The appearance of the house is the first thing that an outsider draws attention to; competent finishing of the facade with wood will allow you to qualitatively transform it. Properly performed installation will not only improve the appearance of the facade, but also increase its service life.

Popularity of exterior wood finishes

Finishing the facade of the house with wood is one of the most common options for exterior decoration of the walls of the building. The growing popularity of natural materials is evidenced by a wide list of proposals from manufacturing companies, because if there is no demand, there will be no supply. In addition, every year natural finishing material made of wood is increasingly found in cottages and country private houses.

A wooden house finished with natural materials looks very respectable, elegant and stylish. Finishing the facade will allow you to hide uneven surfaces, correctly highlight the corners and decorative elements, and also allow you to make the appearance in a peculiar antique style.

Except decorative features, wood cladding will give additional protection to the facade and the entire building from the adverse effects of harmful atmospheric conditions.

Finishing Features

Despite the fact that the tree has a very strong fiber structure, the materials made from it are subject to the damaging effects of the environment. That's why, wood trim buildings should be subject to special treatment, which will increase its service life and maintain a respectable appearance.

It's important to know

Treatment of wooden walls with antiseptic materials should be carried out periodically. If this is not done, the wood material will lose the appropriate protection and after a while will begin to break down.

Hinged finish

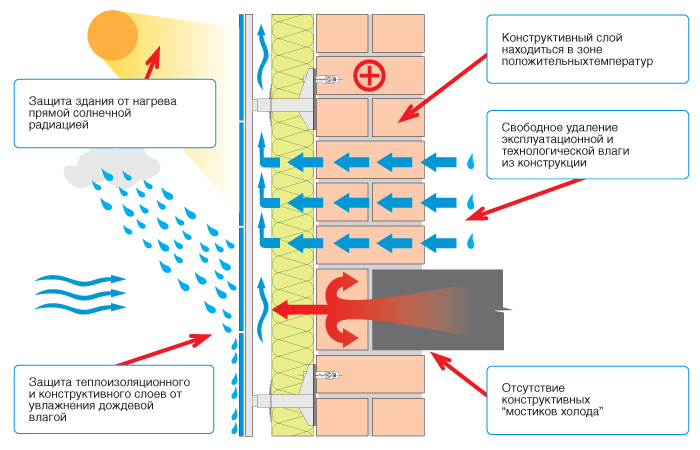

The device of the so-called ventilated facades is The best way for finishing any walls of a building, regardless of the material from which the facade is made: wood, brick or stone. At the same time, such structures perform several functions:

- Strengthen the strength of the bearing wall of the building;

- Perform a high-quality decorative function;

- They create a warm environment for the premises.

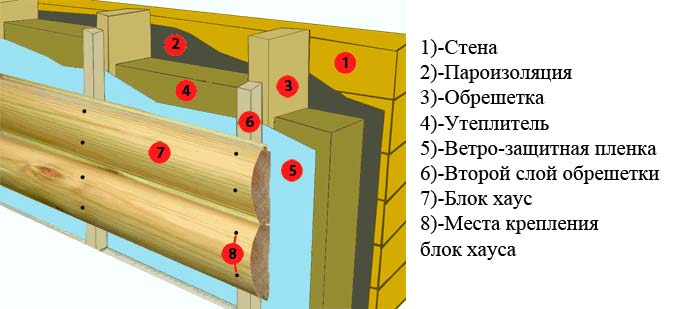

Installation of a ventilated facade

Brackets for the crate are mounted on the walls of the building, then the insulation is fixed. A crate made of a metal profile or timber is fixed to the fasteners. Their thickness, in this case, determines the size of the air cushion of the system. This is what ensures the ventilation of the wooden facade. To ensure high-quality air movement during the finishing of private houses, it is recommended to leave additional eyelets at the top and bottom.

A special membrane is attached to the prepared crate, which will protect the heat-insulating material from the ingress of condensate that forms on the surface of the facade.

When fixing the membrane, pay attention to the correct position of the roll. The absorbent side must be attached to the wall of the house. Incorrect installation will lead to the destruction of the insulation layer and further repair of the entire system.

Wooden finishing material is attached to the crate using special fasteners, depending on the design of a particular product.

Material types

Natural wood products are a unique finishing material that allows you to get unlimited opportunities for implementation. design ideas. Depending on the choice of a specific type of material, you can give the house a kind of unforgettable design.

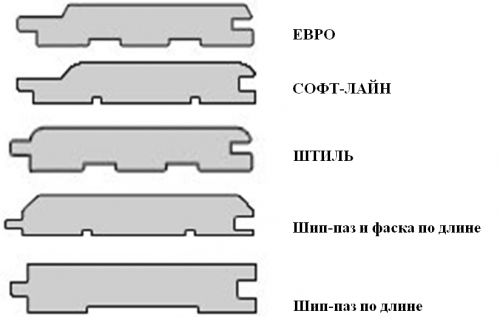

Eurolining

Sheathing a house with wood imitation timber or ordinary eurolining allows you to create the effect that the house is completely made of this wood material. The cladding work can be done independently, since the boards are interconnected by a tongue-and-groove system. Exterior finish This material compares favorably with the low weight of the structure and the creation of a high-quality microclimate inside the premises.

Block house

This term refers to a wooden finishing material that imitates a natural rounded log. The advantage of its use lies in the construction of a homogeneous facade, almost indistinguishable from the real material. Installation is carried out in the same way as eurolining, using the tenon-groove fastening method. The location of the boards is made horizontally to the ground.

The vertical arrangement of the boards is possible only for interior decoration.

A distinctive feature of the material is its design. The board consists of two elements glued together. This reduces the stress of the material, and ensures that there is no deformation on the walls of the building.

HPL panels

Decorative cladding panels made by pressing pigmented cellulose and calibrated wood fibers impregnated with heat shrink resins. For its production, high temperature and pressing are used, under the influence of which reinforced, durable finishing sheets with a specific pattern are obtained.

The advantage of using it over other materials that include a wooden base is its high resistance to physical damage, environmental influences, as well as easy cleaning and maintenance. Durability is guaranteed by the features of production.

HPL panels are lighter than other natural finishing materials, which has a positive effect on their choice when finishing large volumes. A wide selection of color shades and textures that are offered on today's market allow us to talk about a kind of originality. Another advantage is the final finish: after finishing, no additional processing of these materials is required.

Facade varnish

After completion of the installation process, it is recommended to treat the wooden facade with varnish. In most cases, it is alkyd or polyurethane, but in some cases other types are used. It is advisable to use varnish for these purposes, which contains antiseptic fillers. They will prevent the formation of mold or fungus and the appearance of insects in the wood.

useful at work

Yacht varnish has all the listed characteristics.

Oil

With a large amount of upcoming work, you can use oil varnish. This will save money, besides, it serves as a good protection for wooden facades. Distinctive features This varnish can be called resistance to sunlight and immunity to temperature changes and the effects of precipitation and moisture.

Alkyd

In order to protect the wooden facade from cracking, it is recommended to treat it with alkyd varnish. The advantage of its use is its resistance to the negative effects of the environment.

Water based

Such varnish can be called the most environmentally friendly. Its use does not entail any negative consequences for the human body, and the wooden surface will receive good protection against mechanical damage. When performing finishing work using such varnishes, it is worth considering the temperature and humidity of the environment. Even small deviations from the temperature recommended by the manufacturer can affect the time and quality of the absorption of the varnish.

Advice from the "facade"

External decoration of the walls of the house with natural wood is a very serious issue, which should be taken into account with all the nuances. Therefore, when buying finishing materials, you need to carefully weigh all the pros and cons of this event.

The facade is the visiting card of the house, its face. Modern cladding made of plastic, stone, brick or colored plaster, of course, has its advantages, but wood facade decoration gives the house a special charm and warmth.

The price of a good wooden log house is quite high, therefore, at present, people prefer to veneer only the facade. Moreover, the installation instructions for most types of natural wood finishes are quite simple and it is quite possible to do the work yourself. We will talk about the types of cladding, wood species and the intricacies of installation.

Why is the tree

- Modern man is tired of the look of the "stone jungle", he wants warmth and home comfort, and wooden house classically represents reliability and prosperity.

- Wood harmonizes perfectly with any finishing material, so designers willingly use both wood veneer and in combination with stone, plaster, brick or metal.

- From a purely practical point of view, such a cladding well hides defects in load-bearing walls.

- Under the cladding, it is convenient to mount additional insulation at home.

- And finally good protection buildings from bad weather.

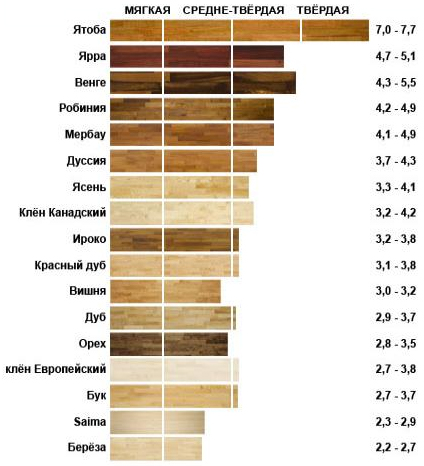

What wood to use

Tip: do not immediately chase exotic, take a closer look at the traditional wood species for your area.

Because experts are well aware of how traditional breeds will behave in your climate zone, and exotic, despite the high price, can fail.

- Pine is a soft wood that is easy to work with. It is especially good for a humid climate, in conifers. great content resins, which leads to resistance to decay and a small percentage of drying out.

- Cedar - has a light yellow color with a reddish tint, has all the advantages of coniferous varieties, but is more durable. Canadian cedar is especially valued in this niche.

- Oak - traditionally refers to the elite species of wood. It has unique strength and durability, perfectly behaves in most of our vast country. Has a wide color scheme, from dark brown bog oak to light golden oak.

- Beech is a flexible and durable tree white color with a reddish or yellow tint. Has a uniform texture.

- Larch is a yellowish-red wood with fairly high strength and unique durability. Our ancestors often built wooden temples from larch. Depending on the orientation to the cardinal points, this wood can change color over time to black-brown or gray with a silvery tint.

More recently, thermo-modified wood has appeared, it is a product of new technologies. under great pressure and high temperature wood is processed on special equipment. The result is an environmentally friendly, very strong and durable material that is not afraid of pests and does not rot.

Subtleties of finishing

General installation rules

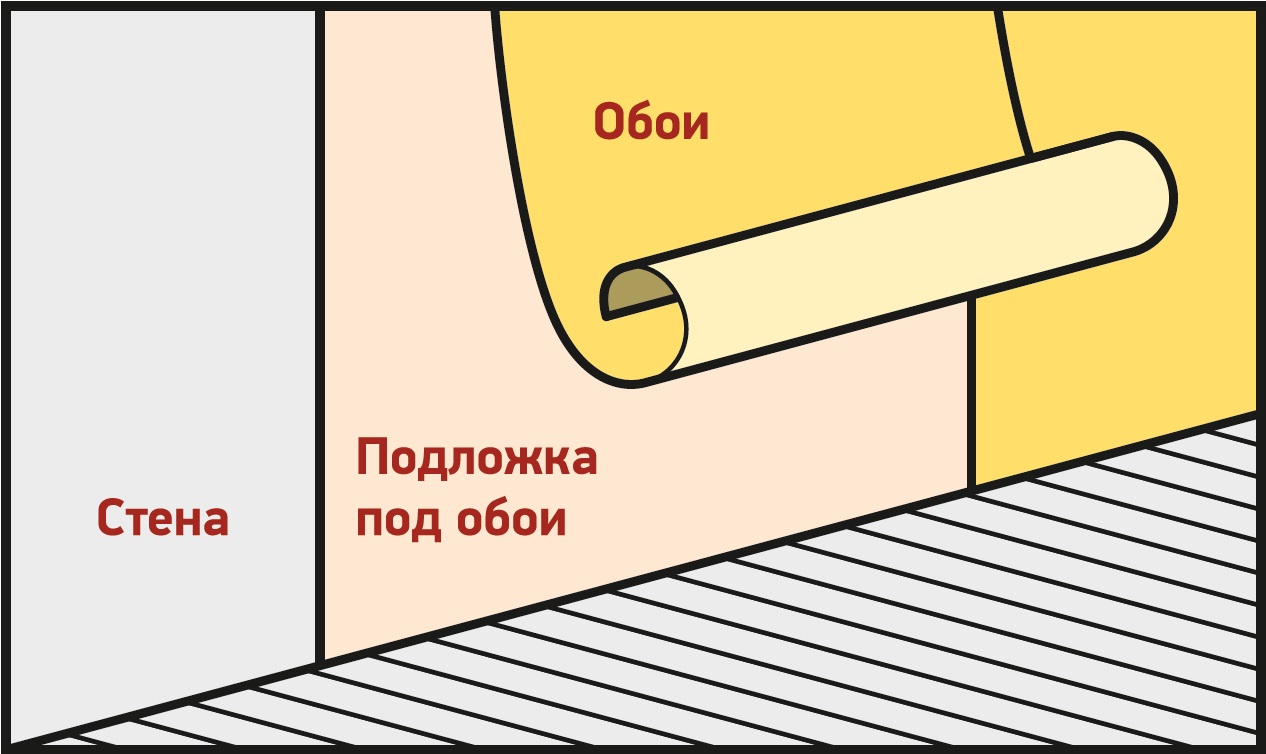

Both natural wood trim and wood-look facade trim are traditionally mounted on a frame.

For each individual material, the size of the frame and the cross section of the beam may be different, but general rules installations are similar.

- Initially, the load-bearing walls are covered with soil, after which a vapor barrier is mounted on them.

Important: pay attention to the laying of the vapor barrier, it should be located so that steam penetrates from the house towards the street, and the penetration of steam into the house is blocked.

Otherwise, moisture will be trapped in the walls, resulting in dampness.

- A primary crate is stuffed over the vapor barrier for the installation of insulation. As a rule, the cross section of the beam is selected according to the thickness of the insulation, but taking into account the fact that a counter-batten with a lining will be mounted on it.

- You can use metal profiles for this purpose, but the installation of a metal crate requires some professional knowledge, so we advise amateurs, when installing with their own hands, to use a wooden beam, it is much easier to work with it. The timber should be treated with a water-repellent antiseptic, for example, using engine oil.

- The insulation is placed between the guides of the crate and fastened with plastic dowels with wide caps, umbrellas. On top of the insulation, if a cotton wool insulation is used, another layer of vapor barrier is mounted, plus a wind protection.

- A counter-batten is stuffed onto the primary crate with insulation. The thickness of the beam for it is taken in the region of 20 - 30 mm. This crate is needed to ensure good ventilation of the facade and fastening of the cladding.

- This installation principle is called a ventilated facade by professionals. With its help, not only facades are finished with wood, but also cladding with most PVC panel materials, siding, MDF, etc.

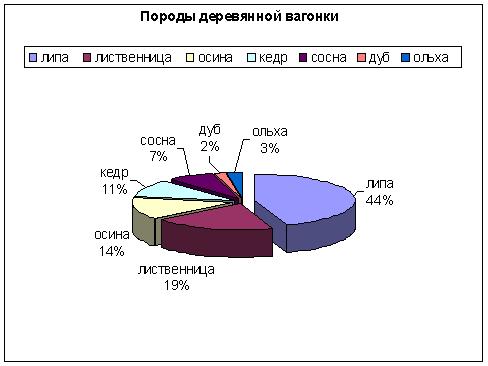

The use of lining

- material, it is a flat, planed boards. Relatively recently, the term euro lining appeared, it is distinguished by the presence of a tenon-groove connection. It is much more convenient to work with such material, for this reason the vast majority of craftsmen work with it.

- Finishing wooden houses clapboard facades are very popular, since this type of cladding is the lightest, it loads the foundation and walls the least. In addition, if the walls of a wooden house are well caulked or already have insulation, the lining can be mounted directly on the wall, since it already has grooves for ventilation on the back side.

- Planks are fastened with special metal brackets called kleimers. Kleimers are fixed with special nails or self-tapping screws. You can also fasten with a galvanized nail, but the nail will be noticeable and not every owner likes it.

There are several commercial types of lining.

- Premium or extra class, is considered the highest quality. The material is completely free of knots, well dried and calibrated.

- And the class also has a high degree of processing, but here 1-2 knots are allowed per 150 mm of the surface.

- The class is already quite different from the previous 2. The number of knots is not limited on it, the presence of resin pockets and cracks is also allowed.

- C class, it is considered a technical material and is practically not used in the decoration of houses.

For exterior or interior decoration of the house, it is customary to use only "Extra" or A-class. It is recommended to treat the material immediately before installation with an antiseptic and a coloring composition.

Important: any type of wooden cladding material that has a tenon-groove connection is mounted with the tenon up when mounted horizontally.

So that atmospheric precipitation or random debris does not fall into the groove.

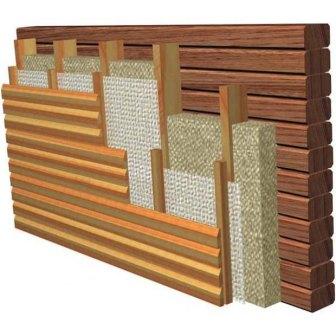

Block house

- Currently one of the most popular materials. The front side of the plank is made like a rounded log, the back side is flat. This allows you to emit a solid log house with 100% certainty. Planks are also connected according to the tenon-groove principle.

- The moisture content of the material is in the range of 12 - 15%. As a rule, it goes on sale already impregnated with a water-repellent antiseptic. As a result, less time is spent on finishing.

- Some craftsmen prefer to fasten the Block House with galvanized nails or self-tapping screws, explaining this by the large weight of the plank. But if the counter-batten is stuffed more often and fixed on each guide with a clamp, this will be quite enough.

wood siding

- By analogy with, it is produced in the form of long wide slats.

This material is of 2 types.- It is glued together by means of a toothed spike from several segments.

- Monolithic planed board of a certain profile.

- The word "siding" itself is translated as lining the wall with an overlap. The installation principle is simple, the bar is fixed in the upper part, and its lower part closes the attachment point of the previous bar.

- Installation is carried out on a vertical crate, preferably with insulation. The positive side here is that with such installation it is quite simple to carry out fragmentary surface repairs.

Wooden panels

- This type of cladding can be called the youngest. Although the panels themselves are assembled from natural wood, the assembly is carried out using special adhesives and varnishes, according to a certain technology. Thanks to this, the panels keep their shape well, do not dry out, do not get wet, and, according to manufacturers, are very durable.

- They can be assembled from individual planks or plywood, glued together using the layering method. This is very convenient, since ordinary lumber can be laid inside this cake, and expensive varieties of veneer can be put on top, as a result we get a beautiful appearance.

- Installation of panels is carried out only on a crate with a ventilated gap. The panels are connected according to the tenon-groove principle. Fixed with clamps.

Please note that unlike clapboard, wood siding, block house or wood shingles, panels should be mounted from top to bottom.

Conclusion

In this article, we talked only about those natural wood finishing materials that, in our opinion, can be made by hand without any fundamental knowledge or extensive experience.

The video in this article shows a wood finish option.

For every owner of a private house, it is important that his building looks good not only inside the room, but also outside. They want the exterior of the building to be pleasing to the eye and devote just as much time and effort to exterior work.

To finish the facade of the house today, manufacturers offer a large number of different materials.

All of them differ in quality and price, but in order to get the desired result, it is necessary to take into account all the wishes and stop your choice specifically on one type.

Only in this case, the decoration of the facade of the house with wood will be correctly combined with the environment and suit the owner of the house according to color, quality and financial criteria.

Wood cladding materials

At the beginning of work, it is necessary to decide on the material with which the outer part of the building will be clad. The choice in this area is quite wide: lining, block house, facade board, wooden siding - all this can be easily found in free sale, you just need to decide on the purchase of material.

Facade decoration with wood is a very common type of facing work. And as a rule, lining is most often used. This material is a processed board, along the edges of which a groove and a spike are cut out for the convenience of connecting the panels to each other.

This is due to the fact that such material is suitable for the price of almost everyone, and the installation of such panels is quite simple, which makes it possible to do this work even on your own, without resorting to the services of craftsmen.

Another positive quality of this facing material is that the lining during installation does not carry a large load on the design of the facade and the building as a whole. Finishing a house under a tree has been carried out with such material for a long time and is in demand today.

For facade cladding, more than modern materials, such as "lumber imitation". This is a type of sheathing that, during installation, copies a wooden beam. This product is in many ways similar to lining, but has its own distinctive features.

First of all, the installation of this material is not carried out in a vertical position, like lining panels, but is mounted horizontally.

Imitation of timber is used mainly for finishing brick buildings, which entails additional work on the insulation of the structure.

Based on this, under this type of finish, it is necessary to install a crate so that when installing the imitation timber panels, a layer of thermal insulation is settled. The panels are connected to each other with the help of spikes and grooves, similar to working with lining.

A novelty material for finishing houses is a block house. It was created specifically for finishing works on building facades.

This facing material is made by drying the wood in special chambers until almost all moisture is released.

The problem of rotting wood is eliminated, and the strength of the material is increased. The shape of the block house panel has a semi-oval profile in section, which gives the lined surface a beautiful aesthetic appearance.

The positive qualities of this material include the fact that it can be repaired. Large scratches are easily removed by sanding with sandpaper. Finishing a house under a tree with such material takes place quickly and efficiently.

Wood siding is also widely used. This material is made by pressing chips and adding a composition of binders. This type of facing material is used on houses with increased fire safety.

Because the composition of this type of siding includes flammable components. It is worth noting the ease of installation on the facades of this material.

What are the advantages of finishing the facade with wood? Wood-clad façades or complete houses are of exceptional beauty.

When choosing a material, home owners pay attention to the texture of wood, which gives originality to each building individually. Material such as wood is environmentally friendly, which makes it possible to once again take care of your health.

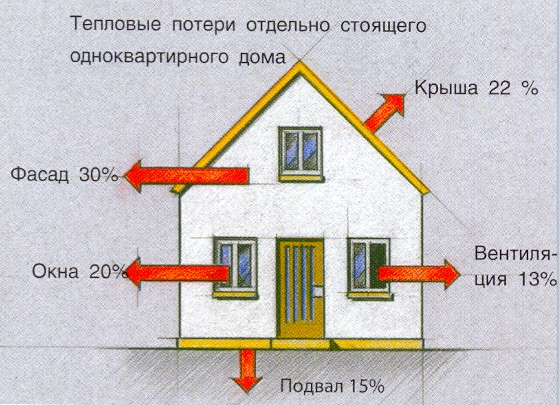

Finishing the house under a tree is an aesthetic appearance of the building and serves as additional thermal insulation, which reduces the cost of heating the house.

The advantage of wood finishing is the protection of the building. Due to the different temperatures indoors and outdoors, condensation forms on the walls, which has a destructive effect.

Thanks to this lining, the formation of condensate is excluded. This is due to the fact that the tree has the ability to "breathe" and pass air.

One of the techniques that are used in wood cladding is the decoration of the building of the house with shingles (wooden tiles). This allows you to bring in good view even the most neglected house. Also shingles gives warmth and durability.

Disadvantages of finishing buildings with wood panels

Wood materials, in addition to being breathable, can absorb moisture. This negative property of wood is called hygroscopicity. Wood can swell, thereby breaking the integrity of the finish.

Another important negative point is that wood is a combustible material. The fire safety of buildings with such cladding should be in the first place.

This property can be eliminated by applying special impregnations, after which the wood will not ignite.

To keep the cladding of the facade of the house in excellent condition, it must be periodically subjected to the application of protective paints and varnishes.

The main enemy of wood is fungus. It negatively affects the structure of the tree, which is destroyed under its influence.

But all of the above properties can be eliminated by processing and proper preparation of the material.

Proper care is the key to the durability of a wooden facade

Wood finishing of any facades will entail some wood care responsibilities. When performing simple actions, such a design will serve for a long time and reliably and delight the owners of the house.

Staining has always been considered the main operation for the protection of wood. Today, the choice of painting materials is presented in a wide range in any hardware store.

If earlier only oil paint was enough for this, today the situation has changed dramatically. So that finishing a house under a tree does not turn out to be a waste of time and money, the cladding must be protected from the effects of all factors that negatively affect it.

For wood to last a long time, it needs to be painted. protective layer. By such an operation they mean coating with varnish or azure.

In order not to spoil the original structure of the wood and paint the panels in different colors, it is necessary to apply an azure coating. But after applying several layers, the structure still disappears, as the layer of azure becomes thicker each time.

When applying varnish, the tree does not lose its original aesthetic appearance. On the contrary, varnish gives nobility to any type of wood, which makes a good impression. Varnish is much easier to use in this type of work, since its application is simpler and easier than that of azure.

According to statistics (and statistics know everything), 40 percent of modern urban families give their preference in housing to a house, not an apartment. At the same time, the option of building your own home, and not secondary housing, is the most attractive. There is a mass different ways how to make a house cladding, but the most common and in demand is the decoration of the facade of a house with a tree. Why?

It all depends on Money that the owner of the house has, on his tastes and preferences. Also, do not lose sight of the main structure, with its bearing walls. Whatever you choose, the result will always please you and those around you. After all, the decoration of the house, as it were, is carried out not only for oneself, but also for relatives, friends, guests and just people passing by, since at first they always pay all attention to the facade of the house.

Ecology comes first

Natural material - wood - is used in in kind, it turns out an environmentally friendly design that is moisture resistant and retains heat well. A guarantee of durability is the facade decoration with wood. wood cladding facade will always give the house elegance and a certain style.

Finishing the facade of the house with wood will create an unusual design look and help hide metal frames and uneven corners. Most often, various blanks made of oak, ash, pine and other trees are used for decorative cladding. From what material the wooden facade decoration will be made, you choose for yourself.

The choice of wood for the facade

Initially, you need to make a choice. It will be correct to use the tree that grows in your area, since you directly know how it behaves under the influence of the environment, how it ages, how it is more profitable to protect and process, in other words, know in advance the service life wooden facade.

Pine, spruce, larch are exactly the types of trees that you should use if decorating the facade of the house with wood is exactly the way you have chosen to decorate your home and protect its outer walls.

Lumber from these types of wood is affordable, easy to process and durable (high resin content), and some types of pine do not crack. It is not for nothing that you can still see churches and houses that were built from these types of trees several centuries ago.

Wooden panels on the facade

Wood paneling is one of the newest ways to clad a house and is only used in Europe and North America. Wooden - these are layers of wood glued in thickness, which eventually form geometric sheets of certain sizes. Thanks to the panels, the house takes on the appearance modern style, and most importantly, the entire building is provided with good ventilation.

Also, having full compliance with wood standards, the cladding can last a long time when the facade is finished with a board, while the reverse side of the cladding must be ventilated.

By impregnating the facade, you protect only from external conditions, but not from internal ones, because any wall of the house, be it a building block, timber or brick, allows water vapor to pass through.

And if there is no ventilation between the wooden facade and the wall, then all the moisture will be absorbed by the wood, and this is already its decay, and as a result, decorating the facade of the house with wood will serve you very little.

Wooden facade protection

Wood is a material that constantly needs additional protection from all weather conditions. Finishing the facade of the house with wood means mandatory impregnation chemicals of this material. Impregnations are of different types.

Salt impregnation

But, unfortunately, after the second painting procedure, the material loses its former appearance. And thanks to modern developments, the decoration of the facade of the house with wood will be saved for a long time. The natural beauty of the wooden façade is preserved by lacquer and azure coating.

When varnished, the wood finish of the facade becomes more expressive, it is easy to apply and protects from external influences. The azure coating also protects and gives the wood different shades and colors.

If you initially take resistant wood for finishing, then you will need to process it much less often, and in order to get the perfect facade, then.

If the facade of the house is finished with wood, then this is a significant increase in sound insulation, a reduction in heating costs, and the design appearance you can always change, thanks to the variety of wood and its shades.

Finishing the facade with wood must be done in positive temperatures (spring-summer) and without rain, so as not to damage the tree and not create additional problems and costs for yourself.

-

Thermal panels with clinker tiles are building material the latest technology. The construction market is obliged to their appearance high level modern technologies. Clinker panels for the facade provide the structure with... -

The range of clinker facade tiles is very wide. Manufacturers offer a wide variety of options for this product. The tile is not inferior in quality to the same brick, although it is much more ... -

Insulation of any room during the construction of a new building or during repair work is an urgent point, on which the further comfort of staying in ... -

Foam concrete blocks are considered to be quite energy-efficient material, and therefore they consider the insulation of foam concrete wall structures to be unnecessary. However, in the winter season, an additional heat-insulating layer does not... -

So, you choose the materials with which the cladding of the facade of the house can be made. What material is better? Photos of different facades with different materials used will help you decide this ...

Any structure, like a living organism, requires constant attention, condition monitoring and regular maintenance. If mistakes were made during the construction of a wooden house, then insulation and finishing of its facade will soon be required. Properly designing the facade, not forgetting about such important things as insulation and waterproofing, you can significantly save on heating the house in the winter and on air conditioning systems: there will be no need to install them. The optimal microclimate in the room will provide a properly arranged facade.

Any structure, like a living organism, requires constant attention, condition monitoring and regular maintenance. If mistakes were made during the construction of a wooden house, then insulation and finishing of its facade will soon be required. Properly designing the facade, not forgetting about such important things as insulation and waterproofing, you can significantly save on heating the house in the winter and on air conditioning systems: there will be no need to install them. The optimal microclimate in the room will provide a properly arranged facade.

The role of finishing the wooden facade

In addition to decorative qualities, which are also important in the decoration of a wooden facade, its competent design provides protection from biological effects, because natural wood is not a durable material. Over time, insects start up in it, which destroy logs, and the walls of a wooden house are also endangered by rodents. In addition, the facade decoration plays an important role, protecting the wooden walls from moisture. Moisture emanating from rain and snow is absorbed into the tree and exposes it to decay, and the action of modern antiseptics with which it is impregnated is limited in time.

If you do not periodically treat wooden walls with special moisture-repellent mixtures, their effect will cease after a few years.

Finishing the facade relieves the wooden walls from the effects of all negative factors, in addition, the sound insulation in the house increases. The wood itself has poor thermal conductivity, and in combination with insulation, the walls of the house will keep warm even longer in the cold season and keep cool in the summer. The disadvantage of wood is flammability, and since most modern finishing materials are fire resistant, the walls of the house will be reliably protected from fire.

Methods for finishing a wooden facade

For facing the walls of a wooden house, you can use several options for finishing:

"Wet" finish

This type of finish involves applying a layer to the primed walls. To do this, the wall must be relatively flat, made of a frame panel or timber. Very often, when choosing any finish option, it is insulated. The heat-shielding material is attached to the wall with mechanical connectors or glued. A layer of reinforcing mesh is applied to it and only then a finishing decorative coating is applied (painting or decorative plaster).

This method of finishing facades is considered standard and can be used not only on wooden walls.

In addition, this method has long been used in many Western countries, Canada and the United States.

Disadvantages of "wet" finishes:

- Poor vapor permeability. The walls of the house must "breathe" so that condensation does not accumulate in them, but this method of finishing significantly reduces their ability to provide vapor diffusion.

- The insulation must be fixed only on a flat surface, otherwise it loses its ability. Therefore, it will not be possible to do without preliminary alignment of wooden walls.

- The characteristic vibrations of natural wood sooner or later lead to the destruction of the plaster layer.

Hinged systems for finishing a wooden facade

If you carefully consider the option of insulating the walls of a wooden house from the inside, visible flaws can be easily detected:

- Main outer wall in this embodiment, the insulation remains open to low temperatures and other environmental influences.

- Due to the capture of the insulation layer by the low temperature zone, its heat-saving properties and characteristics will deteriorate.

- When the walls of a wooden house are insulated from the inside, vapor diffusion may be disturbed, which ultimately leads to an acceleration of destructive processes.

- When insulating a wooden house from the inside, installation of thermal insulation is not possible at the junction of walls to ceilings. In such places, the formation of cold bridges is inevitable, which leads to significant heat losses.

By insulating the wooden walls of the house from the outside, all these shortcomings can be avoided.

Temperature readings are evenly reduced along the entire wall, and sharp temperature drops do not affect the outer walls. To ensure the diffusion of vapors, a windproof membrane is used, which does not allow moisture to pass to the insulation.

BUT reliable protection insulation material from the effects of natural factors will provide high thermal insulation properties of the walls.

The disadvantages of external insulation of wooden walls include the laboriousness of the process itself, because the insulation must adhere to the wall tightly, and with log walls it is quite difficult to ensure this. The aesthetic features of the wooden facade hidden by the cladding are also lost. It will not be superfluous and.

Finishing the facade of the house (video)

Ways to insulate wooden walls

Three main types of insulation are used for wooden facades:

- Wooden walls can be insulated using external cladding with stone or brick, laying a layer of insulation between the wood and the masonry. In the facing masonry, gaps should be provided for ventilation of such a facade, and one should not forget about the air gap between the masonry and the insulation.

- Often homeowners insulate their wooden houses external masonry of aerated concrete blocks (if the wall is even). These blocks have high vapor permeability and have sufficient thermal conductivity to double the overall performance. Aerated concrete provides the tree with fire safety and frost resistance. The use of these blocks in the insulation of a wooden facade eliminates the need to use additional insulation materials and a diffusion membrane.

- For the insulation of a log facade, the best option is to use mineral wool. This material is soft, has low thermal conductivity and low hygroscopicity, is made without the use of toxic substances.

It is important to remember that finishing the wooden facade of the house is possible only after its complete shrinkage. Otherwise, this may lead to deformation of the cladding.