Due to environmental friendliness and ease of work, high-tech gypsum plaster Rotband today occupies a leading position among similar building mixtures. Such a product is produced at Russian enterprises with the participation of the German company Knauf Gips KG. This explains the presence of the word "Knauf" in the name of the dry mixture.

Dimensions

You can buy Rotband plasters packaged in bags of 10, 20, 30 kg. To distinguish a branded dry mix from a fake, you need to pay attention to the packaging. It should be a three-layer durable bag, on the outside of which is depicted short instruction on the application of plaster. In addition, it is recommended to ask the seller to provide a certificate for the products.

Knauf Rotband universal plaster is used for manual plastering of wall and ceiling surfaces in interior spaces that are planned to be used in conditions with normal humidity. Many experts consider specifications dry mix Rotband ideal, namely:

- Temperature range during operation: 5 - 30? С.

- The recommended thickness of the applied layer is 10 mm, if necessary, it is allowed to apply: a minimum layer (5 mm) and a maximum layer (20 mm).

- Time of solution readiness after kneading 10 min.

- Permissible storage time of the finished solution is up to 25 minutes.

- Shelf life in packaged form is six months.

- Drying time of a layer 1 cm thick 45 - 60 min.

- The period of curing is a week.

- The compressive strength of the dried plaster layer is more than 2.5 MPa.

- The strength of the dried plaster layer for bending is 1 MPa.

Colour contrast

It is noteworthy that this plaster is produced in three colors:

- White.

- Grey.

- Pink.

At the same time, the color shade affects the technical characteristics of the Rotband plaster, namely:

- The pink mixture lays perfectly evenly on the wall surface.

- White and gray plaster flow down the wall after plastering and when dried, specific waves remain that will need to be smoothed out before finishing.

This is due to the different grain sizes of the dry mixture:

- White and gray have 0.5 mm.

- The pink has 1.2 mm.

Material consumption

Before starting work related to plastering wall surfaces, it is imperative to calculate required amount dry mix. In doing so, two main points must be taken into account:

- The curvature of the wall surfaces to be plastered.

- The type of plaster mixture used.

Therefore, in order to determine the consumption of Rotband plaster per 1 m2, it is necessary at the first stage to determine the thickness of the applied plaster layer. For this:

- Beacons are set according to the level on the wall surface.

- At certain points (moreover, the calculation is more accurate with a larger number of them), deviations from the wall surface are measured.

- The obtained values are summed up and the average value is calculated by dividing by the selected number of measurement points.

The manufacturer indicates that for plastering 1 m2 of the wall surface with a layer of 1 cm, it is necessary to use 8.5 kg of Rotband dry mix. This means that if the calculated thickness of the plaster layer, for example, is 2.5 cm, then the Rotband plaster will need:

8.5 kg x 2.5 cm = 21.25 kg/sq. m.

21.25 kg/sq. m x 14 sq. m = 297.5 kg.

Since the most common packaging is 30 kg bags, you will need to buy:

297.5 kg: 30 = 9.9 bags ≈ 10 bags.

average cost

The cost of Rotband plaster, which is packaged in 30 kg bags, is in the range of 375 - 400 rubles. If you want to use dry plaster for minor repairs, for example, to restore walls in places where pipes are laid, you can purchase packs of 5 kg or 10 kg.

The average price of Rotband plaster in this packaging is:

- Bag 5 kg: 125 - 150 rubles.

- Bag 10 kg: 225 - 250 rubles.

It should be remembered that many specialized firms provide discounts when buying Rotband plaster mix in bulk. This is very beneficial for large volumes of work, so you can get significant financial savings.

Bulk weight 640–770 kg/m3

Grain size up to 1.2 mm

Solution output: From 100 kg of mixture ~ 120 l

Consumption ~ 8.5 kg/m2

Drying ~ 7 days

Strength: Compressive > 2.5 MPa, Bending > 1.0 MPa

Coeff. thermal conductivity 0.25 W/m K

SURFACE PREPARATION:

Cleaning: Clean the surface from dirt, dust and delaminations, remove the remnants of formwork lubricant from the concrete. Eliminate protrusions, protect metal elements from corrosion. The basis has to be dry and strong, with a temperature not below +5 °C.

Priming: Highly absorbent surfaces, such as silicate and ceramic bricks, aerated concrete, are treated with a brush, roller or spray with a Knauf primer

Grundirmittel, diluted with water in a ratio of 1:3 or Knauf Rotband-Grund, to prevent uneven setting of the plaster mortar. Dense, smooth, slightly non-absorbent surfaces, e.g. concrete, cement

plasters, polystyrene boards are treated with a primer KNAUF-Betokontakt to improve the adhesion (adhesion) of the plaster to the surface. Allow primer to dry after application. Avoid dusting the primed surface.

Installation of beacon profiles: On the surface of the base vertically with a step of 30 cm, apply the Knauf-Rotband mortar mixture in small portions, into which the beacon profiles are pressed, aligning them in one plane. The pitch of the profiles must not exceed

rule length.

Installation of protective corner profiles: Apply Knauf-Rotband mortar mixture in small portions on the inside of the corner profiles with a step of 30 cm. Place the profiles on the corners in the same plane as the beacon profiles, pressing each from the middle to the edges.

ORDER OF PLASTERING WORKS:

Preparation of plaster mortar:

In a plastic tank, pour ~18 liters of clean cold water, based on one bag (30 kg) of dry mix, pour 5–7 trowels of dry plaster mix and mix. Then pour the entire mixture out of the bag and mix with a plaster mixer until a homogeneous, lump-free mass is obtained. Hold for 5 minutes and mix again. If necessary, add water or a dry mixture and mix again. In the process of applying the mortar to the surface to be plastered, it is impossible to add water or a dry mixture! It is not allowed to add other components to the solution!

Plaster application:

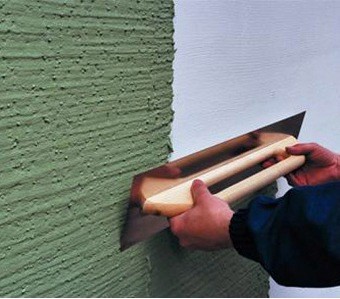

Apply the prepared plaster solution within 20-25 minutes after mixing on the surface, 5-50 mm thick. On the ceiling, the mortar should be smeared with a plaster falcon “on itself” with a layer of no more than 15 mm, thrown on the wall with a trowel or smeared with a plaster falcon from the bottom up, and then leveled with the h-rule in zigzag movements. If you want to get a thicker layer on the wall, you need to first, still soft, “comb” with a plaster comb and only after drying, treat with a Knauf-Grundirmittel or Knauf Rotband-Grund primer and apply a second plaster layer. Plaster ceilings only in one layer with a thickness of no more than 15 mm. Bases made of CSP and expanded polystyrene plaster-to-surface with reinforcement over the entire surface

fiberglass mesh with a cell of 5 x 5 mm. Mesh consumption - approximately 1.2 square meters. m per sq. m of surface.

Surface leveling:

As soon as the plaster mortar begins to set (approximately 45-60 minutes after mixing), level the surface with a metal trapezoid rail or a wide metal spatula, cutting off the excess and filling in the recesses. Irregularities in the corners and on the slopes are cut off with a plaster planer. After drying, it can be glued to such a surface using Knauf-Vliesen glue. ceramic tiles, having previously treated the surface with a KNAUF-Tiefengrund deep penetration primer (in places where water directly hits the tile - with KNAUF-Flehendicht waterproofing). The minimum thickness of the plaster layer for gluing ceramic tiles is 10 mm.

Surface grouting:

If the surface is being prepared for painting or wallpapering, then after a short exposure (about 15 minutes), the plaster must be moistened with plenty of water and rubbed in a circular motion with a hard sponge or felt grater to even out possible irregularities and marks from a trapezoidal rail or a wide spatula.

Surface Smoothing:

After a short exposure, until a matte surface appears, smooth the plaster with a wide spatula or a stainless metal trowel (trowel) with wide movements. Wallpaper can be glued to such a surface. To achieve a glossy surface, it is necessary within a day, but not earlier than 2.5–3 hours after mixing the dry mixture with water, to moisten the plaster again abundantly and re-smooth it with a metal float. After this treatment, it is not necessary to putty the surface of the plaster, it is suitable for high-quality painting. After smoothing the surface of the ceilings, cut the plaster layer with a Stucksage saw to the full depth around the entire perimeter of the room in order to prevent the formation of cracks.

Surface structuring:

The plaster surface can be structured, i.e. give it a different pattern or texture. To do this, after applying and leveling the mixture with the rule, it is necessary to roll the surface that has not yet hardened with a relief roller or give some structure to the molding tool, for example, a trowel, grout, or a hard brush.

RECOMMENDATIONS:

For quick drying of the plaster, it is necessary to ensure good ventilation of the room. Before applying the decorative coating, treat the plaster with a Knauf-Tiefengrund primer. Contaminated containers and tools reduce the time of using the plaster solution, therefore, they should be washed with water immediately after work.

TOOLS:

Plastic tank 50–125 l

Plaster mixer (N > 800 W)

Stainless steel trowel

Falcon stucco

Rule (h-profile) aluminum or wide stainless steel spatula

Aluminum Trapezoidal Rule

Sponge grout

Metal grater (trowel)

Comb plaster

Plaster planer

CONSUMPTION: 8.5 kg/m2

Material consumption is indicated per 1 sq. m of plaster surface with a thickness of 10 mm, excluding losses.

PACKAGING & STORAGE:

Knauf-Rotband is packaged in paper bags of 30, 10 and 5 kg. Store bags with Knauf-Rotband dry mix in dry rooms on wooden pallets. Material from damaged bags should be used first.

Shelf life in undamaged packaging is 6 months.

PACKAGING:

5 kg, 10 kg, 30 kg

Often, the most important component of repair in the premises is the smoothing of the walls and ceiling. Nowadays, there are a huge variety of plaster mixtures, but they are all divided into 3 classes: cement-sand, cement and gypsum mixtures. TM Rotband, Knauf company is a leader in this field, which has established itself as a high-quality and reliable manufacturer of universal gypsum plasters of all kinds.

Application area

Knauf mixes are suitable for all types of finishing works. In the line of this manufacturer you will find ready-made mixtures for work both on the internal walls of the premises and on the external ones, in buildings with low or high humidity, for old and cracked walls from many years of testing, both manual and machine applied Rotband gypsum plasters. They bond perfectly with concrete, bricks, foam, DSP, as well as already applied mix! Rotband gypsum plasters are widely used in kitchens and bathrooms. Ideally combined with cleaned concrete walls and ceilings.

The first and most important thing that needs to be done so that the gypsum plaster lays on the walls with the highest quality is to remove all dirt, all kinds of dust and peeling from them. Sand conspicuous projections and corrosion protection elements from metal. The application area must be completely dry and able to support the weight of the applied gypsum plaster, with a temperature of at least +5 °C.

Material calculation

It is important to understand how many meters of surface you need to process if you want to save your budget and not overpay for material that will then simply be stored in your garage. It is for this that the consumption of gypsum plaster should be calculated.

For a correct calculation, it is necessary first of all to take into account the thickness of the required application layer. To find out, craftsmen usually take measurements of irregularities along the entire length and width of the wall surface using special control point indicators. After summing up the resulting sum of deviations, they divide the sum of all points from which measurements were taken, thereby obtaining the average thickness of the required plaster. The number of counter-points plays a significant role, the more - the better the result will be. As a rule, the manufacturer indicates the required consumption of dry gypsum plaster per 1 sq.m. taking into account one layer of 10 mm, so what follows is nothing complicated, solid mathematics. On Rotband bags it is always written what the consumption of the dry mix will be, per sq.m. - it will be approximately 8.5 kg., then you only need to multiply this value by total area surface and the average thickness of the required layer. For example, to process a surface of 20 square meters, taking into account the obtained values in counter-points: 1.7 cm, 6 cm, 1 cm, we calculate:

|

Wed application thickness, cm |

0.6 (min. wall height) + 6 + 1 = 7.6 |

|

|

Consumption of gypsum plaster Rotband knauf per 1 sq. m., kg |

8,5 * 2,5 = 19,5 |

|

|

Volume per wall, kg |

||

|

How many bags of dry mix will be required, pieces |

||

|

The price of one bag of 30 kg, rub |

||

|

How much does gypsum plaster Rotband cost in the end, rub |

Installation of beacons

Apply the prepared Rotband solution to the base to be processed approximately every 30 centimeters, followed by indentation of the indicator profiles, and then make sure that they are all in the same plane. The distance between the profiles should be no more than 30 cm.

Mounting protective corners

Spread the already mixed solution of Rotband Knauf gypsum plaster on the inside of the profile, also from a long step of 30 centimeters.

Important ! The profiles must be installed in the same plane as the beacon profiles.

Preparation of plaster mortar

As for the preparation of the solution, then the ratio of dry mixture / water will be 1 to 3 or 1 to 5. This amount will be ideal in order to avoid possible uneven setting of the solution in the future. When you have applied the first layer of plaster, you should not immediately start applying the second one, let the previously applied layer dry and repeat the procedure when it is completely dry.

Important ! Avoid dusting the ground surface.

Before cooking, it is advisable to get a plastic tank with about 18 liters of water filtered from dirt (if it is dirty) already filled. Given the ratio of proportions, pour five to seven trowels of plaster and knead. After the solution begins to change its consistency, add the whole mass from the bag there and mix with a plaster mixer until you have a homogeneous mass without lumps. Allow the resulting solution to stand for about five minutes, and then mix again to be sure that there are no defects in the mixture. If you notice that the mixture is too thick, add some water to it.

Attention ! Do not try to add water while applying the mixture to the walls - this will only be a minus!

Also, do not experiment and add other components to the solution, in most cases it will only harm.

Gypsum plaster Rotband. Application

Approximately 25 minutes after the solution has taken on a homogeneous mass, it should be applied to the surfaces to be treated, the layer thickness should be from five to fifty millimeters. As for the application process, for the ceiling, gypsum plaster should be applied with a special plaster falcon, moving “on itself”. For walls, it is necessary to spread the plaster also with a "falcon" up / down or with a trowel. After that, the entire applied mass should be leveled with zigzag movements.

In the case when it is necessary to apply a large layer of plaster, you should first apply the first layer of acceptable thickness and only when it is completely dry, continue applying the next one until you get the thickness you need. As a rule, this is not required for ceilings, a maximum of one layer of gypsum plaster is enough.

Leveling the surface

After the applied mass begins to dry slowly (about 45-60 minutes after application), the treated area should be leveled with a spatula, getting rid of excess mass and filling in possible empty spaces. As for the processing of the joints of walls and slopes, then it is necessary to use a special planer for plaster.

We rub the treated surface

In the case when, according to the plan, it is worth sticking wallpaper on plaster or painting, it is necessary to allow the plaster to at least “infuse” for fifteen minutes, and then wet it strongly with water and “grind” with a special grater. This will help to avoid all sorts of bumps and depressions, as well as smooth out traces of the use of a spatula.

Smoothing the surface

When the gypsum plaster has already visually set, thereby visually beginning to acquire a matte tint, it should be smoothed out with a large spatula, making wide longitudinal movements. After that, wallpaper can be safely glued to the surface. If you want to achieve glossiness from the applied Rotband plaster, then you need to do the following: 2.5 - 3 hours after applying the plaster to the surface, apply a moisturizing layer of water, and then smooth the applied mass again with a metal float.

Structuring the surface

Professionals know about this, but you may not have sat down to hear that the applied Rotband gypsum plaster does not have to be left in the ideally uniform and smooth form as you applied it. Many people like to give the applied mass various shapes and even patterns!

All that needs to be done for this is to give a ride to the henchmen textured roller on a mass that has not yet fully hardened, or be creative and draw a wide variety of drawings using the tools available to you.

Little tricks

If you want to get the desired result in the shortest possible time, then we advise you to ensure high ventilation of the premises in order to quickly dry the plaster. In the case of using decorative variations of plasters, the application area should be pre-coated with a primer.

Probably, the main question that torments everyone after application is how long does Rotband gypsum plaster dry? We will answer right away that the time for complete drying is usually about 7 days, depending on external conditions.

Also, do not use several times already contaminated containers and devices for applying plaster. All this will only shorten the "life" of the plaster mass, so try to wash your tools with water after each layer of plaster.

Tools needed for the job

- Plastic container for 50-125 liters;

- Special mixer for mixing plaster (Power more than 800 W);

- Construction trowel made of stainless steel;

- Falcon for plastering;

- Aluminum rule in the form of an h-profile;

- Trapezoidal aluminum rule;

- Sponge grout;

- Comb for plastering.

Specifications

- Permissibility of application at one time:

- max: 50 mm;

- min: 5 mm.

- Bulk weight: 730 kg/m3

- Permissible graininess: does not exceed 1.2 mm

- Outlet weight:

- 100 kg / 120 l.

- Consumption of gypsum plaster Rotband per 1m2: ~ 8.5 kg / m2

- Drying time: ~ 7 days

- Resistivity:

- for shrinkage: more than 2.5 MPa;

- for twisting: more than 1.0 MPa.

- Density: about 950 kg per m3.

Gypsum plaster Knauf Rotband 30 kg gray

Plaster gypsum Knauf Rotband is a universal dry mix based on gypsum binder, which is used to level walls and ceilings in rooms with normal and high humidity. The consumption of Knauf Rotband plaster is 8.5 kg per square meter. Practical consumption may vary from average depending on operating conditions.

Knauf Rotband plaster provides a smooth surface that does not need additional puttying. Does not crack even with a thick layer.

The consumption of Knauf-Rotband gypsum plaster is 2 times less than traditional cement-sand plaster mixtures.

Application of a plaster layer up to 50 mm thick in one sweep without preliminary spraying. If necessary, it is possible to apply thicker layers in two coats.

The versatility of Knauf Rotband plaster - simultaneous plastering and puttying, the manufacture of decorative elements, repair and restoration work.

The range of gypsum plaster Rotband is represented by the following products:

- Plaster Knauf Rotband 10 kg with enhanced adhesion

- Plaster Knauf Rotband 30 kg with enhanced adhesion

- Plaster Knauf Rotband 30 kg white

High water-holding capacity - the mortar mixture does not delaminate and does not dehydrate even on porous, moisture-absorbing substrates and at elevated temperatures.

Regulates the humidity regime in the room - "breathes", creating a favorable microclimate in the room.

Rotband plaster is made from an environmentally friendly natural mineral (gypsum) and does not contain substances harmful to human health.

Foundation preparation:

Surfaces that strongly absorb moisture, such as silicate and ceramic bricks, aerated concrete, are treated with a brush, roller or sprayer with a Knauf primer.

Knauf-Grundirmittel, diluted with water in a ratio of 1:3 or Knauf-Rotband Grund, to prevent uneven setting of the plaster mortar. Dense, smooth, slightly and non-absorbent surfaces, such as concrete, cement plasters, polystyrene foam boards, are treated with a Knauf-Betokontakt primer to improve the adhesion (adhesion) of the plaster to the surface. Allow primer to dry after application. Avoid dusting the primed surface.

Installation of beacon profiles: after 30 cm, apply the Knauf-Rotband mortar mixture in small portions onto the surface of the base, into which the beacon profiles are pressed, aligning them in one plane. The step of the profiles must not exceed the length of the rule.

Installation of protective corner profiles: apply the Knauf-Rotband mortar mixture with stucco moldings on inside corner profiles with a step of 30 cm. Install the profiles at the corners in the same plane as the beacon profiles, pressing each from the middle to the edges.

Mortar preparation:

Pour clean water into a plastic tank, pour dry plaster mixture and mix with a plaster mixer until a homogeneous, lump-free mass is obtained. You keep 5 minutes and mix again. If necessary, add water or dry mix and mix again. In the process of applying the mortar to the surface to be plastered, it is impossible to add water or a dry mixture! It is not allowed to add other components to the solution!

Application:

Apply the prepared plaster solution to the surface of the wall, throwing a trowel from the bottom up, and then level it with the rule in zigzag movements. If you want to get a thicker layer, you need to first, still soft, “comb” with a plaster comb and only after drying, prime with a Knauf-Grundirmittel primer and apply a second plaster layer. Plaster the bases from DSP and expanded polystyrene with reinforcement over the entire surface with a glass cloth mesh with a cell of 5 x 5 mm.

As soon as the plaster mortar begins to set (approximately 45-60 minutes after mixing), level the surface with a wide metal spatula, cutting off the excess and filling in the recesses. After drying, ceramic tiles can be glued onto such a surface using Knauf-Vliesen glue, having previously primed the surface with a Knauf-Tiefengrund deep penetration primer.

If the surface is being prepared for painting or wallpapering, then after a short exposure (about 15 minutes), the surface of the plaster must be moistened with plenty of water and rubbed in a circular motion with a hard sponge or felt grater to even out possible irregularities and marks from a wide spatula.

To achieve a glossy surface, it is necessary within a day, but not earlier than 2.5-3 hours after mixing the dry mixture with water, to moisten the plaster again abundantly and re-smooth it with a metal float. After this treatment, it is not necessary to putty the surface of the plaster, it is suitable for high-quality painting.