Before we dealt with the issue of constructing sauna stoves, we ourselves spent a lot of time studying this topic. Therefore, we know that people who have an idea about the designs of sauna stoves usually do not deign to explain everything from the basics, and most of the texts on the Internet are completely written by those who are not at all in the subject.

Listen to the article

Designs of sauna stoves: general points and differences for different types

So what is a stove? This is a fire built inside a container. But combustion is an oxidation reaction of fuel, therefore, it cannot occur without oxygen. Therefore, we will call a furnace that container through which, at least temporarily, with the dampers open, flowing air moves.

Traction

This movement is called "traction" and it occurs when there is inlet and outlet openings.

Of course, such a definition suffers from incompleteness, because it does not apply to. IN In them, heating occurs due to the passage of current through a material with high resistance. This releases heat.

But let's return to furnaces, where heat is released due to a chemical reaction. The art of the stove maker is to skillfully vary the amount of incoming air and the amount of firewood in the stack in order to achieve them uniform combustion and maximum complete combustion.

What happens if the combustion is still ongoing, but the air is blocked? Instead of carbon dioxide, dangerous monoxide will begin to form - carbon monoxide. But why block the pipe if it is so dangerous? – The draft is blocked so as not to cool the stove when the wood burns out, because heat flies into the chimney along with the air.

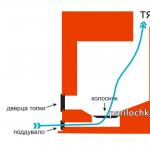

So, we know about the role of air. Let's look at a diagram of the simplest draft furnace. What must be present in it? Three things:

- inlet (air vent or firebox door);

- firebox (aka firebox);

- outlet (chimney).

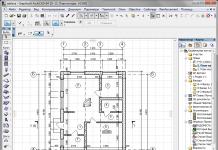

The first division of the stoves can be carried out according to the presence or absence of a blower: Without it, they are called “blind hearth ovens”. In this case, air is supplied through the open firebox door. Here's what both look like in cross-section:

Kamenka

Now let's ask ourselves: what do all sauna stoves have?, but is missing from the stoves that heat houses? Of course it is heater. All sauna stoves, even electric ones, have a container in which the stones are stored. The stones themselves are used as batteries– they accumulate heat. This is necessary so that the high temperature in the steam room lasts longer. Their other function is creating light steam, but in this capacity they are needed only in the Russian bathhouse.

Now let's ask ourselves: what do all sauna stoves have?, but is missing from the stoves that heat houses? Of course it is heater. All sauna stoves, even electric ones, have a container in which the stones are stored. The stones themselves are used as batteries– they accumulate heat. This is necessary so that the high temperature in the steam room lasts longer. Their other function is creating light steam, but in this capacity they are needed only in the Russian bathhouse.

There are two classifications of heaters according to different characteristics: one takes into account contact with fire in the firebox, the second – contact with air.

If there are gaps between the firebox and the heater through which the flames lick the stones, then this is continuous heater.

If the barrier is solid, then it is called a heater deaf.

When the container with stones is inside.

Stoves are either brick, or metal. There is no other option. The first ones are considered very inertial - It takes hours to heat them up, just like it takes hours to cool them down.. The latter are able to heat up in half an hour and during the same time manage to overheat the steam room. Great property!

When choosing a design, you determine for yourself how inertial its body should be. At your disposal not only “clean” options: pure brick, pure, but also combined. For example, you can increase the inertia of a metal stove either by using internal lining of the firebox and heater, or using external. Moreover, the option with a casing and lining at the same time is not excluded).

Important! Answer the question, what is the optimal time for lighting the stove for you - it is this that determines the degree of inertia of the body.

Smoke

What happens when fuel burns? Heat is released and combustion products are formed - steam, gases and solids. The latter we call soot, soot, and all together - smoke. At the moment of leaving the furnace, this mixture is also heated to several hundred degrees. And if you don’t put some kind of heat-intensive obstacle, all this heat will simply fly away into the chimney to increase the greenhouse effect on our planet.

However, once upon a time, not only were there no obstacles, but there were no pipes either. Because they weren’t made from wood! Therefore, the first method for removing smoke is chimneyless, “black”.

In its simplest version it is pile of stones arched over a fire. In the modern version, it is a brick hearth that keeps the same pile of stones from spreading. But the principle is the same: light a fire under the stones, wait for the wood to burn out, release the smoke into the street through or - and you can steam by pouring water on the heated stones.

Then it appears smoke collector– akin to a kitchen hood – the same separated from the stove. A similar option can still be found in the bathhouse today.

Then appears chimney pipe. And if it is simply inserted into the stove (into the firebox or heater - it doesn’t matter), then such a stove will be called direct flow. Heat here is not taken from the furnace gases, so it has the lowest efficiency.

But heat is a pity, so the inventors’ idea went this way: what if we increase the path that the smoke travels inside the stove? This is how the system appeared smoke circulation, where the smoke runs with obstacles inside channels that lead it up and down, or horizontally to the right and left. The system is excellent for heat extraction, but with its drawbacks - channels, especially horizontal ones, must be cleaned regularly, otherwise there will be no traction.

An alternative to the smoke circulation system is bell stove. It has no channels and is practically independent of traction. Hot furnace gases, leaving the firebox, end up under the hood, where they actively share heat with the furnace mass. New portions of hot furnace gases rise, displacing cooled ones down and into the chimney.

However everything said about the chimney primarily applies to brick stoves. It's rare to see a metal stove with smoke circulation. Usually they are primitive - direct-flow, except that they have flame dividers. And their sizes are much smaller than brick ones, there are no passages, and there is no heat-intensive material - where to take the heat?

The stove ends at the chimney. What remains is optional - tank or heat exchanger, which can also be indicated on the diagram of the sauna stove. But it is better to talk about this when analyzing specific structures, to which, in fact, we are moving on.

Scheme of a stove for a brick bath

From the above it already follows that there are several basic diagrams of a brick kiln:

- direct flow;

- with smoke circulation;

- bell-shaped

However, each allows for many implementation options. In other words, the above diagrams clearly demonstrate the characteristic, but do not exhaust the possible.

Bath stove design: direct flow

Metal furnace with lined fuel core

Lining is the lining of the inside of the stove with fireclay or simply refractory bricks. At the same time, the inertia increases sharply, and with it the heating time. So, if you need to overheat the steam room in half an hour, the lining will be superfluous.

BUT! It has one important advantage: it increases the service life of the furnace, because its body is subjected to lower temperature loads. And this is in addition to the fact that such a stove retains heat longer.

We show the simplest diagram with a firebox lining and a closed heater:

Options for placing a water tank on a metal stove

You have already seen above that you can simply place the tank on top of the stove and everything will heat up. But you can do it differently.

Below - schemes for combining a heater and a tank, from the simplest ones, where a bucket is buried in stones or the heater is placed in a separate container where stove gases enter, and the tank stands directly above the fire (the water will boil before the stones heat up) to variations on the theme of rational use of the top of the stove, where you can separate the space for the tank horizontally or vertically, or you can go around the heater on both sides, leaving an air pocket on one of the opposite sides, which is said to promote heat exchange. Full information is provided.

Options for the location of the tank and heater:

Yes, and of course, always, when there is a need for hot water, you can replace the tank with a heat exchanger of one type or another. If you are interested in learning more about this, read.

Metal heater made of pipe

On our website you can find information about how to make such a heater. Here we will only present the diagrams themselves with some comments.

So, the owner has two options for a pipe stove:

- vertical;

- horizontal.

Usually they take a pipe of half a meter diameter. The figure shows that the pipe can be lined from the inside(or you can leave it as is, then it will burn out faster). The fireclay along the walls is shown in yellow.

The owner is also free to choose a stove with a blind hearth or ash pit. The difference between them was discussed above. But pay attention to the oven door with a blind bottom- in order not to keep it open, holes are drilled in it, which provide air flow if the pipe is not blocked by a damper at the top. If you lengthen it a little due to the blower, then the draft will be regulated by opening blower door. Then the holes become redundant.

The water tank is shown in both pictures, but is actually optional. Some make it lower by welding a metal box with a lid on the side of the stove - this for ease of pouring in the absence of cold water supply in the bathhouse.

The horizontal stove has a completely different structure - it turns out to be a heater open. This is a welded basket for stones - With such a stove you won’t be able to get good steam.

Yes, and in the picture we depicted the grate (under the flame) as recognizable, but in reality its grate perpendicular to the direction you see here.

The water tank is welded to the back wall of the stove.

Useful video

Not just diagrams, but also a description of the advantages and disadvantages of vertical and horizontal structures (not necessarily made of pipes). Plus interesting life hacks.

Even more diagrams, even more explanations about them. However, the main concern of the author of the video is that you succeed. So sauna lovers don’t have to watch it).

We hope that you have received some kind of holistic understanding of what a sauna stove is. Other things can only be learned from practice and experiment. Good luck to you!

Where can I buy

It is also possible to obtain useful information from professionals - employees of different types.

In contact with

Probably, any owner of an individual country house, if he does not yet have his own bathhouse on the site, is most likely hatching plans for its construction and equipment. The bathing tradition in Russia is very ancient and persistent, and no modern devices and devices in the form of bathtubs, Jacuzzis, fancy showers, electric heaters or steam generators can replace the real heat from a heated heater and birch broom.

The stove is one of the most important attributes of a Russian bath or a real sauna. The required atmosphere and the required temperature in both the steam room and the washing room directly depend on its effective operation. Currently, there are many models on sale that are specially designed for such conditions. However, many home craftsmen prefer to make a sauna stove with their own hands. Although this task is quite complex and requires good construction or welding skills, it is still quite feasible.

Types of sauna stoves

First of all, you need to understand the main existing types of sauna stoves so that you can choose one of them.

1. By material manufacturing

- For a long time, the main material for sauna stoves was fired brick. This tradition has not become a thing of the past today - many people prefer a brick oven over all others, although, of course, its construction is much more difficult than installing a ready-made one. But it retains heat much longer, and it creates a very special atmosphere in the bathhouse.

Certain difficulties may arise with its construction. So, for a brick structure you will definitely need a foundation that is not connected with the foundation of the bathhouse itself. In addition, the dimensions of the building itself do not always allow such a stove to be placed in it, although, of course, there are projects for very small masonry.

Another difficulty is that the construction of such a furnace requires certain experience so that it does not become a source of potential threat to the life and health of people. Often the desire to have a stone stove forces bathhouse owners to turn to craftsmen. However, you can try to fold it yourself.

- Metal sauna stoves are very popular. Even if they are some departure from tradition, they have a number of advantages:

— Its installation does not take a long time and does not require much space.

— There are a lot of ready-made models on sale, so it’s possible to choose the most optimal option for a specific bathhouse.

— It’s easier to make such a furnace yourself if you have experience working with electric welding.

— For the manufacture of a metal furnace, even seemingly recycled materials are often used - pipe scraps, old rims from trucks, disused gas cylinders, old barrels, etc.

As a rule, only steel stoves are installed in the bathhouse - cast iron is unacceptable in these conditions. Yes, it has a greater heat capacity and maintains the desired temperature longer, but its fragility and instability to sudden thermal changes make it impossible, for example, to splash cold water on a hot stove - cracks may appear.

Additional information about stoves from the website:

The main disadvantage of steel stoves is their fairly rapid cooling after the end of the fire, especially if an insufficiently thick metal sheet was used for manufacturing. However, a massive heater can retain heat for quite a long time.

- The technology of lining a metal body with brick can reconcile supporters of brick and steel sauna stoves.

In this case, a massive foundation will not be required, nor will the masonry joints be sealed, that is, the process of constructing the walls is quite simple.

Combined option - metal stove lined with brickIn addition to good heat accumulation, brick cladding will protect against direct exposure to hard infrared radiation from hot metal surfaces. And one more thing - it can become a good interior addition to a bathhouse, hiding the often not very attractive appearance of a steel stove.

2. By energy carrier used

The vast majority of sauna stoves are designed for heating. There are, of course, models using gas and electricity. Some craftsmen adapt liquid fuel units (for example, diesel fuel) for these purposes, taking the combustion part with the diesel fuel supply system outside.

However, we can emphasize this once again that no other energy carriers, except natural, well-dried firewood, will create in the steam room that healing microclimate for which, in principle, the bathhouse is most often built.

3. According to the location of the firebox

Both brick and metal sauna stoves can have different layouts:

In one version, the entire stove is located in the steam room, that is, its firebox must be fired directly from here. This design is, of course, cheaper, much easier to manufacture and install, but there are also a number of serious disadvantages. So, for example, you cannot create a supply of firewood in a steam room - they will simply become saturated with moisture. Thus, if necessary, to maintain the fire, you will have to run after them to another room or to the street. In addition, a steam room is usually not such a voluminous room, and therefore there is a high risk of getting an accidental burn from touching a hot fire door.

From the point of view of convenience and safety of use, stoves with a combustion chamber door located in the dressing room win, and in the steam room itself there is a heater and, possibly, a tank for heating water. In such a stove you can maintain a fire without disturbing anyone, and in a steam room the overall level of safety increases.

4. According to the method of heating the heater

Finally, sauna stoves differ in the way they heat the stones.

- Currently, constant heating stoves are most often used. In their design, the stones do not have direct contact with the exhaust combustion products - they are placed either in a metal container welded to the stove body, or in special lattice bodies located on the walls or even on the chimney pipe. This stove layout is more typical of a Finnish sauna. The heating temperature of the stones reaches 300 - 400 degrees. Usually stones of a fairly small fraction, like coarse gravel, are used. They are not covered with soot, as they are isolated from combustion products.

The convenience of such a stove is that the process of heating and, directly, taking bath procedures are not spaced out in time - you can maintain the fire and, accordingly, the temperature in the steam room as long as necessary.

- Periodic heating sauna stoves are designed somewhat differently. Their design involves the removal of hot gases directly through the heater, with their subsequent exit into the chimney. The stones are heated to extremely high temperatures - up to 1000 degrees. However, after heating the stove, be sure to wait until the fuel burns completely and carbon monoxide is released - only after that can you proceed to washing. To prevent it from cooling quickly and producing heavy wet steam, it is usually covered with either a lid or a hinged door.

According to this scheme classical Russians usually developed bath stoves - a heated bath was enough for all family members. When water hits such highly heated stones, it instantly turns into steam. The main condition is that they must be massive, carefully selected, round, of a distinct dark gray color, and their total weight must be at least 50 kilograms. From time to time, the heater is dismantled to clean the stones from accumulated soot and replace the destroyed ones.

Schemes of such simple periodic stoves will be discussed below.

- It should be noted that there are models of stoves that combine the advantages of both devices. In them, the heater is divided into two areas - unventilated, located in a special channel through which combustion products pass, and open.

Such stoves are quite complex in design, but they perfectly accumulate heat and produce dry steam, and, if necessary, you can add firewood directly during the washing process.

The stove is the heart of the sauna. In the absence of the proper skills, it is not easy to make it yourself. Think about what is more important: savings, most often imaginary, or the feeling of comfort that accompanies you during the arrangement of the bathhouse and its use.

Those who prefer effective solutions should pay attention to sauna stove options that are sold ready-made. Among them you will find devices that meet all the listed quality criteria, and at the same time have an affordable price.

Thus, among the leaders of the stove market, we can highlight heating installations from the Dobrostal Plant company, the winner of the “100 Best Products of Russia” competition. In the assortment offered by it, the most popular are such laconic stove models as:

- "Heat-Extra 400";

- "Heat-Lux 20".

The device body material is carbon steel, one of the strongest and heat-resistant materials. The ergonomic design of these wood-burning stoves allows them to be used not only as a heating installation, but also as a successful interior solution.

The Zhara-Extra 400 model is designed for heating a steam room ranging from 4 to 12 m 3 . The thickness of the roof and the weight of the stove can also vary based on your requirements.

The “Zhara Lux” series stoves offer a wider range of models, with the ability to choose a device for heating a steam room area from 4 to 30 m 3 .

The structures in question are equipped with a coil chimney, which allows:

- make traction more uniform;

- save fuel.

By the way, the chimney can be disassembled for cleaning at any time.

The devices are supplied with:

- grates;

- decorative elements;

- cast iron door

- closed heater with a funnel for water supply;

- scoop;

- detailed installation instructions.

The stoves of the “Heat” series are able to satisfy the needs of an avid steam room lover, however, if the bathhouse is not a hobby for you, but a real passion, we advise you to pay attention to the “Augusta Profi” model, equipped with a panoramic glass door. The incomparable comfort of using this device will turn all parts of the bath procedure into a pleasure.

The model in question is equipped with:

- closed heater;

- steam generation system.

Using the built-in system, you can independently choose the “mode” for your steam room:

- traditional Russian bathhouse;

- Finnish sauna for real Vikings;

- hammam for lovers of oriental pleasures.

Convection in “Augusta Profi” is established by adjusting special dampers.

The desired model can also be purchased in simplified model variations “Standard”, “Stone”, however, it is the “Pro” version that is the most refined, powerful and multifunctional.

The listed designs represent only a small part of the Dobrostal Plant model range. We advise you to study it and find the ideal heart for your steam room.

Prices for fireplaces and stoves

Fireplaces and stoves

How to make a metal sauna stove yourself

There are countless options for metal sauna stoves, and, by and large, anyone can come up with their own, based on some basic models. As an example, we can cite several very simple stoves, the manufacture of which does not require any special knowledge or skills.

Intermittent heating stove for a small family steam room

This is probably one and h the simplest options. To make such a furnace you will need a metal sheet about 5 mm thick (steel St 3). In this case, it makes no sense to make a stove from a thinner sheet - it will burn out very quickly, and it will not retain heat effectively.

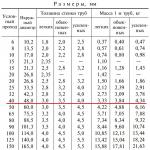

- The dimensions of the stove are small - only 900 mm in length, 800 mm in height including legs, and 600 mm in front width. It can be placed even in a very small steam room.

- For the chimney pipe you will need a piece of pipe with a diameter of 115 mm. Its length can be different - some prefer a short pipe with a flange to connect the chimney, others weld a long enough piece onto which a water heating tank can be placed.

- To ensure that all seams are durable, it is better to make them on a metal corner with a shelf 30 × 30 × 3 mm. The same profile will also be needed for shelves and brackets for internal lattice partitions.

- The height of the stove space is divided into three unequal compartments. The bottom, narrowest one is the ash pan (1) with the ash door. The size of this door is usually small, 2 - 2.5 times smaller than the combustion opening.

- Between the ash pan and the firebox (3), cast iron grates are installed on angle brackets.

- If they could not be found, then you will have to weld a grid of parallel rods with a diameter of at least 10 — 12 mm. The distance between the rods is kept the same - about 10 mm.

- The upper compartment is a heater through which combustion products are removed during heating of the stove (5). Gases pass freely through the grate (4), heat the stones and are discharged into the chimney pipe (6).

- The doors of the combustion chamber and the ash pan have welded hinges and are necessarily equipped with latch valves.

- The back of the heater is welded to one third with a metal sheet (300 × 600 mm), in the center of which a hole is cut into which a chimney pipe is welded, which goes down 100 - 120 mm.

- The diagram does not show the lid that is used to cover the heater when firing the sauna stove. It is easy to make from thin metal (0.8 - 1.0 mm) in such a way that it completely covers the heater and rests slightly down on the walls of the body. This lid will prevent the stones from cooling quickly, and process pre-firing of the bath will prevent the direct release of combustion products into the room, directing them into the chimney pipe. Of course, good traction must be provided for this.

Immediately before starting the bath procedures, this lid is removed and the heater remains in the open position. However, sometimes they also provide a hinged hatch, which is opened when it is necessary to add steam, and the lid is always in place, retaining the heat of the stones longer.

- When the stove is completely welded, thoroughly clean and check the seams, remove burrs and uneven metal. It is recommended to coat the outside of the structure with heat-resistant varnish, specially designed for fireplaces and stoves.

Laying the stones in the compartment intended for them is done later, after installing the stove in place in the bathhouse and connecting it to the chimney. This will be discussed a little later.

The heat from such a stove after heating it should be quite enough for a full-fledged bath procedure for 2 – 3 people.

Metal intermittent heating stove with additional brick walls

Another version of an open type stove, which, however, is somewhat more difficult to manufacture, but its ability to accumulate heat is much higher.

“Double” technology is already used here - a metal body and internal brickwork. In this case, the steel does not need to be too thick - sheets of 1.5 - 2.0 mm are sufficient. Heat-resistant fireclay bricks are used for masonry, and as a mortar it is best to purchase a ready-made dry mortar, specially designed for stoves and fireplaces, and knead it in accordance with the preparation instructions.

- First, prepare a base with legs and heel pads welded to it so that the stove structure is stable.

- Then the first continuous row of bricks is laid on this base. All other rows are made in “half a brick” in the area of the firebox, and in “quarter” - in the area of the chimney ducts.

- After the camera is laid out ash pit(1), a cast iron grate is installed between it and the firebox (2). To leave openings for the blower and loading window when laying, it is fashionable to use jumpers from a metal corner 20 × 20, but only so as not to disturb the evenness of the inter-row seams.

- A grate of metal rods (Ø 12 mm) is installed above the combustion chamber, on which stones will subsequently be laid.

- A window (5) is left on the left or right side of the masonry at the edge of the heater, which will serve for loading stones, for their regular inspection and cleaning, and during bath procedures - for steam generation - it is in it that water from the ladle will splash.

- The winding chimney channel contributes to the most complete heating of the entire furnace structure and complete combustion of all combustion products. In the rear part of this channel, at the level of its upward rotation, an inspection window is left, where a valve will then be installed for maximum heat retention after the fire is completed.

- The top two rows of bricks are made solid, only with a window for the exit of combustion products - in this place the chimney pipe will then be welded.

- When the brickwork is finished and the mortar has set well enough, you can successively weld the walls of the metal casing to the base, which in this case plays the role of a kind of “case”. To make this task easier, and at the same time ensure the tightness of the welds, a 20 × 20 mm corner can be placed along the joints from above.

- When marking the workpiece for the front wall, openings for the ash pan and the combustion chamber loading window are immediately marked and cut out. After the front wall is installed in place, hinges are welded onto which the doors of both chambers with locking devices are hung. The door leaves themselves should be 10–15 mm wider on each side than the embedded windows to ensure tight closure. It would be a good idea to install an asbestos seal around the perimeter or even over the entire area of the inner surface of the firebox door.

- During installation of the side wall, the side of the steam window left in the masonry is also cut out opening and a metal door with a seal is installed. It is better to make it tilt down and equip it with a “cold” handle so that it can be opened during washing to supply steam.

- The last thing to weld is the stove lid with a pre-cut hole for the chimney pipe. Then a piece of pipe with a diameter of 100 mm is welded.

- The stove will be loaded with stones after it is installed in the bathhouse in a prepared place.

Constant heating stoves with open heater

It is even easier to build such stoves from sheet metal or other available materials.

The figure shows an easy-to-make stove made from scraps of a thick-walled metal pipe with a diameter of 325 mm.

The pipe cavity itself is divided into two compartments by a grate. The upper one, the main one, serves as a firebox, the lower one serves as an ashpit-ashpit. Both compartments have their own doors, respectively, for storing firewood and providing air supply and cleaning.

Closer to the far, completely plugged end of the pipe, a chimney pipe with a diameter of 100 mm is welded.

A metal box is welded on top of the cylindrical body, which will be filled with stones. In order to ensure maximum heating of the stones, you can make the chimney in this area not straight, but with a curved elbow - the contact area of the hot pipe with the heater will increase significantly.

It will not be difficult to make a similar stove in the shape of a parallelepiped, using metal sheets as blanks.

Very often, such stoves are equipped with water heating tanks. In the photo of a stove made from a pipe, it is placed on the back plug, which is also the wall of the water tank.

When making rectangular structures, there are many more options - tanks are placed on either side, on top, or even a kind of “water jacket” is made on several sides, with pipes inserted for supplying cold water and extracting heated water.

Another convenient option for solving the issue of heating water would be to install a special heat exchange tank on the chimney pipe.

Such water heaters can be made independently, but it is also possible to purchase a finished factory product, which has a tube of a certain standard diameter. All that remains is to embed this tank into the vertical part of the chimney above the stove and connect the water supply and extraction pipes.

Such tanks can themselves have sufficient volume, or serve only as a heat exchanger and be connected to the main water reservoir.

Video: interesting simple design of a metal stove for a bath

Preparing the site for installing the stove

Making a sauna stove yourself is only half the battle. It is necessary to carefully prepare the place for its installation directly in the room.

Even just a metal stove is a fairly massive structure, especially if you add to its own weight the weight of the masonry and the heaviness of a filled water heating tank. Thus, it is necessary to prepare a base - a kind of podium on which it will be installed. It is best to provide your own foundation for it.

- To do this, a small pit (up to 500 mm deep) is opened in a selected location.

- A sand layer of up to 100 mm is laid on the bottom, then, after compaction, another 200 mm gravel and crushed stone backfill.

- A layer of cut-off waterproofing is laid - usually roofing felt is used for this.

- Then a concrete solution filled with sand and fine gravel is poured to the ground level.

- After this area has completely hardened (at least 3 weeks), a layer of roofing material is laid on top of it, and then a continuous masonry of baked bricks is made

- The laying is carried out either to the level of the “clean” floor of the bathhouse, or even a little, 100 - 150 mm higher, thus constructing a raised podium for installing the stove.

It is impossible to place the stove on a concrete base - despite all its apparent solidity and strength, it will certainly begin to crack and crumble under conditions of high humidity and high temperatures.

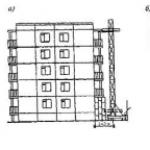

The stove should be located at a distance of at least 200 mm from the walls, especially wooden ones. The walls must be sheathed with heat-resistant material - stainless steel sheet or "isover" - foil thermal insulator based on harmless basalt mineral wool.

Isover is an excellent material for thermal insulation of bathhouse walls where the stove is installedVery often, metal stoves are “dressed” in brickwork. This provides a number of advantages - there is less risk of getting burned on hot walls, plus the brickwork will be another fairly capacious heat accumulator.

More information about this process can be found in. Here are just a few important notes:

- It is recommended to maintain a distance of 100 mm from the metal walls to the brickwork. This is necessary for normal air circulation - a powerful convection flow will be created, facilitating uniform and rapid heating of the steam room. For the same purpose, special windows must be provided at the bottom of the masonry. The metal walls of the stove, lined with brick on the outside without a gap, close together, will burn out very quickly due to disruption of normal heat transfer.

- For masonry, you can only use natural clay stove mortar or special building mixtures intended specifically for such purposes, with pronounced moisture- and heat resistance.

- Covering the stove with bricks must be thought out in advance - this is taken into account when pouring the foundation and laying out the brick podium.

Prices for refractory bricks

Fire brick

Laying stones

The efficiency of a homemade sauna stove will largely depend on the stones - the correct selection and placement of them in the heater.

Even a small stove requires no less than 50 kilograms of installation, but it is still better for a family bath to focus on 80 — 100 kg.

It is better to select cobblestones that are round in shape, even gray in color, and without surface defects (cracks or breaks). It is desirable that the stones be of different sizes - from 50 to 150 mm.

Granite for sauna stove absolutely unsuitable. Firstly, its structure is unstable to frequent processes of strong heating with simultaneous exposure to steam - destruction will begin very quickly. Secondly, granite always contains mica inclusions, and when heated, they can emit quite toxic fumes.

Jadeite is one of the best options for a heater. In addition to its natural beauty, it is also credited with medicinal properties.The best materials, in addition to the usual natural cobblestone, are considered to be soapstone, basalt or jadeite. Such stones of various sizes can be purchased in specialized stores.

It is very important to place the stones correctly. The layout begins in such a way that the largest, most massive of them are at the bottom. They will not interfere with the passage of heat to those located above and will create a powerful supply of heat. Then medium-sized stones are laid out, and only at the very top are small ones.

This order will ensure that the top layer of stones is heated to a temperature of 300 - 400 º - exactly what is needed for dry steam. When water hits well-heated stones, evaporation occurs literally instantly and is accompanied by a characteristic crackling sound.

If the stones are flattened, then their spatial orientation must be taken into account when laying them. The long side should be located along the main heat flow, otherwise a kind of “locking” will occur when the lower stones overheat and the upper ones do not reach the required temperature.

Neglecting the rules for laying stones will sharply reduce the overall healing effect of the bath. The steam will very quickly begin to “get heavier”, and although the overall temperature in the steam room may not decrease significantly, staying in it will begin to do more harm than good - in an over-humidified room it simply becomes impossible to breathe.

Video: how to properly place stones in a sauna stove

Prices for different types of stones for stoves

Stones for stoves

So, a do-it-yourself sauna stove is a completely doable task if you take into account all the technological nuances during manufacturing and comply with the established safety requirements during installation. But a self-made stove will not only help save quite a significant amount, but will also become a source of pride for the owner when the opportunity arises to invite his friends to the bathhouse.

Since ancient times, a brick stove in a bathhouse was especially popular in Rus', which could not be found in one’s own home only in exceptional cases. Over the past few years, baths have literally experienced an incredible rebirth.

First of all, this, of course, is influenced by the fact that more and more people are refusing to live in apartment buildings and are increasingly making a choice in favor of individual construction. That is why the question of how to build a stove for a bathhouse is becoming more and more popular every year.

If you can competently plan the construction process, then you will be able to build your own bathhouse in a short time without any problems, and add a special atmosphere of cheerfulness and health to your home.

Preparation process

All you need to build a sauna on your own site is literally minimal construction skills and a little patience. The first thing to start with is to choose the drawings of the stove for the bath of your dreams.

In most cases, the stove in the steam room is positioned in such a way that one part of the building is responsible for maintaining the level of heat in the dressing room, and the other is responsible for heating the steam room itself.

If we talk about the material that should be chosen for the building at the very beginning, then, in principle, most builders agree that it is possible to use those leftover materials that were not used during the main construction.

The construction process will go much faster if all the necessary tools are prepared in advance.

It is best to have trowels on the right side of the stove, as well as a level, a bucket in which there will be mortar and a hammer.

To the left of the stove, as a rule, there is a bucket of clean water and definitely another bucket with a dustpan, as well as pliers and an ordinary pencil, which will definitely be needed when making various marks.

A pit will definitely be needed for the stove. Particular attention should be paid to its size, namely its depth, which should be at least 0.7 m.

The bottom of the pit, according to the rules, should be covered with about twenty centimeters of sand. After this, the sand is covered from above with crushed stone and broken bricks.

Next, it is necessary to provide a reinforced frame with formwork in the pit. From above, the entire surface must be filled with concrete. Look at the photo of the sauna stove and you will see that usually no more than twenty centimeters are left.

The last two layers of the foundation act as the main waterproofing material. After the foundation is completely ready, it must be checked for horizontalness.

If any shortcomings appear, they can be quite simply eliminated using the flaws that have arisen. After the work has been completed, you can gradually move on to the construction of the bathhouse itself.

The importance of the chimney duct

When installing a chimney, it is very important to pay special attention to the general parameters of the structure. If the homemade metal sauna stove turns out to be quite small, then you shouldn’t make the pipe too massive.

In practice, the approximate thickness of the walls is about half a brick. It is desirable that the cross-section of the smoke passages be the same size.

Final stage

It is very important, after installation is completed, but before use, to dry the sauna stove properly. It is customary to use one of the following methods for these purposes:

Note!

- Forced;

- Natural.

The most preferable, according to the builders, is the second option, but you have to prepare in advance for additional time costs.

Using this method, you can be sure that the oven will dry out as evenly as possible and not a single crack will form.

Remember that if you follow all the advice given to you by the builders, then without any difficulties you will be able to build a bathhouse quickly enough exclusively on your own.

Just remember to make sure in advance that you are prepared for the necessary financial costs.

Photo of a sauna stove with your own hands

Note!

Note!

Bulky, voracious and difficult to manufacture brick sauna stoves are gradually becoming a thing of the past. There are fewer and fewer qualified stove makers. And a qualified person often moves the stove at least once. They are being replaced by lightweight, compact, easy-to-manufacture and economical metal stoves. A home craftsman with plumbing and welding skills will be able to make such a sauna stove out of metal with his own hands.

Choosing a sauna stove design

When choosing a design, you should be guided by the following requirements:

- quick heating of bath rooms;

- burning duration;

- heat preservation;

- small footprint and volume;

- safety.

When designing a furnace, a balance must be struck between these requirements.

Thus, to ensure a long combustion duration, it will be necessary to increase the volume of the combustion chamber, and this will lead to an increase in dimensions and occupied area.

According to the location of the stove body, and with it the combustion chamber, sauna stoves can be:

- Vertical. They occupy a smaller area, but also have worse heat transfer parameters and combustion duration than horizontal ones.

- Horizontal.

Depending on the location of the combustion door, a metal sauna stove can be:

- Loaded from the steam room.

- Loaded from another room. The furnace door is carried out through the wall. This frees up space in the steam room, but to add firewood or adjust the draft you will have to leave the steam room.

Stoves may also have a built-in water heater located next to the heater or on the stove pipe.

Based on the location of the heater, stoves are divided into two subtypes:

- From the inside. They retain heat longer, but when exposed to heat it is easier to get burned by the steam or on the door.

- From the outside. Less economical, but more convenient and safer to use.

When choosing a design, it is important to determine which requirements are paramount and which ones can be compromised

Preparation of materials

The best option for making a do-it-yourself metal sauna stove body is a piece of steel pipe with a diameter of 30-50 cm or a gas cylinder that has become unusable. For the ash pan, a rolled sheet with a thickness of 1-2 mm is suitable; for the door, 3 mm steel is needed.

It is better to take low-carbon structural steel - it has better weldability and is less deformed at the seams.

The grate bars can be welded from 12 mm reinforcement, but it will be easier and more reliable to take ready-made ones, cast from cast iron. The simplest option is thick sheet metal (from 6 mm) with longitudinal slots.

Pros and cons of metal sauna stoves

Metal sauna stoves have a number of undeniable advantages:

- Quickly warms up rooms to the set temperature. Metal quickly releases heat from the firebox.

- Complete extraction of carbon monoxide from the bathhouse through the chimney.

- There is no smoke when the stove is lit.

- Compactness.

- Economical.

- Ease of manufacture.

- Long service life without repairs with minimal maintenance.

- There is no need for a heavy foundation.

Metal stoves also have their disadvantages:

- Fast cooling.

- High wall temperatures can cause burns.

- Not suitable for large baths.

Since the average size of families has shrunk and the way saunas are used has changed somewhat, there is little need for long-term heat retention.

How to improve the performance of a metal stove

The consumer properties of the stove can be improved in two ways:

- heat treatment of the material;

- improvement of the furnace device.

Metal preparation

After cutting the material, it is subjected to heat treatment using the tempering method. The metal of the workpieces is heated to a dark red color. Next, they should be cooled slowly. If slight warping of the workpieces occurs during the tempering, they are straightened with a hammer. It is also necessary to check the dimensions and cut off excess if necessary. This treatment will eliminate warping of the finished product.

Design features of the firebox

To ensure long-term burning of wood without overheating of the stove, some experts suggest eliminating grate bars from the design and burning wood directly on the metal bottom of the firebox.

Additionally, it is proposed to seal the firebox door with asbestos cord to slow down the flow of oxygen. A hole (or a series of holes) is made in the door itself, which is retractable with a damper. This damper regulates the air supply.

Design of a homemade sauna stove

Sauna stoves, both factory-made and home-made, differ in their design details. However, all drawings of a stove for a metal bath contain common basic components:

- firebox;

- heater;

- container with water;

- chimney.

The combustion of fuel takes place in the firebox; it is equipped with a door through which firewood is loaded. The bottom of the firebox is formed by a cast iron grate with slots - a grate. Under the door or directly in it there is a blower through which air enters the firebox. Under the firebox there is an ash pan - a metal tray for ash.

The combustion products heat the walls of the stove and through them a special container filled with stones - a heater. For watering stones, the heater is equipped with a separate door.

When finalizing the drawings of a metal sauna stove that you assemble yourself, you should take into account the design features of the steam room in which it will be installed.

What are metal sauna stoves made of?

For a DIY metal sauna stove you will need:

- 8mm low carbon structural steel sheet;

- a piece of pipe with a diameter of 30-50 cm and a wall thickness of 5-10 mm and a length of 2 m;

- rod or fittings with a diameter of 12-16 mm - 6 meters;

- grate;

- chimney pipe;

- ½ inch valve with long handle.

To assemble an iron sauna stove with your own hands, you will need the following tools and consumables:

- Angle Grinder;

- a set of hand tools;

- welding machine;

- cutting and grinding discs.

When assembling a sauna stove from metal of your own design, you will need a workbench with a vice and a work table measuring 1 * 2 m, or the same free space on a clean and level floor.

Making a firebox

Making a stove with your own hands begins by dividing the pipe into two parts: 90 cm for the firebox and heater and 60 cm for the water container. The remains are used to make a ash pan and fire doors. There should be a cut in the pipe for mounting the blower measuring 20x50 cm. Corners or plates are welded around the perimeter on which the grate will rest. The fire door is made in size 20x35 cm.

Making a heater

A rod or fittings are welded above the door to support the heater. A door is cut into the heater to supply water to the stones.

The stones are placed in the heater with some clearance, not closely.

It is best to take diabase or soapstone. Granite or mica-containing rocks are not used.

Making a hot water tank

The water tank is located above the heater. A 15-centimeter opening is made in it for the passage of a chimney pipe passing through the tank. The tank rests on a plate made of a thick sheet of metal. All seams must be thoroughly welded and cleaned.

Part of the tank lid is made removable, through which it will be filled with water. You need to weld a handle to this cover and protect it with wooden cheeks.

Placing the stove in the steam room

To make using the sauna stove enjoyable and safe, it is recommended to follow the following rules:

- The stove is mounted on a metal sheet (iron, copper or brass). The sheet should protrude at least 0.7 meters from the front.

- The walls and ceiling adjacent to the stove should be sheathed with non-combustible materials at a distance of at least half a meter from the stove and chimney.

- If the firebox is moved into an adjacent room, the opening should also be reinforced with non-flammable heat-insulating materials, such as basalt wool or vermiculite.

- The thermally insulated chimney pipe must be at least 40 cm away from wooden structures.

For the chimney, it is recommended to choose stainless steel with thermal insulation made of basalt wool. For rooms in which people are located, it is not recommended to use materials containing asbestos as thermal insulation. Inhaling asbestos dust can cause serious health problems.

After installation, a metal stove is often lined with 1/2 brick brickwork. This allows you to retain the heat accumulated in the masonry longer and protects against burns due to accidental contact.

Decorative finishing is beautiful and practical

To ensure true comfort, a self-made metal sauna stove should be complemented with appropriate finishing of the sauna rooms. Aspen or linden is traditionally used for the steam room; they do not emit drops of resin, which can cause serious burns if they come into contact with the skin. The floor is also made of aspen, but larch will last much longer.

A good solution is a floor made of ceramic tiles or porcelain stoneware; they must have a rough surface so that no one slips.

It is wise to lay a layer of foil and basalt wool under the lining to improve thermal insulation.

The temperature in the sink is not so high, and the choice of finishing materials is wider. Here it is possible to use economical coniferous species, but one must be aware that in conditions of high humidity, pine or spruce will not last long. Ceramic tile flooring is also a great solution. Walls can also be tiled. The corner in which the shower stall is installed is subject to special waterproofing.

The relaxation room, which has become traditional in a modern bathhouse, is not exposed to extreme temperatures or high humidity. Here, more attention can be paid to the aesthetic qualities of the finish, and definitely to comfortable furniture.

All electrical equipment and fittings used in the bathhouse must have a protection class of at least IP44 and be designed to operate in conditions of high humidity.

Special attention should be paid to efficient and high-quality ventilation of bath rooms.

Have fun!

The stove in a real Russian bathhouse should be economical and produce healthy heat. According to these criteria, wood heaters outperform electric and gas heat generators. But there is a third, no less important advantage: you can make a metal stove for a bathhouse with your own hands, provided that you are good at electric welding. The brick version of the heater is also good, but not available to everyone due to the price of materials and the difficulties of laying in the finished steam room. So choose a homemade unit from the models proposed in our publication and start manufacturing, using step-by-step instructions and drawings.

Choosing a sauna stove design

Ideally, a heat source made of metal should meet the following requirements:

- Warm up quickly and raise the temperature in the steam room. Iron stoves do this very well.

- Keep warm as long as possible. Since steel heats up and cools quickly, you will need a heater that accumulates heat, or an increase in the burning time of the firebox. The third option is to cover the sauna stove with bricks after installation.

- Occupy a minimum of usable space in the steam room. If the volume of this room is too small, then it is better to choose a vertical design with a loading door located in the dressing room.

- The heater must be safe for people washing in the bathhouse. To protect yourself from burns, you can install a convection casing made of thin sheet iron on the housing or, again, build a brick wall around the housing.

Note. The duration of combustion increases with the volume of the fuel chamber of the unit. Here you need to find a reasonable balance between the size of the stove and the duration of its operation. A small firebox will have to be constantly loaded with firewood, instead of being able to wash in peace, and a large stove will take up half the area of the steam room.

Do-it-yourself iron sauna stoves come in the following designs:

- with a body oriented vertically or horizontally in space;

- heated directly from the steam room or from the next room (a remote firebox door is made);

- with and without water tank;

- with external or internal heater.

Vertical heater

The vertical body of the stove shown in the photo gives one advantage - saving space in the bathhouse. There are more disadvantages: short burning time (due to the fact that the flame covers the entire stack of firewood) and not too high heat transfer. According to these important parameters, a horizontal sauna heater outperforms a vertical one, but at the same time occupies a larger area.

Horizontal stove with heater and tank

If the bathhouse does not have an electric water heater, it costs nothing to install a tank for heating water intended for washing on the stove or chimney. It can be welded from ordinary metal, or better yet from stainless steel. There is also a more convenient way to heat water: the tank, located in the washing room, is connected by pipes to a samovar-type steel heat exchanger installed on the chimney pipe.

Steel heat exchanger for chimney

The open heater, which we inherited from the Finnish sauna, heats up to a maximum of 400 °C, but it can be watered with water in order to “give up the park.” Heaters closed inside the stove body accumulate more heat, heating up to 700-800 °C, but at the same time they become polluted by passing flue gases and therefore require periodic cleaning.

Reference. Some craftsmen assemble metal stoves with internal brickwork, the diagram of which is shown above. They serve for a long time without burning through the walls, but are difficult to manufacture, and fireclay bricks cost money. You can find out more about various sauna heaters by watching the video:

Preparation of materials

It is best to make a stove in a bathhouse from a steel pipe with a diameter of 300-500 mm or a gas cylinder. There are several reasons:

- the pipe is a ready-made body of the unit, which simplifies the matter;

- a cylindrical shape is preferable to a rectangular one for reasons of aerodynamics (air flow around) and heat transfer;

- vaulted walls without seams will last longer than flat ones;

- A round firebox is easier to clean from ash and soot.

Advice. It is more convenient to make an ash pan from sheet metal 2 mm thick, and 3 mm iron will be used for the doors. Try not to use high-carbon steel of a grade higher than St35, which can become hot from exposure to high temperatures, deform and burst at the seams. The correct stove is welded from grade St3.

Stages of door manufacturing

The grate can be made from corners or periodic profile fittings. The budget option is a sheet of thick iron with longitudinal slots, the purchased option is cast iron grates. It is advisable to make the doors double-layered with a basalt fiber gasket (pictured) so as not to get burned if accidentally touched.

Heater stove - manufacturing guide

We bring to your attention 3 common designs of metal stoves for baths:

- a simple horizontal stove made from a cylinder, heated inside the steam room;

- heater made of 530 mm pipe with remote firebox;

- vertical sauna boiler “three in one”.

The first option is attractive due to its ease of manufacture, small size and mobility. For homemade products, you will need an old propane cylinder with a diameter of 300 or 500 mm and scrap metal. The second heater is distinguished by an additional section with a door built into the opening of the steam room wall, and an open heater. The third model is a whole boiler, consisting of three compartments - a firebox, a closed heater and a tank for heating water.

Advice. If you cannot find a good pipe or cylinder, cook the stove according to the drawing from sheet steel with a thickness of at least 3 mm (preferably 5 mm). First, you will have to perform a number of operations to assemble the firebox - cutting the workpieces and welding them together with strict observance of 90° angles.

The drawings show options for heating units made of sheet iron

We weld a simple stove

The first thing to do is to correctly cut the cylinder cap along the factory seam. To do this, unscrew the gas valve with an open-end wrench and fill the container with water, after which you can use the grinder.

Reference. Propane is heavier than air and therefore reluctant to leave closed containers. To avoid an explosion when cutting metal, it is customary to force it out with water.

Assemble the heater according to the presented drawing, observing the following order:

- Cut openings at the end of the lid for mounting doors and in the housing for the chimney pipe. Make frames for the loading and ash doors from metal strips, and weld them to the openings.

- Assemble the grate by welding and place it on the corners fixed inside the cylinder. Weld the cut cover back into place.

- Make the sashes as shown in the photo. Place them on the hinges and attach the latches.

- Attach legs and a chimney pipe to the body.

After assembly, the gas cylinder sauna stove is melted outside in order to burn off all the old paint. Then it can be degreased and repainted using the heat-resistant composition of the KO series.

Manufacturing a unit with an external firebox

To make such a stove, you need to prepare metal parts and cut the pipe to size, following the drawing:

Advice. When preparing the metal for the additional heater section, measure the thickness of the wall between the steam room and the dressing room. This way you will know the width of the extension part that will fit into the partition opening.

Perform further work according to the instructions:

- Cut a hole in the top of the pipe, weld the chimney pipe to it, and weld the legs at the bottom of the firebox. Install the grates as described in the previous section.

- Make the front section and weld it to the firebox. Weld a blank metal disk to the rear end of the housing.

- Make doors with handles insulated with basalt wool and install them in place.

Important point. The lower plane of the remote firebox should be flush with the pipe wall for easy cleaning of the ash pan.

All that remains to do on top of the finished stove is to weld a frame for the heater from corners covered with a coarse metal mesh. After firing, staining and installation in the bathhouse on site, fill the mesh with special stones from the list:

- basalt;

- river pebbles;

- gabbro-diabase;

- Soapstone chlorite

How a similar sauna stove is made in practice is described in detail in the video:

Making a vertical boiler

The peculiarity of the round unit shown in the drawing is the presence of 3 chambers - fuel, heater and water tank. Their size can vary according to your wishes, for example, the larger the size of the firebox you make, the longer 1 stack of firewood will burn. Enlarging the heater will allow you to accumulate more heat, which is released for a long time after the fuel burns out.

Advice. You should not greatly increase the volume of the water tank, otherwise it will not have time to warm up by the time of washing.

The boiler assembly procedure looks like this:

- Cut blanks for partitions, bottom and lid from metal with a thickness of at least 5 mm. Prepare the ends of the pipe and weld the round grate bars.

- Make openings in the body for the doors and hatch for loading stones.

- Make holes in the partitions for the chimney and install them inside the pipe. Secure the tank lid to the hinges.

- Make doors from semi-circular cut out pieces and place them on the awnings.

- Install a flue duct and a water drain valve at the bottom of the tank.

If desired, even in this furnace you can make a remote firebox. To do this, you need to increase the loading and ash channel by welding metal blanks of the required width to the side of the pipe, as shown in the photo above. The correct assembly of such a heat generator is shown in detail in the following video:

Installing a stove in a bathhouse

Since a proper steam room is always built of wood, the main requirement when installing a wood-burning heater is fire safety. To survive it, follow simple rules:

- the stove cannot be placed directly on a wooden floor, but only on a sheet of iron protruding 70 cm in front of the firebox;

- wall cladding made of flammable materials also needs to be protected from fire with sheets of roofing iron or mineralite;

- when installing a heater with a remote firebox, the opening in the wooden partition is also sheathed with non-combustible materials, as is done in the photo;

- the distance from the insulated chimney pipe to wooden building structures is 38 cm.

It is recommended to make a channel for venting combustion products outside from a double-walled sandwich filled with basalt wool. Often, the same square-shaped water tank, built directly into the ceiling, is used to insulate the chimney. How to properly install a stove in a bathhouse is shown in the diagram:

Important. Do not use sheet or cord asbestos for thermal insulation inside bathhouses; it emits dust that is harmful to health.

Conclusion

When a homeowner is faced with a choice - to build a stone sauna stove or install a metal one, the majority is inclined to the second option as it is more economical. A homemade iron stove will be even cheaper; in addition, it will be ideal in all respects, because you yourself will think over its design. Don't know how to weld? Save money otherwise by ordering the assembly of the unit in a specialized workshop.

Design engineer with more than 8 years of experience in construction.

Graduated from the East Ukrainian National University. Vladimir Dal with a degree in Electronics Industry Equipment in 2011.

Related posts: