For owners of country houses with individual heating systems, the issue related to the uniform distribution of heat between all rooms is particularly relevant. For this purpose, circulation pumping units are used. And the question immediately arises: how to install a heating circulation pump so that it ensures uninterrupted, highly efficient, reliable operation? In this article we will look at this issue in detail.

Reasons for installing a circulation pump

A standard problem for owners of private houses is the uneven distribution of heat throughout the heating system. If in distant rooms the radiators are lukewarm, but the boiler boils, then you have to look for methods to improve the efficiency of the entire heating system.

To distribute thermal energy throughout the house, the following solutions are most often used:

- increasing the diameter of the heating system pipes;

- installing a pump in a heating system that is already present.

The first method is effective and practical, but it requires significant financial and physical costs, since you will have to dismantle all the old pipes and replace them with new ones. Installing a circulation pump in the heating system will not only ensure the same temperature throughout the house, but will also prevent the occurrence of air locks, which are the cause of poor coolant circulation. In addition, the cost of installing a small pump is much lower than replacing the pipes of the entire heating system, and much less physical effort will also be required.

Design and principle of operation of the circulation pump

Circulation pumps are designed for forced circulation of warm water in closed heating systems. The pump consists of a stainless steel body and a steel rotor or motor screwed to it; an impeller is attached to the motor shaft, which contributes to the release of the coolant. The operation of the pump is driven by an electric motor. A pump installed in a heating system draws water from one side and throws it into the pipeline due to the centrifugal force that occurs when the impeller rotates. The pressure created by the pump must easily cope with the hydraulic resistance of the pipeline, radiator and other elements of the system.

Types of circulation pumps

Typically, heating pumps are divided into two types:

- "wet";

- "dry".

In “dry pump” designs, the rotor does not interact with the coolant; its working area is separated from the electric motor by special stainless steel sealing rings. When started, these rings begin to rotate one towards the other and a thin film of water located between the rings seals the connection due to different pressure levels in the heating system and the external environment. The efficiency of a circulation pump with a dry rotor becomes 80%. In addition, it is quite noisy compared to a “wet” pump, so it should be installed in a separate, well-soundproofed room.

In turn, “dry” pumps are divided into three types: vertical, horizontal and block. For horizontal “dry” circulation pumps, the suction pipe is located on the front of the shaft, and the discharge pipe is located on the housing. The electric motor is mounted horizontally. For vertical pumps, the pipes are located on the same axis, and the electric motor is located vertically. Warm water enters the block pump along the axis and is discharged radially. When operating a “dry” pump, the dustiness of the room should be monitored, as it can cause turbulence of dust and other small solid particles, which can damage the surface of the seal rings, and as a result, the tightness of the pump. It is worth remembering that a “dry” pump requires the presence of liquid as a lubricant, since its absence significantly increases the risk of destruction of the mechanical seal.

“Wet” circulation pumps differ from “dry” ones in that the rotor and impeller are immersed in a coolant, which simultaneously acts as a lubricant and coolant. The rotor and stator are separated by a special “glass” made of stainless steel, which ensures the tightness of the part of the electric motor that is energized. For a heating system, the body of a “wet” pump should preferably be bronze or brass, and the rotor should be ceramic. Compared to “dry” pumps, wet ones are less demanding in maintenance and repair, and in addition, they are much less noisy. However, there is also a minus: the efficiency of a “wet” pump is about 50%. This is due to the fact that it is almost impossible to seal the sleeve that separates the coolant and the stator. “Wet” circulation pumps are mainly used in domestic heating, since such performance is quite sufficient for short-length heating systems.

How to choose a heating circulation pump

The first thing you should pay attention to when choosing a circulation pump is its power. It is worth remembering that for high-quality heating it is not necessary to choose a large pump with too high power. It will only create unnecessary noise, cost much more, and there is no need for it as such.

To choose a heating device, you should make an accurate calculation of the power of the circulation pump that is optimal for your home. To do this, you need to know the following parameters: pipe diameter, water temperature, coolant pressure level, throughput and boiler performance.

It is important to know how many liters of water can pass per minute through the heating system (boiler power). In addition, it is necessary to calculate the amount of water required for the normal operation of the radiator and heating system rings.

The power of the circulation pump also directly depends on the length of the pipeline. As a rule, approximately 0.5 m of pumping head is required per 10 m of pipeline.

To calculate the coolant consumption, you simply need to equate it to the boiler power parameters. For example, if the boiler power is 25 kW, then the coolant flow is 25 l/min. Batteries with a power of 15 kW require 15 l/min of water. It is also worth remembering that the narrower the pipeline, the greater the resistance that will arise along the path of movement of the coolant.

Calculation of circulation pump flow for heating

Any circulation pump has a number of indicators, which determine its performance. The main ones are pressure and flow. These parameters are reflected in the technical data sheet.

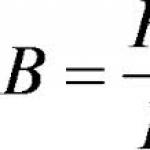

The flow rate of the heating circulation pump is calculated using the formula:

where N is the boiler power; t1, t2 is the temperature leaving the heat source (in most cases - 90-95 degrees) and in the return pipeline (usually -60-70 degrees), respectively.

The pressure of the heating pump is calculated in the same way; according to European standards, 100 W of power is required for 1 sq.m. of private house area.

Circulation pump installation diagrams

There are two typical installation schemes for a circulation pump: single-pipe, double-pipe.

The first scheme is characterized by a constant coolant flow rate and a small temperature difference, while the second, on the contrary, is characterized by a variable flow rate and a high temperature difference.

The following figures show connection diagrams for the heating circulation pump, where: 1 - boiler, 2 - automatic air vent, 3 - thermostatic valve, 4 - radiator, 5 - balancing valve, 6 - expansion tank, 7 - valve, 8 - filter, 9- circulation pump, 10-pressure gauge, 11-safety valve.

Installing a circulation pump - stages and important installation nuances

Before installing the circulation pump, carefully study the instructions and its connection diagram. It is important to take into account the fact that the heating system will need to be serviced from time to time, so it must be taken care of.

First, you should drain all the heating fluid from the system, then, if necessary, clean the pipeline. Installation of the pump and the functional chain of fittings is carried out according to the connection diagram. Upon completion of installation, the heating system is filled with water, then excess air is removed from the pump by opening the central screw. It is worth paying attention that the air should be removed before each time the circulation pump is turned on.

After the heating circulation pump has been purchased, we begin to determine its installation location. It is recommended to install the circulation pump on the return line, in front of the boiler. The thing is that air can collect at the top of the boiler over time, and if the pump is installed on the supply, it will seem to pull it out of the boiler, as a result of which a vacuum can be created, which will lead to boiling of this part of the boiler. If the pump is placed in front of the boiler, the coolant will be pushed into it, as a result of which no air space will be created and the boiler will be completely filled. In addition, with this installation, the circulation pump will operate at lower temperatures, which will increase its service life.

At the selected pump installation site, a so-called bypass (bypass) is performed. It is necessary so that in the event of a pump breakdown or a power outage, the entire heating system does not stop working, and the coolant passes through the main pipeline thanks to open taps. It should be remembered that the diameter of the bypass pipe must be less than the diameter of the main pipeline. After the bypass is ready, proceed to installing the circulation pump.

It is important to remember that the shaft of the circulation pump must be installed horizontally, otherwise only part of it will be in the water, that is, the pump will lose about 30% of its performance, and in the worst case scenario, the working area may malfunction.

In addition, the installation also provides for an upper location of the terminal box.

Install ball valves on both sides of the pumping equipment. You will need them in the future for maintenance and dismantling of pumping equipment.

The system must necessarily include a filter, which is designed to protect the mechanism from small mechanical particles that can cause significant damage to the pump.

A manual or automatic valve should be installed on top of the bypass pipeline line, which is necessary to release air pockets that arise after a certain period.

To prevent arbitrary water flow in the heating system, it is necessary to secure shut-off valves in the pump inlet-outlet area.

When attaching the motor shaft, it is necessary to ensure that the box rotates along the axis with minimal effort. For an open heating system, it is also necessary to provide an expansion tank.

The connecting nodes should be treated with sealant, which will increase the performance of the entire heating system

To make the pump installation process easier and to avoid the need to search for connections and fasteners yourself, find in stores a special device with already selected detachable threads.

The number of circulation pumps required depends on the length of the pipeline. For example, if the length of the pipe is about 80 m, then installing one pump will be sufficient, but if the length exceeds this figure, then it is necessary to use two or more heating circulation pumps.

The cost of installing a heating circulation pump fully depends on the model of the equipment itself, the complexity of the bypass pipes and, of course, the number of pipeline circuits.

Causes of failure of heating circulation pumps

The most common causes of failure of heating circulation pumps:

- incorrect pump installation

The motor shaft must be positioned strictly horizontally, otherwise air may accumulate in the pump, which will damage the device.

- Incorrect terminal module position or cable routing

- ignoring the pump bleeder procedure

- Poor quality cleaning of the system from solid particles

It is worth remembering that all circulation pump malfunctions require specific skills and knowledge, so it is better to entrust the repair of heating equipment to professionals.

Circulation pump improves the performance of heating systems.

The presence of such a device in the circuit will provide the opportunity to regulate the temperature in the rooms and increase heat transfer.

Most devices are arranged quite simply, allowing homeowners to install them themselves.

Functionality of the circulation pump in the heating system

The purpose is to accelerate and regulate the flow of coolant in the circuit:

- in systems with forced circulation(especially if the supply goes to two or more floors);

- in systems designed for natural circulation, it significantly improves heating efficiency.

Photo 1. Circulation pump model UPS 32-100 with a wet rotor, manufacturer - Grundfos, Denmark.

In private homes, a device with a wet rotor is usually installed:

- silent;

- not requiring maintenance;

- With economical energy consumption.

For long circuits and systems serving multi-storey buildings, devices are purchased with a dry rotor, powerful, with high efficiency.

Such devices require regular inspection and maintenance. They have to be installed in special rooms or where their noise will not interfere.

What to consider when choosing the right location

When installing the device in the circuit, the following is taken into account:

- correct orientation(indicated in the instructions, horizontally or vertically);

- correct harness(correctly selected set of additional devices);

- if present two or more branches, then the best option is to install a separate pump for each (in this case, it is possible to immediately achieve an equal temperature in the rooms for each branch and use fuel more economically).

Where is it better to install: supply or return

This is significant when installed in a system with a steam boiler, since the coolant at the outlet has a temperature above 100°C, which is unacceptable. On the return pipe, the temperature is set within normal limits.

Return — the only option for boilers solid fuel with the exception of systems with automated control.

Important! Boilers without automation often overheat the coolant to boiling, so steam enters the pump installed in the supply. This leads to an almost complete stop of fluid movement along the circuit and an emergency situation, even explosion.

The return pump may also be full ferry, but in this case the response time of the safety valve increases, which allows you to solve the problem and avoid disaster.

Where to put the pump: diagrams

Standard circuits for connecting a circulation device have been developed for various systems. The following important points are taken into account:

How the pump should stand: installation process

How to install:

Installation involves sequential placement of the necessary components, without which the pump will fail.

Shut-off valves(put on both sides, if necessary, the section with the pump is switched off from the system).

Provides separate branch for the pump (bypass), this will allow you to use natural circulation.

Additional elements:

- coarse filter(placed in front of the pump);

- check valve(needed in systems with an expansion tank or when installing two pumps);

- air valve to remove air from pipes(in some models it is built-in initially, then it is not needed in the chain).

One pump enough for the system with one boiler, additional devices are installed if:

- two or more boilers;

- complex circuit branches;

- installed buffer capacity;

- with a large length of the contour (several floors);

- at “warm floor” system;

- There is two or more boilers with different types of fuel;

- installed heat accumulator(an additional container in which the liquid is cooled and supplied to the system if necessary);

- pumping devices are installed on bypass, which will allow you to use natural circulation.

Attention! A separate cable with a machine is laid for the pump. It is not recommended to simply plug it into a regular outlet. For safety there must be grounding and an automatic device that triggers during power surges.

An additional pump in the heating system will be the best way out of a situation where home owners have problems heating their home. Installing the unit will help distribute heat evenly in the pipeline. The great advantage of the pumps is their versatility, because they can operate not only on coal, but also on diesel fuel, fuel oil, gas, wood and electricity.

What are the advantages of an auxiliary pump?

The use of additional equipment to improve the operation of the heating system provides residents with many benefits. Firstly, the overall efficiency of the system increases. This affects not only the uniformity of heat distribution, but also the temperature in living spaces. Secondly, the air in the rooms warms up much faster. Thirdly, heat circulation inside the main pipeline is improved.

Another advantage of an additional pump is the elimination of the possibility of air accumulation in one of the channels through which heat circulates. Owners of apartments on the upper floors suffer most from this problem, however, if you install an additional unit, it will help create the necessary pressure and supply heat to the entire building. The big advantage of the pump can be confidently considered its efficiency. In practice, it has been proven that together two units (standard and additional) will consume less fuel.

In addition, if the building is provided with heat by a pair of pumps in the system, then residents can install useful devices such as towel dryers and thermostats. The inhabitants of such a building also have the opportunity to use small-diameter pipes - the quality of heating will not deteriorate as a result. Another important advantage is the low price of the equipment. An additional circulation pump can cost from 5 to 20 thousand rubles. This is not too much money, considering that money will be collected for the unit from all residents of the house.

What device parameters should be considered when purchasing?

Before purchasing and installing equipment, it is worth studying its most important parameters. In order not to make a mistake when choosing, familiarize yourself with such characteristics as coolant density, pressure force and water temperature. You will also need to know the diameter of the pipes used to heat the building.

You can find out exactly what characteristics the pump you have chosen has on the packaging, side wall or in the technical data sheet of the unit. Manufacturers designate pressure with the letter “H”. This indicator means the device’s ability to raise water to a certain height. It is measured in meters. The second characteristic is the fluid consumption of the system. It is designated by the letter "Q" and is measured in cubic meters. This parameter is equal to the boiler power and depends mainly on the diameter of the pipeline.

Circulation equipment is not designed to lift fluid. Because of this, when purchasing a unit, special attention should be paid to the “Q” parameter. If the installed boiler is not equipped with a pump, then further liquid consumption will have to be calculated independently. Most modern heating devices already have similar equipment. Installing 2 devices to improve heat circulation is optimal if the house already has a boiler of an older modification, but over time the building was completed and the heating structure increased.

There is no need to purchase very expensive equipment. In any case, the device will not be used to its full potential. In addition, the installed unit has a high noise level. Most often, the length of the pipe determines the power characteristics of the equipment: for every 10 m of pipe, the device must provide 0.5 m of pressure. In practice, a 100-meter ring will work effectively if the pump produces a pressure of 5 m. When buying a unit for a pipeline, do not forget that the power of the device should be 10% more than the figure calculated by the residents.

Types of additional pumps - choosing the appropriate unit

For efficient media circulation, it is best to use “wet” or “dry” pumps. In the first case, the rotor is located inside the coolant, that is, it pumps water while being directly in it. As the fluid circulates, it cools the engine. A stator is used to supply electricity. Wet pumps have many advantages. Firstly, they are able to last for a fairly long period of time. Secondly, such devices do not require frequent maintenance. Thirdly, they make less noise. And fourthly, they are not large in size.

Disadvantages include not very high efficiency, limited scope of use, and the inability to use pumps for drinking water and other food-related devices. Such units are used only in mansions and residential high-rise buildings.

In the design of dry-type pumps, the rotor is located outside the coolant. Such devices use a seal that is designed to separate the motor and the pump itself. The approximate efficiency of the equipment is 75%, which is why these units are used in situations where it is necessary to regularly pump large amounts of water. Such units are used more in manufacturing and shopping centers than in residential buildings.

Preparing to install equipment

Before you begin installing the pump, carefully read the operating algorithm. The first step is to prepare for installation. To do this, purchase split-type threads and a filter for deep cleaning. Also, before installing the equipment, you need to prepare a check valve. It stabilizes the operation of the heating system. To work you will also need:

- a set of keys;

- a set of large and small flat screwdrivers;

- pliers;

- a pipe whose diameter will be equal to the diameter of the riser;

- fittings

It is worth deciding in advance on the installation location. Modern units can be installed not only on the water supply pipe, but also on the return pipeline. If you plan to install the device on a section of pipe between the return and direct radiator-type wiring, then before doing so you will need to check the ability of the unit to withstand a powerful pressure of hot liquid. It is also worth remembering that in buildings where the premises are equipped with “warm floors”, the injection device is placed at the hot water supply point. In this way, it will be possible to eliminate airiness in the pipes.

If there is a membrane tank, then the pump with a bypass is mounted on the side of the return pipeline, closer to the expander.

Installation of the unit - algorithm in detail

The installation of an additional circulation pump in a standard heating system does not depend in any way on the type and material of the latter. In any case, installation will have to be done using the bypass method. If the house is equipped with a metal pipeline, then you can purchase a ready-made structure that allows you to bypass the main highway. Before installation, you will need to completely drain the liquid and clean the pipes. To do this, the pipeline must be flushed several times. After this, a piece of pipe bent in the shape of the letter “P” is installed on the side of the main pipe.

Fix the pump in the middle of the pipe. Place ball valves on both sides of the device. What are they needed for? First of all, the water circulation will return to normal if you turn off one of the taps. Secondly, in case of repair of the unit, you will have to drain the water; if there are taps, this will not be necessary. During installation, pay attention to the direction in which the liquid moves. It is marked on the pump body with a special arrow. Upon completion of installation, the system is filled with water and the operation is checked. If any problems are detected, they should be eliminated at this stage of the operation.

Next, using the central screw, we expel the stagnant air from the pipes. If everything is done correctly, water will begin to flow from a separate hole in the pipeline. To install a unit with manual control, the air must be removed from the pipes before installation begins. To do this, the device is turned on for a few minutes, after which the equipment valves open. This procedure should be repeated several times. As soon as the pipeline is filled with a sufficient amount of liquid, the pump itself will start. In this case, the presence of air in the pipes is strictly unacceptable.

Device connection technique – what to connect to what?

Residents of the house will not receive high-quality heating if the pump is not connected correctly. When connecting the device to the power supply network of natural circulation systems, an automatic fuse is used. To install the latter, you should choose a place at least 70 cm from the main boiler. In forced circulation systems, the pump will start working after the thermal relay is turned on. In order to ensure simultaneous operation of the built-in and additional pump, the second device will need to be connected to a relay or routed in parallel to the first device.

In electric-type boilers, circulation devices should be connected directly to the boiler. In this case, the pump will only operate when the liquid is heated. The cleaning filter must be installed in front of the pump housing. A valve screwed into the upper part of the bypass makes it possible to ventilate the pipeline, removing any air that has accumulated there.

Please note that the pump connection diagram must contain either a differential circuit breaker (as in our diagram) or a combination of a protective circuit breaker and an RCD (Residual Current Device). This is required, first of all, to protect a person from electric shock in the event of a pump malfunction or incorrect connection

As you can see, there is nothing complicated in the circuit; to operate, a household circulation pump requires a phase and a zero (working zero), and in addition, an indispensable safety element is grounding (protective zero). Therefore, there are three contacts in the pump terminal box, with corresponding markings.

Detailed photo instructions for connecting the circulation pump to the electrical network, according to this diagram - HERE (link will open in a new window).

Most circulation pumps in heating systems are connected according to this standard scheme. The main disadvantage of which is that the pumps have to be turned on and off manually each time, so they are often turned on at the beginning of the heating season and turned off at the end. The disadvantages of this connection method, I think, are obvious: excess energy consumption and a decrease in the service life of the pump.

You can automate the operation of the circulation pump in the heating system in order to reduce energy costs and increase the overall service life of the pump by connecting it through a thermostat.

At the same time, the thermostat measures the temperature of the coolant and, if it is low, the circulation pump does not turn on, so as not to waste cold water (or other coolant) through the system, and when the temperature of the coolant at the boiler reaches the required level, the pump starts.

The connection diagram for the circulation pump through the thermostat is as follows

The heating system itself in the diagram is primitive, presented for a general understanding of the operation of the thermostat, but it can be seen from it that a pipe thermostat is installed on the heating pipe near the boiler, which measures the temperature of the pipe, and depending on it, turns on or off the circulation pump.

Also, if you do not find a special pipe thermostat (as in the diagram), you can use a regular room thermostat with a remote temperature sensor, which is attached to the pipe.

Other schemes for connecting a circulation pump through a thermostat, for example, to regulate the room temperature, most often cannot be used.

And although it seems logical to turn off the circulation of hot water (or other coolant) when the room becomes too hot and turn it on when it’s cold, this approach is wrong.

In this case, the thermostat should control the boiler, turning it on and off if necessary, and not the pumps that drive the coolant through the system.

Scheme for connecting the circulation pump via an uninterruptible power supply (UPS)

Another important task when creating a home heating system is to ensure its maximum autonomy and overall operational reliability.

For non-volatile heating systems, the heart of which are gas or solid fuel boilers that consume little electricity, this solution lies in the implementation of a circuit for connecting circulation pumps through uninterruptible power supplies.

At the same time, the autonomy of the system increases many times over. Familiar to many power outages in the private sector, which, as luck would have it, happen on the coldest, darkest nights and lead to freezing and often destruction of both the heating system and the entire house, are now practically not scary for you.

Preparing to install a heating pump

Before installing a pump, you need to buy it. A lot depends on the right choice.

Pumping equipment can be of different types.

There are many different models on the market from different manufacturers. You need to choose a heating pump whose characteristics correspond to the characteristics of the room, its area, the number of windows, external walls, etc. It is better to give preference to a more well-known manufacturer. You should not buy units that are too cheap due to the high probability of purchasing a fake. And when using such equipment, many problems can arise.

To simplify the process of installing a heating pump, it is better to choose a pump device with detachable threads. Otherwise, you will need to select adapters. But not every user will like this.

Additional equipment and tools for work will be needed:

- check valve Without it, the operation of the pressure pump will be ineffective;

- deep cleaning filter;

- shut-off valves;

- bypass from a pipe section. The diameter must correspond to the diameter of the riser;

- special keys for installation.

- - sealant;

- - rubber or silicone gaskets;

- - a set of keys from “22” to “36”.

Select a pump for heating the room, taking into account its heat loss. The calculation should include heat losses of external walls, thermal conditions, i.e. what will be the average temperature in the building, the area of the room and other parameters. According to the theory, “heat flow depends on heat losses on external enclosures, which are directly proportional to the difference between the outside air temperature T1 and the indoor temperature T, the area S of the heated room, and the heat loss coefficient (W/m² K).” This calculation can be represented as follows:

With a radiator heating system, if the area (S) of the room is 80-120 m², then the pump should produce 0.4 m³ of coolant per hour, with 120-160 m² - 0.5 m³;

With the “warm floor” system, if S=80-120 m² – 1.5 m³, with 120-160 m² – 2.0 m³.

Install the pump in a heating system with radiators on the return line near the boiler, where the temperature is lowest. In apartments and houses with an area of up to 200 m², this is quite conditional, since the coolant differs from the supply in the return pipe by 1-2 degrees. Therefore, in heating systems of small circuits, it does not matter where the pump is installed. The installation of a circulation pump for heating is carried out at the time of installation of the heating system; if it is operational, the coolant should be drained before this. You don’t have to do this if there are taps installed on the incoming and outgoing pipelines that block access to it. Then you should close them and begin the installation.

Install it in the direction indicated by the arrow on the body. It means the movement of coolant. A cleaning filter should be installed before entering the pump. Protect each threaded connection with sealant and gasket between mating parts. The pump must be installed strictly horizontally, otherwise the rotor can be damaged, and its constant “rumble” will be heard. After installing and filling it with coolant, open the central screw located on the top cover. Some liquid will come out of the hole. This will remove excess air from the pump. It can be connected to a 220V network either using a regular electrical plug, or through an electrical machine.

Install a pump in the supply line in the “warm floor” system. This will prevent any possibility of the flow breaking and air entering the system. The formation of air pockets is the biggest nuisance in heated floors.

How to connect a circulation pump to electricity

The circulation pump is an important element of modern heating systems. It is needed for forced circulation of water in the heating system, which allows you to save up to 30% on heating private houses and cottages.

The savings lie in the fact that the coolant quickly passes through the pipes, as a result of which the water does not cool down so quickly and, accordingly, there is no need to heat it very much. This article will discuss the correct connection of the circulation pump to the electrical network.

Diagrams and video instructions will help you carry out electrical installation yourself without errors!

What is important to know?

The wiring diagram and methods of connecting a device such as a circulation pump to electricity can have different designs. The choice of a specific option is determined by the characteristics of the heated object, as well as the location where the device is located. There are two ways to connect it:

- direct connection to a 220 V power supply;

- connection to an uninterruptible power supply, which in turn is connected to a 220 V or 220/380 V network (in the case of a three-phase UPS).

By choosing the first method, the consumer risks being left without heating in the event of a prolonged power outage. This option can be considered justified only if there is a high degree of reliability of power supply, reducing the likelihood of a long power outage to a minimum, and also if there is a backup source of electrical energy at the site. The second method is preferable, although it requires additional costs.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually signed (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Hello. My situation, a 25 x 60 pump is located immediately after a 6 kW electric boiler, then the line from a 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, a branch goes up, then 4 m, down, rings a house of 50 sq. m. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bathhouse there is a branch 40 mm up, it leaves the bathhouse and enters the 2nd floor of a house of 40 sq. m. m. (there are two cast-iron radiators) and returns to the bathhouse in the return line; there was no heat on the second floor; the idea of installing a second pump in the bathhouse for supply after the branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

The most economical and convenient option for heated floors is water floors with connection to boiler. This system allows you to save a large amount of energy and makes it possible to independently regulate the heating temperature. In addition, it is easier to install.

- - wall-mounted boiler for heated floors;

- - collector cabinet;

- - shut-off valves;

- - compression fittings;

- - circulation pump;

- - thermostat (preferably, although not required).

Install heated floors in a sand-cement screed. To do this, prepare all the system components. Remove the existing screed and distribute all the elements of heated floors over the area where they are planned to be installed.

Then hang the boiler for heated floors in a convenient place - so that the loops of water pipes come from the collector. If you are installing floors in your own home, then it is advisable to place the equipment in a specially designated room. Regarding the installation of a boiler in an apartment, it is better to consult with an experienced technician.

Install the manifold cabinet. Its task is to circulate water in the pipes and combine floor heating with other home heating.

Place the supply and return pipes into the installed manifold cabinet. The first will supply hot water to the water floors. the second is to take the cooled liquid and return it back to the boiler. Install a shut-off valve on each pipe so that you can turn off the water if necessary.

Using a compression fitting, connect the pipe from the boiler to a metal valve, and connect the manifold inlet to the valve. Use fittings to connect the heated floor contours to the manifold.

Install a circulation pump in the collector designed to continuously circulate water. It is mounted on the supply pipe. It is better to purchase a pump with a thermostat. which will allow you to regulate the temperature of the floor heating.

After this, turn on the system and check its operation.

The final installation of heated floors is carried out only after the operation of the heating system has been checked. It should function for at least 10-12 hours. And, if everything is in order, the floor surface is laid over the pipes. Otherwise, there is a risk of flooding your own home due to a minor mistake. If the pipes are laid in a sand-cement screed, the system can be turned on only after the solution has completely hardened.

To avoid problems with connecting many different control devices, you can purchase a pump mixing circuit for wall-mounted boilers, which includes a circulation pump and almost the entire set of equipment.

- Installation of water heated floor

- how to connect a heated floor

Installation of Vilo pumps

Today, Vilo pumps are very popular on the market. They have good technical characteristics. A wide variety of sizes of threaded and flanged connections allows you to choose exactly the type of pumping equipment that is ideal for installation in an existing heating system. But the heating radiator itself will not be involved in the work.

It is worth considering how to connect the heating pump to Vilo. Installation of fork units is not difficult. The Wilo pump can be installed directly on the pipeline. There are different models. If the room has a small area (up to 750 sq.m), then you should give preference to the Wilo-Star-RS model. The pumps in this series are equipped with three-stage switches. For power supply, a current of 230 volts is required. The device can operate at a working fluid temperature from -10 to +110 degrees. In this case, the ambient temperature should be no more than +40 degrees.

Installation of this unit involves horizontal placement of its shaft. The terminal box has two cable outlets. Therefore, the Wilo heating pump can be connected to the electrical network from any side. Thanks to the spring-loaded terminals, the cable is connected very easily.

Thus, connecting a heating pump is not a difficult job. And you can do it yourself. The main thing is to choose the right pumping equipment, know the installation features and follow a number of rules when installing the device.

What is a circulation pump and why is it needed?

A circulation pump is a device that changes the speed of movement of a liquid medium without changing pressure. In heating systems it is installed for more efficient heating. In systems with forced circulation it is a mandatory element, in gravity systems it can be installed if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the outside temperature, thus maintaining a stable temperature in the room.

Cross-section of a circulation pump with a wet rotor

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but are very noisy and require regular maintenance. Units with a wet rotor operate almost silently; with normal coolant quality, they can pump water without failure for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than sufficient for heating any private home.

The uniformity of heat distribution in a home with an independent heating structure depends on the type of pump, thanks to which the coolant is forced to move through pipes and radiators.

Advantages and disadvantages of using a pump

Previously, private homes used natural heating. The heat source was a stove, a gas boiler, some were connected to the central heating network. Modern manufacturers of heating equipment offer small-sized devices that have their own advantages:

- The speed of movement of the warm medium has increased. The heat generated by the boiler enters the batteries faster, and accordingly the room warms up faster.

- With the accelerated movement of the coolant, the throughput characteristics of the pipes increase, that is, an identical amount of thermal energy can enter the rooms through pipes with a smaller diameter.

- The highway can be laid with a slight slope, and its complexity and length can take on any value. The main thing is that the pump data matches the required power.

- It became possible to implement heated floors and a more efficient closed-type heating system.

- Possibility to hide heating communications that pass through the premises.

- Pipes can be laid behind suspended ceilings, under floors, behind walls.

The disadvantages of pump heating include the need to use electricity consumed by the pump. If electricity is often cut off in the area, it will be necessary to install a unit in the house that will ensure its uninterrupted supply.

Where should the device be installed in the heating system?

The device is mounted on the line immediately after the heat generator installed on it, up to the first branch branch.

Where is the best place to install the device?

The performance of the pumps on the supply and return branches will be equally effective, since the difference in the static pressures of the coolant in one direction and the other is not significant and does not affect the heating of the room.

Are there any exceptions?

Yes, if cheap boilers operating on solid fuel are used. They lack automation. Therefore, in case of overheating, the coolant boils. Problems begin when the electric pump fills with water and steam. It comes out through the body of the device with the working wheel, and the following is observed:

- Gases affect the pump impeller and its efficiency decreases. The coolant begins to circulate more slowly.

- There will be insufficient liquid flowing into the tank. Overheating of the device is inevitable, and even more steam is formed, and when it enters the impeller, the heated water stops its movement. Increased pressure causes the safety valve to operate. The steam is released directly into the boiler room. An emergency situation is evident.

- If the heat source is not immediately extinguished, the valve will not be able to overcome the load, and an explosion will occur.

As a rule, no more than five minutes pass from the moment of overheating to the time when the fuse valve trips. When installing the pump on the return branch, this time is 30 minutes, and it is quite enough to stop the heat supply.

Hence the conclusion: it is undesirable and, moreover, dangerous to mount a circulation device on the supply branch of the heating main. It is better to install pumps for solid fuel boilers in the return line of the pipeline. This condition does not apply to systems with automation.

Heating system with a complex of lines

In a scheme divided into several separate heating lines that heat different floors or sides of the house, each branch has its own pump installed. When installing a specific device, you can adjust the desired operating mode. Since heat tends to rise upward, it will always be warmer on the top floor, so you can reduce the circulating speed of the coolant. The insertion of the device is carried out in the same way (after the heat generator to the first branch). When installing two devices in a two-story mansion, much less coolant will be consumed for heating the second floor.

Device connection diagrams for different heating systems

If the pump is domestic, it must be installed in an area convenient for its maintenance. On the supply side, the device is mounted after the safety unit and shut-off block of the boiler.

On the return branch of the pipeline, the device is mounted in front of the heat generator. Since water contains various impurities (sand, etc.) that can jam the impeller, a mud filter is installed in front of the pump.

An open-type heating network can operate in two coolant circulation modes: gravity (natural) and forced. The first option is suitable for areas with frequent power outages. This is much cheaper than buying a generator or uninterruptible power supply. Here the ball shut-off valve is mounted on the bypass. While pumping is in progress, the tap is closed and the system operates on a forced principle. When the power is turned off or a malfunction occurs in the device, the bypass valve is opened and the valve leading to the pump is closed. The system begins to act as a gravitational one.

Circulation device and boiler operating on solid fuel

Here the pump is connected to the system on the return branch and connected with a mixing valve and bypass to the boiler circuit. The three-way valve can be equipped with a servo drive and a clamp-on temperature sensor. Since heating devices operate at full power only in the cold season, you can install a heat accumulator that can absorb excess heat and then, upon request, return it to the heating system. On the battery, on one side there are two pipes for connecting it and two on the other side for connecting to the radiator branch.

Pump installation diagram

In order for a household circulation device to function normally, it must be correctly mounted on a pipe or control valve. Fastening is carried out using union nuts. This method of fixation makes it possible to remove it at any time for inspection or repair. Installation of the heating system elements according to all the rules guarantees uniform heating of the mains. When installing the pump, the following rules must be followed:

- The device can be installed in any location. The pipeline itself can be located at an angle, vertically or horizontally. But the rotor axis must be horizontal.

- The plastic box with electrical power contacts must be positioned so that they are on top of the housing, otherwise in the event of an accident they may be flooded with water.

- The pump is installed so that the arrow on it indicates the direction of flow.

Additional equipment

Regardless of the type of system where heat is produced by the boiler alone, it will be sufficient to install one pumping device. With a complex heat supply scheme, it is possible to use secondary devices. The need for this arises in cases where:

- heating a building requires more than one boiler;

- the piping scheme is equipped with a buffer capacity;

- the heating system branches into several lines;

- hydraulic separators are used;

- the length of the heating main exceeds 80 meters;

- need to organize heated floors.

In order to properly connect a number of boilers operating on different fuels, it is necessary to install additional pumps. For a circuit with a thermal accumulator, secondary pumping devices are also required. The main line, in this case, is built from two circuits: boiler and heating.

A much more complex system is implemented in 2- and 3-story buildings. Branching a pipeline into several branches requires the use of two or more pumps. Each of them supplies heat to its floor to specific heating devices.

If the house is designed with heated floors, then two pumps are installed. One of them will be responsible for the coolant, designed to maintain a temperature of 30-40 degrees. Celsius.

Connecting the pump to the electrical network

It is advisable to install a special power supply line with automatic protection. To connect, you need to use three wires: phase, ground and neutral. The connection can be made in one of the following ways:

- use a differential machine device;

- connect to an electrical network with an uninterruptible power supply;

- use an automatic boiler system;

- use a thermostat.

Experts do not recommend turning on the pump using a plug and a standard socket. This method is not safe. There is no grounding and no surge protection.

Conclusion

If all the rules are followed, there will be no difficulties installing the pump and connecting it to the power source. The most difficult task is inserting the device into a steel pipe. But, if you use taps to apply threads to steel pipes, you can personally form a pumping unit.