The combination of efficient operation based on economical use of fuel and ease of use are key requirements when choosing a heating boiler. The main goal of engineering developments is to maximize the use of heat from the burned fuel while reducing the volume of the energy source. The pyrolysis boiler fully complies with the set conditions and is a practical option for heating housing.

Types and arrangement of pyrolysis equipment

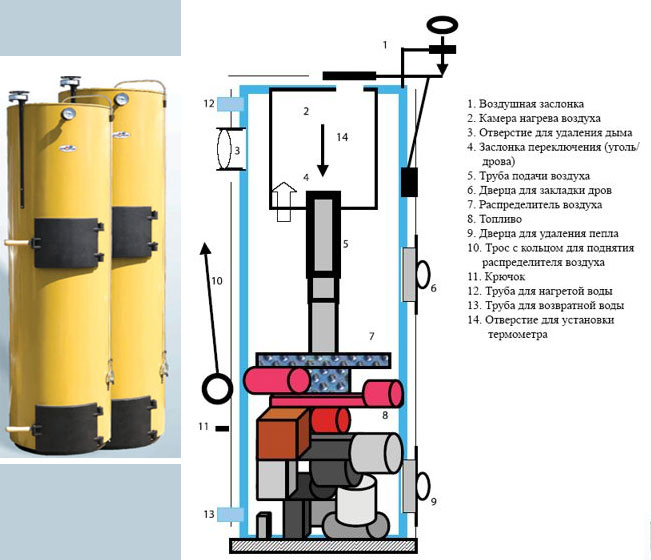

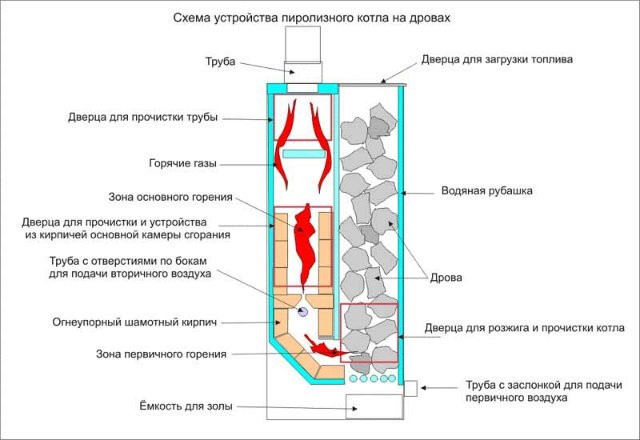

Which boilers can be classified as pyrolysis boilers and are there any design differences between the models? What are the benefits and negative sides aggregates long burning? To begin with, it is worth noting that pyrolysis boilers operate exclusively on solid fuels. The "heart" of the boiler is a combustion chamber, consisting of two compartments:

- Boot part for solid fuel generating gas.

- Afterburning sector, the function of which is the organization of the process of burning pyrolysis gases.

This sector is connected to the smoke path, through which thermal energy moves to the coolant. The remains of the combustion of solid fuels in the form of soot also settle here. Therefore, the second name of the pyrolysis apparatus is a gas-generating boiler. All such units are equipped with traction switches. The absence of this element turns the gas generating boiler into standard direct combustion equipment. It is the closing of the valve that ensures the start of the pyrolysis process during the combustion of solid fuel.

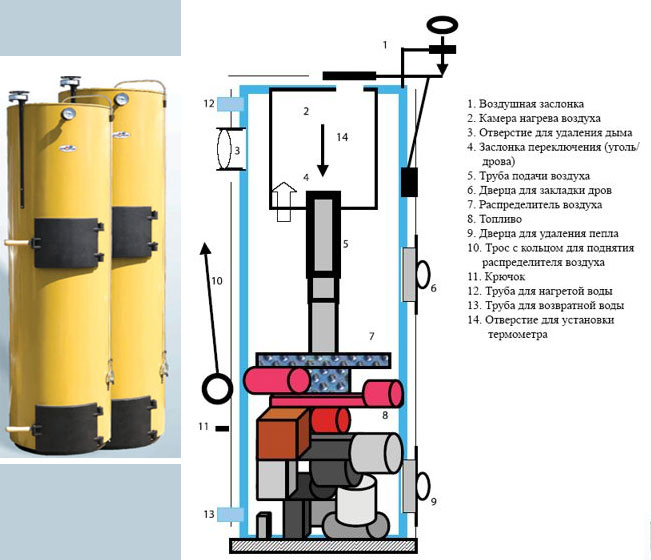

There are various models of pyrolysis boilers, the difference between which lies in the location of the afterburner. It can be equipped at the top or bottom. Features of the popular design of a solid fuel unit with a bottom afterburner are as follows:

- Among the advantages, there is a convenient laying of fuel, while the exhaust gases exit into the chimney installed from below.

- A significant disadvantage of such a pyrolysis boiler is the need for regular cleaning of the lower chamber due to the ingress of ash from the primary compartment.

The design of the pyrolysis solid fuel boiler with an upper afterburner is less common, but has significant advantages. In it, pyrolysis gas enters the afterburner compartment through nozzles, and after complete combustion it moves into the chimney. After cooling, the combustion products are discharged outside. The negative point of this model is the increased consumption of material for the arrangement of the smoke path.

Structural differences between pyrolysis-type solid fuel boilers also exist in the arrangement of traction, which can be forced and natural.

Remark ! Devices with natural draft do not depend on the availability of electricity and are equipped with a high chimney.

For forced ventilation, fans and smoke exhausters are installed, which are automatically controlled. Their work is characterized by a long effective burning time, but subject to the availability of electricity.

Principle of operation

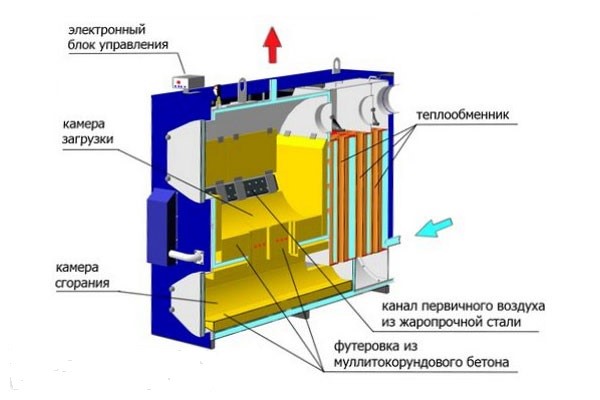

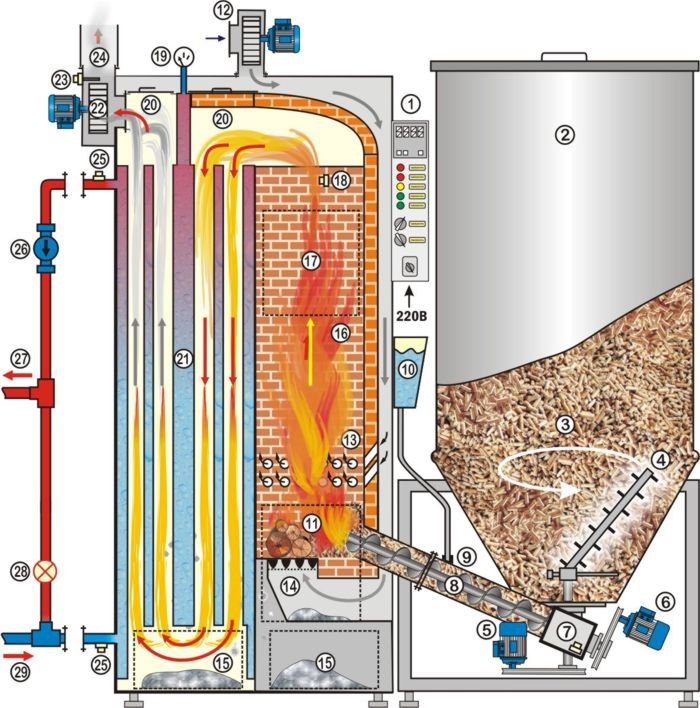

Due to which the pyrolysis solid fuel unit has a high efficiency, we will consider in detail. Thanks to the equipped combustion chamber and turbine, one bookmark of solid fuel is enough for a period of 10 to 12 hours. How it works:

- Gas-generating boilers are equipped with a software device, the function of which is to set a convenient heating mode.

- After receiving the specified parameters, the automatic control of the turbine operation is carried out.

- A certain volume of air is supplied to the compartment for loading solid fuel, which provides the required combustion mode. This allows you to maintain the desired temperature in the system.

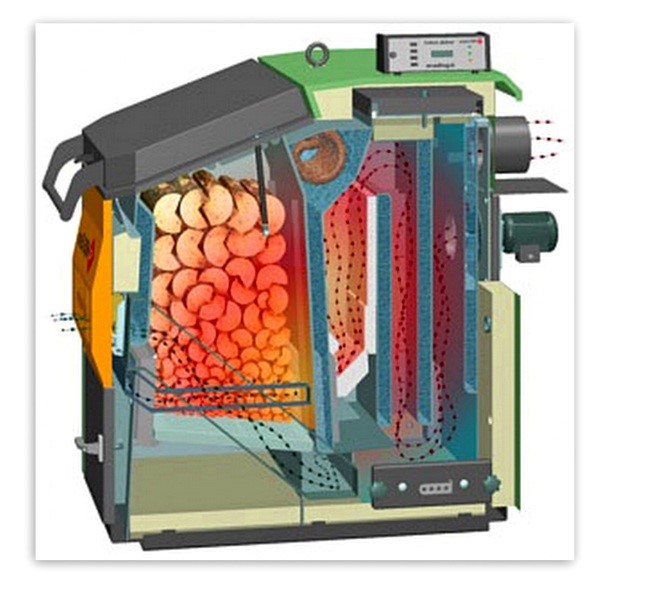

The key principle for the efficient operation of pyrolysis boilers is the use of gas generation technology due to the decomposition of wood. This is done when solid fuel is exposed to high temperatures in the range of 200-800 ° C, subject to limited air supply. That is, the receipt of the main flow of thermal energy is not based in the loading chamber, where the combustion of solid fuel takes place directly. The pyrolysis gas released under conditions of lack of oxygen passes through the nozzles into the afterburner, and, mixing with secondary air there, burns at a temperature of 1100-1200 ° C. Its ignition is facilitated by a smoke exhauster, which creates the necessary traction. This process is characterized by the release of a huge amount of heat. Boiler areas where a small amount of waste in the form of ash and soot accumulates need to be cleaned regularly.

Promotion of pyrolysis gas through the heat exchanger is accompanied by the transfer of thermal energy to the coolant, after which it is removed through the chimney. This ensures maximum use of the generated heat and prolongation of the combustion process of solid fuel.

Important ! For the efficient operation of the pyrolysis boiler, fuel is used whose moisture content does not exceed 20%, otherwise the gas formation process is impossible.

Features of steel and cast iron models

The body of a solid fuel pyrolysis boiler is mainly made of steel with a thickness of more than 5 mm. The disadvantage of this material is the susceptibility to corrosion processes, which has Negative influence for the life of the equipment. To avoid such problems will allow the purchase of a solid fuel boiler, the body of which is made of cast iron, which has high quality and reliability. Compared with steel products, the characteristics of cast iron pyrolysis boilers are higher in the following positions:

- period of operation;

- heat transfer;

- resistance to corrosion processes;

- cast iron boilers are less susceptible to acids and resins.

Nuances of fuel choice

The efficiency of the pyrolysis boiler largely depends on the type of fuel used. In general, such raw materials of organic origin are suitable for it:

- firewood;

- coal;

- pellets;

- peat;

- waste wood processing.

The loading of sawdust and shavings is unacceptable due to the contradiction of the very name of the boiler "on solid fuel". The use of these materials will not ensure the release of pyrolysis gas due to instantaneous combustion. The best option is wood, the combustion of which is accompanied by the formation of large volumes of gas, exceeding all other sources. As mentioned above, a high efficiency of a pyrolysis-type boiler is possible if dry fuel is loaded.

An analysis of the cost of thermal energy sources identified the leaders: among them are pellets and wood pellets. Both types represent the result of woodworking and have a low cost. However, fine-grained material is recommended to be used in combination with firewood.

Remark ! Pyrolysis boilers operating exclusively on pellets are characterized by lower efficiency compared to wood-fired units. The same can be said about coal pyrolysis boilers.

The minimum fuel size for a gas generating boiler is 7-10 cm in transverse measurement. The use of wood chips or sawdust is allowed in volumes not exceeding ¼ of the mass of all solid fuel.

Advantages and disadvantages

The improvement of solid fuel boilers provided pyrolysis units with a number of advantages, among which it should be noted:

- Subject to the operating conditions, the efficiency of the boiler is 85-90%. This is achieved by burning solid fuel without residue.

- The need to load firewood occurs twice a day. When operating the pyrolysis boiler at partial capacity, the process can be reduced to a one-time replenishment within 24 hours.

- Adjusting the temperature in the room reduces fuel consumption.

- The interaction of pyrolysis gas with carbon is accompanied by a minimum release of harmful substances. Together with the almost complete combustion of solid fuel in the boiler, this guarantees a low level of atmospheric pollution. In relation to traditional units, it is reduced three times.

- Reducing the number of cleanings of the pyrolysis boiler due to the complete combustion of all wood components.

According to consumer reviews, solid fuel pyrolysis boilers are characterized by certain disadvantages:

- Dependence on the supply of electricity.

- For the most part, pyrolysis boilers are single-circuit units, therefore, they perform the only function of heating the room. To organize the process of heating water, you should take care of the installation additional equipment, which is accompanied by new material costs.

- The cost of a pyrolysis-type solid fuel apparatus is higher than the price of a traditional solid fuel boiler. However, due to the economical consumption of raw materials, this item of expenditure is successfully covered in the future.

- Despite the automatic adjustment of the heating process, the loading of solid fuel into the pyrolysis boiler is carried out manually. This procedure gives consumers certain inconvenience due to the systematic control over the consumption of raw materials.

When choosing among the many models of pyrolysis boilers, keep in mind that units operating exclusively on pellets are difficult to maintain, and therefore require the involvement of service specialists. The cost of all pyrolysis boilers directly depends on the availability and number of technical improvements.

How to choose a pyrolysis solid fuel boiler for long burning?

Russian cities and villages are developing at a rapid pace, but many regions of the whole are still without gas. And if you belong to the owners of a non-gasified living space, you will certainly be interested in a long-burning pyrolysis boiler, which will be discussed in today's article. The information presented here will help you evaluate the effectiveness of the equipment and the rationality of the choice in its favor.

Why is a replacement needed?

How to choose the model you need?

Today, many manufacturers are engaged in the manufacture and sale of pyrolysis boiler equipment, as a result of which the choice of the best modern model becomes a rather difficult task. Buyers from Russia are offered a choice of cheap, inexpensive and expensive (depending on power and configuration) boiler devices of Russian, Belarusian, production, as well as models from companies from Ukraine. In addition, you can find a lot of offers from German, Polish, Lithuanian, Finnish, Czech and other imported manufacturers that produce specialized, industrial, combined and universal equipment. If you wish, you can find boo, home-made models and even drawings for the manufacture of hot water and air heating devices with a chimney with your own hands. But I strongly do not recommend going to such experiments. It is better to read online reviews and ratings to make right choice in favor of one model or another.

Popular manufacturers and models: stropuva, bourgeois k, buderus, bear, dacon, candle, bosh, liepsnele, breneran, prometheus, atmos, bourgeois, motor sich, kmch, wichlacz, snowstorm, blago, zota, geyser, kvr, sas, viadrus , danko, bastion, defro, viessmann, junkers, cordy, smorgon, buleryan, melitopol.

conclusions

As you can see, coal-fired solid fuel stoves have taken a big step forward, as a result of which the process of heating a room has been greatly simplified. The highest ecological and economic characteristics have allowed pyrolysis devices to become the best solution for heating rooms to a certain temperature. You also need to decide how rational it will be to use the appropriate equipment in your heated area. Perhaps it would be better to opt for a water, cast iron gas-generating or pellet boiler (on pellets), which will heat the area with greater efficiency and lower economic costs.

Have you tried living in a house without heating in winter? Not? And you should not do this, because the 21st century is in the yard and our developers do not stand still. They constantly introduce new ideas and design modern heating devices.

Today, the old Russian stove has already been replaced by pyrolysis solid fuel boilers. Although their principle of operation is similar to stove heating, if you get to know it more closely, it has one difference.

A modern solid fuel pyrolysis boiler is capable of burning not only wood, but also the gas released during their combustion. Manufacturers produce a wide range of such equipment, and in order to choose the option that is necessary for your conditions among this variety, you should find out their differences.

Types of heating devices

So, what is meant by the name pyrolysis equipment? Are there any differences between its various models? And what are the advantages and disadvantages of this type technology. In order to find answers to all the questions posed, we return to the essence. Solid fuel pyrolysis boilers are devices that can only work on wood.

Their combustion chamber consists of two parts:

- Boot or gas generator

- Afterburning, where the process of combustion of pyrolysis gases takes place

A flue path is connected to this part of the boiler, in which the heat from the flue gases passes to the coolant, and the waste of the process - soot - also accumulates here. That is why the solid fuel pyrolysis boiler received the second name - gas generator.

We watch the video, the principle of a wood-fired boiler:

This principle was known back in tsarist times, when it was used to illuminate cities. And since this process consists of several phases, and one of them is the process of burning gases, it would be more correct to call the solid fuel pyrolysis boiler - gas generator.

All devices of this type are equipped with thrust switches. Without these devices, the apparatus could work as a direct combustion device, and only after the valve is closed, the pyrolysis process begins to proceed in it.

All devices of this type are equipped with thrust switches. Without these devices, the apparatus could work as a direct combustion device, and only after the valve is closed, the pyrolysis process begins to proceed in it.

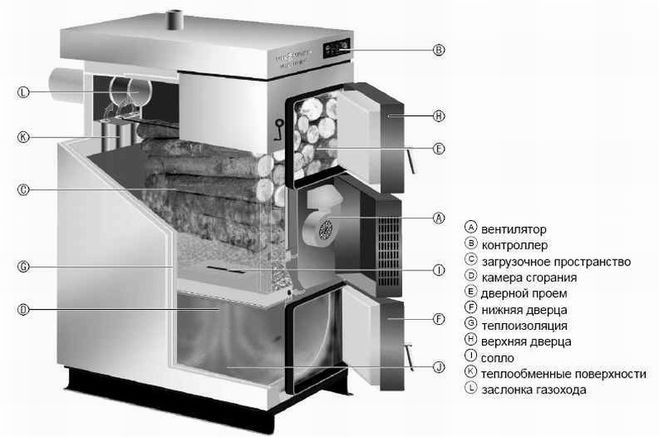

Knowing how it works and design features such equipment, it is worth getting acquainted with it various types. So solid fuel equipment for long burning is divided, depending on the location of the afterburner compartment, into models with:

- Lower

- top chamber

The most widespread are solid fuel pyrolysis heating boilers with top chamber. This is due to the convenient laying of firewood and the possibility of exhaust gases escaping into the chimney located below. However, this design has certain disadvantages. When the firewood burns out, the ash from the primary compartment enters the afterburner, which requires more cleaning.

The coal-fired pyrolysis boiler with an upper compartment, although less common, has advantages over the first model. In it, pyrolysis gas is discharged through nozzles into the afterburner compartment, burns in it and enters the chimney, where it is cooled and then discharged outside. However, in this case, more material is required for the manufacture of the smoke path.

The coal-fired pyrolysis boiler with an upper compartment, although less common, has advantages over the first model. In it, pyrolysis gas is discharged through nozzles into the afterburner compartment, burns in it and enters the chimney, where it is cooled and then discharged outside. However, in this case, more material is required for the manufacture of the smoke path.

There are various models and depending on the type of traction:

- With natural

- With forced

The former do not depend on the supply of electricity and must be equipped with a high chimney. Apparatuses of the second type can be equipped with smoke exhausters and fans, the operation of which is carried out automatically. They are energy dependent, but at the same time have a longer effective burning time.

Gas generating and long burning - comparing the possibilities

Among the heating devices under consideration, two most effective types of devices operating on wood and waste from its processing should be distinguished. We will first consider pyrolysis boilers for long-burning solid fuels. These are one of the most cost-effective devices in this market segment.

Among the heating devices under consideration, two most effective types of devices operating on wood and waste from its processing should be distinguished. We will first consider pyrolysis boilers for long-burning solid fuels. These are one of the most cost-effective devices in this market segment.

They have a specially equipped combustion chamber and a turbine, thanks to the features of which, one bookmark can burn for more than 10 hours. Solid fuel pyrolysis boilers of long burning are equipped with a programmer that allows you to select the heating mode.

Next, the operation of the turbine is automatically controlled, in which a certain amount of air is injected into the chamber, which makes it possible to regulate the combustion process and thereby maintain a certain temperature in the system.

The introduction of this technology made it possible to design boilers with:

- Long burning time

- High economic indicators

Pyrolysis equipment is still relatively young, but has already gained popularity. The solid fuel pyrolysis heating boiler has an operating principle based on gas generation technology or thermal decomposition of wood when it is exposed to high temperatures and a lack of oxygen.

Let's look at the advantages of gas-fired boilers:

And although only well-dried firewood can be used as the main type of fuel in them, they practically do not burn, but gas, the formation of which occurs under the influence of very high temperatures. At the very beginning of the process, wood is burned with the release of pyrolysis gas. The next step is to pass it through the nozzles, mix with secondary air and burn at a high temperature.

When moving through the heat exchanger, the gas gives off part of its heat to the water and is removed through the chimney. This leads to the maximum use of the energy released during combustion and the prolongation of the process itself. But a solid fuel pyrolysis boiler on wood has one drawback - the moisture content of the fuel should not exceed 16%, otherwise the gas generation process will be impossible.

Is the body of the device steel or cast iron?

Most often, a long-burning pyrolysis solid fuel boiler has a steel body. Moreover, the thickness of its sheets should not be less than 5 mm. However, this material is subject to corrosion, which affects the duration of the equipment.

Most often, a long-burning pyrolysis solid fuel boiler has a steel body. Moreover, the thickness of its sheets should not be less than 5 mm. However, this material is subject to corrosion, which affects the duration of the equipment.

Therefore, manufacturers have already developed and produce coal-fired pyrolysis boilers in a cast-iron case, and for those who choose such an apparatus for themselves, before clarifying the issue of the effectiveness of such models, it should be noted that cast iron is one of the most reliable and high-quality materials.

And it is natural that wood pyrolysis boilers made from it have the same qualities. It has significantly higher characteristics such as:

- Heat dissipation

- Durability

- Slight susceptibility to corrosion

- High resistance to resins and acids

Pyrolysis boilers for wood in a cast-iron case have excellent heat dissipation, which means they are more efficient, have a higher efficiency and do their job much better than models in a steel case. And due to the fact that cast iron is less prone to corrosion, the device can operate efficiently with 50% power during the off-season.

Most often, a person who buys a solid fuel pyrolysis boiler is interested in which type of fuel will it work most efficiently on? From a theoretical point of view, any materials of organic origin can be used for it:

- Firewood

- Pellets

- Coal

- Waste from wood processing

However, do not try to look for pyrolysis boilers on sawdust, shavings or other similar materials. best view Their fuel is wood. Although it does not have a high heat transfer, a lot of pyrolysis gas is released during its combustion, and in this indicator it has no equal.

It is only important to remember that it must be dry, only in this case it is possible to achieve high efficiency.

If we compare the types of fuel by cost, then the pyrolysis boiler on pellets or wood pellets is considered the most profitable. They are made from wood waste and have the lowest cost.

If we compare the types of fuel by cost, then the pyrolysis boiler on pellets or wood pellets is considered the most profitable. They are made from wood waste and have the lowest cost.

But they can only be used as an addition to firewood due to the fine fraction. Pyrolysis boilers on pellets are produced today, but they are less efficient than wood-burning ones.

For minimum fuel dimensions should be 70-100mm across. It is possible to use wood chips and sawdust, but again, no more than 25% of the total mass, so when purchasing a pyrolysis boiler, please note that it cannot work only on sawdust.

Solid fuel boiler and others

No matter how touted gas heating, but it has long turned from the cheapest into an unaffordable luxury. It was earlier that entire villages and cities were connected to it, and today they are also looking for an alternative together. Natural gas has risen in price, and the onset of the next winter brings more and more bills to the owners of boilers running on this fuel.

And wood - it was and remains the cheapest type, and the design features that a wood pyrolysis boiler has made it possible to use it very economically, while achieving high equipment efficiency.

And wood - it was and remains the cheapest type, and the design features that a wood pyrolysis boiler has made it possible to use it very economically, while achieving high equipment efficiency.

Some of the modern models of this equipment do not depend on electricity, and the only thing you have to think about is the constant availability of firewood.

There are, of course, also electric models of heating devices. They have many advantages: small size and weight, ease of care and maintenance. But the very high cost of energy and frequent interruptions with it make this equipment also uncompetitive in relation to gas generators.

Liquid fuel devices also lose to pyrolysis ones. Diesel fuel prices are constantly rising, making its use in heating systems unprofitable.

From the point of view of economy and efficiency, solid fuels remain in the first place. And pyrolysis boilers are so far the only ones that can boast not only high efficiency, but also the fact that, unlike other models, they use not only the heat from burning wood, but also the energy released by wood gas.

Summing up

The purchase of a heating device today is at the forefront when equipping a heating system. And if earlier this issue was solved very simply - by purchasing a gas boiler, today an increasing number of consumers are choosing solid fuel models.

The purchase of a heating device today is at the forefront when equipping a heating system. And if earlier this issue was solved very simply - by purchasing a gas boiler, today an increasing number of consumers are choosing solid fuel models.

Among solid fuels, they have the best efficiency. And their only drawback is the sensitivity to fuel moisture. Therefore, you will have to abandon damp and frozen firewood.

But consumers who have bought solid fuel pyrolysis boilers leave extremely positive feedback on the operation of this equipment and provide convincing calculations of their high economic efficiency.

Comparing all existing models of heating devices, considering them specifications, types of fuel used, cost and other aspects of operation, it is safe to say that pyrolysis boilers are the most profitable today. Having bought one for heating a dwelling, garage or bath, you will undoubtedly be satisfied with its work.