other types of wood that differ in texture and color - oak and rosewood.

As the master told me, the machine cut out the figures on the board in such a way that when inserting other reptile figures, no gaps were found. The figures turn out to be fitted to each other very tightly.

In this photo you can see examples of gluing. A multi-colored piece is glued together from different types of wood. This material will be used to glue one of the most difficult boards to make. You can see it at the end of the post.

The master takes a simple board, processes it, aligns the edges. Then the board is cut into pieces, which are turned with the end part and glued together. Moreover, gluing is not done in any random order, but in a special way so that the growth rings are directed in opposite directions, this will prevent the boards from deforming when humidity changes.

Why is this being done? Due to the vertical arrangement of wood fibers, knives do not become dull longer, since the knife blade does not cut the fibers, as in ordinary boards, but penetrates between them - slides. The fibers return to their original state after culinary efforts on it. Accordingly, the board does not deteriorate, and cooks do not have to sharpen knives several times per shift, as is the case with conventional boards.

In addition to walnut, hornbeam, ash, maple, oak and beech, valuable wood species such as American cherry, movingwood, and mahogany are also used as materials. As you can see from the markings on the wood, it is from the USA, some are from South America and Africa.

Other types of wood.

After the wood is cut into pieces and turned upside down, it is glued and clamped in clamps - a special press. As you can see, here the shields are of different thicknesses. The thicker one will become a board, and the thinner shields will be used to cut patterns and figures on the surface of future boards, like the figures from “Reptile”. After gluing, the shield will be ready in an hour, but it is recommended to subject it to load after 24 hours.

For gluing, a special glue is used that does not contain formaldehyde, is approved for contact with food and has great water resistance.

This is what the room looks like where all the tools needed for carpentry are located.

Perfect cleanliness and order! As you may have noticed, the workshop has all the machines and tools for making any wooden product. A real carpenter's paradise).

Special clamps for large boards.

We won’t touch that board with the reptiles for now; we’ll be working on it for more than one hour, so we’ll work on another one. After it is glued, it is driven through this grinding machine - a surface planer. Essentially this is a modern planer.

Then the sides of the board are cut with a circular saw.

The sides are sanded on another machine with a vertical movement of the belt. The corners are rounded right away.

The board is then run through the drum sander again.

This time the surfaces are sanded more delicately. However, that's not all.

Pumps are attached to each machine, collecting sawdust from wood processing. After processing by machines, the product is polished with a manual grinding machine. First, a coarser sandpaper of 120 grit is used, then 240 grit to finally polish the board.

Finishing touches to round the edges and the carpentry work on the board is complete.

After all the above operations, the board takes a bath of mineral oil, which has no taste, color, or smell. The oil is made from petroleum, but it is completely safe and is even used in cosmetics.

The same board with reptiles that is shown at the beginning of the post will turn into the same one. After some time, when the board is saturated with oil, it will be allowed to dry, then treated again with a hot mixture of mineral oil and wax in a 4/1 ratio.

Other boards are also sent to the same oil bath.

Now let's go to the "Show Room" of elite cutting boards). In this room, the boards are packed and awaiting a meeting with their future owner.

Hygrometers monitor humidity levels.

This board just broke my mold of simple, utilitarian kitchen utensils! I can’t even imagine how you can dare to cut food on a work of art).

Many hours were spent to produce a board with a 3D effect. By the way, these boards are the most expensive, and it’s understandable why.

And this board can be safely hung instead of a picture!

The master also makes special boards for beating meat. There are even grooves for blood flow.

I’ll also add that the end boards, due to the material and manufacturing features, turn out to be thick and heavy, but they don’t roll around on the cook’s table/work surface. There is no need to place a rag or wet napkin/towel, hold it at risk. The boards are additionally equipped with rubber (sometimes silicone or plastic) legs, which are insurance against the absorption of water that accidentally gets under the board.

After the board has gone through all stages of the production process, it is packaged in film.

A little hot air and you're done.

This map shows where the ordered boards went - mainly Russia, Europe, the USA, there are even Japan and Australia.

Well, for those who want to make an end cutting board with their own hands - a master class. If you have all the tools and machines shown above, then go for it!

And as a bonus, watch the video of how boards with drawings are made, just cool!

If you have a production or service that you want to tell our readers about, write to me - Aslan ( [email protected] ) and we will make the best report that will be seen not only by readers of the community, but also of the site How it's done

Also subscribe to our groups in Facebook, VKontakte,classmates and in Google+plus, where the most interesting things from the community will be posted, plus materials that are not here and videos about how things work in our world.

Click on the icon and subscribe!

A cutting board is an indispensable attribute of any kitchen. Boards can be both professional (for example, for catering establishments) and household. They differ in shape, size, and material from which they are made. But the most popular were and remain wooden cutting boards. To make a cutting board from (and it is not at all difficult), it is enough to know some simple rules.

A cutting board is an indispensable attribute of any kitchen. Boards can be both professional (for example, for catering establishments) and household. They differ in shape, size, and material from which they are made. But the most popular were and remain wooden cutting boards. To make a cutting board from (and it is not at all difficult), it is enough to know some simple rules.

Firstly, not all wood is suitable for making a cutting board. One material absorbs moisture faster, the other is practically “moisture resistant”. Wood may have a tendency to split. And different types of wood differ from each other in hardness.

In order to make a board for the kitchen, such species as oak, pine, and birch are suitable. Boards are made from beech and acacia. There are also more expensive species (for example, Hevea), but this is not for everybody. The simplest cutting board can be made even from a sheet of plywood.

Rules for making a cutting board

The method of making a board, regardless of the material chosen, is the same. First, the board is marked depending on the shape and required dimensions - here everyone uses their imagination. For ease of use, do not forget about the handle. The handle should be located strictly on the longitudinal axis of the board, so you need to carefully measure and determine this axis.

The board itself and the handle are cut out with a hacksaw or jigsaw. Don't forget about the corners and curves around the handle. They need to be carefully ground down, rounded with a file, sanded - whoever has what. And it's not just that you can get hurt. Small pieces of wood left after sawing can then break off and get into food, and then into the esophagus. And this can already be dangerous.

Next, using the same sandpaper, you need to process the entire surface, paying special attention to the ends. It is better to round right corners of the surface. If you made a handle, don't forget to drill a hole in it. Then the board can be stored hanging in a place convenient for you.

It is necessary to take into account that the wood becomes covered with microcracks, and food waste residues accumulate in them. Therefore, the cutting board must be washed and dried very carefully after each use. It is good to lubricate the board with paraffin, after slightly heating both the board and the paraffin. Wax is also used for such “sealing” of cracks.

Important!

- When making a board, consider not only its surface area, but also its weight.

- And another useful tip - it’s better to have your own cutting board for each type of product.

The process of making a cutting board in the video:

The fact that no housewife can do without a cutting board is not subject to debate. Only with a large assortment of relevant products, one is not tripled by its size or geometry, another by its external design, and a third by something else.

The list of all similar “claims” can be continued indefinitely.But there is a fairly common solution for woodcarving craftsmen to find a rational version of a household cutting board - make it with your own hands, from wood. Knowledge of certain features of the technology will significantly simplify this work.

The first question asked by home craftsmen who do not have sufficient experience in working with wood species is what species is best to use for a cutting board?

Firstly. it is necessary to clarify for what specific purposes it is being done. Many housewives always have not one, but at least two boards on hand for various products. Moreover, they differ both in the width of the tree and in size (and, as follows, in weight and ease of placement on the countertop). Therefore, it is first necessary to understand the specifics of the upcoming use of the board - it is planned as a universal attribute or for a wood carving electric tool for a specific purpose. For example, when working with fish, it hardly makes sense to make it bulky, because cutting it using the chopping method using a hatchet, unlike meat with bones, is not done.

In addition, some boards are generally not used for their intended purpose. They are made with their own hands specifically for home decoration. In other words, they serve only as part of the decoration for a certain interior of the house (country and a number of others).  Due to the absence of carcinogens in the adhesive composition, these particular sheets are recommended for interior work.

Due to the absence of carcinogens in the adhesive composition, these particular sheets are recommended for interior work.

Secondly. It also matters how actively the cutting board is used. If it is done “for all occasions,” then such an indicator as strength should not fade into the background. It is also designed to withstand significant loads, taking into account wood carvings and sketches of animal fish, which will also be used for chopping the same bones.

Third. a kitchen, regardless of the type of structure, is not only a room with excess humidity. It experiences periodic and quite significant temperature changes. This alone is enough to understand that any wood is not suitable for a cutting board.

When choosing a type of wood for a cutting board, you need to pay attention to its compliance with the following criteria:

- minimal moisture absorption, otherwise it will swell quite quickly in the kitchen. The result is deformation of the working surface of the cutting board. Even as a stand for something, it is unlikely to be in demand if the geometry changes significantly;

- sufficient strength. Otherwise, with targeted impacts (this mainly relates to the chopping process), the cutting board will gradually become covered with deep dents. Consequently, its further use for its intended purpose is a big question. This also applies to the possibility of material delamination. Plywood, even the highest quality and most expensive (for example, FB), is definitely not suitable for cutting boards.

It is pointless to list exotic breeds — ; They are used for cutting boards only by professionals (Hevea and the like), who produce original copies to order, and the craftsmen do not require advice. Those who decide to make such a board for their home needs, it is advisable to pay attention to birch, acacia, pine, oak, beech, pear, cherry wood carving elements of the ornament. Such wood is malleable in processing, has good strength and is also inexpensive.

This is the second question that interests many home craftsmen - what linear parameters should they focus on? There is no standard for cutting boards, nor are there generally accepted norms. When cutting them out of wood with your own hands, all sizes are determined arbitrarily.

Firstly, every housewife can say what area of the board is optimal for cutting certain products. Therefore, when determining sizes, one must be guided by the principle of sufficiency. If the cutting board is mainly used for skillful wood carving of meat, then its dimensions are chosen to be somewhat large, but for chopping vegetables, for example, a relatively small one is enough. Secondly, how much food is usually cut at a time. After all, a family of 3 people or 5 - 6 is not the same thing. Thirdly, it is important where and how the main workplace of the housewife is arranged. Will it be possible to fit a board that is too large there?

Again, this is determined by the hostess. The man’s task is to do it with his own hands, and what kind of wood carving unit the cutting board should end up being (dimensions, shape, etc.) is the woman’s decision. Some prefer to store such an accessory in a tube (cabinet) of the kitchen unit, others hang it in the kitchen - there are plenty of options. The main thing is that in everyday life the cutting board is not conspicuous, does not interfere and is always at hand.

As follows, the most important aspect here is the artistic design of the cutting board, and not its strength, durability, etc. In this case, it is entirely possible to get by with wood carving on a lathe and a multi-layer board, and not focus on the type of wood. Its most affordable variety that meets all the characteristics is FC.

Because there is nothing complicated in this work, it is enough to just list the main technological operations:

- Marking a wooden blank according to the drawn up drawing. For ease of use of the cutting board, it is necessary to provide a handle. A nuance - it should be located along the longitudinal axis of the product. Otherwise, the center of mass will shift, and handling this kitchen attribute will become inconvenient in a number of different cases.

- Cut the tree. Considering the relatively small thickness of the material, it is enough to use a jigsaw or a wood carving Penza region hacksaw (for metal, with fine teeth). This will ensure the most accurate cut. It is especially important if you are making not just a cutting board with your own hands, but a complex one (curly).

- Edge processing. Any owner always has some kind of abrasive (sandpaper, sharpening wheel) or an appropriate tool (file, grinder) on hand. All corners and edges of the resulting cutting board must be sharpened to remove various roughnesses, microscopic chips remaining after sawing, etc. This solves a dual problem. Firstly, after using the board you won’t have to remove the splinters from your hands. Secondly, the smallest fractions of wood remaining after cutting can unnoticeably get into the products that will be cut.

- Drilling a hole. It should be in the pen, although this is not necessary. But if you do it in advance, then later, if you want to hang the cutting board somewhere in a convenient place, there will be no problems.

- If a cutting board for wood carving or exclusive furniture is stored in a visible place, it makes sense to leave one side of it for work, and the other side to somehow decorate it artistically. Your own imagination will suggest options - paint and varnish, paste over, laminate with decorative film, etc.

- Modern homes in most cases are finished in a certain style; fortunately, there is a sufficient choice of materials. Therefore, it is advisable to choose the appropriate shape of the cutting board, and not limit yourself to just a traditional rectangle or square.

- Some wood is suitable for a number of parameters for the manufacture of such a kitchen attribute. But there are also some disadvantages that need to be taken into account. For example, birch is good for cutting wood carving boards, but its structure is so porous that this lumber is highly hygroscopic. The conclusion is not difficult to draw - before choosing a specific type of wood, you need to decide on the intended use and storage location of this kitchen attribute. The same is true for oak, although it is durable and moisture-resistant, it is so dense that even a small cutting board made from it has significant weight. And this comes to the issue of ease of use.

That's basically it. And what kind of cutting board to make with your own hands from wood - in size, shape, external design - is up to you, dear reader, to decide.

How to make a wooden bed with your own hands — ; step-by-step instructions and drawings How to make a bird feeder from wood with your own hands — ; step-by-step instructions and drawings How to make a good ax handle for an ax &

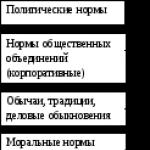

Education Committee of the Vsevolozhsk Municipality

Municipal educational institution

"Novo-Devyatkinskaya secondary school No. 1"

Vsevolozhsk district, Leningrad region

CREATIVE PROJECT

on the topic“MAKING A CUTTING BOARD”

in the subject "Technology and technical work"

Completed:

MELNICHENKO ANDREY

6th-1st grade student

Supervisor:

VINOGRADOV Vladimir Vladimirovich

teacher of technology and technical labor

2016

PROJECT WORK

Content:

Technical information

Drawing up sketches of the main parts of the product

Manufacturing sequence development

Selection of materials, tools, devices for work

Making a sketch of the product

Methods for making a cutting board and drawing up a technological map

Manufacture of a product according to the technological map according to the sketch in compliance with labor discipline and work culture

Brief description of making a cutting board

Economic justification

Environmental assessment of the project

Self-assessment of the result

Description of work (all stages)

Safety precautions at work

Preparatory stage:

Design stage:

Technological stage:

Practical stage:

Project rationale:

Used literature and Internet materials

My work on making a cutting board consists of several stages.

First of all, I outlined a sequence of actions for myself when drawing up a project for making a cutting board:

Discussion of the idea

Awareness of the problem, social significance (for home, school, etc.)

Searching for information on your problem

Independent work on the selection of drawings and sketches to create an object.

Assessing your knowledge and skills to implement your idea

Assessment of time, materials, their cost, product appearance, environmental friendliness, manufacturing techniques.

Justification for choosing this project (theme and purpose of the project)

Historical background on the selected topic

Technical information

Preparatory stage:

For my creative project, I decided to make a cutting board. That's why I named my project "Making a Cutting Board" (project theme).

The goal of my project began the study of the basic properties of wood and methods of its processing, as well as improving knowledge and skill in mastering tools and materials when creating a product with one’s own hands, learning to accurately and clearly perform technological operations; improve your capabilities; assimilate acquired knowledge; evaluate the work done.

A project task was the development of a technological process for making a cutting board using tools and equipment available in the school workshop.

What is a cutting board? A cutting board is a piece of kitchen utensil intended for cutting, or less often chopping, food.

To prepare a meal, you need to prepare all the ingredients, cut, crumble, but this must be done carefully on a cutting board. A beautiful board will decorate the kitchen and can be used as a tray when serving dishes. A cutting board is a necessary thing for any housewife. It is the most popular and widespread. It is most convenient to cut and cut food on a wooden surface. And the sound (knock) when the knife comes into contact with wood is not as loud and unpleasant as when using other types. Plus, the knives are not particularly dull.

The board can be cut in the shape of fish, animals, fruits, and various geometric shapes. I chose the traditional board shape.

The exact date of the appearance of the cutting board is not known. But what is known is that even in Ancient Egypt, housewives laid special devices on the table so as not to dirty the table when preparing food. In ancient times, stone blocks were used as cutting boards, the care of which left much to be desired.

Cutting boards have become an integral part of kitchen utensils since ancient times. Then they were used mainly for cutting meat at the feasts of the Roman nobility. True, at that time lifting a cutting board was not an easy task - the favorite material for making boards was stone.

A variant of a wooden board (pine, oak, beech, birch) appeared a little later and remained virtually unchanged until the 20th century.

The plastic cutting board we are used to appeared only in the middle of the twentieth century. In the 40s, the chemist Müller in Germany and the scientist Andrianov in the USSR simultaneously produced silicone plastics that had high heat resistance and resistance to water, acids and organic solvents, just what manufacturers of household and kitchen items were looking for.

And in the forties of the last century, the production of plastic cutting boards was established.

Of course, it is almost impossible to wash (clean) a cutting board perfectly after use, even with the help of detergents. But the problem can be solved by their quantity.

In EU countries, cutting boards for different products are divided by color:

blue seafood cutting board

white board is for dairy products

raw poultry is cut on yellow boards

on red - raw meat

Vegetables are cut on a green board

In our country there is no such gradation by color, but each operation in the kitchen has its own board.

Separate boards for:

for fish

for meat

for raw vegetables

for boiled vegetables

for bread

for fruits

Before starting work on the project, I studied various sources on the Internet, and also carefully read the topic in the textbook. I studied the history of cutting boards and what wood is best to use to make boards. A cutting board is an indispensable attribute of any kitchen. Boards can be both professional (for example, for catering establishments) and household. They differ in shape, size, and material from which they are made. But the most popular were and remain wooden cutting boards. To make a wooden cutting board with your own hands, you just need to know some simple rules. Firstly, not all wood is suitable for making a cutting board. One material absorbs moisture faster, the other is practically “moisture resistant” - it repels water. The wood may delaminate. And different types of wood differ from each other in hardness.

In order to make a board for the kitchen, such species as oak, pine, and birch are suitable. Boards are made from beech and acacia. There are also more expensive species (for example, Hevea).

The simplest cutting board can be made even from a sheet of plywood. True, this is an impractical material. The plywood cutting board is too simple and not aesthetically pleasing.

2. Design stage:

2.1. Drawing up sketches of the main parts of the product

2.2. Manufacturing sequence development

2.3. Selection of materials, tools, devices for work

2.4. Making a sketch of the product

Before you start making a cutting board, you need to make a blank and make the necessary markings.Marking is called drawing the contour lines of the future product onto the workpiece.

When marking, drawing and measuring tools are used, such as a pencil, ruler, square, compass, jigsaw, drill, and templates.

Templates They are a finished part or its form, made of wood, metal, or paper, cardboard.

Then, if the product is planned to be made with a hole, it is necessary to drill it. Drilling holes is a recess in the parts of the product. They can be through or blind.

The rules for making a cutting board are simple. The method for making a board, regardless of the material chosen, is the same:

Before making any part, performsketch (template) or drawing. Sketch is a hand-drawn image indicating the dimensions and preserving the relationships between its parts.

Types of cutting boards:

Sketch (cutting board template)

3. Technological stage:

3.1. Methods for making a cutting board and drawing up a technological map

ROUTING:

Sequence of operations:

1. Select the workpiece for cutting (Ruler).

2. Mark according to the template (Template, pencil).

3. Cut out a curved contour (Jigsaw, cutting table).

4. Mark and drill a hole Ø 8 mm (Template, awl, drill, drill Ø 8 mm).

5. Select a blank for the hanger (Ruler).

6. Mark according to the template (Template, pencil).

7. Cut out a curved contour (Jigsaw, cutting table).

8. Mark and drill a hole Ø 6 (Template, awl, drill, drill Ø 6 mm).

9. Clean and sand the parts (file, sandpaper)

4. Practical stage:

4.1. Manufacture of a product according to the technological map according to the sketch in compliance with labor discipline and work culture

4.2. Brief description of making a cutting board

First you need to decide on the size of the future cutting board(board thickness and size)

Then - select the appropriate wooden blank(what type of wood)

Cut it out scissors drawing on paper and placing it on the board (but first the board is marked depending on the shape and required dimensions)

We trace the contours of the drawing on the board.

We clamp the board in a vice and drill several holes on the sides of the marked handle of the cutting board so that the wood does not crack during cutting.(drilling machine)

We cut out the board and drill a hole in the handle (the handle should be located strictly on the longitudinal axis of the board, so you need to carefully measure and determine this axis.The board itself and the handle are cut out with a hacksaw or jigsaw.

Don't forget about the corners and curves around the handle. They need to be carefully ground off and rounded.file, emery, rasp - who has what. And it's not just that you can get hurt. Small pieces of wood left after sawing can then break off and get into food, and then into the esophagus. If you made a handle, don't forget to drill a hole in it. Then the board can be stored hanging in a place convenient for you

We make indentations along the edges and clean the boardsandpaper (ends and surface). Further, using the samesandpaper you need to treat the entire surface of the board, paying special attention to the ends. It is better to round right corners of the surface.

It is necessary to take into account that the wood becomes covered with microcracks, and food waste residues accumulate in them. Therefore, the cutting board must be washed and dried very carefully after each use. When making a board, take into account not only its surface area, but also its weight.

5. Justification of the project:

5.1. Economic justification

5.2. Environmental assessment of the project

5.3. Self-assessment of the result

Economical is that all materials for this project can be found in the school workshop, and among production waste Economic information:

The cost of this work can be calculated as follows:

Plywood sheet (55cm x 75 cm) - 640 rubles, from one sheet you get 5-6 cutting board blanks measuring 34x20 cm, one blank costs about 13 rubles 20k

Copy paper (1 sheet) - 2 rubles

If you use waterproof varnish (0.5 liters), its cost is 100 rubles

Total costs excluding labor amounted to 115 rubles 20 kopecks.

Conclusion: a profitable investment since the costs are low.

Environmental friendliness is that in the manufacture of this project, an environmentally friendly material was used - wood.

Self-esteem: Finished work, as a result of which I improved my skills. I began to understand working with a jigsaw better. Also learned that there are many other types of cutting boards. Learned to identify the type of wood. The versatility of my project lies in the fact that the board can be used for its intended purpose, that is, as a cutting board itself, and as a kitchen interior. It is necessary to take into account during manufacturing that the board is comfortable and durable.

Description of work on the project.

Analysis and evaluation of the product: advantages and disadvantages

Safety requirements at work

Sanitary and hygienic requirements

Project design and project protection

In my work, all stages of making a cutting board are followed:

A justification for the choice of this project was made (choice of topic, purpose and objectives of the project), historical and technical information on the selected topic was given, a sketch of the product was drawn up, a sequence for making a cutting board was developed, materials, tools, devices for work and a sketch of the product were selected.

A technological map has been drawn up for manufacturing the product according to the sketch in compliance with labor discipline and work culture.

A brief description of how to make a cutting board is given.

An economic feasibility study for the production of the board has been completed.

An environmental assessment of the project and a self-assessment of the result are given.

advantages and disadvantages.

Conclusions are drawn on the topic.

The basic safety requirements during work and sanitary and hygienic requirements are highlighted.

Product analysis and evaluation:

Advantages of a cutting board:

firstly, a necessary thing in the kitchen;

secondly, it is universal;

thirdly, it is easy to manufacture and economical.

Flaws:

if the cutting board is made of plywood, it cannot be used for cutting vegetables, meat or fish, since microcracks will get into microcracks;

it is very difficult to clean such a board

Conclusion: From an aesthetic point of view, the cutting board should look beautiful.

A board for slicing bread and flour products is a convenient, affordable and necessary thing for every kitchen.

Advantages

High strength indicators. This is due to the presence of hardened glue in the structure of the product, which is stronger than wood fibers;

The board must withstand constant contact with the knife

Moisture resistance. What is more important in the kitchen than mechanical resistance? Resistance to excessive humidity. Juice from cut vegetables and fruits, water draining from them after washing, and steam simply standing over pots quickly render ordinary wood unusable. But the sizing mentioned above quite effectively prevents this;

Beautiful appearance. Plywood, just like a classic wooden product, has an original natural pattern and adds aesthetics to a kitchen item.

Ease of processing. The shapes of plywood cutting boards can be very diverse.

Acceptable price. Taking into account all the high performance indicators, fiberboard is cheaper than solid wood

Durability. The service life is not limited to ten years, subject to proper care.

Flaws:

cannot be used for cutting vegetables, meat or fish, since microcracks will get microbes;

Toxic glue may have been used in the manufacture of purchased plywood.

Safety requirements for making cutting boards:

1. Put on overalls and put them in order.

2. Be careful when working with cutting tools, do not point the cutting edges towards yourself.

3.Work only with a serviceable tool; if any malfunctions are detected, do not correct the problems yourself, but inform the teacher. Follow safety rules when working with an electric jigsaw and drill.

4. Securely secure the workpiece when cutting with a jigsaw

5. When cutting with a jigsaw, use a cutting table.

6. You need to work with a jigsaw without jerking or bending the blade.

7. Do not bring the cut, sawed or planed product too close to your eyes to avoid dust or shavings getting into your eyes.

8. Remove dust, shavings, and sawdust with a broom brush.

9. You cannot keep your left hand close to the canvas.

10. Work in a well-lit room.

Sanitary and hygienic requirements

1. Before starting work, you must wash your hands.

2. Adequate lighting must be provided when carrying out the project.

4. It is necessary to provide access to fresh air in the room

5. Strictly carry out the work according to the technological map for the production of a cutting board

7. Literature used:

Internet:

stroi-specialist.ru›For the home handyman›razdelochnaya-doska.html

better-house.ru›sdelaj-sam…doska-svoimi-rukami/

kulinarochki.ru›istoriya-razdelochnoj-doski/

ru.wikipedia.org›Cutting board

idei-na-kuhne.ru›doski-razdelochnye-iz-dereva….

Simonenko V.D. and others. Technology. Textbook for 6th grade. –M.: Ventana-Graf, 2012.

DIY Magazines.

Melnichenko Andrey, student of 6-1st grade

Everyone who works with wood ends up with a lot of scraps. You can simply throw them away, or you can use them. In this article we will tell you how to make a cutting board of incredible beauty from scraps of different types of wood. The key points in this project are choosing the right (non-toxic, waterproof) glue and having wood scraps of different shades.

:

- table saw

- jointer

- planer

- router with set of cutters

- router table

- clamps

- glue brushes

- orbital hand sander.

Materials:

- wood trimmings of different species

- waterproof non-toxic wood glue

- mineral oil and rags

To make our own cutting board, we used scraps of maple, walnut, mahogany, cherry and other woods whose color and texture we found interesting. When we talk about wood scraps, we mean wood, not laminated timber, plywood and other composite materials.

Wood cutting board manufacturing technology

1. Process the wood scraps on a jointer. This processing is necessary so that the boards fit together clearly. Try to ensure that the height of all the boards is approximately the same; the width can be whatever you want.

2. Process the front sides of the boards on a planer. This will ensure uniform thickness and smooth surfaces. It is advisable not to make the boards too thin; the thickness should be at least 15, and preferably 18 mm.

3. Cut the boards lengthwise using a table saw. The minimum width of the boards should be approximately 12 mm. The stripes do not have to be the same width; vary it at your discretion.

4. Arrange the boards in the desired order. Try to achieve an interesting look by experimenting with combinations of colors and sizes. The number of planks depends on the size of the cutting board.

5. Glue the boards together. It is advisable not to glue everything together at once, but to divide them into several groups. The width of each group should be as wide as your planer can handle it. The glue must be non-toxic and moisture resistant. Apply a thin layer of glue to the side edges of each board, and then tighten all the parts with clamps.

6. As a result, you should have several groups of planks. Sand the surfaces of each group with an orbital sander, taking care to remove all the glue. Then planer each group, removing as thin a layer as possible from each side. Now you can attach the pieces of the cutting board to each other and give an intermediate assessment of your efforts.

7. Glue the board parts together using the same technique used to glue the boards. Remember that due to its large size, the cutting board cannot be processed on a planer; it will have to be sanded by hand. Therefore, try to glue the parts together as accurately as possible and wipe off any excess glue with a damp cloth. To tighten the parts together you will need quite large clamps.

8. Sand the board and cut it to the desired size. Grind with a hand sander and remove any glue deposits. When cutting a board, try to make it proportional, that is, choose the length of the board based on the width. It is also advisable to take into account the size of the sink, because if the board does not fit in the sink, washing it will be problematic.

9. Round the edges of the board using a router with the appropriate bit. A special table equipped with guides will greatly simplify the task.

10. Cut a groove around the perimeter of the board, which is needed so that the juice released by the food during cutting does not flow onto the table. You need to cut out the groove using a router with an appropriate rounded cutter. To make the groove even, use a plywood template. Secure the template with masking tape on three sides, and move the router along the fourth. Then remove the tape from one of the sides and secure the one along which you made the groove. Depending on the depth of the groove, you can get by with one or more passes.

11. Sand the board. Grind using a grinder, each time changing the sandpaper to a finer one, up to No. 220.

12. Apply a safe coating. This could be, for example, mineral oil. Make sure the oil is well absorbed into the wood, applying several coats if necessary.