The presence of a cellar under the garage solves a number of important problems. It can store vegetables, fruits, canned food. This is possible if there is ventilation, which will ensure the optimal temperature and humidity level in the underground room.

Why do you need a hood in the cellar of the garage

Many car owners equip small cellars under their garages where they store canned food and other food supplies. If the basement is not properly constructed, the shelf life of supplies is drastically reduced.

The great thing about cabbages, carrots, and all other crops, as evidenced by David Cavagnaro and Nancy Bubel in the previous two articles, is that all you need to store them for months is a cold, well-ventilated space. The backup refrigerator works very well, but even better and more spacious - a real root cellar. The basement root cellar is convenient and useful.

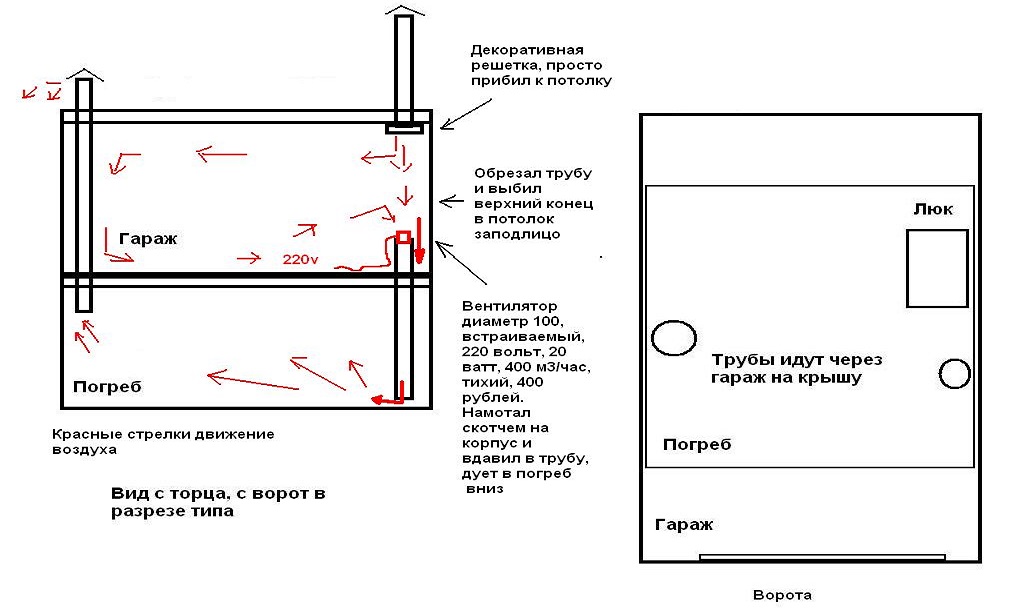

Most modern basements are too warm for long-term winter storage, but you can create an indoor version of basements that have served as pets for a long time by hiding from the corner of the basement and adding vents, as shown in the picture above. The two vents create a siphon effect that allows the flow of cold outside air into the insulated basement room to be regulated, allowing temperatures to stay near freezing during the winter months.

High-quality ventilation will protect the room under the garage from a number of negative factors:

- With insufficient air exchange, condensation appears in the pit and humidity increases. This leads to spoilage of products, the appearance of mold and fungus on the walls, and stale air.

- In winter, the air temperature in the underground cellar is much higher than in the garage. In the absence of ventilation, the air rises and carries out the moisture accumulated in vegetable pit. This leads to corrosion on the car body and metal objects in the room.

- In the absence of ventilation in the basement, stored supplies become toxic. This is affected by the operation of the car engine and toxic fumes from chemical fluids in the garage. To minimize exposure to toxic compounds, the ventilation system must be able to remove air from the pit and allow it to enter. This is solved by installing supply and exhaust ventilation.

A competent exhaust system will avoid the consequences of adverse factors. Thanks to the supply pipe, fresh air will freely flow to the stored food stocks. Excess moisture, toxic and poisonous substances will come out through the exhaust pipe.

Fred Matlack of Vera Cruz, Pennsylvania came up with this great design and the basement basement he built in the basement worked just as he planned. “You just have to watch the temperature to make sure you close the vents before the temperature drops below freezing, which can damage some crops,” Matlack says.

As you adjust your wall studs for length, make them short enough to leave an eighth to a quarter inch gap between the top of the wall and the joists above when they match the top and bottom plates. Basement floors are often wet, so consider using composite deck material instead of wood for the bottom wall slab. Insulation is your next challenge and there are good reasons to consider using rigid foam sheets instead of traditional fiberglass cotton swabs.

Types of ventilation systems

The operation of any exhaust system is based on the principle of air circulation. Spent vapors containing many harmful impurities leave the room, giving way to fresh air. This means that for the organization of standard ventilation, two different pipes are needed: one for the inlet, the other for the outlet.

The most important is moisture resistance. Courtesy of Lutheranism Len Churchhill. Traditionally, this cold room was an underground space built under or next to the house, insulated from the ground and vented with such cold air that warm air could also flow in autumn. Then, when winter temperatures hit, the vents were closed and the basement remained cold but not freezing. Photo courtesy of Len Chorthill.

A few universal truths remain the same, which will help you create the optimal root basement, although each basement situation is unique. Since you need access to the great outdoors, choose a basement position that includes a window. It's possible to run holes through the basement wall for the 3" or 4" vent pipes you need to install, but it's much easier to just pull the glass out of the window, replace it with plywood, and then run the pipes through the holes in the wood.

Experts distinguish between two types of ventilation systems:

- Natural. Excess moisture and other harmful substances are removed from the basement using thermal convection. The heated steam that has accumulated in the upper part of the pit spontaneously rises and leaves the room, making room for drier air coming from the street.

- Forced ventilation. Air exchange between the basement and the street occurs with the help of additional mechanical superchargers. Such a scheme is much more efficient than the natural one, however, it requires some financial costs and constant access to electricity.

Let's take a closer look at the pros and cons of each system.

In cold regions, you can create an insulated panel to replace window glass. Laminating a half-inch layer of top-coated plywood on each side of a 1" or 2" piece of extruded polystyrene foam is a terrific way to create an insulated vent access panel. Polyurethane construction adhesive is perfect for holding a wood and foam sandwich.

When it comes to any basement cellar, exterior walls create ideal interior temperatures. This is what provides cooling, and the more masonry surface you have, the better. That's why you'll want to choose a corner location for your setup if you can. This ensures maximum exposure of the exterior walls while minimizing the need to build and insulate interior walls. And if you have a choice, choose a spot with the highest soil height on the street.

Natural

The natural exhaust system is characterized by ease of installation, the absence of complex regulation mechanisms and autonomy. It is enough to fix two pipes, one of which will serve to remove the exhaust air from the room, the other - to enter.

If the hood is installed in a pit, only the outlet pipe can be dispensed with. Air can also enter the underground room through an ordinary manhole with a ladder, through which the owner descends into the cellar.

Is there one of your possible options for influencing the north? It's great if you can get it. Once you've chosen a location for your basement and replaced the window pane with a solid panel that accommodates the vent pipes, take a look at the walls. Get yourself a helper, grab a sheet or two of plywood or board, and get ready to use your imagination. It's amazing how temporarily propping up sheeting can help you present the floor plan of your new room, leading you to better results.

Further installation takes place in stages

How long should your basement be? Is a 3ft door enough? These questions are much easier to answer when you have something to hold, watch, move, and adjust. Once you have placed the location and location in your basement, mark the corresponding outlines on the floor with a large felt-tipped marker. While you will need to build some sort of wood frame for the wall and doorway, it doesn't have to be as muddy as a typical bearing wall for home. You can extend the stud spacing up to 24 inches in the center if you need to save money, but regardless of the wall design, you need to mount it top and bottom.

Among the advantages natural ventilation can be distinguished:

- Ease of installation.

- Low cost of materials and installation work.

- No noise.

Installation of fans and other devices is not required

A few tricks can do this. This way you won't have a problem tilting the wall into place, but you can still secure it with 3½" screws that go through the top plate and into the bottom edge of the joists. Bring a softwood wedge driven with glue into the gap before proceeding to the house screws. Choose a brand that is completely strong, then cut and nail it just like regular lumber. Composites are rot resistant and will not introduce musty odors into your basement even if they get wet.

The main disadvantage of such a system is unstable operation. In summer, air circulation may stop. In cold weather, frost forms in the pipes, which can block the hole. To avoid problems, special fans should be installed in the pipes in summer, and insulation should be arranged in winter.

There are other disadvantages of natural ventilation:

Attach the bottom of your basement wall to concrete floor using construction adhesive and concrete nails or screws driven into pre-drilled holes. Any basement can get damp from time to time, and fiberglass has little to no ability to resist mold growth and deterioration when water is present. Foam, on the other hand, carries moisture much better. It's also easier to use than fiberglass, and it's non-irritating. Extruded polystyrene is especially good in this regard.

It is also a highly effective thermal insulator. Just be aware that in some jurisdictions the foam must be covered with a fire retardant sheet in order to meet the code's specifications. When you are planning your insulation strategy, be sure to include your basement ceiling. Heat descending from heated areas above can raise the basement temperature too high for food. These simple and inexpensive source control measures eliminate contamination or reduce emissions from cleaning products, gas appliances, building materials and furniture.

- You cannot control the operation of the system.

- Do not heat or cool the air.

- There are no filters, as a result of which harmful substances from the street can penetrate into the basement.

Forced

In the process of forced ventilation, air is forced into the room, filtered, heated or cooled (depending on the season and system settings) and distributed through the ventilation ducts. Such a system, installed in the cellar under the garage, will provide an optimal indoor climate, regardless of weather and other conditions.

The powerful chemicals in many traditional cleaning products can be toxic to human skin and lungs. In addition, propellants in aerosol products can be inhaled, so it is advisable to use pump products. Learn how from common household ingredients. Or, you can purchase non-toxic or less toxic formulated cleaners from most stores.

Perchlorethylene, the most commonly used dry cleaning solvent, is a potential carcinogen. These products can release harmful gases that pollute the air and can cause health problems. Minimize the use of hazardous products as much as possible. For basic household chemicals, buy them in smaller sizes that you can use right away. If you need to store any hazardous chemicals, store them in a ventilated and covered outdoor shed away from children, pets, and sources of fire.

Fans or turbines can be built into the pipe

Among the disadvantages of forced ventilation can be noted:

- Difficulty of installation.

- A large number of mechanical parts that can fail.

- The need to connect to a centralized power supply.

- High cost of equipment.

Which one to choose for DIY installation

The main criterion by which the type of ventilation is selected for a particular cellar under the garage is the area of \u200b\u200bthe room.

A natural ventilation strategy relies on the buoyancy of hot air and wind to increase the amount of outside air entering your home. Natural ventilation can reduce overall energy consumption by 10-30% compared to home use of a forced air cooling system.

While natural ventilation is best built into the overall design of the home, there are simple ways application of natural ventilation in any home: open the upper and lower sashes with double windows and open windows on opposite sides of the same room, ventilation. Opening windows at night during the summer will bring in cool fresh air inside, and the house's thermal mass will help keep the interior cool the next day. A greater difference in temperature between indoor and outdoor air at night will also result in faster air exchanges and polluting the outside air from the inside more thoroughly.

- Owners of small garages (up to 50 square meters) who agree to conduct periodic inspection and cleaning of pipes may be limited to natural system ventilation.

- If the basement is located under a large garage intended for parking large trucks and buses, it must be equipped with forced ventilation that provides air exchange with the help of additional fans or other mechanical superchargers.

Natural air exchange device: instructions

The design of a natural hood consists of a number of elements:

Also, the outside air can be cleaner at night due to fewer cars on the road. Make sure your gas range has an exhaust fan that goes outside - some exhaust systems are tubeless hoods that pull air from the stove right into the house. Bathroom fans are also important, as poor moisture management in a home can allow mold to grow. Also, if the walls, doors, and windows of your home are tightly sealed and energy efficient, you may need to open the window slightly when the exhaust fan is running or when you use the fireplace to avoid creating negative pressure.

- An inlet pipe through which fresh air enters the cellar. Diameter - from 100 to 250 mm.

- Exhaust pipe through which the exhaust air leaves the room. Diameter - similar to the input structure.

- Condensate collection tank

- fine mesh

- Conical visor.

For the air duct, pipes made of any suitable material are used - tin, asbestos cement, polyvinyl chloride and others.

The need for ventilation

With no other way for outside air to replace the air exiting through an exhaust fan or chimney, air can be drawn through exhaust pipes for your stove or heater hot water. Be sure to fix any leaks and clean up any household leaks as quickly as possible. Permanent water and moist materials provide a habitat for the growth of mold and microbial plants.

Filters actually become more efficient at capturing and removing airborne contaminants as they become dirtier and accumulate in "deposit dust". However, this increased efficiency comes at a cost as the pressure drop increases and the amount of air decreases. It's a good idea to change the oven filter at the start of the heating season, as the dusty cake from the previous year has been sitting in a cold, dark basement all summer and may have started to grow mold.

Before installing the ventilation system, it is necessary to carry out thermal insulation and waterproofing work. It is desirable to carry them out even at the stage of construction of the cellar. If for some reason this was not done, the work should be completed before the installation of the exhaust system.

Cellar walls are carefully impregnated with penetrating insulation. This prevents the penetration of groundwater into the room. For thermal insulation, it is necessary to finish the walls and floor. Ecowool is best suited for this, a fairly expensive and high-quality material that repels rodents. In order to save money, you can use other heat-insulating materials, for example, polyisocyanate plates. The cheapest option for warming is to place carefully compacted sand under the floor and finish the walls with geotextiles or expanded clay.

Work on the arrangement of a natural exhaust system is carried out in several stages:

- Fixing the exhaust duct. The lower end is located one and a half to two meters from the floor, depending on the height of the basement. The outer part is brought out. The top end of the pipe must be higher highest point garage roof about half a meter. There are two options for installing the exhaust pipe:

- Through. With this method, the pipe is passed through the floor of the garage and is led out through the ceiling and roof.

- Through the wall. The lower part of the ventilation pipe is located horizontally, goes through the side wall of the cellar outside the garage and rises up next to the main building.

- Supply air duct installation. The lower part of the pipe enters the cellar in the corner opposite to where the hood is installed, and is fixed at a level of half a meter from the floor. The other end of the pipe is brought out to a level of 20-30 cm above ground level, for air intake.

- Checking the air draft, inserting a fine-mesh metal mesh into the pipes to protect against birds and rodents. The outlets can be additionally covered with small caps to protect against snow and rain.

To control ventilation, special dampers can be installed. They help regulate air exchange in winter, when it is critical not to overcool the room. Otherwise, food stored in the cellar may freeze.

Installation of forced ventilation in the basement

The forced ventilation system in the basement under the garage uses the principle of fresh air supply, regardless of the temperature conditions outside.

The fan is installed on the inlet pipe

Due to calm weather, the air temperature outside in summer is often higher than in the cellar. You can solve this problem with a fan.

Before installing the exhaust system, you need to carefully consider the installation location of the fan. It cannot be mounted in a cellar or on a roof: it is a complex electrical appliance that will fail if moisture enters. Due to the increased noise it is not recommended to put it inside the garage.

There are two options:

- Install a fan on the inlet pipe at the place where the air is taken. The entrance to the channel is additionally protected by a mosquito net. Due to the fact that the outlet of the pipe is low, in winter it is necessary to monitor the level of snow.

- Install a duct fan.

The first part of the installation of a forced ventilation system is no different from the natural one. Inlet and outlet pipes are installed. The inlet pipe goes from the ground to the cellar, the outlet pipe - from the basement ceiling through the garage roof or goes out parallel to the floor and rises outside the room.

Further installation takes place in stages:

- A fan is built into the pipe.

- The cable for powering the fan is laid.

- The switch is mounted.

- Outside, the exhaust pipe is closed with a fine-grained grate to protect against rodents, birds, and random debris. A protective visor is also installed, which excludes the ingress of precipitation inside.

Connection details can be seen in the video.

An example of the correct connection on the video

Conversion of a natural exhaust system into a forced one

Not always the simplest exhaust system can cope with its duties. Increasing the efficiency of natural ventilation is necessary in the following cases:

- The appearance of excess condensate in the cellar.

- The appearance of fungus, mold.

- Stale air in the room.

The efficiency of an exhaust system can be improved in several ways:

- Increasing the diameter of the ventilation pipes. With cellar sizes not exceeding 10–12 square meters, the exhaust pipe can have a cross section of 120 * 120 mm, and 150 mm if it is the only one.

- Increasing the height of the exhaust pipe. This will increase traction.

- Make additional exhaust and supply channels.

- Put a fan in the pipe that provides forced air circulation.

The first three options require a serious revision of the ventilation system. The fourth option is to create forced ventilation based on the existing natural exhaust. The conversion process takes place in several steps:

- Connecting power cables to the power supply installation site.

- Dismantling the decorative grille.

- Fan installation.

- Installation of a decorative grille.

- Connecting the fan to the power supply.

In most cases, it is enough to install one fan on the exhaust pipe. To enhance the effect, the second can be built into the input channel. For maximum thrust gain, a centrifugal fan is installed. It has increased power and noise level. This design is installed outside, during installation it will be necessary to partially disassemble the channel.

After completing the installation or re-equipment of the ventilation system, it is necessary to check the draft. To do this, a lit candle or match is brought to the ventilation duct. In the presence of good traction, the flame leans slightly towards the duct.

With good traction, the candle flame leans towards the air duct

Estimated installation costs

The cost of ventilation units can be up to one hundred thousand rubles. This occurs when a complex programmable system is used to create a forced system. Similar structures are installed in large and specialized basements, for example, in wine cellars.

|

Material |

Cost, rub. |

|

Plastic pipe for ventilation, 1 m |

|

|

Elbow (necessary in the presence of bends, for example, if the pipe rises from the outside), pcs. |

|

|

Ventilation grille, pcs. |

|

|

Exhaust fan |

|

|

Exhaust fan centrifugal type |

|

WP_Query Object ( => Array ( => 1 => rand) => Array ( => 1 => rand => [m] => [p] => 0 => => => => => 0 => => => => 0 => => => => 0 => 0 => 0 [w] => 0 => => => => => => => => => 0 => = > => [s] => => => => => => => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => Array() => => => 1 => 1 => 1 => 1 => => => 50 => =>) => WP_Tax_Query Object ( => Array () => AND => Array () => Array () => wp_posts => ID ) => WP_Meta_Query Object ( => Array () => => => => => => Array () => Array () =>) => => SELECT SQL_CALC_FOUND_ROWS wp_posts.ID FROM wp_posts WHERE 1=1 AND wp_posts.post_type = "post" AND (wp_posts.post_status = "publish") ORDER BY RAND() LIMIT 0, 1 => Array ( => WP_Post Object ( => 4586 => 2 => 2016-09-18 15:13:35 => 2016-09-18 11:13:35 =>

Organization of work

Security

Installation of storage systems

Assembly order and steps

In conclusion, all bolted connections are checked, the bolts are tightened with a moment, regardless of their diameter and thread pitch, after which the shelves are hung. => Do-it-yourself installation of basement racks => => publish => open => closed => => montazh-stellazhej-301 => => => 2016-09-16 19:07:18 => 2016-09- 16 15:07:18 => => 0 =>?p=4586 => 0 => post => => 1 => raw =>)) => 1 => -1 => => WP_Post Object (= > 4586 => 2 => 2016-09-18 15:13:35 => 2016-09-18 11:13:35 => Shelving maintenance and repair the process of storage, but also the sorting and selection of goods.Despite some differences in warehouse systems, the installation of racks, the detailed procedure of which is determined by the manufacturer's instructions, is carried out approximately the same.How exactly - the video in this article will tell you about it, as well as useful information provided.

In conclusion, all bolted connections are checked, the bolts are tightened with a moment, regardless of their diameter and thread pitch, after which the shelves are hung. => Do-it-yourself installation of basement racks => => publish => open => closed => => montazh-stellazhej-301 => => => 2016-09-16 19:07:18 => 2016-09- 16 15:07:18 => => 0 =>?p=4586 => 0 => post => => 1 => raw =>)) => 1 => -1 => => WP_Post Object (= > 4586 => 2 => 2016-09-18 15:13:35 => 2016-09-18 11:13:35 => Shelving maintenance and repair the process of storage, but also the sorting and selection of goods.Despite some differences in warehouse systems, the installation of racks, the detailed procedure of which is determined by the manufacturer's instructions, is carried out approximately the same.How exactly - the video in this article will tell you about it, as well as useful information provided. Organization of work

It is unlikely that anyone would think of assembling multi-section storage racks with their own hands. Such work is carried out by specialized teams of installers with relevant experience and knowledge. And they are confirmed by a special document - the admission of the CMO to carry out installation work. A certificate for the production of a certain type of work is issued legal entity which organizes the training and equipment of its people. Most often, such teams have organizations that manufacture racks, or companies that sell them. A document confirming the right to assemble or dismantle racks On the presented photo you can see how the document confirming the contractor's right to engage in installation work looks like. There is also an appendix to it, which will specifically indicate the types of work covered by this certificate.

A document confirming the right to assemble or dismantle racks On the presented photo you can see how the document confirming the contractor's right to engage in installation work looks like. There is also an appendix to it, which will specifically indicate the types of work covered by this certificate. Security

Such strictness is due to the fact that the price that has to be paid as a result of an illiterate or negligent attitude to installation work is too high. In the event of a collapse of the racks, not only material values \u200b\u200bcan suffer, but also people in the warehouse. Therefore, both the assembly and the operation of structures must be properly controlled. So:- There are general requirements that apply to any installation work, the observance of which allows to ensure the proper level of security. This is the proper organization of the place of work, the use of means and devices for the protection of working people.

- It is also very important that when mechanizing work, for example: unloading, only those devices that are completely safe are used. This also applies to electric tools - they must be certified, meet the requirements of the current standard, and, of course, be in good working order.

Installers must have overalls, safety helmets and mounting belts

Installers must have overalls, safety helmets and mounting belts - The guarantee of safety at the place of assembly of the rack is correct placement his designs. Installation of the next tier should be carried out only after the work on the previous tier is completed. This is due to the fact that under the place where the installation is carried out, there should not be people.

- Considering that the height of storage systems can be 12 meters, which is comparable to the height of a four-story building, the installation of racks is equated to climbing work. That is why mounting belts must be in the arsenal of the working team.

Installation of storage systems

In order for specialists to start working, the customer must provide them with certain conditions. First of all, it is necessary that on the site intended for the assembly of frames, it was organized ceiling lighting. To use power tools, two- and three-phase power supplies with a voltage of 220V and 380V must also be provided.- The warehouse must be closed and dry, with an air temperature of at least +5 degrees. As for the delivery of structures to the assembly site: in order not to have to reload components several times from place to place, it must be possible to unload a flatbed truck at the warehouse gate, and move the cargo from the body to the premises with a forklift.

Warehouse properly prepared for installation work

Warehouse properly prepared for installation work - For normal operation, a frame assembly area must be defined, which requires a certain amount of space - at least 30 meters long. What is important, the floors of the warehouse must be prepared in advance by the customer, since this is not the responsibility of the installers.

- The floor should not be potholes, it should be clean and dry - but these are not all the requirements. At the base of the floor should be reinforced concrete slabs with a thickness of at least 17.5 cm, in the manufacture of which concrete of class B25 and above was used. It has a sufficiently high compressive strength - and this is important, since the floors of the warehouse are under enormous stress.

- Small surface irregularities are allowed, but only within 5 mm per 4 rn, or 15 mm along the entire length of the area occupied by the rack. Such defects are easily eliminated by metal leveling plates, which are necessarily included in the system kit.

Marking for the installation of racks using a polymer tape

Marking for the installation of racks using a polymer tape - Pre-assembly marking should be carried out in such a way that the anchoring of the thrust bearings of the racks does not fall on the joints of the floor slabs, or the places where the internal reinforcement passes. The marking lines along which the rows of racks will be mounted are beaten off with the help of geodetic devices, and applied by gluing a polymer tape.

Note! All work on the assembly of warehouse racks is carried out in accordance with the working documentation provided by the manufacturer. By the way, it is necessary to coordinate with him any changes in terms of rack placement, as well as increasing or decreasing level marks.Such changes, after agreement, are made to the documentation, and only after that you can proceed with the installation. Deviations associated with the sequence of technological operations, as a rule, worsen the quality of the assembly - therefore, they should not be allowed in any case.

Assembly order and steps

Of course, not all racks are assembled in the same way, as they may have different design features. The joints of the bearing and fixing elements are carried out strictly according to the drawings, but the assembly order is approximately the same in all cases. We have already mentioned markup.- She is very milestone, since often in the process of its implementation, errors made when measuring the dimensions of the room are revealed. It is this fact that may determine the need to make adjustments to the documentation. If no deviations were found in fact, proceed to the second stage - the assembly of the side frames.

Assembly of frames from vertical racks and braces

Assembly of frames from vertical racks and braces - They are assembled in a horizontal position - that is why a thirty-meter platform is required for work. Connections of load-bearing elements can be welded, that is, monolithic, or they can be detachable. Welded joints are stronger and more reliable, but they do not allow dismantling the rack if necessary.

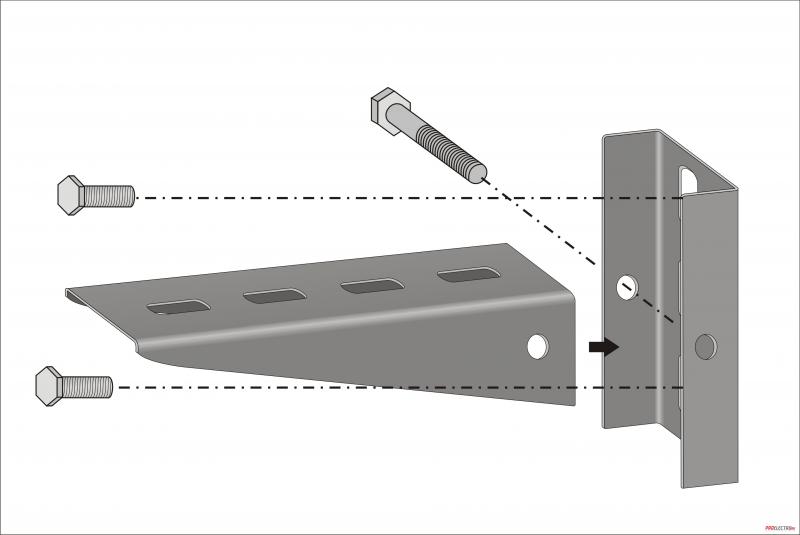

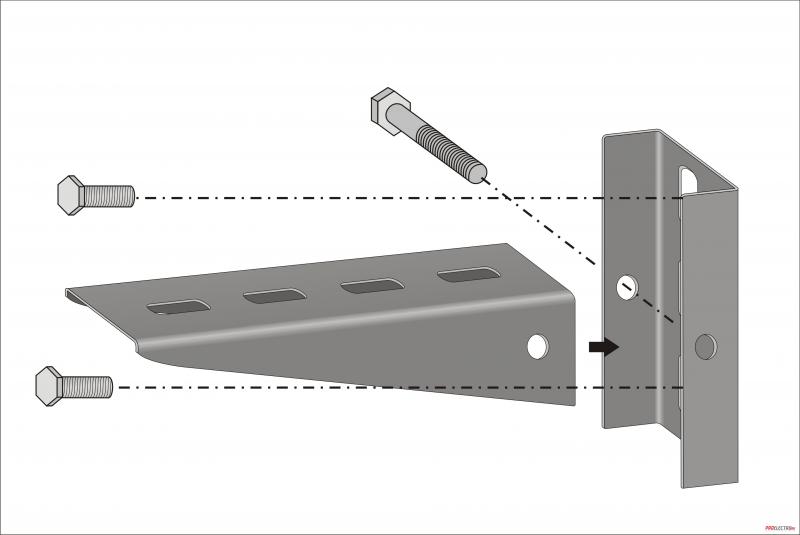

- Therefore, systems with detachable connections the most popular, and they are performed different ways. In some cases, bolts with threaded fasteners can be used, in other cases, fastening keys are used connecting horizontal beams with uprights through perforation.

Bolt-on console option

Bolt-on console option - , hooks are provided on the racks, on which a horizontal bearing element is put on. One way or another, the installers must learn all this information from the accompanying documentation, which each of them gets acquainted with before starting work.

- The perforations on the top and bottom of the uprights may vary, so make sure they all lie in the same direction before starting assembly. They are connected in pairs by braces, which provide the structure with spatial rigidity. First, they put the extreme, that is, the upper and lower braces, and then the intermediate diagonal ones. They are fastened in a certain position indicated on the assembly diagrams.

- First, the bolts are tightened without effort, and only after the entire diagonal system is installed, they are tightened torque wrench, with the moment that should be indicated in the documentation in the corresponding table. Then, the assembled frame is set to a vertical position, either manually, if it is small, or using machinery.

List of the main elements of the prefabricated rack

List of the main elements of the prefabricated rack - After two frames are raised and installed on the thrust bearing, horizontal beams are mounted on the two lower tiers and connected in the manner provided by the manufacturer. Thus, one section of the rack is ready. She is hoisted into the design position according to the markup, and the frames of the adjacent compartment begin to be raised.

- While some people are fixing the frames of the second section, others at this time are adding the upper beams to the first. If the rack is paired, then the frames of the second row are attached to the already finished first line using special row connectors.

- When all rack frames are installed in the desired position, they are leveled along the planes and, if required, leveled using metal plates. If the finish coating of the floor of the warehouse is not a concrete screed, but, say, asphalt, then plates are used to better distribute loads on it. bigger size. But such a possibility is also negotiated with the rack manufacturer.

Racks ready for loading Only after the spatial position of the assembled system is verified and adjusted, the frames with the thrust bearing are firmly fixed to the floor with anchor bolts, which are inserted into the base to a depth of 15-16 cm. With a height of structures exceeding 3 m, the rack is also attached to the wall in two places , ceiling or columns. In conclusion, all bolted connections are checked, the bolts are tightened with a moment, regardless of their diameter and thread pitch, after which the shelves are hung. => Do-it-yourself installation of basement racks => => publish => open => closed => => montazh-stellazhej-301 => => => 2016-09-16 19:07:18 => 2016-09- 16 15:07:18 => => 0 =>?p=4586 => 0 => post => => 1 => raw =>) => 0 => -1 => 316 => 316 => 0 => => => => => => => => => => => => => => => => => => 1 => => => => => => = > => => => => => => => Array ( => query_vars_hash => query_vars_changed) => Array ( => init_query_flags => parse_tax_query))

Racks ready for loading Only after the spatial position of the assembled system is verified and adjusted, the frames with the thrust bearing are firmly fixed to the floor with anchor bolts, which are inserted into the base to a depth of 15-16 cm. With a height of structures exceeding 3 m, the rack is also attached to the wall in two places , ceiling or columns. In conclusion, all bolted connections are checked, the bolts are tightened with a moment, regardless of their diameter and thread pitch, after which the shelves are hung. => Do-it-yourself installation of basement racks => => publish => open => closed => => montazh-stellazhej-301 => => => 2016-09-16 19:07:18 => 2016-09- 16 15:07:18 => => 0 =>?p=4586 => 0 => post => => 1 => raw =>) => 0 => -1 => 316 => 316 => 0 => => => => => => => => => => => => => => => => => => 1 => => => => => => = > => => => => => => => Array ( => query_vars_hash => query_vars_changed) => Array ( => init_query_flags => parse_tax_query))