There are certain types of natural materials that have been used to decorate buildings, as they say, from time immemorial. This may include, ceramic tiles and clay bricks, various types of wood and stone.

But life does not stand still, more modern materials for facade decoration appear, which allow not only to clad, but also to insulate the house at the same time. Moreover, to do this quite quickly, which allows to reduce labor and energy costs.

And this, in turn, reduces the cost. square meter housing.

As a rule, facade panels are elements of ventilated facade systems. This system consists of a frame, insulation and decor.

Its essence lies in the fact that during installation, a gap is left between the wall of the building and the insulation, which will prevent the accumulation of condensate there, and create a kind of heat shield.

So:

- The production of materials for finishing facades has gained considerable momentum. last years because the demand for these products is steadily growing. And the assortment is such that it is very difficult to make a choice: there are wood options, and metal-plastic, and multilayer, and various imitations.

- Some are also successfully used in interiors. Each of them has its own design, dimensions, installation method, but there is one factor that unites them - this is an elegant and solid appearance of the clad facade, which does not require updating for many years.

Coated metal panels

This type of panels is made of galvanized metal sheets, 0.5 or 0.7 mm thick, which are coated with a polymer.

So:

- Such a cladding will not only be a reliable coating for any facade, but will also help create a memorable design. After all, the polymer layer on the panel can have any relief and a bright, juicy color, as in the photo below.

- The variety of shapes and reliefs allows you to combine the panels as you like, making it possible to clad the facade of any configuration. The width of the joints between them can also vary, allowing you to adjust the lining around the perimeter of the facade.

Upon purchase, you will be given installation instructions in the store. - Metal panels such as PF may have a hidden or visible fastening. Manufacturers also make them according to individual orders if non-standard shapes are required in the form of trapezoids, semicircles or corner elements.

These panels can vary in appearance, and be corrugated or flat, have a rib or wood texture. Naturally, the price is higher, the more complex their configuration and decor.

When installing metal panels, the same components are used as with. To learn more about the process of installing the frame and panels, watch the video, look for articles on this topic.

Fiber cement textured panels

The undoubted advantage of this type of panels is the fact that they qualitatively imitate other finishing materials for facades: brick and stonework, decorative plaster, tiled lining.

So:

- They are made from cement, with the addition of synthetic fibers and loose cellulose. Most often, the top layer of fiber cement panels is ceramic.

That is why they have high strength, do not change color during operation, are not afraid of fire, and are resistant to any external influences. - The areas of application of these panels extend not only to the plinths of houses, but also to the interior decoration of residential premises and office buildings.

- There are options for fiber panels with polyurethane, acrylic coatings, spraying marble and granite chips. The manufacturing process looks like this.

First, the dry ingredients are combined and balanced, and the solution is mixed.

The resulting plastic mass is sent to the molding extruder, where the products are given necessary form. Then they are fired and treated with protective primers and a decorative coating is applied.

The result is panels of remarkable quality and appearance.

Wooden panels for facade

Wood also did not remain aloof from the production of facade panels. They are based on wood fibers pressed at high pressure and temperature.

The binder, in this case, are polymeric compounds.

So:

- The protective and decorating layer is a painted surface, wood veneer, or polyurethane spraying. Therefore, there are many variations in the appearance of wood panels, which allows you to beautifully combine them in one facade.

- What is important, wood boards are light in weight. And finishing the facade with light materials significantly reduces the load on the walls and foundation of the building.

This type of panels is easier than others to process: drilling, sawing. - Between themselves, they are connected in a tongue-and-groove way, they are easily mounted on glue, or crate. This is perhaps the easiest way to finish the facade of a wooden house.

In this case, nails can also be used during installation. For screws and nails, the panels have a special perforated edge. - The service life of wood panels is lower than the two previous options (up to 15 years), but they are also much cheaper. This has its plus - the facade will be easy to update.

Although, there are waterproof options, which include molten paraffin or ceresin. - They make the wood board not only more resistant to moisture, but also significantly increase its strength. Accordingly, with the quality, the cost of the product also increases, and can vary from 450 to 3500 rubles per panel, depending on the manufacturer.

- There is also an easier option. facing material, with which you can make a chic facade. Not so long ago, the so-called OSB boards appeared on the domestic construction markets.

This is an imported material, outwardly similar to the familiar chipboard.

- The structure of the OSB boards is similar to the one described above, so they are not afraid of moisture. This material comes from the factory in large sheets, and you can cut them with your own hands, and at your discretion.

As well as decorating.

And look: what a beautiful half-timbered facade can be obtained using wood boards and panels. In our example, both OSB boards and decorative wood panels, which we just talked about, are used.

What are thermal panels

If, when installing ventilated facades, you still need to take care of the insulation, then the use of thermal panels immediately “kills two birds with one stone”. They themselves are a heat-insulating material, only they also have a decorative surface. Therefore, having purchased thermal panels, you do not need to buy materials for finishing the facade.

So:

- The technology of their manufacture includes several stages. The main raw material is polystyrene or polyurethane, which is foamed and dried granules. In special block forms, first lay the material that will be decorative layer, for example: clinker or stone tiles.

- At the next stage, granular insulation is loaded into the molds and heated with hot steam. In this case, the granules are melted, pressed with tiles, and the finished panels are cooled, after which they must lie down for a day.

It turns out such compact, and wonderfully joined products.

- These extraordinarily light facade finishing materials help to solve several problems for the stasis. Insulating and lining a small house with any material is not a problem.

But the finer the details of the cladding, the more effort and time it will take to produce exterior finishing work.

![]()

What can we say about multi-storey buildings, which also need to be insulated and decorated? This is where thermal panels are simply irreplaceable.

In addition to the fact that they will create a high-quality exterior of the building, their use will significantly save the construction budget. Moreover, their decorative layer can be natural, and not just imitated.

Currently, the construction market presents a variety of materials for the facades of houses, and each has its own positive and negative sides. Often facade finishing performed in a combined style, where there are various materials.

The task of the designer is to harmoniously link them together. It could be decorative plaster and natural stone, styrofoam and siding and there are many such examples.

The system, which is a unique method of facade insulation, which appeared in our country quite recently.

It has quite serious advantages:

- The use of this technology is possible regardless of what the base is made of: brick, concrete, frame or plywood.

- Significantly saves electricity, which is the reason for the reduction of cash costs for heating.

- When plaster is applied directly to concrete, its further deformation does not occur, due to the impossibility of penetration of water and various aggressive substances into the interior.

- If for some reason moisture appears inside the structure, it will easily evaporate through the facade insulation materials. The walls don't get wet.

- Sudden temperature changes do not cause any deformations.

- The operational period of the "wet" facade is up to 30 years or more.

- The price of this material for facades is relatively low and labor costs are also small. We can talk about significant savings in resources during the facade insulation by the “wet” method.

- With the help of this coating, fire resistance is significantly increased.

- Modern facade materials allow you to create a variety of colors and textures, with the help of which the appearance of the building is transformed.

easy way

Light and heavy wet facade system

The difference between these two methods primarily lies in the amount of consumable materials and what material is taken for facade insulation.

easy way

Styrofoam boards for plaster

Any surface can serve as a base plywood, brick or concrete. The density of the insulating material must exceed 150 kg/m 3 . It can be expanded polystyrene plates. Glue and dowels are used as fasteners. With the help of a heater, any irregularities on the walls will be hidden. Then the polystyrene boards are covered with a layer of plaster (up to 1 cm).

hard way

Finishing according to the "heavy" method somewhat different. It differs in that the installation of thermal insulation and plaster is carried out separately. First, special hooks with dowels are installed. Thermal insulation is mounted on them, and it is preferable to use mineral wool, with a density up to 100 kg / m 3.

Mineral wool is fixed with fasteners and a special mesh, the role of which is to protect the walls from thermal deformations. Next and final stage will be applying plaster, a layer in the range 2-3 cm.

As a thermal insulation material for the facade, mineral wool has more positive qualities than polystyrene foam. It has the ability to prevent the growth of fungus, mold and insects. It has high vapor permeability and incombustibility

Mineral and polymer compositions are well suited as plasters, due to high level vapor permeability. This will enable the walls "breathe".

Ventilated or hinged facade

This is one of the most common ways in which facades are insulated. Characteristic features of modern building design include the strict functionality of each element. Now you can hardly find single-layer structures that perform both a load-bearing and enclosing role.

Advantages

- The low cost that materials for ventilated facades have.

- Easy to install and convenient for further maintenance.

- Possible partial repair and replacement of a small area.

- The ability to give the building an original appearance.

- The lightness of the structure does not carry a serious load on the walls and foundation.

- The supporting structures of the building and insulation are well protected from precipitation.

- A wide choice, which provides material for the facade of the house, for almost any wallet, that is, a different price category.

- The versatility of the nodes, which lies in the fact that they can be used on different buildings.

- There is no need for preliminary alignment of the walls: the system can be adjusted in thickness.

Ventilated facades allow, first of all, to give the facade a noble look, while using modern finishing materials. And besides, to increase the thermal properties of enclosing structures and to resist harmful atmospheric influences.

Materials for finishing the facades of private houses are on the sales market in large quantities. But this question can sometimes confuse the owner.

After all, the facade is a kind of visiting card of the home. And the design is done for quite a long time and therefore it is necessary to make the right choice.

This topic will be the focus of our article. You can see photos of materials and decide on the appearance.

The video will help create the desired design.

Selected facade material country house in the form of a stone of natural origin. Will talk about the sophistication of the taste of the owner.

And about his abundance. Not only granite can be used for cladding, marble looks great, but the price of such material is quite high.

There is a natural material that costs and is cheaper, these are quartz rocks, sandstones, limestone and others. There are plenty to choose from.

In the decoration, not only the stone is important, but also the correct design of the structure:

- Do not finish the whole house with the same material, do it in combination. This will add sophistication and be evidence of refinement of taste;

- In the plinth look great, both polished products and in natural form;

- Decorate the facade with columns, cornices and borders. All this should be done from natural stone;

- If you want to decorate the facade in a seasoned style, then do it with tiles. It is available in large quantities in retail and you can choose the texture you need.

Here the material is both fully polished and having a rough surface.

With this material, you can fully realize your imagination.

Advantages

Let's look at the advantages of this material from a practical point of view:

- This is an environmentally friendly product that will never harm human health in any temperature mode of use;

- The durability of the stone is not even in doubt. Such a design can stand for decades.

It will not be affected by rain or summer heat. Moreover, this is a completely non-combustible material; - The stone has a fairly high energy saving;

- Facing can be done by hand, and this will reduce the cost of work.

Flaws

Like any other material, this one has its negative sides:

- Of course, it should immediately be said about the weight, it is really great.

It will be expensive to transport materials. And the installation will also be quite heavy; - Processing and fitting is also not so simple and takes a lot of time. Although if you use stone in the form of ready-made slabs, then this process will be much easier;

- The price is much higher than other finishing materials;

Facade decoration with artificial stone

Those who do not have enough funds can resort to facing the facade with this particular material. It is suitable for laying on almost any surface, regardless of whether it is wood or metal.

These facade materials country houses suitable as well as for decorating any type of room.

The composition of such a stone includes sand, cement, dyes and various fillers. Therefore, there are many options on the market with different colors and textures.

There are elements that are sometimes difficult to distinguish from natural stones. There is a structure that imitates brick or pebbles, for every taste.

Advantages

Let's look at the advantages of this finish:

- They can perfectly decorate and make luxurious cornices and columns. If desired, you can give the house a medieval look or make the design completely modern;

- This material is much lighter than the first option. And therefore, transportation will cost less, and installation is easier;

- The tiles are mold and mildew resistant. Can be used in various weather conditions;

- Large selection of colors and shades;

- The first option is much easier to handle. And if you hire people, then the work will cost less.

Flaws

Now let's move on to what can repel the thought of using this material:

- Significantly inferior in durability to the first option. But there is a positive here, you can always replace a damaged element;

Attention: When choosing this material, you should immediately pay attention to the following. Some products require additional treatment with chemicals that repel water.

And that's time and money. Therefore, you should first look at the quality certificate and find out the parameters of use.

Otherwise, trouble may arise later.

- Do not use abrasive materials for cleaning and repair. This material has a rather low resistance to these agents.

Brick or clinker cladding

Facing brick is most often used for facade decoration. This material can have a different texture and color.

You can also choose different shapes.

Listing materials for facade decoration country house will be incomplete without mentioning the clinker, which some refer to as a type of brick. It's still tile though.

It also has a different texture and color. It will look good if you make a finish in combination with a mosaic.

Quite often, this material is used in decoration in combination with brick. Separate parts of the façade.

The advantages of such a cladding

There are undoubted advantages in such a finish:

- The durability of the house is top notch. Such a design will serve for many years;

- You do not need additional processing and care;

- The composition of these materials includes only natural ingredients that do not harm health;

- Not a high price, also attracts the consumer;

- Serves as an additional heater. Easy to install and maintain.

Flaws

Now let's move on to what can turn off the consumer:

- If it is clinker, not brick. Then, for fastening, you will have to use mixtures of a special type, they are developed specifically for the water absorption of clinker. It is also quite difficult to replace.

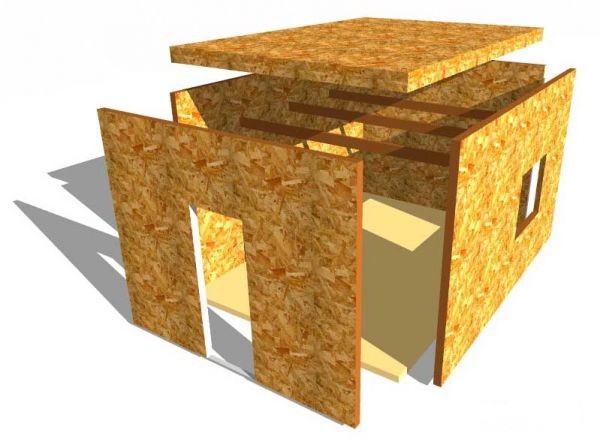

Sandwich systems in facade decoration

Often used materials for finishing the facade of a country house in the form of sandwich panels. They are not so long ago, but are popular.

This treatment makes the facade fully ventilated. Laying is carried out as follows, thermal insulation is laid between the panel and the wall and a gap remains.

Such an air cushion holds heat well and protects the house from the penetration of excess moisture.

Advantages

So:

- It's pretty lightweight material, which is not difficult to transport and delivery will not cost much;

- This is an environmentally friendly material that will not harm human health. Helps to create the desired microclimate in the room;

- It has high thermal insulation and will save on heating;

- Possess great colors and available at retail. Allow you to create the desired design of the house;

- It is possible to do everything with your own hands, which reduces the total cost of finishing;

- Not a long installation time. Ease of processing and care also speak in favor of this material.

Flaws

- Light weight can be attributed to the disadvantages, it will not allow you to withstand additional loads. It is not necessary to allow accumulation of snow on the roof with such a finish, otherwise it can bring trouble;

- If installed incorrectly, heat transfer is quite significantly reduced.

The use of siding for decoration

This is perhaps the most common option. It is used for almost any building water.

Advantages

Let's see what attracts people to this product of production:

- Price and quality, they match. The house gets a pretty good look and for a moderate fee;

- It is possible to carry out and warming the room. And it's not that hard to do. Moreover, everything can be done by hand;

- The material perfectly tolerates high humidity and frost;

- In the event of a breakdown, you can always replace the part and it will not take so much time;

- Ease of maintenance is also a plus.

Flaws

This material also has its drawbacks:

- Not a rich appearance;

- Possibility of mechanical damage;

- With direct sunlight, the plane loses its original appearance.

Probably the most beautiful and high-quality houses are finished in combination, using different materials. Then you can endure good options and in terms of heat transfer and design, come up with a rather original design.

Detailed instructions for any type of material and its installation are on the pages of our website.