A gear motor is a design that combines a gearbox and an electric motor in a single unit. The scope of this unit is extremely wide, it can be found in any industry where it is necessary to change the torque power and adjust the speed of the electric motor.

Types of gear motors by transmission type:

Planetary; jagged; combined.

Worm; wave;

These types of motor reducers, in turn, are one-, two- and three-stage and serve as general-purpose drives. In rare cases, you can find 4-ex and 5-speed motor gearboxes. Also, these units differ in the type of gears: bevel, cylindrical and combined. Various installations and arrangements of a shaft at reducers are possible: horizontal or vertical. An important element is the layout of the motor-reducers.

The main types of layouts:

1) The motor reducer is cylindrical coaxial.

Two- or three-stage with a range of gear ratios from 3 to 200. In this gearbox, the output shaft is located on the same axis as the electric motor (hence the name "coaxial").

2) The motor reducer is cylindrical with parallel shafts.

Two-stage with a range of gear ratios from 5 to 200. Distinctive feature is a hollow output shaft. This makes it possible to mount the gearbox on the equipment shaft without flexible couplings.

Areas of use.

Motor gearboxes have been able to win a significant place in almost any industry. This unit is used in medical technology, machine-building industry, specialized tools, in servo mini-drives, as well as in means of processing and storing information. The motor reducer is an automation tool, and is also applicable in control systems and process control devices. Increasingly, you can find its use in the mining field, woodworking, elevator equipment, Food Industry, ventilation systems. The most common in the industry are cylindrical, worm and planetary gear motors.

Gearmotors are mechanisms that combine both electric motors and a gearbox in one housing. They are indispensable units in construction, as well as wherever a change in torque power or adjusted speeds of electric motors is required. The motor-reducer is used for the construction of winches, conveyor, concrete mixer.

Types of gear motors

Regardless of manufacturers, the gear motor is divided into types:

cylindrical - very reliable, has a considerable resource of operational power, is used to provide a large machine with high speeds. It happens chevron, spur and helical;

conical - has not a parallel, but an intersecting axis of the input and output shafts, which will allow it to be used to change the direction of kinetic gears.

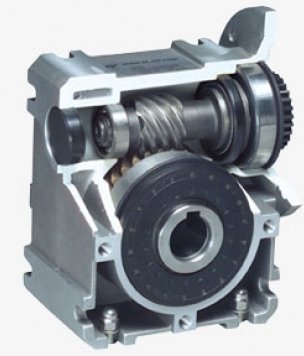

Worm - this gearbox is distinguished by a high gear ratio, high heat dissipation and low KP

planetary - has a small size and weight, but has a high load capacity, with which you can get a good gear ratio;

mixed type - several gears are available in one housing. In modern construction, a gearbox combined with a motor is used very widely. Gearbox types are selected depending on the intended applications. As a mixed gearbox, a bevel-cylindrical is given:

The construction of any buildings requires not only carefully prepared projects, the availability of the necessary building materials, but also a certain mechanization that facilitates the physical efforts of people.

Most construction mechanisms are powered by an engine, and their rotary motion transmitted to different devices using reducers. Mechanisms of these types have the possibility of self-locking, because it is used in the system for lifting or moving workers, or material. It can be a winch, a concrete mixer and other types of construction equipment. The worm gearbox is used in construction sites and in gantry or tower cranes.

Consider the 2 most popular gearboxes

Worm gear: its pros and cons

It is best to buy worm gearboxes directly from the manufacturer of these types of products. For example, using the Internet. "Worm" has whole line positive properties. Its silent operation, smooth running and large gear ratios are especially appreciated among the consumer. Compared to others, it has a smaller size and lighter weight. But it must be taken into account that the efficiency of "worms" is not too high, because there are restrictions on their power. In addition, in the work often have to use additional cooling. The classification of the worm gear occurs according to the shape of its teeth.

Cylindrical motor gearboxes: their pros and cons

Competition "worms" can be cylindrical gearboxes. They are mechanisms based on the transmission of rotations between shafts, which are located in a parallel plane.

Such mechanisms are often found in various machines with the help of which building materials are processed. For example, metal-cutting equipment or in a wood processing unit. Concrete mixers work perfectly with such gearboxes.

Cylindrical devices have many positive characteristics:

high endurance mechanisms;

independence from the values of current strength and voltage in networks;

high efficiency values, which contribute to the absence of overheating of parts.

The main task of any mechanism is to perform work with the highest possible efficiency. Such mechanisms include the motor reducer, which is a system of an electric motor and a gearbox that converts its power in the right direction. They are relatively inexpensive, quite reliable and have a high efficiency.

There are several popular types of gear motors, among which are:

- worm;

- cylindrical;

- planetary;

- wave.

Each of these types has its own advantages and disadvantages, so when choosing, you need to carefully get acquainted with their technical characteristics.

This type of gear motors is used on mechanisms with continuous or intermittent operation. They gained popularity due to the fact that the drive is very unpretentious and convenient, as well as a large number of gear ratios - from 5 to 100. During operation, they have a low level of vibration, and as a result, reduced noise. According to the drawing of a gear motor of this type, one can see another important feature of them. They have a self-braking function, so if a load is lifted with it, and the engine stops working for any reason, the gearbox will stop at one point and the load will not fall. At the same time, such

The mechanism can rotate the shaft in both directions without preference, which is especially when used in construction, conveyor, lifting and other systems.

Along with the obvious advantages, this type also has disadvantages. The main one is low efficiency. It does not exceed 80% due to the fact that the sliding of metal surfaces of mechanisms occurs at high speeds. This does not allow making motor gearboxes of this type of small sizes in this case, power losses will be even more noticeable.

Helical gearboxes are by far the most common in industry and technology. They have a high efficiency, over 90%, as well as low wear of mechanisms even under the most adverse conditions. A typical representative is the 4MTs2S gear motor used in various areas of industrial production. It is designed for long-term operation, up to round-the-clock modes. Works in a network of 50-60 Hz, various powers.

Its positive qualities include:

![]()

- the possibility of shaft rotation without direction preference with the same number of gear ratios;

- high efficiency, which allows you to significantly save on electricity;

- a wide range of operating modes at different speeds;

- the reasonable price of a gear motor of this type makes its use economically justified;

- ease of installation.

Among the shortcomings of the units of this design can be identified:

- the load must be constant and in one direction, which significantly narrows the range of their application;

- the mechanism can only work in a non-aggressive environment. Dust content should not exceed 10 mg/m³;

- inability to use in industries where explosive materials are used.

These geared motors allow to achieve optimal performance when the gearbox and the electric motor are coaxially located. They are lightweight and compact. That is why, for example, a car windshield wiper gear motor works on this principle. In industry, ZPM gear motors are most often used, which show high performance. They are used in many industrial units, although this mechanism is not suitable for use in a unit for lifting loads.

The positive characteristics of planetary gear motors include:

- the ability to change the load on the shaft, not only in magnitude, but also in time, the unit copes equally well with both direct and reverse loads in the nominal operating mode;

- designed for long periods of operation from 8 to 24 hours;

- the ability to use at low pressures, which are equivalent to lifting to a height of up to 1000 m above sea level;

- designed to operate in climates with a wide range of temperatures, from -45 to +45 ° C and high humidity. For tropical latitudes, engines are specially adapted.

At the same time, some disadvantages of these gear motors can be noted:

- they are not used in machines that require precision, since there are problems due to the choice of gaps between gears, and the repair of gear motors of this type is also difficult;

- during operation, they have an increased moment of inertia, in which they are clearly inferior to units of a cylindrical design;

- can only work in non-aggressive and non-explosive environments.

Wave motors reducers

One of the most modern and high-tech types of this equipment. A wave transmission type that combines the reliability of a gear train with the dynamism of the flexible elements that are used in its design. They have a general industrial application, they are lightweight and compact, as well as the ability to obtain a large gear ratio with a minimum number of moving parts.

Their advantages include:

- the ability to seal the unit by separating it from the engine, so these gearboxes can be used in dusty workshops or in explosive industries;

- works well at any load that does not exceed the nominal, it turns equally in both forward and reverse directions;

- works normally at high and low pressures;

- can be used on high-precision machines;

- have very good running smoothness.

The disadvantages include:

- reduced torsional rigidity;

- increased mechanical tension of the flexible elements, which quickly fail due to improper operation.

For determining specifications here are two motors:

How to choose the right gear motor?

Today, many companies offer their catalogs of gear motors of various types and purposes. First of all, the customer is interested in the ratio of price and quality. Today, imported units are very popular, for example, Bonfiglioli or Bauer gear motors. This is really high quality equipment that lasts a long time. But with all this, a lot of money has to be spent on its repair, since spare parts are delivered from abroad. That is why many customers prefer a domestic manufacturer in their price lists of gearmotors, the prices are much lower, as well as the cost of repairs. And only for high-precision machines there is a need to think about whether it is worth sacrificing quality? But here, too, the domestic manufacturer begins to step on the heels of importers. For example, the gearbox of a Mercury outboard motor can be completely replaced with a domestic one. Therefore, before you buy a gear motor, clearly define where and how it will be used, and then you can make the right purchase.

An imported analogue of the domestic 4MTs2S gear motor is an imported cylindrical gear motor, which can be in an aluminum and cast iron housing. These gearmotors are built on a modular basis and do not require maintenance throughout their entire service life.

Gearboxes- products for material and technical purposes. These mechanisms serve to change the speed of rotation when transferring rotational motion from one shaft to another.

Motor reducer - is an electric motor and a reducer connected into a single unit (in some countries it is called a geared electric motor). The motor-reducer is more compact compared to the drive based on the gearbox, its installation is much easier, in addition, the material consumption of the foundation frame is reduced, and for the mechanism with a plug-in design (with a hollow shaft), no frame structures are required. A large number of design solutions and standard sizes makes it possible to equip enterprises with precision gearboxes for drives of various purposes, sizes and capacities. The motor reducer, as a universal element of the electric drive, finds its application in almost all areas of industry.

According to the type of transmission, they are divided into gear, worm and hydraulic.

motor reducer- is an electric motor and a gearbox connected into a single unit (in some countries it is called a gear motor). The motor-reducer is more compact compared to the drive based on the gearbox, its installation is much easier, in addition, the material consumption of the foundation frame is reduced, and for the mechanism with a plug-in design (with a hollow shaft), no frame structures are required. A large number of design solutions and standard sizes makes it possible to equip enterprises with precision gearboxes for drives of various purposes, sizes and capacities. The motor reducer, as a universal element of the electric drive, finds its application in almost all areas of industry.

The most widely used in industry planetary and helical gear motors made according to the coaxial scheme relative position motor and output shaft. As well as worm gear motors with an arrangement of the electric motor under 90 hail. to the output shaft.

For gearmotors general machine-building application refer:

Scope of gearboxes:

automation tools and control systems, control devices, automatic and automated control systems, servo mini-drives, information processing and presentation tools, special tools, medical equipment. The most widespread in the industry are planetary gearboxes and cylindrical gearboxes, made according to the scheme of the mutual arrangement of the electric motor and the output shaft. Such mechanisms are suitable for use in moderate climatic conditions, when installed indoors or outdoors under a canopy. As standard, they are dipped primed and then topcoated with a blue-gray air-drying alkyd enamel. There are also special coatings. For extreme environments and outdoor installations, a paint finish is available for worldwide use. Upper limit temperature 105 K (at coolant temperature +40°C), Maximum permissible continuous temperature 155°C.

TYPES OF REDUCERS.

Cylindrical gearbox.

The helical gearbox is one of the most popular types of gearboxes. It, like all gearboxes, serves to change the speed of rotation when transmitting rotational motion from one shaft to another. It is the gear drive that is one of the most common types of drives of modern mechanical systems for general industrial use. More than a hundred years ago, our industry was faced with the task of meeting the needs of the country in spur gearboxes. The opening factories successfully coped with this. At present, the production of high-quality and reliable products is ensured by a powerful production base. Now they produce various types of products: one-, two-, and three-stage spur gearboxes. Ensuring the required functional parameters and reliability of the machine as a whole largely depends on the operability and resource of the cylindrical gearbox. Indicators of durability and reliability of drive elements and in particular gearboxes and gearmotors, depends on reasonable choice of the gearbox itself when designing the machine, i.e. compliance of this choice with the current regulatory documentation (ND). The wrong choice of gearbox reduces its market competitiveness, causing damage to the manufacturer, and can lead to significant economic losses for the consumer of engineering products due to unscheduled downtime, increased repair costs, etc. One of the most important requirements for ensuring the competitiveness of a cylindrical gearbox is the best correspondence of its passport characteristics to real operational conditions of loading and operation of the machine drive.

Helical gearboxes include the following gearboxes:

Worm gear.

A worm gearbox is a special type of gearbox by the type of transmission (along with gear and hydraulic) with a worm thread profile. Gearboxes - products for material and technical purposes, serve to change the speed of rotation when transmitting rotational motion from one shaft to another. All this is mechanics, or rather, machine parts. A worm gear is used to transmit motion between intersecting (usually at right angles) axes. One of the significant advantages of worm gearboxes is the ability to obtain a large gear ratio in one stage (up to 80 in general purpose gearboxes and up to several hundred in special gearboxes). These gearboxes have high smoothness and quietness in operation and self-braking at certain gear ratios, which makes it possible to exclude brake devices from the drive. There are various options for these mechanisms, for example, single-stage universal, two-stage, three, single-stage with a worm located above the wheel and also with different parameters: Ch-80, Ch-100, Ch-125, Ch-160, 2Ch-40, 2Ch-50, 2Ch-63, 2Ch-80, RFU-125, etc.

Bevel - cylindrical reducer.

Bevel-helical gearboxes are a kind of gearbox according to the design of the working elements. It, like all gearboxes, serves to change the speed of rotation when transmitting rotational motion from one shaft to another. It is the gear drive that is one of the most common types of drives of modern mechanical systems for general industrial use. This type gearboxes have high efficiency and considerable durability. There is a bevel-helical gearbox for conveyor line drives, for driving a traction mine electric locomotive, etc. The drive of the latter, for example, also includes a wheel pair and axle boxes. Ensuring the required functional parameters and reliability of the machine as a whole largely depends on the performance and resource of the bevel-helical gearbox. The indicators of durability and reliability of drive elements and, in particular, gearboxes and gearmotors, depend on the reasonable choice of the gearbox itself when designing the machine, i.e. compliance of this choice with the current regulatory documentation (ND).

Gearmotors are mechanisms that combine both electric motors and a gearbox in one housing. They are indispensable units in construction, as well as wherever a change in torque power or adjusted speeds of electric motors is required. The motor-reducer is used for the construction of winches, conveyor, concrete mixer.

Types of gear motors

Regardless of manufacturers, the gear motor is divided into types:

The construction of any buildings requires not only carefully prepared projects, the availability of the necessary building materials, but also a certain mechanization that facilitates the physical efforts of people.

Most of the building mechanisms are powered by an engine, and their rotational motion is transmitted to various devices using gearboxes. Mechanisms of these types have the possibility of self-locking, because it is used in the system for lifting or moving workers, or material. It can be a winch, a concrete mixer and other types of construction equipment. The worm gearbox is used in construction sites and in gantry or tower cranes.

Consider the 2 most popular gearboxes

Worm gear: its pros and cons

It is best to buy worm gearboxes directly from the manufacturer of these types of products. For example, using the Internet. "Worm" has a number of positive properties. Its silent operation, smooth running and large gear ratios are especially appreciated among the consumer. Compared to others, it has a smaller size and lighter weight. But it must be taken into account that the efficiency of "worms" is not too high, because there are restrictions on their power. In addition, in the work often have to use additional cooling. The classification of the worm gear occurs according to the shape of its teeth.

Helical gearbox: its pros and cons

Competition "worms" can be cylindrical gearboxes. They are mechanisms based on the transmission of rotations between shafts, which are located in a parallel plane.

Such mechanisms are often found in various machines with the help of which building materials are processed. For example, metal-cutting equipment or in a wood processing unit. Concrete mixers work perfectly with such gearboxes.

Cylindrical devices have many positive characteristics:

- high endurance mechanisms;

- independence from the values of current strength and voltage in networks;

- high efficiency values, which contribute to the absence of overheating of parts.