Constantly facing the problem of high cabinets and shelves? Do you have to use chairs all the time to get the right item or clean up in a hard-to-reach place?

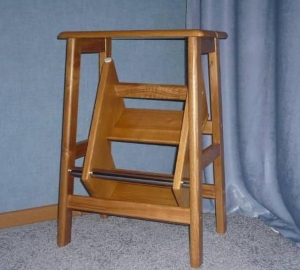

It is inconvenient to take out a heavy metal stepladder from the pantry every time. It is best to make a multifunctional ladder chair with your own hands.

This piece of furniture fits perfectly into any interior, takes up minimal space and serves as an indispensable assistant.

Choose a suitable design model, prepare the right materials, tools and start making a practical and beautiful step-stool.

There can be many options for making a step-ladder chair, the main difference between them lies in the design.

There can be many options for making a step-ladder chair, the main difference between them lies in the design.

For example, you can make any of the following multifunctional chairs with your own hands:

- transforming chair;

- high step stool;

- ladder chair;

- step stool with spiral module.

A transforming chair: when folded, it is indistinguishable from an ordinary chair with a back, and to get a stepladder, it is enough to “lay out” the design details. At good design Such a chair fits harmoniously into any interior design. When unfolded, the ladder consists of three steps.

A high step stool involves the manufacture of a structure that includes a high chair, as well as a retractable module, which, if not needed, slides under the stool seat. The stepladder is made in the form of a pair of durable steps (the seat of the chair, respectively, can be used as the third step). Steps slide out with drawer guides.

A kind of step-stool is a ladder-chair. It can be both with a back and without it.

Another option for a step-ladder chair is a stool. compact size, from under the seat of which the steps extend in a spiral. This is very interesting idea multifunctional chair, which also has an unusual appearance, both in the unfolded state and in the folded state.

Materials and tools

Natural wood is used as the main material for the manufacture of the step-ladder chair. You can also use plywood.

Natural wood is used as the main material for the manufacture of the step-ladder chair. You can also use plywood.

These materials are distinguished by numerous valuable properties. First of all, these are natural, environmentally friendly materials, which is important at the present time. In addition, they are easy to process and finish.

The main thing is that wood is different high level strength, reliability and durability.

The tools and materials that will be needed to make a step-ladder chair depend on the type of furniture chosen.

Fastener materials and tools , required to make a chair:

![]()

- Sandpaper;

- Dowels / dowels, screws;

- self-tapping screws;

- Glue;

- Electric jigsaw;

- Hacksaw;

- Drill with drills;

- Plane;

- Clamps.

- Piano loop (for a transformer and a ladder stool);

- 2 sets of rails with which steps are extended with a length of 31 cm (only for a high stool);

Transforming chair

First of all, you should draw patterns for blanks. Prepare the following details for them:

First of all, you should draw patterns for blanks. Prepare the following details for them:

- 2 front sidewalls (2 x 27 x 40 cm) - A;

- 2 rear sidewalls (2 x 32.5 x 85 cm) - B;

- 3 backrest strips (2 x 5 x 40 cm) - B;

- Rear seat (2 x 16.5 x 40 cm) - D;

- Front seat (2 x 9 x 40 cm) - D;

- 3 steps (2 x 12 x 36 cm) - E;

- 6 planks (2 x 2 x 9.5 cm) - F.

Stages of work:

- The details of the future step-stool must be carefully sanded. To process sharp ends with a milling cutter.

- The back of the chair can be made from slats or solid. It is attached to the sidewalls with self-tapping screws.

- steps and seat are connected to the sidewalls with the help of grooves. grooves choose chisel half a tree cut. When assembling, the joints are lubricated with glue and amplify screws that are screwed into drilled guide holes.

- Two parts structures are connected piano loop appropriate length.

Note! The chair will turn out more decorative if the back and seat are made of wood of a different, contrasting color.

High step stool

To make a high step stool, you will need separate blanks for the chair and steps.

To make a high step stool, you will need separate blanks for the chair and steps.

The design of the chair consists of the following elements:

- 4 large legs (1.9 x 10 x 72.5 cm);

- 2 rails for the bottom

(1.9 x 10 x 42 cm); - 2 bars for the top

(1.9 x 3.8 x 18 cm); - Drawers: 2 upper (1.9 x 12.5 x 34.5 cm), lower (1.9 x 10.5 x 34.5 cm);

- 2 plywood linings located on the sides (30.5 x 17 x 25 cm);

- Upper step (1.9 x 27 x 44.5 cm).

For steps prepare blanks with the following parameters:

- 4 medium legs (1.9 x 10 x 47 cm);

- 2 crossbars (1.9 x 10 x 40 cm);

- 2 small legs (1.9 x 10 x 21.5 cm);

- 3 front drawers (1.9 x 9 x 22 cm);

- 1 back side (1.9 x 10.5 x 30 cm);

- 2 steps (1.9 x 18 x 29.8 cm).

Stages of work:

- For a high step-ladder stool, it is necessary to properly cut and prepare all the details, carefully sand each workpiece to perfect smoothness.

- In order for the stool to be stable, the legs should be parallel at a 10-degree slope. Make sure that the ends of the crossbars and the plywood lining diverge.

- If dowels are selected as fasteners for the middle legs, make grooves for them (dowels are inserted into the holes).

- The ends of the tsarg should be cut at an angle of 80 °.

- When sawing the bottom step, make two cuts 3.8 by 3.8 cm so that it aligns correctly with the legs of the smallest size.

- The large legs and upper rungs are connected with screws, the same is done with the sides and the top step.

- Middle legs are assembled dowels, crossbars are attached. All together these details fasten back and front tsars.

- Use screws, to connect the small legs and crossbars, attach the front side, steps.

- Install the stool and steps as they will stand when finished, screw guide. If there are no flaws in the design, disassemble construction in reverse order and connect all the parts again using glue. Clamps are used for dense workpiece compression.

Ladder chair

For this model transformer you need to prepare the parts with the following parameters:

For this model transformer you need to prepare the parts with the following parameters:

- Seat(28 x 36 cm);

- Walls located along sides(28 x 62 cm);

- 2 grounds(28 x 32 cm, 20 x 28 cm);

- 4 transverse planks (2.5 x 6 x 36 cm);

- 2 support planks (2 x 2.5 x 6 cm);

- Walls on the sides of the module (20 x 23 cm);

- rear wall (23 x 24 cm);

Stages of work:

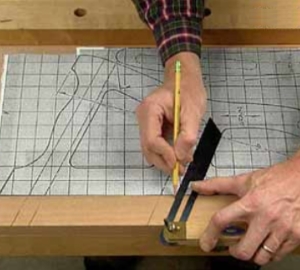

- First of all, it is created drawing ladder chairs, and along it patterns all parts that are subsequently applied to wooden blanks for cutting out elements of the future transformer.

- Every detail is meticulously grinding, free from sharp edges and corners.

- Once all the details are ready, you can proceed to assembly. The side parts of the stool are fastened in pairs, crossbars are fastened with self-tapping screws.

- Compound stool and steps is performed using piano loop.

Advice: By getting rid of pointed edges and corners, you will significantly extend the life of the step-stool - the sharp ends can break off under significant loads.

Step stool with spiral module

To create this model of a multifunctional chair, make wooden blanks:

To create this model of a multifunctional chair, make wooden blanks:

- 3 legs (diameter - 3.8 cm, length - 57.1 cm);

- 3 legs (diameter - 3.8 cm, length - 36.8 cm);

- 3 legs (diameter - 3.8 cm, length - 16.5 cm);

- 1 stepped leg, tapering upward (7.6 x 16.5 cm; 5.7 x 20.3 cm; 3.8 x 20.3 cm);

- Seat and base (30 x 58 cm);

- Upper step (24 x 52 cm);

- Lower step (17.5 x 45 cm).

Stages of work:

- The inner corners of the steps, except for the top, are rounded. Holes are made in opposite corners for a stepped leg. The diameter of the holes must match the diameter of the leg.

- The first time the design is assembled, so that you can make sure that there are no shortcomings. At this stage, mark the base for cutting out excess sections.

- If all the parts are cut out and connected correctly, you can disassemble the structure and process each element with sandpaper.

- Now you can completely assemble the chair using self-tapping screws, and after pre-treating the joints with glue.

Product finishing

The traditional finish of a wooden product will suit any model of a step-ladder chair. To treat all parts with an antiseptic.

The traditional finish of a wooden product will suit any model of a step-ladder chair. To treat all parts with an antiseptic.

After assembling the structure, it is necessary to carry out the final grinding procedure. Next, the surface of the chair is covered with a primer mixture.

After the primer has completely dried, you can cover the piece of furniture with tinted varnish or paint. If you opt for paint, then you can fix the coating with a transparent varnish.

Since the multifunctional chair will be used quite often, this finish will suffice. In order for the design to be harmoniously combined with the interior of the room, choose the appropriate tone of the paintwork material.

How to make a beautiful wooden transforming chair with your own hands, look at video:

To make such a useful thing in the household as a do-it-yourself step-stool, you will need drawings, suitable materials and patience. In fact, this is a very simple design, but at the same time it can replace a bulky staircase.

Design features

The peculiarity of this version of the stool lies in the fact that it combines two items at once: an ordinary element of seating furniture and a small step-ladder. Of course, this is a huge advantage of this product. It is especially useful in the household when you need to get to the top shelves in cabinets or wipe furniture from above, change a light bulb or hang curtains.

The stool is easily transformed into the desired configuration

What is the essence of such a stool? The fact is that steps are attached to its legs, so a miniature and rather compact staircase is obtained from an ordinary stool. Such a chair can be:

- stationary;

- folding;

- transformer.

The first option is a high stool with inclined legs and additional cross bars, each of which is a step. The folding version is more convenient to use, since if necessary it can be taken out and unfolded, and then folded and put in the pantry so that it does not take up space. The transformer is a chair that turns into a full-fledged home step-ladder with a support on the back in one movement.

Used tools and materials

In order to make such a wonderful stool, you will first need boards. You can additionally use plywood, it is very durable, and therefore perfectly cope with its role.

In order for the ladder to withstand the load, it is necessary to use durable wood species. Habitual pine can dry out and crack over time.

To do the job, you may need the following tools:

- jigsaw;

- drill;

- Sander;

- chisel;

- a hammer.

For fastenings, you can use wood glue, nails, hinges and corners.

The work may need tools to make the right angles

Easy option

The easiest option is a stationary stool-ladder. To make it yourself, you will need a minimum set of elements. The essence of the design is to add a few additional details to the usual version of the furniture in such a way that the result is a strong and quite stable staircase. And although its height will be relatively small, it will certainly come in handy more than once on the farm.

To get started, prepare all the structural elements, you will need:

- legs: two long and two short;

- cross bars;

- seating boards;

- boards for degrees;

- fastening bolts or nails.

Measure the length of the legs; they should be positioned so that the short parts rest against the floor perpendicular to the surface, and the elongated ones are installed with a slope of 70-80 degrees with a flat base.

Scheme of a structural solution for a simple step-stool

Connect the long legs together with three strips that act as steps. Each step is fastened into recesses and glued with carpentry glue, and for greater reliability, parts can be hammered together with nails.

After that, you need to connect the short legs with transverse slats. This is done as follows: one at the bottom and one at the top, and the third is attached diagonally to the resulting square. To fix the structure, long and short legs are connected diagonally on each side. The seat is attached to the top with two supporting cross bars.

If you use not nails, but bolts and hinges to fasten the transverse diagonal strips, you get a folding version.

Folding chair-transformer

A folding stool with ladder functions is not the limit. The folding chair-transformer looks much more interesting. It is made of figured boards and contains solid elements that not everyone can do at home due to the lack of a special tool.

Folding step-ladder chair

To make a ladder out of a chair with a back, you need to turn it over. This movement is possible thanks to the installation of hinges at the junction of the two parts of the seat. In the usual position in the middle are boards adjacent to each other, so to speak, the third leg. If you unfold it, the seat folds in half. Now it is a step, and the back serves as a support for a four-level stepladder.

Protective treatment

So that over time the step stool does not fall apart, it must be processed immediately after completion of the assembly work. To do this, use antiseptic water-repellent impregnation, drying oil, varnish, stain or paint.

For a chair often used as a step-ladder, a triple layer of varnish is optimal.

So that the ladder does not jam and the chair can be folded and unfolded without much effort, all turning parts must be oiled. Such a stool is simply indispensable in the household, so do not spare your time and effort and do something similar.

The article outlines the phased implementation of a folding transforming chair, drawings, photographs, videos are given, according to which you can make a step-stool yourself from profile pipe and plywood. Are given.

- How to make a folding transformer chair out of wood: a step-by-step guide

- Drawing

- Material

- Mounting

- Dimensions of a small wooden staircase Ikea

Folding chairs will free up a lot of extra space. They can be kept in the pantry or on the balcony until guests arrive and do not clutter up the room with unnecessary furniture. In the folded position, the chairs will not take up much space in the kitchen until the moment the family sits down at the table. They are convenient in the country, when transported in the trunk for a picnic. Self-made, transformer structures can be stronger and more attractive than purchased ones, and their size, shape, color match the design and space of the room.

How to make a folding transformer chair out of wood

Drawing

Having thought over the desired configuration, work should begin with a drawing of the future chair. It’s good if there is a drawing or photograph of the product that you can focus on in order to clearly see the parts and the location of the parts. You can take a model as a basis, which is made according to the principle: the front frame of a longer length will be both the back and front legs of the chair, and the shorter frame will become the rear legs and support for the back, the seating position is fixed by a cross member mounted on the rear frame. The product is offered in medium standard sizes.

The drawings will help to think over the connections, the number of parts, material consumption.

Material

Blocks for the front and rear solid wood frame can be bought ready-made or cut yourself from a dry, suitable size board.

You will need five crossbars: two on the legs of the chair, one fixing the position of the seat, two on the back of the chair. All of them can be of the same size 50x20 mm. Their length is equal to the width of the seat.

You can fasten the cross bars with frame bars in various ways, which will determine the set of materials:

To connect the long and short frame, two furniture hinges 60 mm long and 20 mm wide are required.

Two long flat or countersunk head furniture screws are needed to secure the movable seat to the front frame of the chair.

The seat is made of a solid board, adhesive material, 15-20 mm thick or a wooden frame with plywood glued to it. The depth of the seat is 500–550 mm, the width for our example is calculated: 430 - 2 x 40 = 350 mm (subtract two widths of the front frame bars from the width of the finished chair).

Mounting

How to make a do-it-yourself step-stool from a profile pipe and plywood according to drawings, photographs and videos

A low stepladder in an apartment and a private house is an indispensable item. It is needed to change a light bulb, wipe dust on hanging and high furniture, get to the mezzanines, will be needed during repairs, for gardening and a lot of household work. When such a stepladder folds into a stool, it becomes a common part of the interior of the kitchen, corridor, veranda.

The frame made of a profile pipe and the width of the base make the structure durable and stable. Parts are mounted on ordinary bolts, and the seat and steps made of plywood simplify the design of the product. The height of a folding stepladder on two steps will be the same size as a regular stool, transformers on three steps fold into a high stool.

Drawings, photographs, video footage will help you build a step-stool from a profile pipe and plywood with your own hands.

Dimensions of a small wooden staircase Ikea

In everyday life, there is often a need for a low ladder, two or three steps. Since such small ladders are not produced due to their extreme instability, they are replaced by transforming stools and ladders. Variants of such structures made of solid wood are represented by Ikea with the models “bekvem” and “molger”.

Ikea "bekvem" - these are two designs: a stepladder 63 cm high with three steps made of beech and a stool-ladder 59 cm high, 43 cm wide, 39 cm deep, made of birch.

How to make folding transforming chairs, a do-it-yourself step-stool from a profile pipe, plywood - drawings, photos, videos, dimensions of a small IKEA wooden ladder

A stepladder is a versatile and very useful device for handy work on the farm. It is difficult to imagine a replacement for her when repairing at a height, a meter above human height, or when harvesting a bountiful harvest from trees. Pluses to the perception of the stepladder-stool-chair are added by the fact that it can be made without any specific knowledge, and also without a significant waste of time. Moreover, there is a stepladder, a stool and a chair of several types, which will be discussed in the article. A general visual representation can be obtained by watching a special video:

To fix the structure of the stepladder, you need carpentry glue, nails, hinges with corners, as well as the desire to make a chair or stool. To make a stepladder-stool-chair, you will need a certain set of tools and materials. Among them:

- boards or very strong plywood;

- drill;

- jigsaw;

- Sander;

- a hammer;

- chisel.

Do-it-yourself stool-ladder

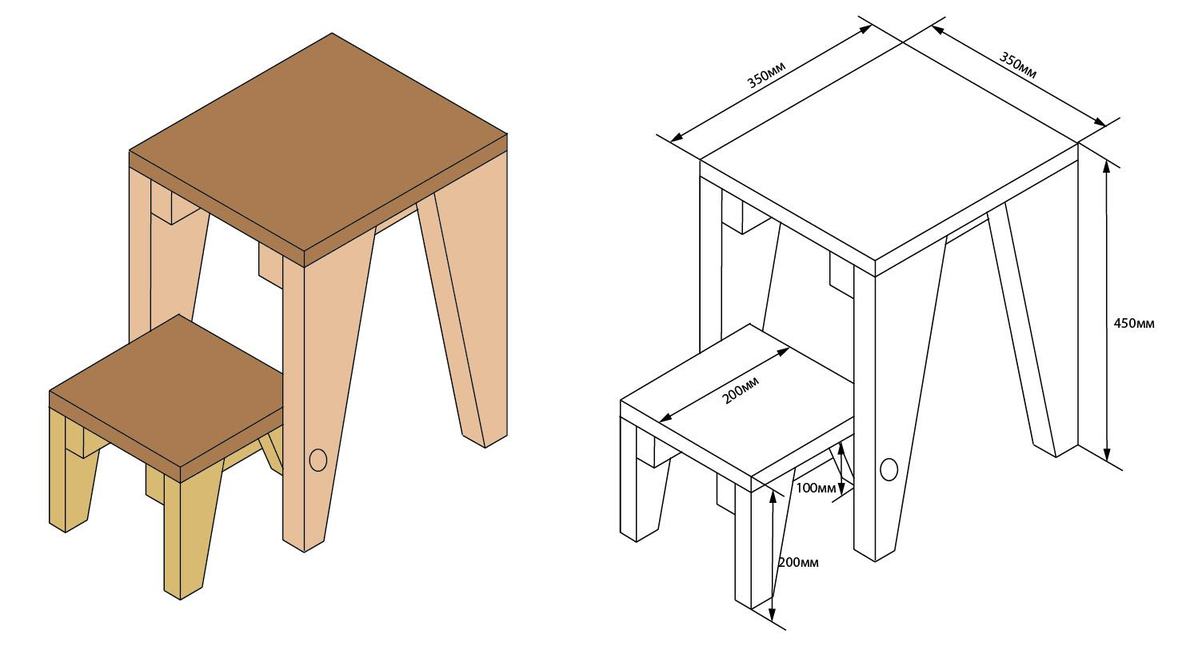

A general schematic view of such a finished stool and a drawing (you can already do it yourself):

We do not know for certain in whose head the idea of \u200b\u200b"crossing" a ladder and a stool first appeared, but we can only rejoice at the ingenuity of this individual, whose invention - a step-ladder-stool - helped a great number of people in the household. A useful stool can be in the kitchen, pantry or other similar place, where it is problematic, but still necessary, to reach the uppermost shelves with your height.

Such a stool-ladder can be made with your own hands from improvised materials. The article will tell you one way how to make a stool-ladder, which will help you climb to the topmost shelves.

First you need to take the source material for the ladder. For example, old window frames will be used as the starting material. The wood from which such products were made is perfectly preserved. All thanks to the generous coating with a thick layer of paint, to protect against negative influences. But still, they should be carefully examined - as a rule, the boards from which the sides of the window frames are made are already drying out and will become an unreliable material for building creativity.

After preparing the tree for the construction of a stool-ladder, first of all, it is necessary to put together a seat with your own hands, along which you can continue to navigate when creating the entire stool. The seat should be quite high (over 2 cm), and also have a fairly large size so that you can sit on it. Here it is better to choose a size from 35 * 35 centimeters.

The legs of the stool should be about half a meter long, wide enough to create the correct emphasis on the ground and be able to support the weight of a person.

In order to connect the constituent parts of the stool and they did not fall apart at the first load, it is necessary to attach the legs of the ladder stool to the seat with your own hands.

The step is made according to the same principle as the stool, according to the above drawing, with the only difference that its dimensions are smaller than the stool-ladder. As you can see in the diagram, one pair of stool legs is shorter than the other. In this more short couple the legs of the stool must be made a hole having a diameter of 12 millimeters. It is necessary for the rods on which the entire structure will rotate.

For fixing, holes for self-tapping screws are drilled near the rod hole. Screw the rods into the holes of the stool intended for them and make sure that their centers are at the same distance from the legs of the ladder stool.

To ensure increased stability of the step, it is necessary to work well on the fulcrum so that it is good not only in the open state, but also in the folded state. It is necessary to drill and attach another wooden plank from the bottom edge of the leg of the stool-ladder to it across.

To get rid of the aesthetically unattractive numerous screw heads, they can be sealed with glue and then cut off with a hacksaw. Due to the visual similarity, they will not contrast very much in their color.

Do-it-yourself step-ladder chair

This home use item is also designed to reach the necessary things among many other "necessary" things, to clean up the order for which there is not enough growth. The step stool has much in common with the ladder stool, except that in a more familiar state, the design is not like a stool, but a chair. The clear benefits of the chair are listed below:

- there is no need to store the ladder and chair separately;

- the step chair can be used as a place to sit in Everyday life;

- just one movement of the above design will allow you to turn it from a chair into a stepladder for the necessary minor repairs or get something from a considerable height;

- the use of a chair not only in the apartment, but also on summer cottages, outbuildings, storerooms, etc.;

- availability of manufacturing and the ability to choose the material from which the chair will be made.

And here is the actual scheme of the chair, which was mentioned earlier:

What is the manufacturing process of this step stool? It is necessary to perform the procedure in the following sequence:

- First, the main support of the chair is made. It is generally shown on the left.

- then the rest of the seat is made with the back of a stepladder chair. The back of the chair should not be solid, but with free space where you can put your foot.

- in the upper part of the chair structure, in the middle, hinges are installed like those that are installed on the door.

- check the operability of the chair design and the correct execution and following of the scheme. If everything works as it should, then when turned 180 degrees, a high-quality stepladder should be obtained from the chair. If something is not even, you need to look for the problem and solve it until the desired result is achieved.

Do-it-yourself step-ladder stool

About the features of making such a useful tool in the household as a stepladder-stool, I advise you to watch the video:

What is the versatility of the application and use of such a ladder-stool? The fact that it can be used in many situations, namely, a stool can be:

- folding;

- transformer;

- stationary.

A folding stool is more convenient in practical use among those living spaces where there is little space. A transformer is a stool that can turn into a full-fledged stepladder with one movement. A stationary step-stool is when the legs are located at a significant inclination and have transverse slats, each of which can be used as a step. The scheme-drawing of the ladder-stool is as follows:

Explanation for the ladder stool diagram:

The extreme legs of the stool should be set so that they rest on the floor at an angle of 90 degrees, and the long ones at an angle of 70-80 degrees, but at the same time their base should stand firmly on the floor. Long legs are interconnected by three pieces of wood, so they play the role of steps. For each step, a certain recess must be cut before this, in which they will be placed. For strength, they are filled with carpentry glue and hammered with nails.

Next, attach the straps to the shorter legs of the stool stepladder. For greater reliability, they are attached in this way: one at the bottom and at the top, and one more - diagonally on the legs of the stool. Also, to fix the design of the stool diagonally, small and large legs are connected on both sides.

Here are three step-by-step guides to design the ladder, stool, chair of your choice. But to put together a stepladder, a chair or a stool is not enough, you still need to look after it so that it lasts as long as possible. This is achieved by additional processing after the assembly of the chair or stool is completed, without shelving. As a protective treatment, antiseptic impregnation with additional moisture resistance, drying oil, stain, varnish or paint is used. In order to avoid jamming during the layout of the ladder-stool-chair stairs, all hinges, all turning parts must be lubricated with oil, and in case of regular use, lubricated with a certain period.

When making a ladder-stool with your own hands, you should use the following formula:

2h+s= 400…450 mm

- H- designation of the height that the riser has. 150-200 millimeters are considered the best combination.

- The length of the tread is indicated as S. It is better to do it at 100-200 millimeters.

Several defining parameters:

- A very high children's ladder-stool should not be. The maximum allowable value is 500-700 mm. Here it is important to pay attention to the angle of inclination of the stairs, the height of the chair.

- No more than 400 millimeters is always the distance between the edge of the seat and the beginning of the steps. Only in this case, the operation will be convenient.

- The upper plane should be such that a person can calmly not only stand, but also sit. Most of the foot area is usually on the plinth.

In addition, the fulcrum must be secure in any of the positions. To connect the long legs, three pieces of wood are enough.

On the final stage it is allowed to set the front edges of the retractable steps in one direction. To do this, we simply completely pull out the free parts of the guide elements into the groove of the prolegs. After that, we firmly fix the structure.

The mount should be as strong as possible, then it will not warp. You can even use glue to connect important elements to each other. You can choose from different manufacturers and prices.

This type of ladder-stool is easy to assemble on your own.. It is important to find a competent drawing in advance, and then strictly follow the technical recommendations, observing all the requirements. Tools and materials for work are very easy to get.

It is necessary to treat the tree with protective compounds immediately after the assembly is completed. Then the ladder will not lose its attractive shape for a long time. appearance. To solve this problem, paints or stains, varnishes, drying oils, impregnations are quite suitable. A triple layer of varnish is the best solution for a wooden structure that is often used. It is also recommended to lubricate all turning parts with oil so that the ladder does not jam. And the chair can be easily folded, laid out at any convenient time.