- The device of the wood-burning boiler "Motor Sich"

- Pros and cons of Motor Sich boilers

- Feedback on the work of gas-generating boilers "Motor Sich"

The use of the pyrolysis method in the design of solid fuel heating devices makes it possible to achieve amazing efficiency even when working on such low-calorie fuel as firewood. However, it has one significant disadvantage: good efficiency will only be when using dry firewood. The hero of our today's review, the Motor Sich pyrolysis boiler, is devoid of this drawback, and can safely work even on freshly cut wood. In this review, we will consider the design of the Motor Sich gas-generating boiler, its advantages, specifications and reviews of owners using it to heat their homes.

Boiler production long burning"Motor Sich" is engaged in Lebedinsky Motor-Building Plant. This company is based in Ukraine and is engaged in the production of pyrolysis-type heating devices for both domestic and industrial purposes. In the Russian market, Motor Sich hot water boilers are sold by the Atom company.

The device of the wood-burning boiler "Motor Sich"

Motor Sich boilers operate using the pyrolysis method. Its difference from classical combustion is that combustion takes place in two stages. At first, the wood laid in the boiler heats up and slowly smolders with a lack of oxygen. Pyrolysis gas begins to be released from it, which is then burned in a separate chamber when mixed with secondary air. This combustion method is much more efficient than the traditional one, but it is more difficult to implement. That's why pyrolysis boilers usually more expensive than direct combustion boilers.

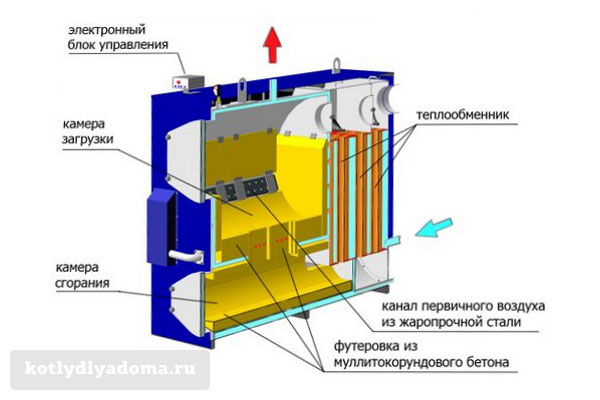

Photo 1: Gas-generating boiler "Motor Sich" with a water circuit

The body of the wood-burning boiler "Motor Sich" is made of steel with a thickness of 6 to 10 mm. Inside it are located one under the other two chambers. Firewood is loaded into the upper one, and the lower one is used to burn wood gas. The entire rear part of the boiler is occupied by a tubular heat exchanger, after which the exhaust gases are discharged into the atmosphere through a chimney.

Photo 2: Firebox of a wood-fired boiler "Motor Sich"

Photo 2: Firebox of a wood-fired boiler "Motor Sich" Usually, in pyrolysis heating devices, such as the lining, only the afterburner is used. The Motor Sich model has a ceramic concrete lining of both the upper and lower chambers. This allows you to achieve high temperatures for burning firewood, eliminating the possibility of burning through the walls. It is thanks to this special coating that even damp firewood burns effectively.

Photo 3: The device of the household heating boiler "Motor Sich"

Photo 3: The device of the household heating boiler "Motor Sich" The principle of operation of the Motor Sich boiler is as follows. Firewood is loaded into the combustion chamber and ignited. The firebox door closes tightly and primary air begins to flow through special openings in the walls. The fuel slowly smolders, releasing pyrolysis gas, which is injected into the lower chamber through a connecting nozzle. In the lower chamber, it mixes with secondary air and burns at a high temperature. Flue gases passing through the pipes of the heat exchanger and transferring energy to the coolant are discharged into the environment through the chimney.

The Motor Sich plant produces both household models with a power of 16 to 80 kW, and industrial models from 100 to 300 kW. Below are the technical characteristics of pyrolysis boilers suitable for use in private homes or small industrial premises:

As you can see, the efficiency of Motor Sich pyrolysis models is higher than that of traditional devices, such as classic ones. Let's see what other advantages they have and maybe we can find a couple of disadvantages.

Back to indexPros and cons of Motor Sich boilers

As you managed to find out, the device of a pyrolysis boiler is more complicated than a typical solid fuel heater. And the cost of such devices is usually significantly higher. What other advantages does this intricate design give, let's try to figure it out:

Long service life

The use of special thick steel, lining of the loading and combustion chambers, strong welds and a reliable electronic control system - all this can significantly increase the life of the Motor Sich boilers compared to similar models.

Ability to use raw wood

Sensitivity to fuel moisture is one of the main problems of pyrolysis boilers. The presence of the lining of the loading chamber makes it possible to use wood with a moisture content of up to 50%.

High efficiency

With normal combustion, the efficiency leaves much to be desired. The fuel does not burn completely and a large percentage of useful energy flies into the chimney. In the Motor Sich boiler, everything that is possible is squeezed out of firewood. As a result, the efficiency of the boiler on dry wood reaches 90%.

economy

Using the potential of the fuel to the maximum, you direct all its energy to heat your room without wasting it.

long offline work

Classic solid fuel boilers need to be loaded every few hours. When using enough dry wood, the Motor Sich boiler is able to work without reloading up to half a day.

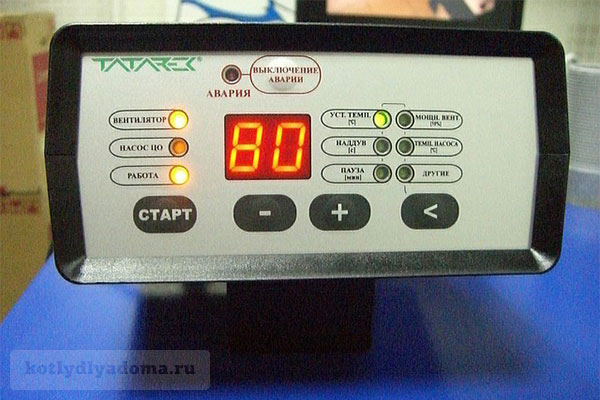

Photo 4: Motor Sich pyrolysis boiler control unit

Photo 4: Motor Sich pyrolysis boiler control unit In addition to the advantages mentioned above, it is worth noting some of the disadvantages of the complicated design of the Motor Sich pyrolysis boiler:

Mandatory power supply

The combustion process in the Motor Sich boiler is organized in such a way that only forced draft is possible, which is carried out by electric fans.

High price

Pyrolysis boilers are significantly more expensive than classic ones. Most likely, such a device will not be bought by those who are focused on more budget models.

These disadvantages are observed not only in the Ukrainian boilers "Motor Sich", but also in all, which we talked about in our previous reviews on the site kotlydlyadoma.ru. Let's now find out what their owners think about Motor Sich models.

Firewood is a natural fuel that was used by our ancestors. This natural resource has not lost its effectiveness even today. Due to the fact that gas is becoming more expensive, many are thinking about using firewood as a raw material for heating their homes. Thus, heating costs can be reduced. Many have already begun to think about using an alternative to natural gas.

A wood-fired pyrolysis boiler comes to the aid of such people, which is capable of generating heat from cheap fuel. When wood is burned, a gas is released that is used to generate heat energy. Let's take a closer look at the principle of operation of such equipment, what advantages it has and how to properly maintain the pyrolysis boiler.

Device and principle of operation

Pyrolysis wood boiler is intended for heating various buildings by burning wood: logs, pressed briquettes and various wastes. But, it has some difference from the classic equipment that runs on solid fuel. Thanks to them, the efficiency of such boilers is much higher. Let's find out how it works.

Let's start with the fact that the furnace in the boiler is divided into two parts. The first compartment is the gasification chamber or loading chamber. In it, with a lack of oxygen, firewood smolders, releasing pyrolysis gas, which passes into the second compartment and burns out there, when primary air is supplied. In simple terms, the principle of operation of the boiler is as follows:

- The wood is placed in the first compartment on the grate and set on fire. Due to the adjustable window, into the chamber in required quantity oxygen is supplied to keep the fuel burning. After the temperature reaches 200 ˚C, the boiler switches to the next mode. 200 ˚C is the minimum temperature required for the pyrolysis process.

- When the firewood has been burning for approximately 20 minutes, the boiler switches to gas generation mode. At the same time, an adjustable window (damper) does not allow oxygen to penetrate in the same amount inside. The automatic regulator passes oxygen in a limited amount. Firewood begins to gradually smolder and char, releasing pyrolysis gas.

- Then the gas enters the afterburner. At this time, secondary air is supplied to the boiler, which is necessary for burning pyrolysis gas. It enters the boiler cold, but as it passes the first chamber, it heats up to the required temperature. There he keeps the gas burning. The upper compartment has special air distributors, in which holes are made. Under pressure, secondary air escapes from them. It guarantees the ignition of unburned fuel gases by converting 90% of the fine particles in the smoke into energy. At the same time, the combustion temperature in the cameo can reach 1200 ˚C

It is worth noting that such wood-fired pyrolysis boilers for the home are distinguished by their environmental friendliness, because when the process of thermochemical afterburning takes place, the emission of harmful substances into the atmosphere is minimized. Note! The flue gas outlet temperature is 130-160 ˚C. It turns out that the heat produced by the boiler is transferred to the coolant with maximum efficiency. The coolant, passing its way through the unit from the bottom up, receives energy from each surface inside the boiler. Thanks to this design, a constant efficiency of 85% is achieved.

Advantages and disadvantages of a pyrolysis boiler

To decide whether you should use a pyrolysis boiler or not, we will look at its advantages and disadvantages. At the same time, we took into account user reviews and technical characteristics of the unit. So let's talk about the benefits first. They are the following:

- Ease of maintenance and automation of the whole process. If there is no main gas supply, then this is the best option for heating your home.

- Infrequent loading of firewood. It is required to put fuel into the boiler every 11-15 hours. When compared with others solid fuel boilers, then it is exactly -3 times rarer.

- Ecological cleanliness, because everything burns down almost completely. And there are no toxic combustion products in the flue gases. When the gas generator is running, the CO 2 content is three times less than usual.

- A small amount of ash remaining after the combustion process. This will make it easier for you to clean the boiler, as you do not have to take out the combustion products often.

- Huge speed of heating the coolant to a temperature of 60 ˚C.

- Due to the two chambers, the efficiency increases significantly (80-95%), which saves on fuel.

- Ease of installation of the boiler, which does not require major modifications to the heating system.

- The ability to adjust its power in the range from 50 to 105%.

But, despite all the advantages, boilers have their drawbacks.

- The main disadvantage is the high cost. If you compare the unit with traditional counterparts, then it will cost you 1.5 times more. Although, given how efficiently it uses fuel and gives off heat, the costs will quickly pay off. But, the fact remains.

- Pyrolysis heating devices are single-circuit, so they will not be able to heat water for everyday needs. You will have to buy an additional boiler.

- Not fully automated. From time to time you will have to manually load the fuel.

- The design of the boiler requires a fan for the smoke exhauster, which will remove the smoke. And, as you know, such pumps require connection to the electrical network.

Based on the foregoing, we can say with confidence that a wood-fired pyrolysis boiler is a worthwhile alternative to natural gas.

A little about fuel for boilers

The raw material for the unit is wood, having a length of 38-45 cm, and a diameter of 10 to 25 cm. Additionally, sawdust and other wood waste can be loaded with them. However, their volume should not exceed 30% of the volume of the loading chamber. Boilers are able to burn wood with a moisture content of up to 40%. To achieve maximum performance of the device, it is better to use wood with a moisture content of 20%. This will not only increase the efficiency, but also extend the life of the boiler.

And how much firewood is needed for a pyrolysis boiler? Compared to direct combustion boilers, fuel consumption is reduced up to 5 times. On average, 11 kg of wood is required per day for high-quality heating for every 100 m 2 of area. It should be noted that the consumption also depends on the moisture content of the wood. For example, 1 kg of material with 20% moisture per hour will release 4 kW of heat. If the humidity is 50%, this figure will decrease by 2 kW / h. It turns out that the consumption will be increased by 2 times.

Do-it-yourself pyrolysis boiler

When you do not want to overpay for the purchase of a ready-made boiler, you can build home-made pyrolysis boilers on long-burning wood. It is clear that without certain skills and tools, it will be difficult. The main type of work is welding, so if you don’t know how to do this, it’s better to ask a friend or stop by buying a finished structure.

It all starts with the fact that you need to collect information about the unit and its features. You need to make a drawing in advance, from which you will build. If you are not an expert, you can find it on the Internet, or use the drawing below.

It remains only to purchase the material and assemble the boiler. There are many on the internet detailed information about how to make it yourself. You can watch the video to see firsthand how to assemble it quickly and easily.

Service Rules

Regardless of whether you bought a boiler or made it yourself, you need to know the rules of operation. In order for it to work efficiently and continuously, adhere to the following recommendations:

- the first time you need to start the unit idly. For 6 hours, heat the boiler by opening all valves in heating mode. During this period, the chambers can be covered with a resinous film that prevents further metal burnout.

Pyrolysis boilers are gaining more and more popularity in domestic markets, which is quite understandable. A well-established heating system creates comfort and coziness in the house. Modern world dictates its conditions to us in this matter: gas or electricity are offered at rather high prices, and many country houses and completely devoid of such benefits of civilization. There is a demand for alternative heating sources that could work on more affordable raw materials - coal and wood.

In general, it is possible to obtain thermal energy from any solid fuel which releases gas during combustion. It is this principle that formed the basis for the operation of such a device as wood-fired pyrolysis boilers. Their use has a positive effect on the efficiency index, significantly increasing it to the highest rates - 92-95%. But before buying such equipment, you should take into account all the nuances of its work, which is best done together with a specialist.

Pyrolysis boiler device

The operation of this equipment is in the process of gas generation or pyrolysis. If we consider in more detail the process of obtaining thermal energy by burning wood, then it can be divided into several stages:

- Fuel is placed in a special chamber, and then ignited. It is noteworthy that it is possible to control the combustion mode after reaching a heating temperature of 200 degrees, since this indicator is the minimum necessary for the pyrolysis process to occur.

- The gas generating mode is switched on by moving the dampers after approximately 20 minutes of intensive wood burning. At this moment, a large production of CO begins, which becomes possible due to the limited supply of oxygen to the furnace.

- Further, the resulting gas is sent to a separate chamber for mixing with oxygen. It is this step that is fundamental for the transformation of a kind of raw material into the fuel mixture necessary for combustion, which is carried out by a special burner.

The well-thought-out arrangement of boilers and their principle of operation greatly increase heat transfer. If we compare them with conventional solid fuel units, then the rate of pyrolysis equipment will be approximately 20% higher.

Distinctive features of the pyrolysis boiler from analogues

Speaking about the unique features of the device, first of all, you should pay attention to the presence of two combustion chambers. The first of them is intended for loading fuel and its long-term combustion with subsequent release of CO. The second plays the role of an accumulator and a furnace, where the resulting gas is burned. This feature affects the weight of the boilers, which can reach several centners. An excellent example of this is the pyrolysis boilers of the Teplogarant company - "Bourgeois-K" STANDARD-10 or, for example, the model "Bourgeois-K" MODERN-12, whose mass is 150 kg and 270 kg, respectively.

Speaking about the long duration of burning, it is worth noting that the combustion process can be safely called a real smoldering, due to which one bookmark can be enough for a significant time of the boiler. There is virtually no heat loss.

A notable feature of the pyrolysis boiler is the air supply system. The first versions of such a device were designed for the implementation of the natural circulation of oxygen, but in practice this option turned out to be extremely inefficient. Therefore, over time, this model was significantly revised - the circulation process was equipped with pumps and fans. The mechanical system showed much better results, which formed the basis of modern devices.

Why should you pay attention to Teplogarant?

The Teplogarant company is one of the largest Russian manufacturers of pyrolysis boilers, their brand name is the Bourgeois-K model. A wide range of products is able to offer equipment for both domestic and industrial use - with enhanced performance. Representatives of this company, unlike resellers, provide customers with not only full warranty obligations, but also the opportunity to get a very comprehensive individual consultation, as well as consider in detail the conditions of a particular project for the most optimal selection of equipment.

Teplogarant's work is based on maintaining a competitive pricing policy. This is due to the implementation of the most advanced technologies combined with the rich experience accumulated by the company over the years, as well as the absence of intermediary markup.

Let's consider several products of the company using the STANDARD and MODERN household model ranges as an example. Their main difference lies in the power and, as a result, the efficiency index, which for the latter can reach 92%, while the former shows a result of 85%. At the same time, it is important to understand that when choosing these values, it is necessary to build on the requirements imposed on the device, put forward by each individual project. This will help you save quite a lot of money.

Pyrolysis boiler "Bourgeois-K" STANDARD-20 and its, one might say, a modernized version "Bourgeois-K" MODERN-24, are excellent options for all owners of houses and premises not connected to a centralized heating system. Possessing a relatively high efficiency and high duration of operation, reaching 12 hours on one tab, the devices are able to heat a room up to 200-250 sq.m. Moreover, it is worth starting from the fact that the improved model has not only a higher power - 24 kW versus 20 kW, but also most other indicators, which makes it more reliable equipment for maximum areas. True, this will also affect its value.

The same principle applies to models "Bourgeois-K" STANDARD-30 and "Bourgeois-K" MODERN-32, but they have much increased technical data. Their power reaches 30 kW and 32 kW, respectively, and the working area has increased to 300-330 sq.m. It is worth noting that this significantly affected their dimensions and weight. The first of them weighs 330 kg, and its modernization - 435 kg. At the same time, they have identical characteristics such as the diameter of the chimney connection, its minimum height and the required draft in it, the temperature of the flue gases, the volume of the furnace and the size of its door, as well as the maximum length of wooden logs. As for the delivery set, the MODERN range is supplemented with a thermomanometer and a draft regulator.

If there is any doubt about any issue, best solution there will be an appeal to qualified consultants of the Teplogarant company. After all, despite the obvious advantages of a particular model, the need for them may simply be absent.

Maintenance of the pyrolysis boiler

- Before using the device, it is necessary to start it empty for the first time. For six hours, the boiler is heated in heating mode, while the valves must be fully open. This is necessary so that a resinous film forms on the walls of the chamber, which in the future will prevent the metal from burning out.

- Quite convenient is the fact that most models of pyrolysis boilers were made taking into account the minimum participation of a person in their work. They are more preferable for those who do not want to check the status of the device at regular intervals. Sensitive and fine automation will take over all the main functions and tasks, for which it will be enough to follow only the heating of the coolant to the required temperature, which is usually 200 degrees.

- As the main raw material, it is best to use only firewood. This is explained not only by the danger of experimenting with such equipment, but also by the fact that wood has the best gas generation performance, leaving its “solid” counterparts far behind. It should be noted that Teplogarant's products do not set high requirements for the quality of firewood, which can often be found in foreign devices that are less adapted to our conditions. The great whimsy of foreign boilers for raw materials makes them extremely expensive to maintain.

Having touched on the topic of firewood, I would like to mention the main reasons for their rapid combustion. Basically, this problem is caused by a violation or complete absence of the gas generation process. This can be caused by a high moisture content in the raw material, not preheating the combustion chamber, or any problems with the automation, if any.

As for the first case, it is better to ensure that the moisture content of firewood does not exceed 20%. However, the listed models of the Teplogarant company are able to work with humidity up to 25%. If this indicator is exceeded, then even the most expensive pyrolysis boiler will work like an ordinary wooden stove, completely losing all its efficiency. If you do not preheat the combustion chamber, this will significantly increase fuel consumption. Before starting the gas generation process, the air inside the chamber must warm up to 200 degrees. At correct operation noticeable fuel savings in the range of 10-20%. In this matter, the presence of automation helps especially well, but it is far from typical for the entire range of boilers. But, despite its clear advantage, such a system tends to fail sooner or later, requiring repair or replacement. In general, the device is simple and inexpensive to maintain.

In the absence of coal and cheap electricity, the problem of heating is solved with the help of firewood. In addition, the rise in the price of natural gas significantly affects the family budget. Many citizens who previously gasified their private homes are now looking for alternative sources of heat. In this case, a pyrolysis boiler will help, which you can do with your own hands or a wood-fired boiler.

The pyrolysis boiler heats various rooms by burning wood - waste, logs, pressed briquettes. The gas-generating boiler differs in its design from the usual solid fuel equipment that also burns wood. You can understand the benefits of installing a pyrolysis boiler by understanding the principle of its operation.

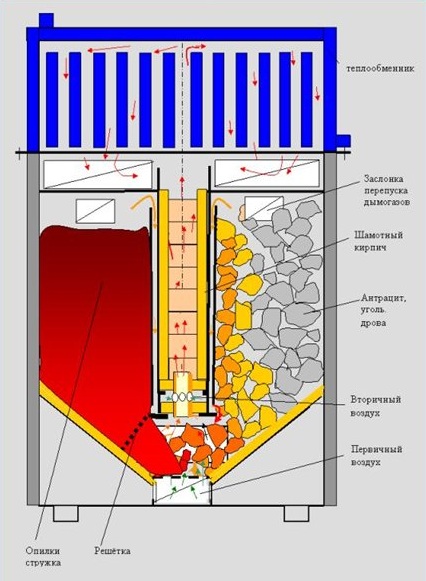

Design

The furnace of pyrolysis boilers is divided into 2 parts. In the first of them - the loading chamber, with an insufficient amount of oxygen, the firewood burns and pyrolyzes, and the released gases burn out in 2 parts of the boiler - in the combustion chamber, where secondary air is supplied. At the same time, heat removal from the loading chamber becomes minimal.

These two spaces are separated by a grate on which the briquettes are located. Primary air passes from top to bottom through the layer of wood. Top blast is considered the main difference between gas-generating boilers and other household appliances. The furnaces of these structures are characterized by increased aerodynamic resistance, therefore, most often their draft is forced. Sometimes the draft is carried out with the help of a smoke exhauster, and not with a blower fan, as is typical for small boilers.

Principle of operation

The wood-fired boiler operates on the basis of the principle of thermal decomposition of wood, which means that under the influence of external factors, dry wood decomposes during combustion into a solid residue in the form of coal and a volatile part in the form of gas.

Scheme and principle of operation of the pyrolysis boiler

As a result of the process taking place in the loading chamber at high temperature and lack of oxygen, generator gas is released. Passing through the nozzle, wood gas mixes with secondary air and burns at a temperature of about 1200?. The released gases pass through the convective part of the heat exchanger, transferring their heat energy to the working fluid and are then removed through the chimney.

Both the loading chamber and the combustion chamber of the pyrolysis boiler are lined with refractory lining, and this significantly increases the temperature inside the boiler, creating ideal conditions for high-quality and efficient burning of firewood.

Main advantages

Today, firewood is used to burn various devices: heat storage furnaces, air and water boilers. Among other equipment, pyrolysis boilers are most in demand among consumers. Pyrolysis boilers differ from conventional solid fuel apparatuses in that they burn not only the wood itself, but also the escaping wood gas. In the process of combustion, soot is not formed at all, and ash is in minimal quantities, and therefore the apparatus needs to be cleaned less often.

Due to the increased loading chamber and higher efficiency, pyrolysis boilers are able to maintain the set temperature much longer than traditional boilers. Some models can work the whole day on one bookmark of wood fuel. This ability of pyrolysis boilers is their undeniable advantage.

The gases exhausted in the boiler contain less carcinogens. During combustion, wood gas reacts with active carbon, therefore, at the stage of exit from the combustion chamber, flue gases are mainly a mixture carbon dioxide with water vapor.

Another advantage of gas-generating boilers is the ability to control power in the range of 30-100%. Pyrolysis devices can dispose of some waste without polluting the environment. We are talking about rubber, plastics and polymers. At the same time, wood-fired boilers need power supply, are large in size and demanding on fuel.

Efficiency

It is known that the operating time of the boiler varies over a wide range depending on certain factors: indoor and outdoor temperatures, type of fuel, its humidity, insulation of the house and how accurately the heating system is designed. But there is no doubt that gas-fired boilers are much more efficient than traditional ones.

In the process of burning wood, it is impossible to obtain such high temperatures, as in the combustion of wood gas emitted by them. In addition, a smaller volume of secondary air is needed to burn the gas, so the temperature rises and the efficiency as well as the burning time increase as a result. It should be noted that the wood gas combustion process is easier to manage.

Fuel

The fuel for pyrolysis boilers is wood 400-450 mm long and 100-250 mm in diameter. The dimensions of fuel briquettes are 30x300mm. Sawdust and small wood waste can be burned with firewood, but they should not be taken more than 30 percent of the volume of the loading chamber. In such boilers, wood can be burned, the moisture content of which reaches 40%.

It is better to heat pyrolysis boilers with drier wood, then the device will operate at maximum power and its service life will increase. When burning 1 kg of firewood with a moisture content of 20%, the calorific value is 4 kW / h, and a tree with a water content of 50% is characterized by a calorific value of only 2 kW / h per 1 kg of firewood.

In other words, the calorific value of the fuel directly depends on the water content in the wood: with an increase in the volume of water in the wood, its useful energy content is significantly reduced, and the consumption of briquettes is doubled.

Why making a boiler is profitable

Pyrolysis heating boilers on firewood become in recent times increasingly popular because they can be used without being dependent on ever-increasing natural gas tariffs. Of course, good gas generating devices with good characteristics can be purchased on the market, but many buyers are still confused by their rather high cost.

At one of the last construction exhibitions, a simple domestic boiler cost at least one thousand dollars. Therefore, many consumers decide to make a pyrolysis boiler with their own hands.

Necessary tool for the job

For self-manufacturing a wood-fired boiler, you just need to have the desire and the necessary tools. Of course, it will be necessary to make considerable efforts to achieve a good result.

First of all, you should accumulate as much information as possible on this heating device and its features. Then you need to make calculations to determine the optimal type of combustion for a particular building - with a slot burner or grate. Then you need to purchase the necessary parts in a specialized store.

To make a pyrolysis boiler with your own hands, you will need the following materials:

- steel sheet (4mm);

- steel pipe 4 mm thick;

- electrodes;

- several profile pipes;

- round rod (20mm);

- centrifugal fan;

- temperature control automatics;

- fireclay brick;

- asbestos cord;

- nuts and bolts.

Schemes and drawings of boilers

The required amount of material can be accurately calculated based on the drawings. Paid drawings and literature on this subject can be found on the Internet. Guided by this material, you can make a good device. In the scheme of the pyrolysis boiler, the furnace, the heat exchanger and the place of water supply are indicated. There is no need to create a wood-fired boiler scheme from scratch, it is better to use circuit diagram with only a few changes.

An approximate diagram and drawing of a pyrolysis boiler for do-it-yourself manufacturing. To enlarge, click on the picture.

For the manufacture of a gas-generating boiler with your own hands, a 40 kW heater circuit, developed by designer Belyaev, is suitable. It will need to be optimized for laser cutting with fewer parts. The design of the device can be changed so that its internal volume remains unchanged, and the heat exchanger jacket is significantly increased.

It is not necessary to ensure the tightness of the pipes, since leaks and freezing of the heating system are not typical for a pyrolysis boiler. Therefore, such a device is an ideal solution for giving, where it will be heated only occasionally.

Having assembled the boiler according to the scheme, you can proceed with its installation, then further testing. If the assembly was done correctly, the boiler should quickly reach the required mode, and the heating system should warm up in a maximum of half an hour. The temperature in the room rises very quickly.

Benefits of the Blago gas boiler

The inventor of the Blago boiler is Yu.P. Blagodrov, who declared the advantages of his brainchild. The Blago pyrolysis apparatus surpasses other boilers in terms of the duration of burning wood in conditions of maximum calorific value.

Blago pyrolysis boiler operation scheme

In this machine, grates completely cover the bottom of the fuel bins. That is why, with natural draft, it is noted high level the heat of combustion of firewood and a longer burning period due to the layout of the fuel bins. This allows you to increase the volume of fuel bunkers without reducing efficiency.

The device of this model of a pyrolysis boiler allows the fuel to burn in any of the 2 combustion chambers and in the third - to gas. The Blago boiler is non-volatile, it always produces the required power. Compounds of phenolic groups - resins, tar, alcohols, essential oils burn completely.

The rails installed in the combustion chamber act as good heat accumulators. Sawdust, coal and peat briquettes can be burned in a gas-generating boiler. In the cold season, fuel can be constantly added to the combustion chamber in order to maintain the optimum temperature in the room.

So, although on the street of the 21st century, firewood as a natural resource is still used for heating. This explains the fact that among all solid fuel boilers, pyrolysis apparatuses are of the greatest interest to the population.

Video of an alternative point of view on the pyrolysis boiler: