Living outside the city is the dream of every city dweller. Peace and quiet, the absence of a large number of cars and people, as well as autonomy in providing communication systems attract many. But it should be noted - really high-quality living conditions in country house can only be ensured by choosing the right equipment for the heating system.

The basis of any heating system is the boiler - it is the choice of such a unit that special attention should be paid. The choice of equipment on the domestic market is simply amazing, heating units with a variety of operating principles are presented. At the same time, against the background of all equipment, heating boilers stand out. long burning on solid fuel with increased productivity, high heat transfer and low cost.

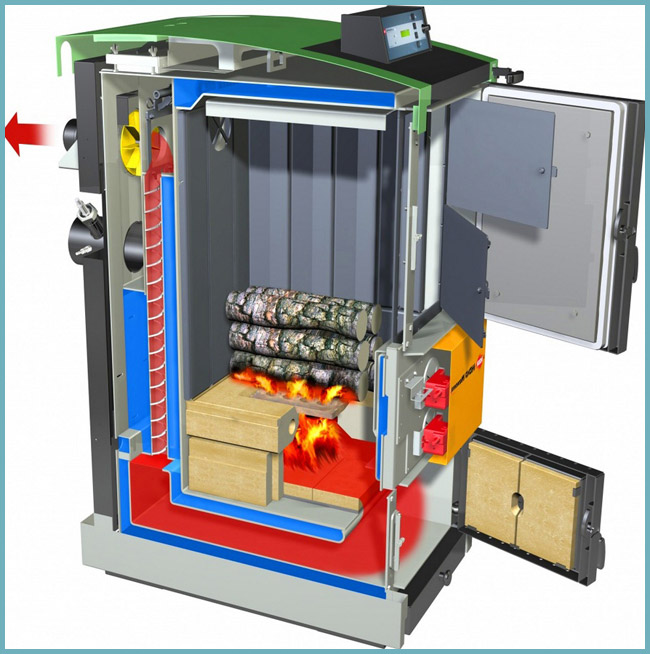

Heat sources of long-term combustion: features, design

Heating boilers for long burning on wood are an absolutely innovative type of heating equipment, reliable and practical devices, the installation of which will provide optimal conditions for living in a house. Using affordable fuel, the cost of which is much lower than the same gas, you can significantly save on heating, maintain the optimum temperature in a house of any size.

Modern units that run on solid fuels and use the principle of long burning work quite simply - the same firewood, coal or peat do not burn, but smolder in the furnace. This process is maximally slowed down, since a limited amount of oxygen enters the combustion chamber.

In addition, when compared with conventional equipment, in specialized boilers, fuel smolders in much larger volumes, which makes it possible to obtain gas with high heat rates.

It should be noted that the gas obtained as a result of the smoldering of the fuel enters the combustion chamber of the boiler under high pressure, where it ignites. The process of combustion of gas occurs under the influence of oxygen. Also, various unburned residues, such as soot or heavy compounds, burn out in the combustion chamber.

Technical characteristics of heat sources

Currently solid fuel boilers long burning on coal, wood, peat is not a problem to acquire. A wide range of all kinds of equipment is presented on the domestic market, differing from each other in performance indicators, outlet temperature and power. In addition, the overall dimensions and weight of the units can be different.

Advice. Solid fuel heating units that run on coal emit a fairly large amount of smoke containing ash and soot. As a result, if the choice fell on such devices, then it is important to ensure the effective operation of the ventilation system.

It should be noted that today for all types of furnace units there is a certain average instruction, indicators and performance characteristics:

- The working pressure of all equipment is about 1 atm;

- The minimum temperature of the water that enters the boiler is 5C;

- The temperature of the coolant at the outlet of the boiler is 80C;

- The average power of heat sources is 100 kW (there are models with large operating power parameters);

- Duration of work from loading one batch solid fuel in the furnace - at least 11 hours;

- Efficiency - not less than 89 percent. Often, for all boilers using the smoldering process, this coefficient is the same, but much also depends on the humidity and type of fuel;

- The temperature of the exhaust gases that go "into the pipe" is not more than 270C.

Read here.

The main types of long-burning boilers

Heating boilers for long-term combustion on wood, coal or peat can be divided into several categories according to the method of obtaining heat:

- classic units. Their principle of operation boils down to the fact that the heat released during the combustion of fuel heats the antifreeze or other coolant of the building's heating system;

- pyrolysis equipment. Absolutely innovative technology is used. The main source of heat is firewood, which, under the influence of high temperatures smoldering (200-800С) decompose into charcoal and gas. The released gas mixes with oxygen and burns, thereby releasing the heat needed to heat the coolant.

The maximum performance of pyrolysis boilers is achieved when they operate on dry wood. Also, in this case, it is possible to provide the highest efficiency (fuel burns completely), good heat transfer performance.

The main advantages of long burning boilers

Modern powerful and reliable solid fuel long-burning heating boilers are equipment that has a lot of advantages. Among the main advantages of heat sources in this category are:

- High performance, good heat transfer;

- Beautiful appearance, a variety of models. Our website presents whole line photo and video devices that can be safely installed in the interior of various premises, including a residential building;

- Easy adjustment combustion process. Each owner of such long-burning equipment, depending on the situation, can regulate the heating temperature and other parameters with his own hands;

- Ability to automate the process. Many boilers are equipped with special control panels and other devices, thanks to which you can both regulate the operation of equipment and signal the occurrence of emergencies;

- Low price of fuel used in machinery. The same firewood, coal or peat at the moment are much cheaper than gas that is familiar to everyone. Yes, and there is no centralized connection to the main gas pipeline - the boilers operate completely autonomously.

Outcome

Heat generator using the principle of long burning - the best choice for a private house or some other object. Such equipment has a very low cost, unique efficiency indicators, they are economical and can work without failures for a long time.

A solid fuel boiler for heating a private house is a modern alternative to traditional heating methods. With it you will not freeze in the winter at the dacha or in a country cottage. A variety of models will allow you to choose the one that suits you.

Classification of solid fuel boilers for long burning

The main feature of all varieties of such boilers is that they are installed where it is not possible to use other heating, for example, gas. They burn for a long time, up to several days, they heat exclusively due to solid fuel. The principle of their operation is simple and similar to heating with a conventional wood or coal stove: you load fuel into the boiler, it burns, releasing heat. Add raw materials as needed.

Cast iron heating solid fuel boiler

This is the advantageous difference between units designed for long-term burning and other types of solid fuel boilers: they do not need to be loaded often, you can not even get up at night. Some varieties do not depend on electricity. This makes them even more convenient for places remote from city life. Taking into account these and other characteristics, the following types of solid fuel boilers are distinguished, involving long-term burning:

What fuel is used:

- firewood;

- coal;

- pellets (granulated wood waste);

- sawdust;

- universal. In such boilers, you can burn almost everything - from coal to waste.

Advice. Do not burn the boiler with gasoline, diesel fuel, kerosene, laminate or chipboard residues, as well as glossy paper (for example, magazines or catalogs): they emit toxic substances.

How fuel is loaded:

- manually;

- automatically.

How it is burned:

- traditionally;

- using pyrolysis (without oxygen access);

- "top down" (top burning).

What are boilers made of?

- steel;

- cast iron.

From a huge number of models, choose the one that is most suitable for your home in terms of area

How many cameras have:

- one;

Their functionality:

- single-circuit, which only heat the room;

- double-circuit, which, in addition to the main function, are also used for heating water.

What are the features of boilers of different types

When choosing a boiler, decide how you will load it. Coal gives off more heat, and burns much longer without additional loading. Firewood is considered the most environmentally friendly fuel. When giving preference to such a boiler, please note: it must have a sufficiently large chamber for the furnace and a wide door. So you can load a lot of large firewood at the same time, which will increase the burning time.

Attention! For the best energy efficiency, use wood with a moisture content of less than 20%.

pellet boiler

Boilers that are heated with pellets are mostly automated. You do not need to load them with raw materials every few hours, the manufacturers have provided a special hopper and mechanized feed for this purpose. Wood pellets burn almost completely, leaving a small amount of ash. However, pellets are not yet widely spread as a type of fuel due to the price, availability in warehouses and the cost of the boilers themselves.

A feature of automated devices is that they require an electrical connection. Without it, automation simply does not work. If there are power outages in your holiday village, it is better to opt for manually loaded boilers. For the convenience of owners, some automated models are equipped with control panels. In particular, they allow you to adjust the frequency of downloads.

Pellet boiler operation

If you choose a universal unit, it is better that the main type of fuel for it is coal. Rugged construction, designed for black or brown "gold", will easily accept any fuel. For comparison - wood boilers, which are mainly made from thin sheets of metal, are not designed to burn coal. Dispose of cardboard, shavings, sawdust, husks in universal solid fuel devices.

Most often, manufacturers produce 2 types of boilers: cast iron and steel. There are also ceramic ones, but they are almost not common. If the heating device is made of cast iron, its service life reaches 50 years. This metal is resistant to rust, but sensitive to temperature changes. Steel boilers are cheaper, but they last about 20 years.

Is there a difference in how the fuel is burned in the boiler

In classical boilers, fuel is ignited from below, and the flame, rising, consistently “eats” everything that was put there. Most often, this is how boilers work, which need to be reloaded every 2-8 hours (depending on the model and type of fuel used). Long-burning devices usually have large volume fireboxes. This is what allows classic models to do without “additives” for as long as possible after loading.

Wood boiler device

There are shaft-type boilers where you need to ignite the fuel at the top, and combustion (or rather, gradual smoldering) also occurs from top to bottom. This innovation had a positive effect on the duration of the work. Without additional laying, firewood burns for about a day, coal - on average up to 6 days. It is impossible to top up or report something until the first load has decayed. Due to the economy and high efficiency, such models are more expensive than traditional ones.

Pyrolysis boiler automatic control device

Another type of boilers according to the method of burning fuel is pyrolysis. In them, firewood, coal or waste is burned under the influence of high temperatures, but without oxygen. Such boilers usually consist of two chambers, raw materials are put into one and set on fire. After a while, the oxygen supply is limited, and the fuel begins to smolder. As a result of this, gas is released (or generated), which enters the second chamber and burns separately. Because of this feature, these boilers are also called gas-generating boilers.

Advantages and disadvantages of solid fuel boilers

The positive properties of long-burning solid fuel devices include:

Among the negative aspects of the operation of solid fuel boilers for long burning, it is worth highlighting both general and those that are characteristic of individual models:

Advice. You can keep the fuel in the boiler room, if its size allows. It is better if the distance between the boiler and the fuel is at least 40 cm.

What else to consider when purchasing a long-burning boiler for a country house

Such boilers may well become not only a replacement for conventional heating, but also be an addition to it. With good care and correct operation they serve for many years without requiring repair and fully recoup the cost of their purchase.

How to choose a solid fuel boiler: video

Boiler for heating: photo

Among all models of solid fuel boilers, long-burning boilers, those that use the principle of upper combustion, have occupied a considerable market niche. Stropuva, SWaG, Buran are the most famous. In addition to them, there are still a lot of small manufacturers and simply clones on the market. famous brands. For reference: the very principle of upper combustion was patented in Lithuania by the manufacturer of solid fuel boilers Stropuva. A lot has been written about the advantages of these boilers on the Internet. You can easily go to the website of any online store and read about all the advantages of this type of combustion and the boilers themselves, but there is another side to the coin - the disadvantages of long-burning solid fuel boilers.

The easiest way that the average layman goes when choosing a solid fuel boiler is typing: long-burning solid fuel boiler reviews, in the browser and, of course, first of all runs into manufacturers' websites. (A low bow to the team of those who support these sites and follow their positions). Following are the forums where the happy owners of solid fuel boilers communicate, discuss, complain, boast, swear, in general, create a certain information background, which forms an opinion, based on which the consumer will decide whether to buy a long-burning boiler or not. In principle, this is the correct approach, but it should be borne in mind that this is information from the lips of non-professionals, and their conclusions are made on the basis of a single boiler - which is in their home.

And that is why, for those who are going to buy a long-burning solid fuel boiler, I have collected in one place the most Full description all his shortcomings.

BURN TIME

There is information on the websites of manufacturers: A long-burning boiler ensures the duration of burning on one tab: firewood - up to 36 hours, briquettes - up to 2 days, coal - up to 5 days.

On the websites of selling stores, I managed to find data that the boiler can burn up to 30 days !!!.

And do not think that I am inventing, try it yourself - you will find.

In reality, a long-burning solid fuel boiler burns for the time stated by the manufacturer only if the boiler itself is twice as long as necessary, that is, a forty is needed for a house of 200 meters, the house itself is perfectly insulated, and the heating system is properly wired, which is extremely rare. In order to achieve such a burning time, it is necessary that the fuel in the boiler smolder, and not burn, and at the same time the required temperature is in the coolant - and this can only be achieved if the boiler has more power than necessary. The records, twenty when heating a house of 200 square meters, which I personally observed, are 12 hours on wood and 48 on coal. It was not possible to stretch it longer, because it was necessary to lower the temperature, and this parameter has a limit - 55 degrees. If it is lower, then the three-way valve closes and the coolant circulates along a small circuit, without even getting into the system, the boiler heats itself. (By the way, there are several more connection options, and one of them is through a hydraulic arrow, as for me it is better, because there is no this threshold of 55 degrees and at the same time that mold is not formed, from which the boilers are saved by three-way and four-way valves. But I will write about tying solid fuel boilers separately)

Off-topic: This “to” was always annoying - up to 3 days, up to 100 mbit, up to, up to ... It would be more correct to write “from”, but who would go for it.

POSSIBILITY TO MAINTAIN THE COMBUSTION TEMPERATURE WITH THE HELP OF A BIMETALLIC REGULATOR

The manufacturer claims that, subject to the use of the same type of fuel, adjustment should be carried out no more than once a season.

In fact, this draft regulator behaves disgustingly. The range in which it can maintain the temperature of the coolant will fluctuate within 20 degrees, so you will not be able to adjust exactly 65 degrees. There will be 55 and 75. This damper reacts to everything - to air humidity, and to pressure, and God knows what else, it is extremely difficult to set it up as we would like - to be honest. (By the way, there is a solution to this problem, and it’s quite simple - it’s installing a controller. The entire factory design of the damper is thrown out, a fan mounting adapter is installed, and a circulation pump and a temperature sensor (thermocouple) are switched to the control unit. Voila !!!. All this joy is not worth it many more than a hundred dollars for how much it becomes easier to manage the boiler ... The temperature can be set with an accuracy of 5 degrees, the air is either forced, forced and shut off. Well, more on that another time) Yes, and please do not confuse electronic controller a boiler with just a fan, which manufacturers sometimes put on some models. It's just a forced boost and that's it.

THE SOLID FUEL BOILER IS ABLE TO WORK WITHOUT ELECTRICITY.

It is not true. For the operation of any solid fuel boiler, and not just a long-burning boiler, not only in the system, in general, it can be done by gravity, as was done before the advent of household circulation pumps, circulation is also needed on a small circuit, which, as you know, needs to tie all solid tops. But to arrange a gravity flow of the required performance on a small circuit is not possible. Accordingly, there can be no talk of working without electricity. For those who do not know: if you do not bother with small circuits, do not install three-way valves or hydraulic mixers, but embed a solid fuel boiler in a straight line, like a gas one, for example, then due to hit cold water so-called lep, condensate (acid) will form from the system into the boiler’s hydraulic jacket, which will corrode your boiler in a season, not to mention the smell that will be in your furnace.

WHEN OVERHEATED, SOLID FUEL BOILERS ARE FOLDED IN AND THE MANUFACTURER DOES NOT REPLACE THEM UNDER WARRANTY

But this is the truth. And in this case, I am completely on the side of the manufacturer. How can the boiler warranty be extended after overheating? Operating conditions are grossly violated. On the forums that I mentioned earlier, sometimes there are dissatisfied people who claim with foam at the mouth that there was no overheating !!!, but this is not true - there was definitely overheating, even if the owner did not see it. A solid fuel boiler of long burning folds inward only in one case - when overheating. This is absolutely accurate. It is not the excess pressure that forms in the hydraulic jacket that folds the boiler, it just exits through the blast valve of the security system. The solid fuel boiler adds up the ability of the metal to expand, and, like everything in nature, it does this in the easiest direction, in this case, inwards.

There can be many reasons for overheating, but in any case, this is not the fault of the manufacturer.

So take care of your boilers and think about the security system. Remember - the normal pressure for a long-burning solid fuel boiler is 1.5 bar., And the maximum allowable coolant temperature is 95 degrees.

COLD BATTERY PERIOD

Yes, there really is such a problem. The fact is that firewood cannot be thrown into this boiler during the combustion process, this is due to the principle of combustion. You need to wait until it burns out completely, and only then load it with fuel again. It is at the moment when the remains burn out and this pause occurs. Depending on the particular details, it can reach one or two hours. It is possible to overcome this only by installing an additional storage capacity, no more.

SOLID FUEL BOILERS OF LONG BURNING HAVE INCOMFORTABLE LOADING DOORS

This is true. Almost all, except for some manufacturers. For such a boiler, they are clearly too small. This is public opinion and I support it. Moreover, literally ten centimeters are missing from the bottom, and then it would be much more convenient to pack it with fuel. But what we have is what we have. This disadvantage can be overcome.

Even these doors are sometimes not airtight. For a natural draft solid fuel boiler, this is generally normal, but for a forced air boiler it is not desirable. At high fan speeds, smoke will seep through the cracks in the doors into the furnace.

The problem is not difficult to solve. There are two places where there can be gaps - this is where the doors fit to the body, where everything is covered with heat-resistant sealant (for some boilers this joint is welded) and somewhere along the perimeter of the cord inserted into the door for sealing. If it seeps where the sealant is, just cover it with the same one, it is on sale - take one that can withstand up to 1500 degrees. (Does not apply to solid fuel boilers where this joint is welded) And if this is a cord, then just buy and insert a new one ( it is not glued there, but tightly inserted), there are a lot of offers on the Internet. Just measure the size. Nothing complicated.

Solid fuel boilers of long burning

Solid fuel boilers of long burning What are solid fuel boilers, and what are the principles of their operation

It would seem that heating a house with solid fuel (wood, coal, peat) will disappear from use in the 21st century. But this statement turned out to be premature: today many more modern houses fueled by these energy sources. Of course, not an old stone stove is used to heat the room, but modern heating boilers on solid fuel.

These heat generators can operate on a different type of energy carrier:

- coal pellets;

- firewood;

- ordinary coal;

- peat pellets.

The principle of operation of a solid fuel boiler is quite simple: any of the above energy carriers is loaded into the furnace compartment of the boiler and ignited. The heat from combustion heats the water, which, circulating through the pipes, heats the house. Such heating boilers for long-burning wood have a number of negative features:

- short burning period (2-8 hours);

- the need to remove the ashes;

- the need to regularly throw new portions of the energy carrier into the furnace.

- low efficiency.

It was possible to get rid of these shortcomings with the development of fundamentally new solid fuel heat generators, which are long-burning solid fuel boilers. They are divided into two types:

- pyrolysis;

- upper combustion boilers.

Pyrolysis solid fuel boilers of long burning

The mechanism of operation of the pyrolysis boiler is based on the principle of splitting the energy carrier into pyrolysis gas and coke. This problem is solved with the help of a low burning rate of fuel, which, in fact, does not burn, but smolders. As a result of this smoldering, pyrolysis gas is formed, which burns when combined with air.

A long-burning pyrolysis boiler on wood or any other solid energy carrier structurally consists of two chambers: in the first, the fuel itself is split, and in the second, the pyrolysis gas is burned. In such a unit, the combustion process is under the control of automation: to increase the intensity of combustion, the system slightly opens the damper of the combustion chamber, letting more oxygen into it, and to reduce the temperature, it closes it.

Pyrolysis gas generators have a number of advantages:

- high efficiency of burning the energy carrier (there is a minimum of waste);

- long period of work without reloading;

- environmental friendliness (it emits a minimum of harmful gases that undergo thorough filtration);

- high reliability.

Pyrolysis units, due to the fact that they consist mainly of mechanical elements, are extremely easy to operate. If you want to install a long-burning boiler with your own hands, then this version of the heat generator is optimal.

But pyrolysis models also have certain disadvantages. They work on forced draft, so they depend on uninterrupted power supply. The fuel loaded into the pyrolysis boiler must be absolutely dry, and its volume in the furnace must comply with the requirements of the heat generator manufacturer.

Upper combustion boilers

The burning of fuel in conventional boilers and furnaces of fireplaces and stoves occurs from the bottom up, which is explained by the physics of combustion. But such a scheme is not always effective, since the burning rate is too high, which is why not all materials completely burn out. This disadvantage has been eliminated in top burning boilers, where the fuel burns out gradually from top to bottom.

This mechanism has been implemented thanks to design feature heat generators. They do not provide a grate and an ash pan. In the pan there are no elements that support combustion at all.

The fuel burns out when there is a shortage of oxygen, which is supplied to the combustion chamber through movable nozzles, and the oxygen supply volumes are controlled by automation. The fuel in the chamber burns out layer by layer, due to which such equipment demonstrates a number of advantages:

- high efficiency;

- minimum volume of waste (ash);

- minimum flow fuel;

- environmental friendliness (minimum amount of harmful emissions).

This type of long-burning solid fuel boiler is also equipped with automation that controls the intensity of combustion by limiting or increasing the supply of oxygen to the chamber.

The average power of such equipment is 6 kW, which is enough to heat a small house. Ease of maintenance is the main advantage of upper combustion boilers: you only need to load about 50 kg of firewood or other energy carrier into the furnace, after which you can forget about the existence of the boiler for the next 30 hours.

How to choose a solid fuel boiler for long burning

If you have decided on the type of device, then in order to buy a long-burning boiler that would best meet your requirements, you need to find out a number of nuances:

- the volume of the heated room;

- average temperature in the room;

- the level of thermal insulation of the house;

- type of solid fuel.

Power Selection

In order for the boiler to provide a comfortable temperature in the house, it is important to choose a unit of optimal power. This parameter is calculated by the formula P=S/10, where P is the power of the heat generator, and S is the area of the heated room.

By the volume of the chamber and the type of its loading

When choosing equipment, an important role is played by the volume of the combustion chamber and the way it is loaded. Since this criterion affects the main labor costs when using the boiler. It is better to give preference to units with large chambers, which are fed from above. This arrangement allows you to fully load the boiler with combustible material and reduce the time between procedures.

According to the material of the heat exchanger

The transfer of combustion energy to the coolant (water) occurs through a heat exchanger; in such devices it can be of two types - cast iron and steel.

- The first option has a long service life (30 years), but is afraid of temperature changes and hard water.

- And the second requires regular cleaning, but is resistant to sudden changes in temperature and chemical composition coolant. The time of its operation is 2 times less than cast iron.

Professional consultants who work in specialized stores of heating equipment will help you decide among the many technical parameters.

If the price is a determining parameter when choosing equipment, then it makes sense to pay attention to a domestic-made long-burning boiler. Russian models are distinguished not only by an attractive price, but also by high reliability.

Outcome

Having acquired a long-burning solid fuel boiler, you are guaranteed to provide your home with uninterrupted heat supply, the cost of which will not be too burdensome for the family budget.

Which solid fuel boiler for heating a private house should be preferred? We understand the features, pros and cons of modern long-burning heating units.

Frequent loading of the firebox is the main disadvantage of classic solid fuel heat sources. The fuel in them burns out quickly enough, and the generated heat is not enough for a short time. Modern long-burning boilers, which increase the process of burning solid fuel material tenfold, allow solving the problem.

Long-burning heating boiler for a private house

Highly efficient heating units make the most of the thermal energy released by the fuel during combustion, therefore they are ideal for heating private houses, as well as industrial premises.

The market for solid fuel boilers for long burning is quite extensive - the range includes models from the simplest to the most adapted to the interests of the user.

All units of this type work effectively even at minimum power, demonstrating a difference in the amount of accumulated heat in comparison with classical boilers by approximately 10 times

Heating boiler for wood

A suitable heat source is selected taking into account the following factors:

- what type of fuel will be used (coal, firewood, peat briquettes, waste from wood processing and similar solid combustible substances);

- what type of boiler is needed (simple, combined or universal);

- how much big square will be heated;

- how often fuel will be loaded;

- what budget is planned for the purchase of the boiler.

Principle of operation

According to the principle of operation, the installations are divided into two types:

- operating according to the classical scheme with the inclusion of a blower-fan;

- models with top loading and air supply.

![]()

Heating system of a private house with a boiler

In both of these options, the operation of the blower is controlled by a special electronic unit - it controls the temperature of the water, increasing or slowing down the performance of the fan. In units with a supercharger, a decrease in the inertia of the processes is provided, due to which the duration of the combustion of solid fuel increases.

In models with top loading, respectively, the supercharger is located in the upper part of the case. Air is supplied from top to bottom, fuel is burned in a similar direction, as a result, a fully charged installation is able to operate for a very long time (from 8 to 48 hours).

In general, long-burning units have a lot of advantages, but there are also some disadvantages. Regardless of the principle of operation, they must be cleaned from time to time - if cleaning is neglected, the equipment may simply fail.

Scheme: long-burning boiler device

At full power, the boiler equipment does not heat up immediately, but after a certain time. Another disadvantage is that it is impossible to quickly stop the operation of a long-burning boiler if necessary.

Differences in the type of solid fuel used: what to consider when choosing

Between themselves, long-burning boilers differ not only in the principle of operation, but also in the type of fuel used. Each of the heating units operating on a solid type of fuel has its own advantages and disadvantages, which should be considered when choosing.

wood burning boiler

The most important thing when choosing this model is the volume of the firebox itself for laying firewood, which will fit in it with one load. The larger the capacity of the firebox, the longer the firewood will burn.

Wood boiler for heating

coal boiler

If coal is used as a fuel, first of all, you should pay attention to the material of manufacture when choosing a suitable model. It is better to give preference to structures made of cast iron or stainless steel.

The wall thickness of the furnace also plays an important role, since the temperature will be very high when burning coal. It is recommended to choose a model with the thickest walls, which will keep warm for a long time.

Coal boiler for heating

pellet boiler

This type of boilers is able to work offline for the longest period of time, therefore it is very popular with consumers. Its time battery life directly depends on the size of the hopper - the tank can hold from a minimum of 20 kg to several tons of granules. Therefore, it is rational to choose models with a capacious bunker in order to reduce the number of fuel tabs.

- high efficiency;

- profitability;

- automatic control (in the presence of electricity, the equipment independently pours fuel into the furnace using an auger);

- there is no need for frequent cleaning, since the fuel burns out almost completely.

pellet boiler

- rather high cost;

- energy dependence;

- fuel required High Quality(whole low-ash pellets), otherwise the burner will clog very quickly.

pyrolysis boiler

The operation of the pyrolysis boiler occurs by distillation of fuel at elevated temperatures with a limited supply of oxygen, contributing to the decomposition of wood into the so-called pyrolysis gas. Pyrolysis-type boilers have two furnaces, in one of which the primary combustion of fuel is carried out, and in the second - gas afterburning.

pyrolysis boiler

- requires high quality solid fuel;

- high price.

Types of pyrolysis boilers for long burning