One of the first natural materials that people used in construction was stone. But with the development of building technologies, it is in the background. Today it is used, as a rule, for facing works. But this pleasure is expensive and laborious. Therefore, a modern technology for the production of "artificial stone" was developed, which can only be distinguished from the real one at close range.

The latest technologies make it possible to produce a facing stone that copies the shape, texture and color of natural stone. It is produced from Portland cement, light natural fillers, such as expanded clay and natural dyes.

Advantage Features

- Durability and strength (stone is the strongest material and is able to retain its original appearance for a long time).

- Fire safety (the less combustible materials in architecture, the safer for the house).

- Presentability (stone has always been considered an elite material).

- Aesthetic properties (an abundance of types and textures, unique imitation properties of artificial stone satisfy the most sophisticated requests).

Types of natural stones for facade cladding

For finishing works few varieties of stone are used, within which there are noticeable differences in color and even texture of the material.

- Dolomite, consisting mainly of minerals, today is stylized as "small chips and aging". The color range is large. The advantage of this stone is a high degree of strength and stability. But for cladding, these properties are not fundamentally important, so artificial stone successfully replaces it.

- Sandstone - one of the varieties of sedimentary rocks, consists of grains of sand connected by a mineral. Differs in a variety of shades, a complex layered texture. Because of this, it is most often often used as a facing stone. Easily assembled by hand.

- Lemezit - burgundy limestone. It is used in decoration because of the rich color and rough texture. But it does not differ in special strength.

- Slate- a layered structure of a mineral rock. A very fragile material, most often used for finishing the roof of a house. But it can also be installed on walls.

- Shungite - a rock consisting of coal, formed in a layered way. It is much stronger due to the composition, on which the color of the stone also depends (it can vary from dark gray to black). The invoice is determined by the processing method.

- Marble - a rock with a texture filled with veins that make the color combination even more diverse. The material is very strong and durable, used for decorative finishes elite buildings.

Types of artificial stone imitations for facade cladding

Artificial facing stone is an excellent solution for people of medium and low income who want to decorate the facade of the house with their own hands. Today there are such varieties of artificial stone.

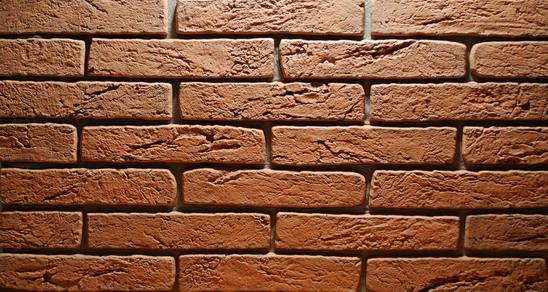

- Clinker imitates natural "chipped stone", is produced in the form of clinker bricks (used for facing masonry of facades), tiles stylized as brickwork, perfectly imitates sandstone of all types and forms of surface treatment.

- Concrete considered the most popular facing stone for finishing the foundation due to its low cost; can imitate any surface, it is made in the form of a chipped stone tile gray color and decorative facing under marble and granite.

- Architectural a more durable version of concrete, imitating natural stones sandstone and limestone. It is made from Portland cement with the addition of mineral fillers and modifiers that give strength and improve the appearance of the material.

- Polymer sand(facade) - a material that imitates "torn / chipped stone" brickwork. It is mainly used for lining plinths, foundations, it is made of a polymer with characteristic properties (lightness, softness, resistance to temperature extremes).

- facade stone, made on the basis of resin - the best imitation of natural stone for home decoration. Made from crushed natural stone. It can be rectangular, square or with any type of surface.

- ceramic stone produced in the form of a tile/brick imitating any natural stone.

Important! The artificial stone has no radioactive background. Strength and durability are not inferior to the properties of natural stone, but it is much lighter (3-4 times). Walls and plinths decorated with ragged stone look attractive, additionally protected from moisture and damage, and the thermal conductivity of the walls increases by almost 25%. Can be installed by hand.

Such wall cladding is in harmony with the classic types of wall surfaces (log, timber). broken stone contrasts well with plastered areas and is considered the best option for facing the foundation.

The main advantages of artificial stone

- decorative possibilities;

- a light weight;

- relatively low cost;

- ease of installation with your own hands;

- low labor costs for the installation process;

- versatility.

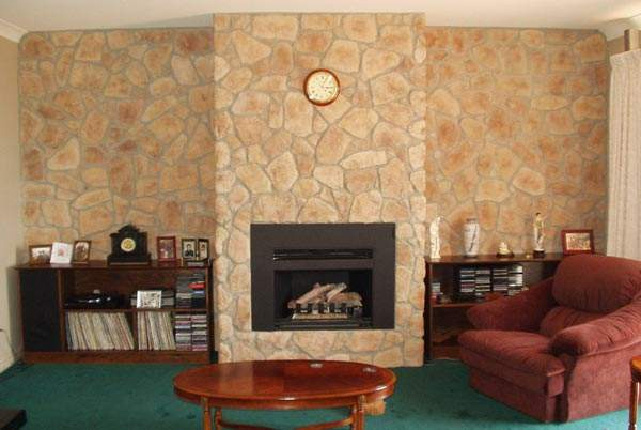

This stone is suitable for cladding various kinds surfaces: wooden, metal, brick, concrete, etc. It can be used for indoor and exterior finish at home. Facing stone can be used for finishing stoves and fireplaces: it is non-combustible and does not emit smoke when heated. Since during its production all the material is impregnated with dyes, it does not lose its color qualities over time, it does not lend itself to aggressive environmental influences, which is especially important for the foundation.

Mounting methods

Today, artificial stone is installed in two ways.

With stitched seams

This method is more popular, moreover, it allows you to significantly save material with a slight increase in labor costs. The stones are fixed at a distance of 1.5 - 2.5 cm from each other. In this way, such types of facing stone are installed as "Ragged stone", "Jurassic marble", "Medieval castle", "Old brick", etc.

Stitching is milestone process of facing with artificial stone. It provides complete sealing of the masonry and improves the aesthetics of the appearance of the finish. A special bag is used to fill the seams. Jointing is done with a solution that was used for grouting.

Seamless

Separate types of stones (for example, slate, dolomite, etc.) are installed without seams, tightly adjacent to each other.

Important! With seamless cladding, the elements are laid from the bottom up, and the upper rows are pressed against the lower ones. When the first laying method is selected, between facade elements it is necessary to leave a gap of 0.3 to 1 cm.

Mounting options for decorative cladding elements

Fastening decorative elements to the plinth or wall is of two types:

- Wet (special mixtures and adhesive mastics are used for masonry).

- Dry (without the use of glue, fastening systems are used for installation)

- Combined (the stone is attached to the wall mechanically, and then the space between the tile and the wall is filled with mortar).

When using the first method, it is recommended to use special mastics that neutralize the impact of climatic factors on the facing stone. But mastic will not be enough to completely protect the building from water vapor, it is important to provide internal vapor barrier. This also applies to the combined type of fastening.

Important Installation Aspects

- As a result of fitting and trimming a stone, there is always waste: you need to buy 10% more material than is provided for by the calculations.

- Recently built walls cannot be faced immediately (at least after six months), only after shrinkage of the walls.

- Strict observance of the temperature regime - from + 5C to + 25C.

- White plaque on the back of the stone must be cleaned with a metal brush.

- The decoration of the facade begins with the design of the corner elements.

- If the tile is laid without jointing, it is necessary to monitor the tightness of the fit of the elements. If laying with jointing is done by hand, observe the recommended joint width.

- Regardless of the installation method, long vertical seams should be avoided.

Helpful installation video

- Categorized in

Facades lined with stone look respectable. In addition, facing the facade of the house with stone is quite practical. Thanks to the stone, the facade not only has an attractive appearance, but also extends its service life, increases its many operational qualities: resistance to natural precipitation and ultraviolet radiation.

Stone for facade cladding can be natural and artificial. Natural stone is more expensive, and the work on finishing the facade with it is more. But even with a very picky examination, your house will look perfect. Artificial stone for facade cladding is in no way inferior to natural stone in terms of performance. In addition, it is adapted for wall cladding, so it is much easier and more practical to use it. Manufacturers offer a wide range of facing stone to choose from.

Types of stone for facade cladding:

Natural stone

For the decoration of buildings, such types of stone as quartzite, slate, sandstone, basalt, limestone, granite and marble are used. All of the listed types of stone, except for resistance to external influences, are characterized by an attractive appearance.

Most often, limestone, marble and granite are used for cladding buildings. The use of natural stone for home decoration is an indicator of the good taste of the owners and their high status. You can give your home a luxurious look by using white sandstone for cladding. Marble decoration will tell a lot about the owners of the house without words. And granite will give the house monumentality and nobility.

Natural stone is ideal for exterior decoration of homes. Unlike artificial stone, natural stone is long years retain its natural look. The building, lined with a natural look, will easily fit into any natural landscape, and will not look ridiculous in a large metropolis.

Fake diamond

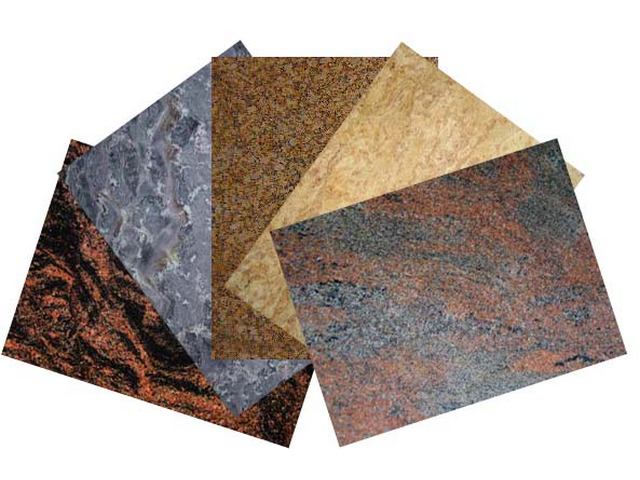

Manufacturers of artificial stone delight with the widest variety of shapes, colors and sizes. For the production of artificial stone, special forms are used (artificial facing stone can be produced both in the form of bars and in the form of slabs), the production itself is carried out using different technologies.

The main advantages of artificial stone compared to natural stone are its low weight, rather low cost and a wider range of colors and shades. Facing artificial stone may look like pebbles, limestone, dolomite, cobblestone, sandstone, marble and any other types of stone. Artificial stone is produced from natural ingredients: sand, expanded clay, cement and stone chips. So, it can only be called artificial.

When choosing an artificial stone for facade cladding, one should pay attention to its following characteristics: thickness, uniformity, color, as well as strength and resistance to low temperatures. It is worth giving preference to an artificial stone of uniform thickness, with a homogeneous composition (the filler should be no larger than 5 mm in diameter), it should be painted in full thickness, and not just on the surface.

What to choose - artificial or natural stone - largely depends on the amount that the owner of the house can afford to spend on facing it, as well as on the design solution chosen by the owner.

The facade of the house is an indicator of the taste, well-being and social status of its owner. Facing the building with stone gives it a solid, elegant and respectable appearance, allowing for many years to forget about the need for its external repair and maintenance in its original form.

This noble material does not require maintenance, pleases the eye and reliably protects the structure from any external influences.

For use both natural and artificial stone. Both of them are distinguished by such characteristics as durability of operation, resistance to temperature extremes and other weather phenomena, wear resistance, environmental friendliness, high noise insulation and protective properties.

A natural stone

Natural stone in the cladding of buildings is used not only in the form of slabs. Various decorative elements are also made from it: columns, balustrades, pilasters, stair steps and railings, etc.

The most popular and sought-after breeds:

- Granite;

- Marble;

- Limestone;

- Travertine;

- Quartzite;

- Slate; dolomite;

- Shell rock, etc.

All types of stone have different cost and complexity of processing. The most expensive are granite and marble, minimum price- in limestone, shell rock.

Attention! Often, to reduce the cost of cladding, a combined finish is used: plaster + stone or different types stone. At the same time, it must be remembered that contact between carbonate (shell rock, limestone, marble) and silicate (sandstone) rocks should not be allowed, when they come into contact, destructive chemical reactions occur.

Despite all the advantages of natural material, it also has significant drawbacks, which often become the reason for the rejection of this type of finish. In addition to the high cost, this is a lot of weight and complexity of installation.

So:

- Facing buildings with stone requires careful preparation: building a foundation that can withstand heavy loads and strengthening bearing walls. And this is additional costs and labor costs.

- During finishing, it is necessary to cut individual elements of the cladding to size. Only true professionals can do this accurately and efficiently.

In a word, natural stone is a very expensive pleasure. Moreover, not only the material itself costs a lot of money, but also preparatory work and the installation itself.

Note. In the event of damage to one or more stone tiles from the cladding, it will be very difficult to find a replacement for them in exactly the same color. Therefore, purchase material with a small margin.

Fake diamond

This material is made from a mixture of high-grade cement with sand, natural stone chips, various additives that improve its strength characteristics and moisture resistance, and fillers that reduce the weight of products.

Attention! Some types of artificial stone are made on the basis of gypsum. Such a stone is not suitable for facing the facade of buildings - it is used for interior decoration.

The main advantage of this material: having a practically indistinguishable from the natural look, it has 2-4 times less weight.

This is achieved just by introducing into the raw mass of such fillers as:

- Expanded clay;

- Ceramic chips;

- Expanded perlite;

- Pumice natural, etc.

Due to the low weight of the products, building cladding does not require such thorough preparation of the foundation and surface, and the ease of processing reduces qualification requirements to the performers. Moreover, having some experience in laying the usual ceramic tiles, you can finish the facades with your own hands.

The work is facilitated by the fact that the back of the artificial stone tiles is always flat, and its shape is correct, kept in the given dimensions, which eliminates the need to adjust the elements to each other.

The production of this decorative finishing material is carried out by vibrocasting: the mixture is poured into molds and subjected to vibration, as a result of which it is compacted, and the strongest and heaviest particles settle to the bottom. As a result, the tile acquires increased strength of the outer decorative surface, which will bear the maximum operational load.

To obtain desired color, products are painted, and this happens in one of the following ways:

- Only the front surface is subjected to coloring during the production process. Chips on such a stone will be clearly visible.

- The dye is introduced into the raw mixture and mixed with it. An artificial stone made in this way for facing buildings more realistically imitates natural stone, it is not afraid of minor damage, rain and sunlight, it will not lose its original appearance even after many years.

As for the shape and texture, they are very diverse and can imitate both natural rocks and completely fantastic ones that have no analogues in the surrounding world.

In general, artificial stone by type can be divided into three large groups:

- Brick-like - imitates different types of ceramic bricks, including aged and antique ones;

- Sawn stone - tiles of a standard rectangular shape and the same size, the front face of which imitates a chipped natural stone;

- Chipped stone - imitation of pebbles, cobblestones, boulders and other naturally formed stones.

That is, if you want to line your house with marble, granite, onyx, sandstone or other types of stone, but without having enough money for this, you can easily replace them with a cheaper artificial counterpart without losing appearance and practicality.

In addition to a significant reduction in the load on the supporting structures and a significantly lower cost, this material has other advantages.

So:

- High strength, which it possesses - the building will be reliably protected from any external influences;

- Moisture resistance is higher than that of natural stone due to the absence of pores. Accordingly, it has better frost resistance;

- Reduced thermal conductivity - due to the introduction of special additives;

- Environmental safety - all components are completely harmless.

Mounting methods

Facing the facades of buildings with stone, regardless of its origin, can be done in two ways - dry and wet.

The first is the fastening of individual elements (tiles or panels) mechanically to a pre-mounted frame. It allows you to radically change the appearance of wooden and frame buildings.

At the same time, they can be insulated by fixing heat-insulating plates on the walls, which are completely hidden by decorative cladding.

For this type of finish, stone slabs of large size and the correct standard shape are used, or artificial stone panels in the form of several tiles.

For reference. Such facades are called hinged ventilated systems. detailed instructions on their device is given in other articles on our website.

The so-called "wet" method consists in gluing the stone directly onto the walls using cement mortar or special glue. They carry out facing of stone buildings, brick, panel or block, which do not require additional insulation.

The use of cement mortar reduces the cost of installation, but makes it more laborious, and the lining itself less reliable. Under the influence of atmospheric phenomena, cycles of freezing and thawing, the stone can fall off over time.

Special facade glue is quite expensive, but due to special additives that improve its moisture-resistant properties, it provides reliable adhesion of the cladding to the surface and also simplifies installation.

Conclusion

A beautiful, rich, eye-pleasing appearance of the house is very important. without any doubt indicates not only the solvency, but also the solidity and lifestyle of the owners.

But more importantly, it should be practical and durable. And for that matter it's hard to find best material than natural or artificial stone.

The video posted on this page will tell you more informatively about how to choose it and finish it. We advise you not to save on work, and invite really competent specialists with a good reputation to perform the installation.

Modern society, tired of high-tech buildings made of glass and concrete, is increasingly drawn to natural materials. Finishing stone for outdoor work has been used since ancient times, but now more and more often finishing stones are used to decorate a home from the inside.

In this article we will talk about the types of this material, it will also be given short instruction cladding with your own hands.

Types of stone

There are currently two equivalent groups on the market facing materials, this is a natural, natural stone and a decorative artificial analogue, completely copying the external resemblance to natural.

natural stones

This type of material is distinguished not only by a high price, but also by a fairly large weight. Not every house can withstand such a cladding, a prerequisite for its arrangement is a strong foundation. But if it is available, facing with natural stone will delight your grandchildren and great-grandchildren with its pristine beauty.

Important: there is a strict rule for natural stones, silicate rocks are not compatible with carbonate ones.

Sandstone or quartzite does not combine with marble, shell rock or dolomite.

Upon contact, silicic acid silicates react with calcium carbonate and the rocks are mutually destroyed.

The following breeds are the most popular here.

- Granite is a long lasting stone distinctive feature granite is its great weight.

- Basalt - differs from granite only in appearance, otherwise their characteristics are similar.

- Marble is a dense and rather strong stone, it has a wide palette of colors and shades. Facing marble slabs are cut exclusively at the factory and require high professionalism when laying. Marble finishing belongs to the elite category.

- Quartzite is a hard rock with a large amount of quartz inclusions.

- Limestone is considered a soft rock. Limestone is better known as a finishing stone for interior work, only a few types of limestone can be used for exterior cladding.

- Sandstone is also a fairly soft stone, easy to process.

- Slate - has a layered structure, is very popular because of its natural appearance, affordable price and ease of installation.

Tip: buy from reputable companies that provide a quality certificate. Otherwise, you run the risk of buying a low-quality product and, worst of all, it may contain an increased radioactive background.

Artificial analogues

- Here the range is much wider, in addition, thanks to modern technologies artificial stones have an order of magnitude less weight, they can be used both for facade cladding and for interior decoration of the house.

- Despite the fact that the price of artificial material is much lower than natural, they practically do not differ in appearance. Plus, such a stone has clear geometric shapes, which leads to simple, quick and high-quality installation.

- The production of finishing stone, with the exception of polished marble, does not require too much power, it can even be organized in your own yard or garage. To do this, you will need molds for finishing stone and vibrating machines.

![]()

- Depending on which stone you want to copy, the composition of the mortar is selected, usually based on cement. Forms are filled with the solution and placed on a vibrating machine. From vibration, the composition is compacted, and mineral fillers and dyes settle on the front side, resulting in an exact copy of the natural material.

flexible stone

- Finishing material flexible stone occupies a separate niche. The fact is that this coating is a symbiosis of natural and artificial material. In its production, a special type of sandstone is used, which is cut in a thin layer, about 2.5 mm, and placed on an elastic base. The result is a 100% natural flexible coating.

- This material can be used both for interior decoration and for outdoor work.

It has a number of undeniable advantages.- The guarantee for this material starts from 35 years and more.

- He feels great in the temperature range from -30º C to +65º C.

- For such a cladding, a flexible stone has a negligible weight, 1 m² weighs about 5 kg.

- The material is extremely plastic. Although this can sometimes be a disadvantage, it requires a perfectly flat surface, as any unevenness will show up on the coating.

- At correct installation it is hard to damage, scratches do not appear on it.

- It has a protective coating that allows you to use any detergent.

- Extremely simple instruction for installation, accessible to almost anyone.

- This material is available in 2 types. In the form of individual plates or in rolls, like wallpaper. They are practically no different and are mounted on the same technology. Initially, the coating has a protective factory film, it is not necessary to remove it immediately, so as not to stain the front surface with glue.

- Glue is used special, it is for a flexible stone. It should be applied with a notched trowel, with a tooth size of up to 6 mm. The base must be pre-primed. You can spread several sheets, the glue does not set immediately.

- Particular attention should be paid to laying the canvases, they are joined clearly end-to-end. It is recommended to heat up the edges of the sheet with a building hair dryer when joining. If bending is necessary, the canvas is also heated with a building hair dryer.

Tip: do not try to bend a sheet of flexible stone to a cold one, you will only ruin it.

Even if mounting on a slightly convex or concave surface, the sheet will crack without heating.

Material mounting technology

- As mentioned earlier, natural stone has a solid weight, therefore, with a large squaring of the cladding, a powerful foundation and strong walls are needed. Otherwise, the technology of finishing with natural or artificial material is the same.

- Initially, the surface is cleaned and its evenness is checked by the building rule.. To do this, as often as possible at different angles, the entire plane of the walls is probed by the rule.

The video in this article shows the stone finish of the interior surfaces.

Important: before finishing with stone, the newly built building must stand for at least six months. Since due to shrinkage of the structure, the lining can be damaged or even fall off. On the wooden houses only ventilated cladding can be installed.

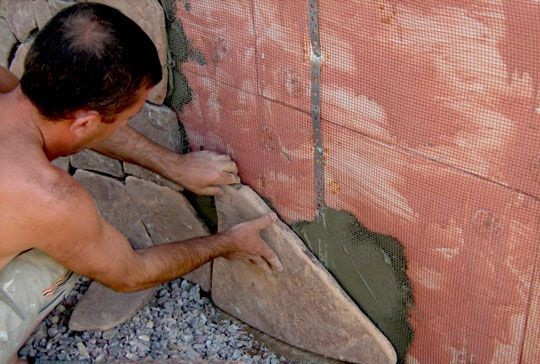

- Walls must be well primed before installation.. For heavy stone and large areas it is recommended to fill the reinforcing mesh. A galvanized mesh with the smallest link is taken and fixed to self-tapping screws. After that, an intermediate layer of mortar is thrown over it and leveled. In small areas and internal works mesh may not be used.

- The stone can be laid on a cement-sand mortar, although it is better to take special ready-made mixtures, they are of course more expensive, but we do not recommend saving here. Both the wall and the facing stone are pre-wetted with water. The thickness of the adhesive should be within 6 - 10 mm.

- Laying is carried out, starting from the bottom corner and further along the rows. You can mount with or without bracing. Stones of geometrically correct shape are mounted end-to-end, for rounded or torn edges, jointing is used.

- For jointing, a solution is taken and poured into a strong plastic bag. After that, the corner of the package is cut off, and the solution is squeezed out along the perimeter of the stone. Further, using a plastic, wooden or metal spatula, the solution is compacted, it is given a certain shape.

Important: work should be carried out only at a temperature not lower than + 5ºС. Moreover, the positive temperature should be kept for at least 4 - 5 days, since the lining will fall off in the cold.

The video in this article shows the principle of laying stone.

Conclusion

It is not necessary to completely stone the entire house. Fragmentary finishes in combination with plaster or other coating can give a more spectacular design solution plus it will be cheaper. Most often stone, corners or arches over windows and doors.