Every home needs an exterior finish. At the same time, cladding is needed not only to create an external effect, but also to protect the walls of the house from mechanical influences and various weather factors, such as moisture, sunlight, wind, which can eventually destroy even the most durable materials.

Therefore, the right cladding should combine reliability and beauty. All these qualities are characteristic of tiles for exterior finish, which is used at the final stage of insulation of wooden, brick and reinforced concrete buildings. The plates themselves are made from a variety of materials. They do not crumble and do not burst, perfectly withstand heat stress and frost.

Significance of exterior finish

Exterior decoration in the process of repairing a building or building a new house performs several important tasks, in particular:

- Protects the facade from adverse external influences. The walls of the house are load-bearing structures, the existence of the building itself depends on the reliability and endurance of which. Therefore, the exterior finish of the facade, protecting the walls from temperature extremes, precipitation, wind and ultraviolet radiation, prolongs the service life of load-bearing structures, especially if the house is built from fragile and short-lived building materials;

- Protects the insulation from sunlight, dampness and wind. Many types of thermal insulation, having good fire resistance and insulating characteristics, are destroyed by ultraviolet radiation, wind, or quickly absorb water. All this affects its performance. To ensure the reliable service of the insulation, you need a good cladding. Facade plates perfectly cope with this task;

- Giving the house an aesthetic appearance. Modern cladding materials are distinguished by a wide variety of textures, materials and colors, thanks to which the facade can be given any desired look.

With all these tasks, slabs for exterior cladding perfectly cope.

They are distinguished by:

- simplicity and ease of installation work;

- resistance to any atmospheric influences;

- a wide range of materials and shades.

Finishing the house with these plates reduces heating costs. In addition, this cladding protects the walls from rotting and rust. They are easy to care for: just wash them with water and ordinary detergents.

Varieties of facade plates

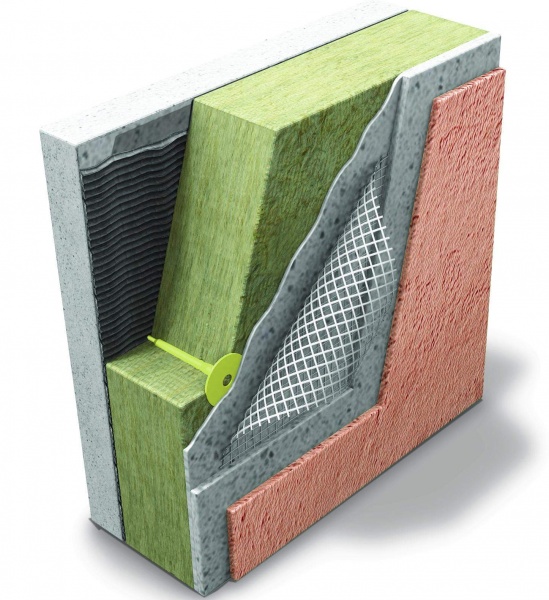

Plates for home decoration can be solid or composite. Solid panels have large dimensions and speed up the process of facing the building. The number of layers in the plates can also vary: one, two or more. Multilayer tiles are particularly durable. It is a durable heat-insulating building material with excellent performance characteristics.

Plates for home decoration can be solid or composite. Solid panels have large dimensions and speed up the process of facing the building. The number of layers in the plates can also vary: one, two or more. Multilayer tiles are particularly durable. It is a durable heat-insulating building material with excellent performance characteristics.

Modern manufacturers produce slabs for finishing from a variety of materials: wood, vinyl, metal, fiber cement, and so on.

But regardless of the material of manufacture, slabs for wall decoration must have the following properties:

- long service life;

- good sound and heat insulation;

- excellent moisture resistance;

- high strength;

- simplicity and ease of installation;

- environmental safety for the environment and human health;

- pleasant exterior.

Depending on the material of manufacture, the following panels for exterior decoration of the house can be distinguished:

- ceramic;

- polypropylene;

- fiberglass;

- thermoplastic;

- fiber cement;

- wooden;

- metal;

Ceramic tiles

The most popular and in demand in repair and construction work today are ceramic siding slabs. This material appeared relatively recently. It is made from cement and various silicates or fibers. The resulting panels for cladding the walls of the house outside can have different sizes and colors.

Their main advantages are:

- excellent thermal insulation;

- fire resistance;

- extremely low absorption;

- resistance to wide temperature difference;

- high reliability and long service life;

- environmental Safety;

- a wide range of different textures and tones.

The main disadvantage of ceramic plates is their high weight when compared with other types of panels. Therefore, ceramics are not very suitable for wall cladding made of fragile and light building materials.

Polypropylene panels, the so-called basement siding, have long gained popularity. This widely used building material looks like long thin strips that are quite easy to mount on walls and among themselves. It is lightweight, durable, affordable and easy to care for.

Polypropylene panels, the so-called basement siding, have long gained popularity. This widely used building material looks like long thin strips that are quite easy to mount on walls and among themselves. It is lightweight, durable, affordable and easy to care for.

The exterior cladding of the house with polypropylene siding gives it a neat and well-groomed appearance. The disadvantages are: high fragility, low thermal insulation, poor compatibility with other facing materials.

fiberglass tiles

In the exterior decoration of the walls of the house, fiberglass slabs are also used. The material is made of fiberglass and a variety of resins. The size of such panels ranges from one to three square meters. Fiberglass boards can look in a wide variety of ways: like wood, natural stone or brick.

The advantages are:

- original exterior;

- high strength and reliability;

- quite a long period of operation;

- resistance to temperature extremes, extreme heat and frost;

- ease of installation and repair;

- resistance to ultraviolet;

- high hydrophobicity.

They have practically no flaws, so the price for them is quite high.

Thermoplastic boards

A new type of cladding first appeared 40 years ago. Then German experts combined clinker bricks and polyurethane foam to get a beautiful, durable and warm material for wall decoration.

The basis of thermoplastic panels is always polyester, and the coating can be not only brick-like, but also very different. With the help of such tiles it is easy to realize various design ideas. They are easy to install, look beautiful and retain their performance characteristics for quite a long time. In addition, they are not susceptible to fungus, mold and rust.

Thermoplastic does not need repair and maintenance, just pour it with water from a hose. It is resistant to aggressive environments and mechanical stress. It can be mounted directly on the wall or on the crate. Thanks to their beautiful appearance, such panels give the house a European exterior.

The material from which this cladding is made consists entirely of natural components: cement and quartz with lightening additives, which are sometimes used as cellulose. Such plates are covered with ceramics, acrylic or photoceramics. Due to antistatic impregnation, the panels repel dust and dirt. And even in case of contamination, simply rinse the lined wall with water from a hose.

The ease of fastening allows the use of fiber cement panels for cladding not only low-rise buildings, but also multi-storey buildings. Plates are mounted on a metal or wooden crate. If insulation is laid between the wall and the cladding, this will create additional thermal insulation of the facade. The modern market offers over 400 varieties of fiber cement boards: wood-like, plaster, brick, natural stone of all colors and textures.

The ease of fastening allows the use of fiber cement panels for cladding not only low-rise buildings, but also multi-storey buildings. Plates are mounted on a metal or wooden crate. If insulation is laid between the wall and the cladding, this will create additional thermal insulation of the facade. The modern market offers over 400 varieties of fiber cement boards: wood-like, plaster, brick, natural stone of all colors and textures.

Wooden panels

Unique large-format wood structures are used today for a wide variety of cladding work. Natural material makes it possible to improve appearance at home, enlivening it with warm wood tones. Despite the fragility of the source material, the panels are durable, resistant to various external influences and have a long service life. It's all about the special impregnation with resins at high pressure and temperatures, as well as a special protective film that is stretched over the finished boards.

All this protects the panels, and hence the walls of the house themselves from moisture and sunlight. Impregnations also protect wood from fire, pests, decay and fungus. The finished material is not afraid of mechanical influences and natural factors. Another plus wooden cladding- noble appearance.

metal panels

Facing plates made of metal are distinguished by such positive characteristics as: strength, long service life and original appearance. Modern manufacturers produce not only smooth, but also corrugated, corrugated and perforated panels. They can differ not only in different shapes, but also in color.

Of course, on the market you can find metal plates for various types of wood, as well as for natural stone. This cladding is mounted on a metal profile.

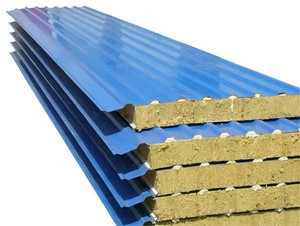

A special position among other types of facing plates is occupied by a sandwich panel. These are multilayer rigid structures that can be used not only for exterior decoration, but also for creating partitions indoors, as well as for building insulation. The unique properties of the material allow it to be used for additional insulation. So, when finishing the facade wooden house, retains thirty percent more heat than when facing with other materials.

A special position among other types of facing plates is occupied by a sandwich panel. These are multilayer rigid structures that can be used not only for exterior decoration, but also for creating partitions indoors, as well as for building insulation. The unique properties of the material allow it to be used for additional insulation. So, when finishing the facade wooden house, retains thirty percent more heat than when facing with other materials.

This is due to the structure of the plate: a heater lies between the two layers of the cladding.

In addition to additional savings in energy costs, sandwich panels are able to please with such characteristics as:

- high strength;

- excellent sound and heat insulation;

- fire resistance,

- ease of installation and ease of use;

- high degree of tightness;

- almost zero level of moisture absorption;

- long service life;

- rich selection of shades.

Along with the positive characteristics, it should be noted the small disadvantages of this cladding. In particular:

- quite a lot of weight;

- the need for careful storage and installation;

- installation is possible only with certain experience and qualifications.

Plate installation

The installation of slabs is one of the most important and serious steps in outdoor decoration. And although the installation itself is not particularly difficult, the appearance of the building will depend on its quality, therefore, if possible, it is better to take the help of professionals.

Regardless of the material from which the plates are made, any weather is suitable for their installation, except for severe frosts. If it is necessary to insulate the house, the plates are installed on a specially mounted crate. It is better to calculate the length of the plates in advance; for this, the size of the facade is measured.

When erecting a new building or during the repair of an old facade, the question arises of its further decoration. The exterior walls of the house are finished using various building materials. Each of them has its own advantages and disadvantages, which should be considered when choosing. Installation technologies are very different. In addition to the decorative function, a well-installed cladding contributes to an increase in the service life of the entire building. A wide variety of finishes allows you to decorate the building beautifully, in the desired style. The combined method of facade design is shown in the following photo.

Wall decoration outside is necessary work, but it is not easy to create a spectacular decoration of the facade. The use of various facing coatings makes it possible to achieve, when ennobling the appearance of the building, effects that improve its performance and living conditions inside the building. outer skin structures with the right choice allows you to:

- ensure the protection of the walls of the structure from the destructive effects of environmental factors: moisture, temperature fluctuations;

- improve (in most cases) the level of thermal insulation of the building, which significantly saves money on heating;

- create an additional soundproof layer that prevents external noise from entering the housing, which is especially important when there are noisy neighbors and highways nearby;

- qualitatively, beautifully decorate the house;

- increase the level of fire safety of a wooden building;

- maintain natural circulation of steam and air.

Insulation of the facade allows you to maintain a comfortable temperature in the summer without the use of air conditioning systems.

The diversity achieved in design is incalculable. One example of harmonious decoration is shown in the photo below.

It is easier to properly clad a house, to maintain the functional state of the created cladding, than to repair load-bearing structures. Decorating is one of the main tasks in arranging a facade.

Facing methods

Facade works place increased demands on finishing materials. Despite their great variety used for wall cladding, 2 groups are distinguished. They are presented in the table below.

Wet facades are understood as a set of materials, the installation technology of which requires the use of plaster solutions and adhesives mixed with water. This is the most large group. The peculiarity of such decorative coatings is their integrity with the supporting structures.

Dry facades are installed on a pre-assembled frame made of metal profiles or wooden slats. In this case, binding solutions are not used. This option is considered simple in installation and further maintenance. A ventilated siding facade is shown in the photo below.

Decorating the walls of the house different kind requires different technological approaches. Wet and dry options have their own advantages and disadvantages, determined not only by the installation method, but, first of all, by the material used. In practice, a combination of sheathing coatings is often found, which gives originality and originality. The choice of what you can finish the building on the outside is very large.

Plastering and painting

Among the "wet" ways to finish the walls of a house outside, a popular option is plaster for bases made of brick, monolith, cinder block, aerated concrete. It is applied directly to the rough surface, or on top of the insulation layer. It is also commonly used for interior decoration but the composition is different. Facade varieties are widely used in rooms with high level humidity.

The traditional option is mixtures based on sand and cement. New formulations are becoming more widespread:

- silicate;

- acrylic;

- polymeric;

- silicone.

For outdoor work, only moisture-resistant mixtures are used. Compounds based on gypsum or clay are not suitable.

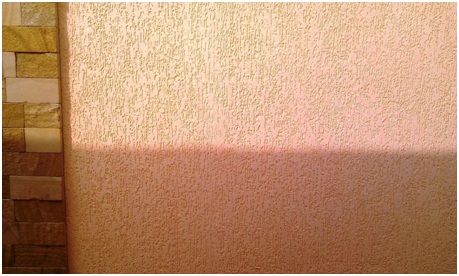

According to the appearance created on the finished surface, the plaster is divided into textured and smooth.

The first is well suited for both professionals and beginners, because it is easier to hide minor flaws with its help.

Creating a smooth facade for subsequent painting is a complex, highly skilled job.

The main advantages of the plaster coating are as follows:

- relative cheapness compared to other materials that decorate the walls of buildings from the outside;

- a wide variety of colors, application options (created textures, patterns) allows you to implement various design solutions;

- the simplest design methods are available to beginners in construction;

- well combined with other finishing coatings;

- plaster solutions are easily applied to the insulation.

The cons are:

- relatively short operating time (about 20 years) compared to analogues;

- often after repair, its traces remain visible.

The technology of working with decorative compositions differs in obtaining various effects on the surface. The result of finishing ("bark beetle") is shown in the photo below.

With the help of paint, surfaces are made of various materials: plastered, brick, stone, wood, panel. The created layer protects from moisture, dust, solar radiation.

When applying paint, the surface is pre-prepared accordingly.

For staining, compositions are used based on the type of base.

The created plaster layer closes cracks, joints, levels the surface. Along the way, sound and heat insulation is improved. The coating protects the base well.

Using brick for decoration

Brick is an expensive material for outdoor decoration. The job also requires certain skills. A beginner will not be able to veneer qualitatively. The work process itself is very labor intensive.

An attractive point when using bricks is the durability, reliability of the created finish. At the same time, it is possible between bearing walls and lining lay insulation. And its combustibility, environmental safety do not play a special role.

Bricks are made from various components. As a result, the final product differs in its characteristics and appearance. The following types of bricks are laid out as a facing coating:

- decorative: produced with strong pressing without the use of firing, it has high strength, resistance to low temperatures, ease of processing, but has poor thermal insulation properties;

- ceramic: has good thermal insulation performance, durable, attractive in appearance;

- clinker: it is distinguished by a wide variety of textures, colors.

The photo above shows a brick house.

When using a brick, its significant weight should be taken into account. The foundation must be able to withstand the load created by such a decorative coating.

Finishing with natural and artificial stone

Wall decoration with natural stone is evidence of success and prosperity, a demonstration of taste. The formed coating has a number of the following advantages:

- long service life;

- high strength;

- spectacular appearance;

- processing with modern compositions gives excellent performance even to inexpensive (porous) varieties of natural stone.

The material is used both for complete finishing and for partial finishing (for example, basement, corners). Use pre-treated stones, or in their natural form. It is more problematic to work with the latter with your own hands.

The following types of stone are on the market:

- granite;

- marble;

- sandstone;

- calcareous tufa (travertine);

- slate;

- limestone;

- quartzite;

- gabbro;

- syenite;

- labradorite and others.

Each of them differs in price, properties.

The main disadvantages of using natural stone:

- high weight of the cladding;

- high cost of material, installation;

- labor intensity, complexity of work.

The option of incomplete finishing of the house with natural material is not shown in the photo above.

Artificial finishing stone- This is a good option for decorating the walls of the house outside. By its properties, it is close to natural material. His appearance is also aesthetic. When using it, less costs will be required than when using a natural analogue.

The choice of textures and colors of natural and artificial stone large, which allows you to give buildings a magnificent, unique look. However, "fake" counterparts are more affordable.

Facing tiles

When choosing a decor, this option deserves special attention. Different kinds material can be fixed dry or wet. Common varieties are porcelain stoneware and clinker tiles. They perfectly mimic natural counterparts.

The advantages of the material are as follows:

- light weight;

- fire resistance

- durability;

- high strength;

- compared to natural stone and brick - lower price;

- ease of replacement during repair;

- a large selection of colors;

- frost resistance.

The design of the building with porcelain stoneware is shown in the photo above.

Facing tiles are a good option for sheathing a building at an affordable price, while obtaining a high quality coating.

Decoration with facade panels

Sheathing the walls of the house with facade panels, which are made from various materials, is a category that is very extensive in composition. It includes the following products:

- siding;

- thermal panels;

- sandwich panels.

The following types of panels are also used:

- glass;

- vinyl;

- metal;

- polyurethane foam;

- fiber cement.

Examples of the appearance of the panels are shown in the photo below.

Varieties differ in their characteristics, structure and dimensions. The advantages and disadvantages of all panels are different.

Among all the options, siding is popular. Its advantages are:

- attractive appearance;

- resistance to temperature fluctuations and biological effects, corrosion;

- ease of installation and maintenance;

- long service life;

- mechanical strength;

- low price.

Install frame siding. Often additional insulation is used. The disadvantage is poor compatibility with other types of design.

Facade panels are widely used for exterior decoration of buildings due to their affordability and relative ease of installation.

Wooden lining in the exterior of the house

Clapboard is a natural finishing material for the exterior walls of a house. Sheathing with boards allows you to give the building an attractive appearance, insulate it and further reduce outside noise.

Clapboard has all the disadvantages of wood. Additional processing is required.

Often boards are made from:

- pines;

- oak;

- ash;

- alder;

- lindens.

For the facade, it is better to use moisture-resistant wood species. They have a higher price, but at the same time durability. AT recent times popularity is gaining imitation of logs and lining.

Recommendations for the choice of material and work

To finish the walls of the house outside, you can choose from the existing variety of affordable and suitable materials. Plastering and painting remain the cheapest and most affordable types of decoration. They also go well with other types of decorative coatings.

The photo above contains an image of a successful combination of plaster with artificial stone.

Popular materials for exterior wall decoration have noise and heat insulation characteristics, resistance to fire, to one degree or another, therefore, they are selected for a specific type of base, operating conditions. For example, wooden structures should be additionally protected from fires, but their thermal insulation performance is much higher than that of concrete or brick, so the insulation properties of the skin are less important than its fire resistance.

With a planned replacement of the skin, it matters right choice finishing material for specific conditions. It is also recommended to take into account its harmonious combination with the environment and structural elements that will not be affected by the repair work.

When choosing heavy facing material it will be necessary to calculate the bearing capacity of the structure, mainly the foundation.

- work on exterior design should not begin before the installation of window and door blocks;

- before carrying out decoration activities, it is better to wait a while so that the building shrinks (one year), and the created coating does not deform;

- after this process, it is required to check the level of the condition of the walls, if necessary, to level;

- in most cases, it is possible to install a decorative coating all year round, but when using some finishing materials, work should be carried out at a temperature ranging from +5 to +25 degrees to avoid compression and expansion of the sheathing material;

- it is necessary to take into account the admissibility of additional load on the base.

The right choice of material for cladding and adherence to the technology of its installation are an integral guarantee of obtaining a high-quality result. For savings Money it is recommended to purchase the kind of sheathing that you can install with your own hands with your experience and skills.

Exterior wall decoration requires a serious approach. Not only the appearance of the building depends on it, but also, to a certain extent, its durability. The saturation of the modern construction market allows you to choose a facing coating for various types of bases. When choosing a design method, an important role is played by the possibility of self-assembly of materials. Some of them are quite easy to install with your own hands, while the use of others requires the involvement of professional builders.

Popular facade design options are shown in the following video.

The video below contains examples of beautiful and practical home decorating.

A deterrent to the spread of some types of coatings, which have a number of positive characteristics, is their high price. But any of the considered cladding options with high-quality performance finishing works allows you to beautifully decorate the house.

Even at the design stage of a building, they think over the decoration of the outer walls of the house. This is considered the final stage of construction work. But, do not assume that wall decoration is not so important. Thanks to her, the house takes on a finished look, is transformed and looks exclusive. Without finishing, the house looks unfinished and unattractive. But, this is not the only function on the account of the finish, there are at least three more. We will cover all of them in this article.

In addition, you will learn how the exterior walls of the house are finished. Since there are quite a lot of materials to work with, you will learn the advantages and features of each of them in order to make the right choice in your direction.

Facade decoration - what is it for?

Each person, before doing something, thinks about the rationality of their actions. This applies to all areas of life. If we talk about the construction of a house, then without fail they veneer the facade. But why? Maybe it's just a waste of money and effort? Not at all! And now we will tell you why, considering 4 reasons:

As you can see, there are quite a few advantages of finishing facades. This suggests that you should not underestimate this work and treat it lightly. But if the owner decides to ennoble the facade of his house, then the question arises, what types of materials can be used? Let's find out.

Varieties of finishing for the facade

Visiting a specialized store selling finishing materials, you may be confused, as their number is really large. But don't be scared! All materials can be divided into two main categories:

- Wet facades.

- dry facades.

And already in these groups, the availability of material is quite large. If you pay attention to the name, it immediately becomes clear what is the peculiarity of the first or second group. Wet facades can be called the largest and most diverse group. It includes all surface finishing technologies using water. What does it mean? Finishing mixtures are kneaded on the spot with water, or ready-made adhesive mixtures are bought. It is noteworthy that the advantage of such a finish is that the building envelope and the material after processing create an inseparable cake. And what about dry facades? Everything is much simpler here. The material is unnecessary to prepare, knead and add water to it. It is already ready to work, without additional processing. This is wood, and siding and other materials, which we will talk about later. In the meantime, let's look at the representatives of the wet facade.

Finishing plaster

This is one of the brightest representatives, which is familiar to everyone. The plaster is prepared at the facility and applied both to the walls themselves (gas block, brick) and to the insulation, whether mineral wool or foam. Most often, plaster is made on the basis of cement - a simple and effective option. But there are also more expensive compositions based on polymer binders.

I would like to say about gypsum plaster compositions for work outside. They are not as effective as the manufacturers claim. It is known that gypsum is almost the largest hydrophobic material of all known in construction. Therefore, it is prohibited to use it for finishing the facade. Therefore, when choosing a material for finishing, stop at cement or polymer compositions.

But, plaster is also different, so the materials can be divided into the following subcategories:

Textured plaster is ideal for beginners, as the work on applying it will not bring difficulties. Its advantage is that finished surface embossed and rough, which helps to hide small errors in the walls. On a smooth facade, they would be visible. There are a lot of technologies for applying such a finishing material. In most cases, texture and pattern are formed with a spatula. The most striking example of this is the bark beetle.

In other cases, you can get the desired texture by spraying onto the surface (fur coat).

As for smooth plaster, not everything is as simple as it might seem. Making a smooth facade finish for painting is one of the most difficult types of work that requires high professionalism. Since the walls are constantly in sight, the sun shows all its shortcomings and defects. But when the work is done by masters, it looks very beautiful. Finishing is applied with spatulas, over the entire surface of the walls. But the decoration of the corners of the room outside requires special attention. To process the corner of the house, there are special spatulas, thanks to which the finishing of the corners of a wooden house from the outside is even easier.

Advice! To protect the corners of a building, you can protect them with styrofoam. Watch the video to see what this finish looks like.

Pros and cons

Regardless of which option you prefer, plaster has its positive and negative qualities. Among the advantages I would like to note the affordable cost of the material. The plastered facade has a very presentable appearance, despite its cost-effectiveness. In addition, it is pure material. It will not harm you or your household.

The disadvantages of the coating are its short service life and the inability to carry out repairs. No matter how correctly the material is applied, it will not serve you for more than 20 years. And it is quite difficult to restore the damaged area, since everything is quite noticeable.

brick finish

Brick has been used in construction for many centuries. Comparing plaster and brick, it becomes clear that the price of the material is much higher. Yes, and the process of wall cladding is more complicated, since masonry is used. However, finishing the walls outside the room with brick is a guarantee of reliability and durability. The facing brick has the same characteristics as the brick in the structure, only its appearance is more attractive.

And the best part is that the masonry is not tied to the main wall, so you can put a layer of insulation between the wall and the finish. And it doesn’t matter what environmental characteristics and fire safety it has. Between the layers of bricks, foam or mineral wool will be protected. This finish is perfect for brick house. Here's what it looks like in the photo.

Note! The walls can also be faced with natural stone.

Dry facades

If in the first case you had to deal with solutions and dirt, then with a dry finish everything is much easier. You don’t have to get your hands dirty, and the process of processing walls is not so complicated. The most prominent representatives of the dry facade are siding and wood.

Siding

It is considered the best option for finishing wood or brick house. It looks very attractive, rich and original. It is also noteworthy that even a beginner can sheathe a house with siding. And if any section of the wall was damaged, it is very easy to replace it. The material is strong and durable. If your walls have defects and flaws, it is easy to hide them with siding. It is clear that they should not finish the mansions, since he will not decorate them, but for an ordinary wooden, aerated concrete, wood concrete or brick house, just right.

Advice! You can watch an additional video on how to install siding for your home.

wood paneling

By means of a tree, any house can be processed. And even if it was made of brick, no one will know. Wood is an environmentally friendly material. It was used by our ancestors, but is still in demand. The tree looks original and rich. But, the downside is that such a coating will not last you for a long time. Constant moisture destroys the material.

Note! When mounting wood, use stainless steel screws.

Conclusion

You have seen a lot of materials that are used for finishing facades. All of them are special in their own way, they have both advantages and disadvantages. As always, the decision is yours, so analyze the pros and cons to choose the perfect option for you.