At present, the construction market is replenished every day with more and more new and modern materials. Today, construction dry mixes, which consist of binders, are popular and widely in demand. As a binder, cement, clay usually acts, and sand is used as a filler. Such mixtures are very easy to use, they greatly facilitate construction work, and also improve their quality. Their use is always profitable, practical and quite economical. These mixtures are divided into several types depending on the purpose. They are widely used for cladding buildings, for finishing walls and floors, for leveling various surfaces and much more.

What is sand concrete m 300

Sand concrete m 300 can be safely called one of the most popular widely demanded and effective mixtures today. This is enough the new kind building mixture, although it is already attracting increased interest due to its versatility and excellent characteristics. It has been successfully used in a wide variety of construction and finishing work, as well as almost at all its stages. It is a modern self-leveling compound, hardens quickly thanks to the components of which it is composed, in particular, cement and some additives, has grey colour. This material has a number of significant benefits, compared to many similar mixtures.

Sand concrete m 300 can be safely called one of the most popular widely demanded and effective mixtures today. This is enough the new kind building mixture, although it is already attracting increased interest due to its versatility and excellent characteristics. It has been successfully used in a wide variety of construction and finishing work, as well as almost at all its stages. It is a modern self-leveling compound, hardens quickly thanks to the components of which it is composed, in particular, cement and some additives, has grey colour. This material has a number of significant benefits, compared to many similar mixtures.

- One of the main advantages of this sand concrete is its high strength and reliability, long service life.

- The material carries the most high loads, not afraid of mechanical and other damage.

- Has a high density.

- resistant to precipitation and high humidity.

- Handles corrosion very well.

- Has excellent sustainability to high temperatures, as well as their differences.

- Much reduces load on the ground and structures.

- Sand concrete m 300 - universal material, Can be used for both internal and external work.

- The material is very easy to work with, saves time and costs.

- Allows you to create perfectly flat surface.

- It has a fairly low price, which makes it affordable for almost all buyers.

The use of sand concrete m 300

Due to the versatility and practicality of the material, it is widely used in almost in all areas of construction. It is great for both interior and exterior building work. Ideal for the construction of durable structures and concrete products. Sand concrete is necessary for the construction of utility, household and residential premises, as well as large building complexes. Very often this building mixture is used for floor screed, for pouring foundations, with installation work. This material is well suited for sealing various seams, for leveling horizontal and vertical surfaces.

Due to the versatility and practicality of the material, it is widely used in almost in all areas of construction. It is great for both interior and exterior building work. Ideal for the construction of durable structures and concrete products. Sand concrete is necessary for the construction of utility, household and residential premises, as well as large building complexes. Very often this building mixture is used for floor screed, for pouring foundations, with installation work. This material is well suited for sealing various seams, for leveling horizontal and vertical surfaces.

Sand concrete m 300 is indispensable for emergency work, where necessary fast curing speed and good resistance to external factors. In addition, this mixture also finds its application in restoration work, for laying garden paths, stairwells. Often used for the manufacture of borders, various types of paving slabs and much more. In some cases, it is used as the main solution for the preparation of expanded clay concrete, this is done by adding expanded clay to the sand-concrete mixture.

In order to get an excellent result, before using sand concrete m 300, it is necessary prepare the surface on which the material will be applied. The base must be thoroughly cleaned of dust, dirt and paint coatings, and crumbling surfaces are also removed. Large cracks and seams must be repaired. Then the surface is best moistened or primed.

What is sand concrete made of?

Manufacturers of this mixture try to apply the latest technologies and developments, it is also very important to observe the correct proportions, if this is not done, the quality of the material may deteriorate significantly, and in the end we will not get the expected result. In addition, changing the proportions directly affects not only the strength, but also the frost resistance and water resistance of the material. Sand concrete m 300 is produced in the form of dry mixes, sometimes in the form of ready-made blocks.

The main component of this mixture is cement. Today, there are many different types of it, but for sand concrete, Portland cement is mainly used, which consists of clinker and gypsum. Clinker is first crushed and gradually added to gypsum, resulting in high quality and durable Portland cement. Also, this mixture contains sand. Many manufacturers use fine and coarse-grained river sand, they also add some special additives that improve the quality of the mixture. These can be: various plasticizers, anti-corrosion components, granite chips, etc.

The main component of this mixture is cement. Today, there are many different types of it, but for sand concrete, Portland cement is mainly used, which consists of clinker and gypsum. Clinker is first crushed and gradually added to gypsum, resulting in high quality and durable Portland cement. Also, this mixture contains sand. Many manufacturers use fine and coarse-grained river sand, they also add some special additives that improve the quality of the mixture. These can be: various plasticizers, anti-corrosion components, granite chips, etc.

By their own technical specifications This sand concrete is divided into three groups:

- A mixture with a fine fraction, used for sealing seams exterior plaster, has increased strength and reliability.

- Mix with medium fraction 2-2.2 mm, used for the manufacture of self-leveling floors, paving slabs, ties, etc.

- A mixture with a large fraction. It finds its application for pouring a wide variety of foundations, which, thanks to this mixture, have high strength and a long service life.

The division into the above groups takes place on special equipment using special grids, vibration installations and some other tools.

How to calculate the consumption of sand concrete m 300

When working with sand concrete, many people ask themselves how to calculate the flow rate of the mixture. As a rule, on square meter square leaves 18 - 20 kg dry mix, with a layer thickness of about 10 mm. It is important not to forget that the thickness of the layer on the floor slabs must be at least 20 mm. In order to calculate the consumption of the mixture for all rooms, it is recommended to use the method that we will now describe. For example, we took the work on the floor screed.

If there are significant differences, then it is necessary to determine the average layer thickness over the entire area of \u200b\u200bthe room. For this you need to find most protruding part and relative to it, make several measurements, at several points in the room. Then determine the absolute deviation from the point you have chosen, that is, the most protruding part. It is necessary to multiply the value that turned out by two, this will be the average thickness of the screed.

If there are significant differences, then it is necessary to determine the average layer thickness over the entire area of \u200b\u200bthe room. For this you need to find most protruding part and relative to it, make several measurements, at several points in the room. Then determine the absolute deviation from the point you have chosen, that is, the most protruding part. It is necessary to multiply the value that turned out by two, this will be the average thickness of the screed.

In order to calculate the consumption of the mixture on the walls, it is not difficult. When laying brickwork, one must not forget that the mixture is also used to fill the joints. You also need to know that the mixture is packed in bags from 40 to 50 kg, it is desirable to store them at a temperature 5 to 30 degrees heat, protecting from moisture and damage.

Material cost

Sand concrete m 300 has enough acceptable price and suitable for every buyer. You can buy this material in almost every building supermarket or small store, but it is very important to purchase a high-quality product from a trusted company. In addition, you need to know some facts, for example, on what criteria does the cost of sand concrete m 300 depend.

- First of all, the quality and type of material.

- From the brand of sand concrete composition, the higher the brand, the higher the price, respectively.

- From the weight of the packaging bag, as there are several standard packages of this mixture.

- An important role and brand of the manufacturer.

The average price of a 40 kg bag of sand concrete m 300 is from 100-120 rubles. One of the most inexpensive and frequently used mixtures is Stone flower sand concrete m 300. This is a high-quality mixture, which is practically in no way inferior to its more expensive counterpart, has an excellent quality-price ratio. There is a great opportunity to buy sand concrete with delivery, many manufacturers offer this service for their clients. This is a very convenient and cost effective option.

The average price of a 40 kg bag of sand concrete m 300 is from 100-120 rubles. One of the most inexpensive and frequently used mixtures is Stone flower sand concrete m 300. This is a high-quality mixture, which is practically in no way inferior to its more expensive counterpart, has an excellent quality-price ratio. There is a great opportunity to buy sand concrete with delivery, many manufacturers offer this service for their clients. This is a very convenient and cost effective option.

By choosing as building material sand concrete m 300, you will get an excellent result and unsurpassed quality work. And the excellent characteristics of this building mixture allow you to achieve the expected results when minimum expenses time and money.

Sand concrete floor screed m 300 (video)

Construction is one of the areas in which the quality of the work done is highly dependent on the technical characteristics of the materials used. That is why the range of building materials is constantly updated with new ones, the most suitable for a certain category of work. Various dry mixes are in great demand, which are easy to use and highly effective. One of best solutions for the implementation of an extensive range of works - sand concrete M300.

What is sand concrete m300?

This is a relatively new type of self-leveling dry mixes, which has proven itself well in repair and construction. Easy to use, hardens quickly. It is very durable, has a high density, easily endures heavy loads. Resistant to high temperatures and sudden changes in operating temperature. Not susceptible to high humidity, does not give in to corrosion. Due to its properties and technical characteristics, it is successfully used both in external and internal construction and repair work. The high versatility of this mixture makes it much more popular than other material variations, such as M400.

High-quality sand concrete, which allows everyone to purchase this mixture without high financial costs, is widely applicable in finishing, repair and construction work. It can be used wherever it is necessary to erect especially durable buildings and structures. It is relevant in the construction of premises for various purposes, with the exception of industrial ones (in this case, heavier grades of concrete are used).

High-quality sand concrete, which allows everyone to purchase this mixture without high financial costs, is widely applicable in finishing, repair and construction work. It can be used wherever it is necessary to erect especially durable buildings and structures. It is relevant in the construction of premises for various purposes, with the exception of industrial ones (in this case, heavier grades of concrete are used).

This material is perfect for removing seams, leveling surfaces and even for emergency work. It is very often used for floor screeding, where its special strength and self-leveling come in handy.

Often used for external work - laying tracks, concrete stairs. As a mixture, it can be used for the manufacture of paving slabs, curbs, in the preparation of expanded clay concrete.

What is sand concrete made of?

The main components of the mixture are high-quality cement or Portland cement, as well as sand. Various fillers can be used as additives, providing certain technical characteristics to the final composition of the dry mix or finished block. You can choose the most suitable from three types:

The main components of the mixture are high-quality cement or Portland cement, as well as sand. Various fillers can be used as additives, providing certain technical characteristics to the final composition of the dry mix or finished block. You can choose the most suitable from three types:

Fine fractional mixture, ideal for various plastering works

A mixture with an average fraction size of about 2 mm, optimal for pouring and screeding floors or making paving slabs

Coarse-fraction mixture, which is suitable for high-quality pouring of the foundation

How to calculate the consumption of sand concrete

The consumption of a dry mix of sand concrete is 18-20 kg per 1 sq.m. with a mortar layer thickness of 10 mm. If you want to calculate the cost of floor screed, do not forget to calculate the average thickness of the required mortar layer throughout the room.

Sand concrete cost

Despite the high demand, the price of this material remains absolutely acceptable. On average, sand concrete in Moscow costs around 90-160 rubles, the price for a bag of 40-50 kg. Of course, its cost can vary significantly depending on the manufacturer. At the same time, one of the best are mixtures of the Ruseyan and Willis brands, which are in no way inferior to more expensive foreign counterparts.

The building material sand concrete is a mixture consisting of Portland cement, sand (different fractions of grains) and chemical additives. Typically, sand concrete M300 is used for pouring screeds and blind areas, concreting flights of stairs, fastening structures, pouring local foundations and sealing joints. In addition, sand concrete is used as the basis for mixing expanded clay concrete.

The basic composition of sand concrete grade M300

- Portland cement brand M300, M400 or M500;

- River washed and sifted sand with a grain fraction from 1.5 to 4 mm;

- Granite chips (sometimes);

- Screening (sometimes);

- Additives (sometimes).

Groups of sand concrete M300 depending on the purpose

- Material with sand of fine grain fraction - from 0.8 to 1.2 mm. Scope - external plasters of all types, sealing masonry joints;

- Material with sand of medium fraction of grains - from 1.8 to 2.2 mm. Scope - production of paving slabs, borders and eurofences; construction of self-leveling floors and screeds of all types;

- Material with sand with a large fraction of grains - from 2.5 to 4 mm. Scope - construction of foundations of various types.

Proportions of M300 sand concrete for self-preparation

As already mentioned, the basis of dry sand concrete is sand of various grain fractions (up to 2/3 of the volume), a smaller part is Portland cement grade M300, M400 or M500. In this case, additives can be added, you can not add. For example, the recipe for sand concrete for floor screed is as follows: Portland cement M300 - 1 part, coarse river sand - 2-3 parts. To knead the plaster mortar, the amount of sand is increased to 4-5 parts. Plasticizer - up to 2% of the volume of the solution.

In general, for the preparation of one ton of sand concrete, about 220-240 kg of Portland cement M300-M400 and 800 kg of filler (sand and crumbs, or only sand) will be required.

It should be noted that each manufacturer has his own recipe for the preparation of sand concrete M300. Therefore, its exact composition may differ in terms of the type and amount of additives and additives.

Peskobeton is a construction mixture in which Portland cement is used as a binder, and building sand is a filler. Therefore, it is also called sand cement. Depending on the amount of Portland cement and the size of the sand particles, the material is assigned a grade from 200 to 500. The most popular (class B22.5), which at a low cost has good strength and density - the ratio of these indicators practicallyperfect. Weighs concrete grade M300 - 2.4 t / m 3.

Sand concrete is cheaper than brick or foam concrete, it is advantageous to use it when arranging the bearing layer of industrial floors. It is a light, inexpensive and durable material, the use of which saves money during construction and reduces the load on structures and soil.

|

|

|

|

|||

| PERFECT | M-300 | M-500 |

The main advantages of sand concrete: plasticity, high density, frost resistance and resistance to deformation and wear make this material indispensable, both in large-scale construction, and in the construction of household and utility rooms, when used in the private sector, in minor repairs. A modern sand-cement mixture necessarily contains modifying additives that improve the moisture resistance of the material and its resistance to corrosion and wear resistance.

Sand concrete has established itself as a versatile material, easy to transport and easy to prepare a working solution. Used for arranging high-strength floors and monolithic panels, it is successfully used for:

- building foundations

- brickwork

- construction of concrete walls

- concrete screed devices

- sealing joints and seams

- manufacturing iron concrete structures

- leveling concrete floors and bases

- fixing defects in concrete structures

- concreting stairs

The solution prepared from sand concrete quickly hardens. Therefore, this material is used not only in construction, but also in situations where a quick response is needed. For example, in emergency situations.

It is produced in packaged form with various proportions of components, depending on the intended use.

Sand concrete M-300 manufacturer: Center for Building Materials (CSM)

Peskobeton M-300 produced by TsSM will be used as a primary leveler for floors, horizontal concrete bases. The material is ideal for sealing joints between concrete structural elements and for eliminating pouring defects.

The recommended application thickness is 10-50 mm. When using a reinforcing mesh, it is permissible to fill with a layer up to 100 mm

ATTENTION!

An excess amount of mixing water can lead to a decrease in strength and the formation of cracks.

Foundation preparation

Before use, crumbling and crumbling surface areas must be removed from the base. Cracks wider than 1 mm should be widened and repaired with mortar. Treat highly absorbent surfaces with a lax primer.

The corrected base must be cleaned of dust, grease and oil and paint residues. This is necessary to achieve better adhesion. The base surface must be dry.

Solution preparation

Pure water is used to prepare the mortar mixture. Gradually add the dry mixture to the liquid, while thoroughly mixing with a low-speed mixer or a drill with a nozzle until the lumps disappear and a homogeneous mass is formed. Wait 5 minutes for the mixture to mature and mix again without adding water. The finished solution must be used up within 45 minutes. Re-mixing is allowed during thickening.

Application recommendations

The finished solution must be poured onto the base and spread over the entire surface of the area to be leveled. Works should be carried out in dry conditions, at air and base temperatures from +5 to +30°C and relative humidity not more than 80%. In order to avoid too rapid evaporation of moisture, the surface must be covered with a plastic film for a period of at least 3 days. Take measures to eliminate drafts.

At breaks in work more than 15 min. equipment and tools should be cleaned of residues of the solution, washed with water.

Storage

The guaranteed shelf life of the mixture in a complete branded package in dry conditions is at least 12 months from the date of manufacture indicated on the package.

Package

The sand concrete mixture is supplied in kraft valve paper bags. Weight - 40 and 50 kg.

No. p / p |

Name of indicator |

Norm for the brand |

|

Viability of solution not less than, min. |

||

|

Setting time, min. |

||

|

Full load capability, after hours |

||

|

Readiness for laying the coating, days |

||

|

Compressive strength after 28 days, MPa |

||

|

Adhesion strength at separation, MPa |

||

|

Frost resistance, cycles |

||

|

Consumption, kg/m2 with a layer thickness of 10mm |

||

|

Layer thickness, mm |

||

Universal dry mixes under the general name "sand concrete" can be used in construction for almost any purpose.

Sand concrete is a dry mix, which is based on sand with a binder of Portland cement.

They are called universal because they replace whole line building materials. This material is used for the construction of buildings, during their decoration and reconstruction.

Sand concrete appeared 10-15 years ago and firmly took its position in the range of building materials. Almost any construction is not complete without it. It is widely used for leveling floors, walls, stairs, ceilings.

The composition of the material is a dry mix, which is based on sand with a binder of Portland cement. The composition can be added Additional materials, based on the purpose and methods of application. The density of the material will depend on the amount of sand and Portland cement in the mixture. For example, if there is more sand, it is light, and if there is more Portland cement, it is denser.

Why is the material so popular? First, it has a number of advantages over concrete. The advantages include:

- universality;

- great strength;

- anti-corrosion resistance;

- water resistance;

- light weight, when compared with concrete;

- no shrinkage.

The uniqueness of the material lies in the fact that it can be used as alabaster, plaster, putty, mounting adhesive, etc.

Versatility - what is it? The material can be used as plaster, alabaster, putty, construction adhesive, tile adhesive, concrete, and this is not the limit.

All grades of sand concrete can be conditionally divided into three types:

- Universal;

- Laying;

- Plaster.

By the names you can guess for what purposes they are intended. The most versatile building mixtures from this series are the M300 and M400 brands. They can be used both for pouring the foundation and for plastering surfaces. But there are also specialized dry mixes, for example, the M150 brand is best used for laying bricks or concreting stairs.

Another sign of the popularity of the building material is its ease of use. If earlier, in order to prepare the correct composition of the concrete mixture, it was necessary to observe the proportions of the components, and not every qualified builder achieved these proportions, sand concrete is already prepared, and the only proportion that needs to be observed is the amount of water. After all, the quality of development is somewhere around 80% dependent on the quality of the material, and already 5% on the qualifications of the builders and 15% on the technology of work.

Material selection

When choosing a mixture, it is necessary to pay attention to the packaging of the material, the manufacturer, the brand. If sand concrete is handicraft with a low cost, then the quality, respectively, is lower from this. Poor quality is mainly determined by the use of low grades of Portland cement.

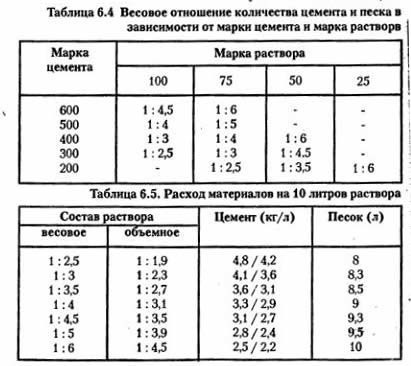

Table of the weight ratio of cement and sand.

When using low-quality material, you are more likely to corrode metal structural elements and fittings due to the high content of sulfides and chlorine. Also, when the composition dries, peeling, scattering of the layer may occur.

Factory-made materials produced in large production volumes are more reliable. Plasticizers, modifiers or additives that improve the properties can be added to the composition of such sand concrete. But these mixtures also have a drawback - the absence of an antifreeze additive. That is, at temperatures below 5 degrees, the material is prohibited to use.

When buying, you need to determine why you need sand concrete. In practice, sand concrete can be made independently, but such a mixture will be inferior in quality to the factory one. Factory ones are divided into large-fraction and small-fraction. The fraction determines the characteristics of the sand: whether it is coarse or fine, the larger the fraction, the coarser the sand. The coarser the sand, the higher the grade of the sand concrete mixture. Here is some of them:

- M400 - construction of bridges;

- M300 - construction of concrete structures, foundations, floors;

- M200 - carrying out installation and masonry work;

- M150 - leveling the ceiling, walls, sealing joints between bricks or blocks.

Sand concrete of the M300 series is often used both by large developers and in low-rise buildings individual building.

What sand concrete is used most often? The most common dry concrete mixtures is sand concrete of the M300 series, which is used both by large developers and in low-rise individual buildings.

Sand concrete of the M300 series is a multicomponent universal mixture. The properties of sand concrete of the M300 series are affected by:

- characteristics of the sand that is part of the mixture (its quantity and grain size);

- the presence of impurities in the sand, its chemical composition;

- dispersion and activity of cement;

- dispersion and volume of additives that are part of the sand concrete mixture (plasticizers, water-retaining and air-entraining components).

If the mixture contains an insufficient amount of plasticizers, increase