Steel doors alone are not enough to provide maximum protection for residential and commercial buildings. This is due to the fact that intruders can enter the premises through the windows. Therefore, in order to protect your property as much as possible, you need to mount gratings on them. Many trust this work to specialized companies or hire a team of builders.

For this, you will need to spend an amount in the amount of 15% of the cost of the grate, and no one will guarantee the choice of high-quality metal and compliance with all installation technologies.

As a result, only with a real hacking attempt will the reliability of the lattice be checked. Therefore, it is worth doing all the stages of work with your own hands in order to feel completely safe.

Lattice Selection Criteria

In many ways, the ease of use and safety of window grilles depends on the type of their design. Therefore, their choice should be taken responsibly. Another factor is the complexity of their self-manufacturing and providing the necessary technical conditions for installation. To understand exactly how to make the right choice, you need to use the following recommendations:

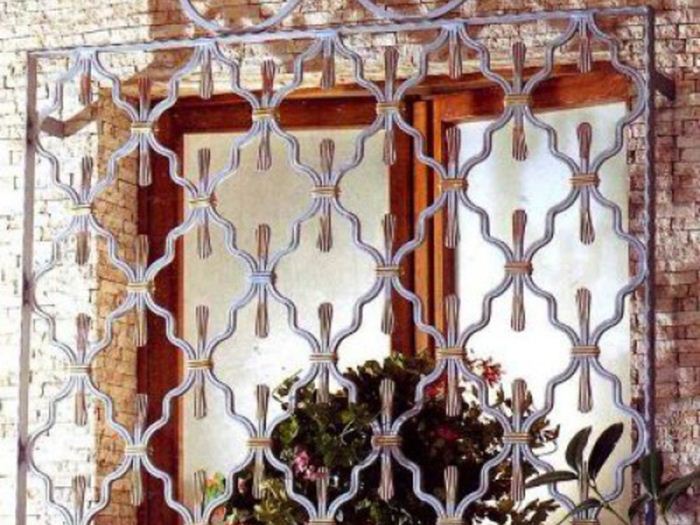

- The facade of the building should not lose its decorative appearance, and the lattices should fit into it logically and harmoniously.

- The weight of the structure must fully correspond to the bearing capacity of the walls.

- Provide all the necessary functionality of windows.

- The thickness of the reinforcement is chosen in such a way as to have a minimal effect on reducing the amount of light penetrating into the room, but to have sufficient strength.

- Ease of installation and high level strength of attachment to the wall.

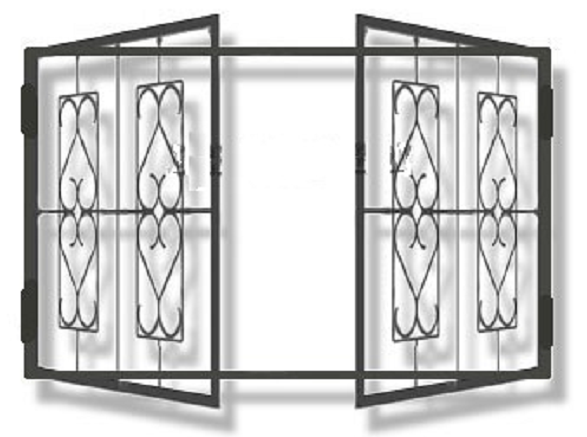

The main types of window grilles designs

- Swing. They are a one- or two-leaf system, which is fixed on steel hinges to a frame embedded in the wall. It is almost impossible to break the frame structure, since the load will be evenly distributed over the entire area of the window opening. It is quite simple to make a lattice yourself. However, due to the large weight, it can only be installed on walls made of monolith or stone, where it is provided solid foundation. An exception may be in a situation where installation is performed on windows with an area of up to 1.5 m2. The advantage is the ability to open the shutters to hit maximum number light into the room.

- Deaf. The design is a one-piece grille, which is tightly welded to the window and is non-removable. It is extremely easy to manufacture and install, as it does not require special design experience or knowledge of building technologies. During operation, they turn out to be much more reliable than the swing structure due to the lack of weaknesses such as hinges and padlocks. In addition, they may violate fire safety regulations due to the inability to carry out evacuation through the window. This fact should be taken into account, especially when installed in government and commercial enterprises. They can be attached to a steel frame or load-bearing reinforcement of reinforced concrete walls using welded or riveted joints.

- Sliding. Differ in high-quality appearance, convenience at operation and complexity of production. They have a double-leaf design, consisting of many elements (usually in the form of an accordion), interconnected in a special way. Folding sashes at the top and bottom will move along rails to increase strength, but fine tuning and fitting is required to ensure they work. Therefore, only a professional can make them on their own. In terms of strength, they are superior to swing ones and are slightly inferior to deaf types of gratings. Do-it-yourself installation of gratings on windows is similar in principle to a hinged structure. The main advantages include not only the ability to hide the grille, but also to fold it in such a way that it takes up a minimum of space.

Measurement and design

Before drawing the drawings, it is necessary to measure the window opening. To do this, using a tape measure, slopes are measured at a distance of at least 4-5 cm from the edge. This is done in order to install and firmly fix the steel frame to the wall. However, the dimensions of the frame itself should be slightly smaller by 5 mm horizontally and vertically in order to ensure that they can be centered relative to the window. To determine the dimensions of the sash, you need to subtract the thickness of the frame, that is, a total of approximately 60-70 mm. For two wings, you need to take into account the small gap that goes to install the hinges and the lock: you need to divide the width of the canvas in half, and then subtract 5 mm from it.

Based on the measurements, you need to make a sketch in a convenient scale. It must contain the main frame elements and sashes. Additionally, you will have to draw up a detail in order to calculate the amount of building materials needed and estimate the costs. For the frame and sashes, you need a steel corner with a shelf width of at least 30 mm and a thickness of 3-5 mm. For the grate, it will be necessary to use reinforcement with a diameter of more than 10 mm, taking into account the distance between them of 5-10 cm. If it is possible to make custom-made forged patterns, then when choosing a pattern, you should focus on the number of attachment points to the frame, as well as the degree of space filling.

We construct a lattice

Do-it-yourself window grills are made in several stages. At the first stage, steel rods and corners are cut to the required dimensions. To make a decorative grille, you will need to round off some elements. For this, special bending machines are used, which will ensure high accuracy and compliance with dimensions. If this is not possible, then they do this: one end of the bar is securely fixed in a vice, and a pipe is put on the other end and bent in the right direction with a certain radius. Flat patterns are cut from sheets of steel. For complex repeating elements, you will need to make a steel template, and then make similar elements using it. This will reduce the time for measurements and alignment.

At the second stage, the corners for the frame structure are laid out on a flat hard surface. This will prevent distortion in the plane and, accordingly, ensure maximum strength characteristics. It is also important to observe the perpendicularity of the corners and the parallelism of the opposite sides of the frame. Then the frame is welded. In the end part, rods are additionally welded to fasten the frame to the wall on its outer surface with a length of 15 cm and a diameter of 10 mm. On the opposite side, welding is not done, since installing the frame on the seat will become impossible. If the grate is fastened without a stiffening frame, then this stage is skipped and the manufacture of the wings is started immediately.

The third stage is the manufacture of sashes. Similarly, all the elements are laid out on a flat surface in the required order, and then they are sequentially welded. Then two hinges are welded to each leaf at the point of contact with the frame structure. In order not to reduce the overall strength of the structure, 20 cm retreat from the top and bottom. Loops are welded at the attachment points of the locks.

At the fourth stage, the assembly is checked for correctness and, if necessary, the sashes are adjusted to the frame, as well as fasteners. A grinder cuts off places with excess metal deposition in order to improve quality decorative look. The grille is then primed and painted.

Installation work

To attach steel frames to windows, it is necessary to drill holes in the wall with a perforator of a suitable diameter for inserting reinforcement. Their depth should be at least 15 cm. They take the frame and drive it with mounting pins into the holes made. If necessary, they are trimmed with a grinder. On the opposite slope, pins are driven in, but not completely, but so that there is enough metal left to weld it to the frame. Then the frame is applied, the excess is measured, cut off, and then its final welding is performed. At the same time, they monitor the observance of the parallelism of the plane of the grate, wall and window.

Then they take the sash, insert it into the frame, mark the attachment points of the hinges, and then they are sequentially welded. In this case, the pins in the hinges must have opposite directions so that it is impossible to remove the sash.

Similarly, on the other hand, the second part of the sash is welded. Welding areas must be primed and painted.

In case of damage to the slopes or external wall decoration, they are sealed with facade plaster, and then a decorative coating is applied.

If it turned out that the reinforcing pins do not sit tightly in the seats, then it is necessary to seal them with cement mortar.

To improve the appearance of the facade of the building, brackets can be attached to the bottom of the frame and pots with seedlings can be placed on them. If the window is wide, then in order to prevent the lattice from moving or deforming, it is possible to strengthen the bracket by additional installation of anchors in the wall.

Conclusion

At self-manufacturing gratings needed Special attention pay attention to the choice of its design, since not only the safety of the premises, but also the functionality depends on it. When choosing materials, you should pay attention to high-strength steel grades. This will ensure high strength and reliability of the structure, as well as ensure a long service life. An equally important factor is also to ensure a rigid attachment to the wall, otherwise the grate will not be able to effectively cope with its main task.

Lattice on the window - do-it-yourself manufacturing features

Metal bars in window openings country houses or city apartments located on the ground floor - this is a real guarantee of the safety of their residents. In addition, the window grille with decorative forged elements will decorate the facade of any building. Naturally, the cost of a high-quality grate is not a cheap pleasure, but everyone can save money by doing the work on its construction with their own hands.

The main types of window grilles

Do-it-yourself window grille can be made as deaf, with rigid attachment to the walls, as well as hinged or sliding with locking mechanism. opening from inside the room. Deaf structures, although they are considered the most reliable protection for housing, but if you approach from the point of view of fire safety, their use is possible only if there is an emergency additional exit.

Lattices with a sliding opening system, as in the photo, are difficult to manufacture, and therefore it is rather problematic to build such a protective structure with your own hands. In such a situation, it is possible to save only on self installation sliding system for the window.

The most popular and easiest to manufacture is the hinged design of window protection, which, in addition, is convenient to use and provides good security for homeowners. At the same time, the swing grate is made with a locking system that opens from the inside.

To make such a design use different materials. starting from a metal rod and ending with forging elements. At the same time, the easiest to manufacture are gratings made of metal rods fastened with a welding machine.

The preparatory stage for the construction of the lattice

The first stage is due to the choice of a suitable lattice design for the window. Today, deaf and opening structures are made. But regardless of the system used to protect the work of making a lattice with your own hands, start with preparation .

Also, for the trouble-free work on assembling the window grille with your own hands, you can not do without good tool:

- electric grinder;

- electric welding;

- drill with rebound function and a set of drills for metal and stone;

- normal hammer.

Several options for metal gratings

![]()

How to make a lattice for windows with your own hands?

If a person has at least some experience in welding, then it will not be problematic for him make your own window grille. if you follow a certain sequence of actions.

A high-quality metal window grille with forging elements will become a truly worthy decoration of the facade of the building. You can also show a little imagination when painting such protection by applying paint with patina, gilding or other rich shades on the windows. From the bottom of the structure, you can fix a flowerpot. in general, the whole decor is limited by the imagination of the owner of the room.

Installation of metal window grilles

Do-it-yourself installation of a lattice to protect window openings with your own hands can carried out in several ways:

Also, when installing the lattice on the windows, you need to take into account the material from which the structure was built. If it is stone or concrete, then metal pins are used. In the case of a wooden building, special eyes are used, through which the grate is fixed with screws. But since there are more stone buildings, then install bars on windows possible as follows.

- Places for fastening pins are marked in the window opening. If a hinged structure is installed, then the attachment points should not coincide with the locations of the loops.

- With the help of a perforator, recesses up to 150 mm are drilled according to pre-planned marks. Metal rods are driven into the holes so that their edge protrudes several centimeters, but not less than the gap from the window opening to the frame of the structure.

- The structure is welded by electric welding, and the ends of the pins, if necessary, are trimmed with a grinder. After that, the welding seams are cleaned, and the whole structure is opened with paint.

I would like to note that painted grating will last much longer and will have a complete appearance.

By analogy, they are attached, and sliding structures, however, you will additionally have to attach guide skids along which the protective system will move. Since sliding structures are easier to crack, when installing them with your own hands, you need to take care of additional protection.

Also want to consider removable structures. which are fixed on hooks and, if necessary, can be easily dismantled. But right away I would like to note that such protection for windows is the most unreliable, so experts do not advise installing systems that are more decorative than protective. Also, this type of grating is appropriate as a temporary protection or if it is planned to replace window structures in the near future.

Window grill options

Nikiforov Sergey Viktorovich

http://balkon.guru

Beautiful carved shutters, which used to be traditional in Russian huts, are now increasingly being replaced with reliable and strong bars. Window grilles are more of a functional solution than a design one. Their main purpose is to protect your home from third-party entry and possible break-in for the purpose of theft.

But no one canceled the beautiful appearance, so window bars are a design addition to the overall style of the house and the site as a whole. They can be different types and types, with exquisite wrought iron elements, with flower stands, in different color solutions. The main thing is that they reliably perform their security function.

In our article, we will try to tell in detail about the methods of manufacturing window grilles, their types, design, explain which grilles are sliding and which are deaf, we will show their samples, you will learn how you can make and install window grilles with your own hands.

Window bars - your safety

Since window grilles are primarily designed to protect against unauthorized access, they are most often used by residents of the lower floors in apartment buildings, corporate offices, and country houses.

There is a whole list of enterprises and office premises where the presence of a lattice on the window is mandatory and provided for by the Safety Rules. These include:

- banking institutions,

- cash desks of enterprises,

- cabinets for working with secret documents,

- computer departments and classes,

- jewelry stores

and whole line other facilities where the construction of gratings and steel locks protect against external penetration.

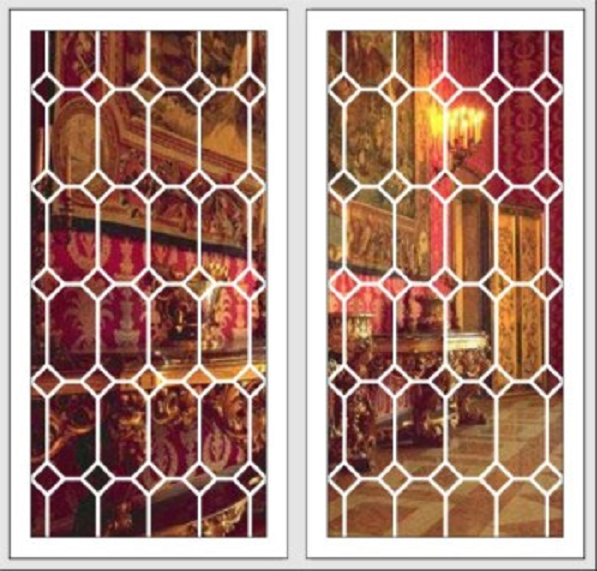

Metal window bars with original design, can become a decoration of the facade of the building (see photo below), they add a touch of unique uniqueness to its architecture.

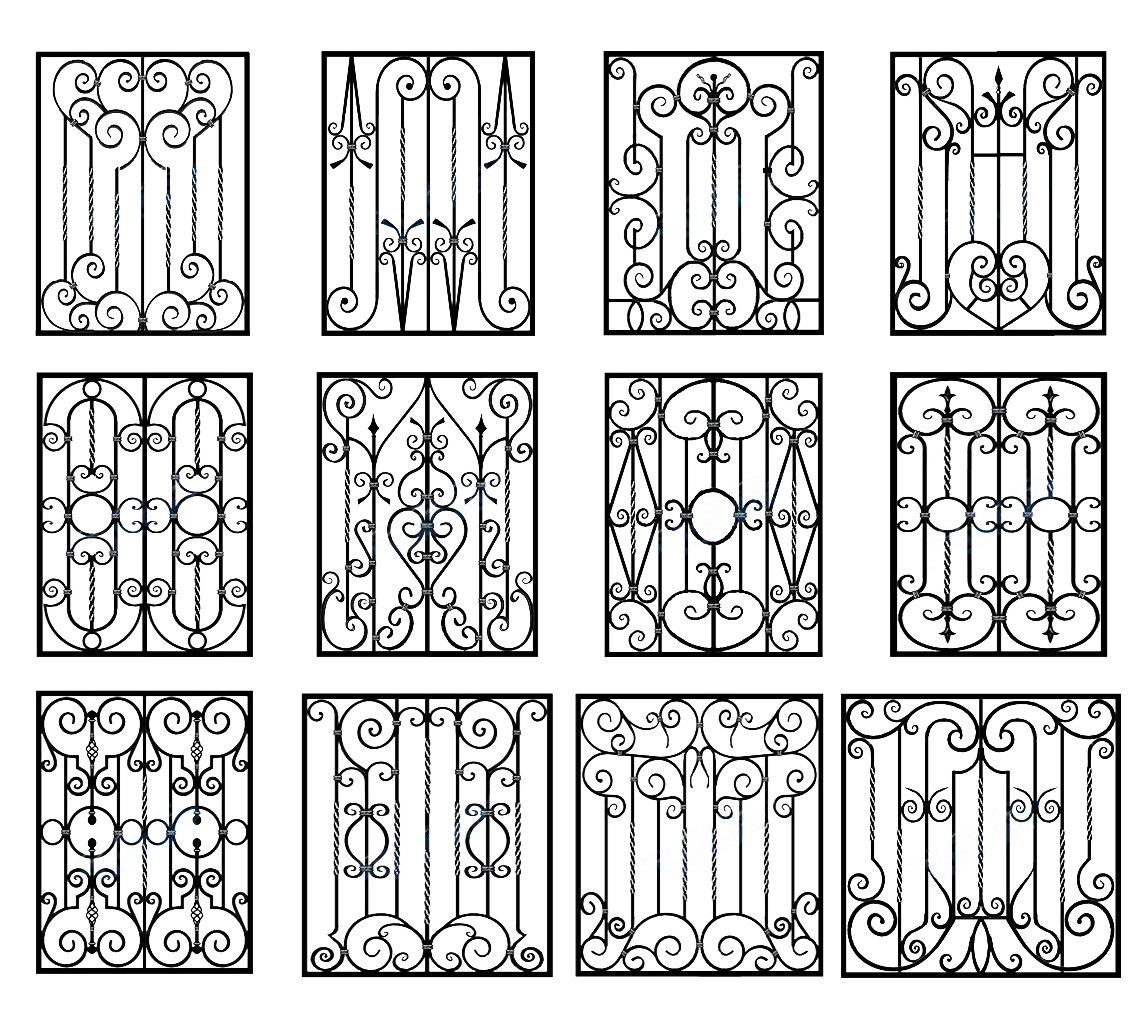

Various drawings of such lattices for windows, as well as their samples, openwork or simple, you can find in the photo on the Internet, order from specialized companies or come up with your own. To do this, you need to know what types of window grilles exist.

Window grilles are classified according to different parameters:

- production method: welded, forged;

- type of opening: hinged, sliding, deaf;

- fastening type: stationary, removable;

- at the place of attachment: external, internal;

- by appointment: decorative, decorative-security, security.

Let's consider each separately.

Mode of production

Welded

Welded window grilles are made by welding and forging metal according to pre-made drawings, where all dimensions and design elements are strictly defined.

- Patterns on the gratings are created using hot or cold welding technology.

- They are made from: profile pipe, corner, circle, reinforcement and strip.

- To do this, use the method of semi-automatic welding, which ultimately allows you to achieve excellent quality of the external seams of the product.

- The manufacturer always has ready-made samples of products in stock. Therefore, you can simplify your choice by taking a closer look at ready-made simple or complex window grilles or their drawings.

- Welding of window grilles is also used during their assembly.

But it is worth noting that the design of the welded grating is inferior in reliability to the forged one. Such gratings are recommended to be painted.

Forged

Until the end of the 19th century, welding technology as such did not exist, so forging was popular, window grilles were made by hand. The skill of a blacksmith can turn metal into fine lace, flowers, vines.

- Wrought iron window grilles have become a piece of art, which is why they are much more expensive than those made by welding.

- You can order a forged lattice of any design, but this will affect the cost of this product.

- Upon request, the product can be painted "antique".

Often these two production methods (window grilles and welding) are combined.

Mount type

Stationary

Window grilles are fastened into the window opening “tightly”, it is impossible to remove them quickly and without special tools.

Such fastening is the most reliable in terms of security qualities, but it becomes very dangerous in unforeseen situations, for example, in case of fire.

Therefore, at least one of the protective grilles in the room must be removable.

Removable

Window grilles are attached to the wall with bolts, which, if necessary, can be unscrewed and the grille can be removed.

But it still takes some time and creates inconvenience, therefore, in many cases, window grilles provide the possibility of opening them.

opening type

Sliding

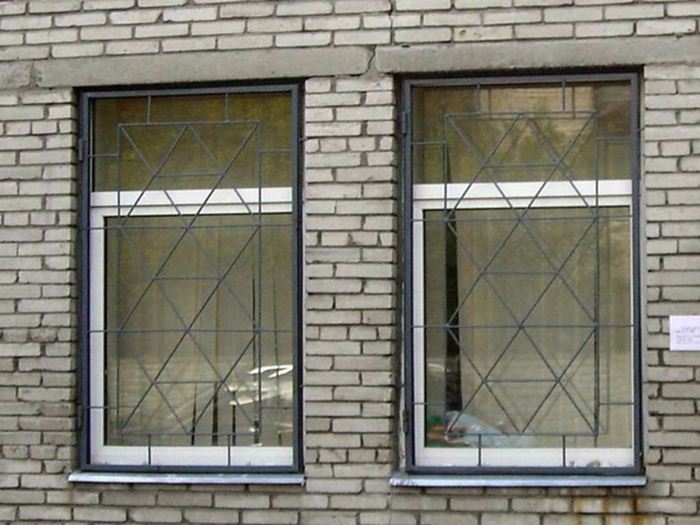

Window bars (pictured) are rarely used in residential buildings because they are mounted with inside windows and open only 80% of the width of the opening, they are most often used in shops, offices and warehouses.

- Sliding gratings (mostly steel) are simple in design, they consist of vertical bars that are connected to each other by movable elements in the form of an "X".

- They can move in one or different directions; when opened, the sliding bars are almost invisible.

- Also a plus is the fact that the sliding bars do not make it difficult to care for the windows: you can easily remove the steel locks from the bars and wash the window.

They are fixed directly to the wall.

Swing

Swing window bars (pictured) consist of several shutters and are locked at the junction with locks. They are reliable, convenient and, if necessary, they are easy to open.

Deaf

The name speaks for itself - they do not open like sliding doors, and they are used mainly in warehouses.

Place of attachment

Window grilles are mounted either outside the window opening (the most popular and optimal fastening), or from its inside.

Purpose

According to their purpose, window grilles are divided into three types:

Decorative

They are made according to the design and drawings, according to the style of the project and the wishes of the customer. Functionally, they serve more as a decoration than a security element.

In security and decorative gratings, the structure is already reinforced, metal elements are placed with a smaller interval, their strength is increased (pictured).

In addition to the fact that they contain simple rods as a base, they are decorated with decorative elements.

Openwork forged window grilles amaze with the grace and elegance of their lace, the technology and skill of modern blacksmiths turn them into unusual examples of design art. Quite often, the forging of the window lattice becomes an addition to the general style of the building's architecture.

Security

Window grilles are the simplest in design, but at the same time, their design is the most reliable.

- You can see samples of such gratings on the windows of factories, warehouses, and sensitive facilities.

- Steel elements and locks enhance their reliability.

- Very often they are painted in the general tone of a window or building.

You can order the manufacture of window grilles in specialized companies, after looking at samples of finished products, drawings and sketches of possible options, make a design according to your project. Regardless of whether it is forging a window grille or welding, simple or decorative, you will always be offered the most optimal solution.

We make a lattice on the window with our own hands

You can easily find samples of finished window grilles on the houses you pass by every day, and in the photo, and in magazines or on the Internet.

Drawings and sketches

To make a window grill with your own hands, you first need to make accurate measurements of your windows, then make drawings and sketches of decorative elements (pictured).

But at the same time, it must be remembered that the design must be such that it remains possible to evacuate in case of danger (for example, fire). Otherwise, such protection carries a potential danger to the people living in this building.

For private houses, swing window bars are best suited.

Acquisition of the necessary material

The next step is to purchase required material and accessories.

Some complex forging elements (flowers, openwork leaves, bunches of grapes, etc.), which require special skills and technologies, can be purchased ready-made.

It is also necessary to purchase steel strips, rods, welding consumables, fasteners, locks, steel corners, which are needed in order to fix the remaining parts to the outer frame of the lattice structure.

The very design of the window lattice, for making with your own hands, is not as complicated as it might seem at first glance.

- In order to connect the parts, welding equipment is usually used, but sometimes the so-called rivet fastening is used to connect the elements.

- You will also need tools for cutting metal into individual steel blanks. In this case, an angle grinder can be an excellent option. If the profile thickness is small, then you can use a small power grinder.

- In the absence of such tools, you still have the option of using a hacksaw, but this option requires a significant amount of time and effort.

Be sure to use a protective mask and clothing when carrying out welding and assembling the window grille with your own hands.

Manufacturing

For welding work, you need to prepare an even, non-combustible base.

- Steel sheets will not work here, as there is a possibility of attaching your structure to it. A good option in this case would be a workbench, which has a slatted tabletop.

- Next, based on the sketch and drawings, you need to cut the steel parts. Sorting the received parts by shape and size will greatly speed up and simplify the assembly work.

common among ordinary people the opinion “there are no bars and locks against a thief” often turns out to be based on one’s own experience of reassessing the protective properties of roller shutters or roller shutters, internal removable grids, anti-vandal plastic windows, widely advertised by manufacturers of such goods. Practice shows that we often perceive protection against accidental impact or impact as a real system that protects against deliberate actions of a criminal. And those are two big differences.

The protective grill on the first floor window should:

- Warn and stop a potential intruder by their presence and appearance before the intrusion attempt begins;

- To be precisely a steel grate on the windows, made of high-quality material;

- Have secrets and tricks for which the criminal is clearly not ready.

Almost all state institutions in their offices on the first floors have bars on the windows, even in the presence of guards or alarms. This requirement is met for the first floors, although most people believe that even wrought iron window bars are not capable of stopping an intruder equipped with modern tools for cutting steel structures.

The gratings on the first floor are designed to detain the criminal for some time, which is necessary for the response of the main security forces. But if, under certain conditions, there is no money or opportunity for additional measures, steel bars in the windows of the first floor will become the main protection against breaking.

What can the installation of steel protection on the ground floor give?

For windows on the first floor, it is extremely important to have protective elements. Most often, external grilles are used on the window opening. This is especially important for windows on the first floor overlooking backyards, poorly visible from neighboring windows or from the street. Such places are just perfect for attempts to enter the premises. The outer lattice structure must be welded to a steel frame, securely concreted into the window opening. In the simplest case, the frame is welded to pin fittings hammered into the stone of the walls of the first floor.

In their attempts to break open the outer lattice frame, attackers use two opposite methods. In the first case, the emphasis is on a quick and strong impact on the structure. For example, using a cable and a car winch.

In the second case, the bars on the first floor can be secretly cut using hand tool for several days, masking the traces of their actions.

The job of a burglar

The development of metal cutting technology led to the emergence of simple and efficient mechanical and hydraulic shears and cutters that can easily “bite” sheet metal - up to 5 mm, and round reinforcement - up to 10 mm.

Such devices weigh up to ten kilograms, work quite quietly, and can be easily misused. Hardened carbon steel or manganese steel reinforcement resists this technique very well. In the latter case, it is possible to cut a rod on the ground floor with a diameter of 8-10 mm only with the help of a grinder, spending a lot of time on this.

It is useful to bar the windows, balconies and loggias not only on the first floor. According to statistics, penetrations into the premises through windows occur not only on the first, but also on the second and third floors. Especially if they are new plastic double-glazed windows, and tall trees with a dense crown grow in front of the house, well hiding the window opening from prying eyes.

What should be metal window grilles

No matter how window grill manufacturers try to make them less visible, decorate or give the fittings a pretty pattern, protective structures will still annoy with their presence. Therefore, it is necessary to choose whether the bars on the windows of the first floor will perform a decorative function or a protective one.

Folding types of lattices for windows

Often they resort to installing hinged or sliding bars on the windows. In the normal state, they open or retract so that you can use the window without interference; at night, such structures are closed with a padlock or built-in lock.

Important ! According to the fire safety rules in a room on the ground floor with windows covered with bars, at least one window on the ground floor must have a sliding bar structure that can be opened from the inside. In the event of a fire, it acts as the first emergency exit.

Swing structures of lattices

Swing systems are classified as schemes consisting of one or two gratings suspended on canopy hinges and opening like a window sash. The structure itself is a solid welded product made of steel bars with a frame; it does not have movable joints. In the closed state, any load or shock from the grate is transferred to the outer frame, tightly built into the first floor window opening. Often, to increase durability, the edge of the lattice opposite from the canopies is reinforced with pins.

Such mobile systems have all the advantages of stationary lattice structures, if the following conditions are met during their manufacture:

- For the manufacture of the grating, steel bars with a diameter of at least 11 mm were used; forged tetrahedrons would be an ideal material;

- For connection, a welded or forged-welded connection was used;

- The frame, into which the bars of the lattice are welded, is made of a metal corner or a T-section profile with a shelf thickness of at least 5 mm.

- The outer frame is fixed in the window opening with three pieces of reinforcement on each side of the frame. The segments are hammered into the wall to a depth of at least 10-12 cm.

Adhering to the listed requirements and observing the welding technology, you can make welded gratings for windows with your own hands. For a simple non-separable grille on a window of a standard design measuring 150x80cm, you will need a metal corner No. 50 with a length of at least 5m, and steel bars with a diameter of 11mm with a total length of 8.5m.

The lattice on the window is made in the form of steel vertical bars, welded with a pitch of 12-15 mm into a box-shaped frame from a corner. The frame is welded by electric welding, in the corners and places of welding, the seams are cleaned with a power tool.

To install the grille, you must: first, mark the position line of the frame in the window opening on the first floor. The second is to evenly make holes along the line with a perforator to a depth of at least 10 cm. Pieces of rods of 12 cm are hammered into holes using a sledgehammer. The protruding ends of the segments are aligned to a length sufficient for welding to the frame. Third - the frame is inserted into the window opening and welded to the mount. All welding work is carried out by electric welding with an electrode of at least 5 mm in diameter.

Important ! There should be no gaps of more than 2 cm between the frame and the slopes. The old way of hacking involves the use of a hydraulic jack, which can easily crush the structure not only on the first floor.

Unfortunately, with all the positive qualities, the sliding lattice design on the windows of the first floor is the weakest link in the system. Not only because of the lock, but to a greater extent because of the fastening system - canopies or rollers. Rollet protection systems suffer from the same defects. The set of protective lamellas itself takes the load from bumps and cuts well, but the guides along which the flexible fabric slides are easier to open than a tin can.

Folding lattices on windows with an internal arrangement

It is worth paying attention to the widely used folding options for lattices on windows. The basis of such schemes is made up of lightweight metal rods interconnected by means of hinges. The X-shaped pair is the main protective element of the lattice frame. By changing the angle between the bars, the grating can be easily folded into a compact structure or moved apart to its full working length. In the window opening, the structure is fixed on two gutters fixed on the ceiling part and the window sill part of the window opening.

The design is very convenient to use and very popular as an additional internal protection in large windows - showcases for external roller shutters. But the resistance of such a scheme to hacking is quite small. In practice, it is not difficult for an intruder to open the lock on the ground floor or cut the hinge for attaching the bars of the lattice.

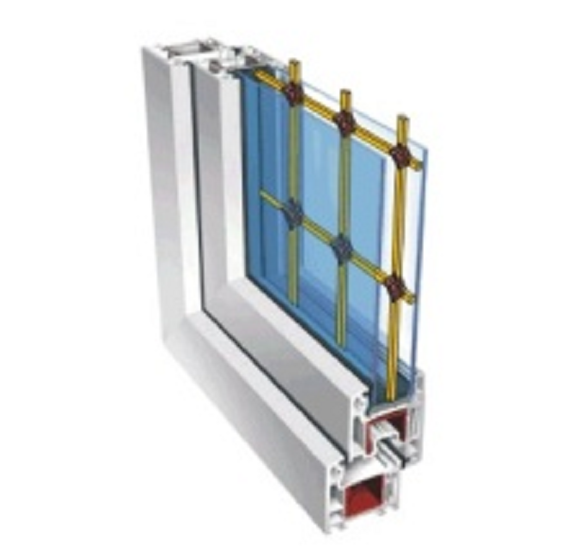

The demand for the installation of additional protective elements on the windows of the first floor has led to the emergence of a variety of designs of plastic windows with bars inside. The main emphasis is placed on the reliability of metal rod gratings, the presence of a steel frame and special anti-burglary window fittings. Coloring in cute White color and the correct selection of the cell pitch makes their presence absolutely harmonious and does not spoil the appearance of the first floor window.

It is possible that the manufacturer is right, declaring the high durability of such plastic window with a built-in lattice system for burglary.

But, if we compare the cost of buying and installing such a window, it will be much more expensive than the sum of the costs of installing separate double-glazed windows and gratings. good quality. In the manufacture of a plastic window with a WK3 class grating for the first floor, high-quality materials will be used, they will no doubt be in demand, but only for windows on the first floor of expensive apartments and houses.

Beauty or reliability

Most residents of apartments on the first floor have to either put up with the presence of a steel lattice frame, or install very expensive shock-resistant double-glazed windows. Often, they try to give the gratings themselves a more elegant and aesthetic appearance, fortunately - modern technology can do a lot at will. But it is worth remembering: the lattice structure on the windows of the first floor, assembled from elements that are dissimilar in length and shape, can greatly lose strength. It will not be difficult for attackers to determine the weakest link at a glance.

Bars on the windows in most cases are used only by residents of the first floors. Their motivation is simple and clear - the grid is the best remedy from unauthorized entry.

Welded gratings for windows with installation can be ordered from companies specializing in this. The advantage is that the gratings will be installed hinged. That is, in case of fire, they can be opened from the inside. In addition, the external design of purchased gratings is much more attractive than that of homemade ones.

Of course it's metal. Since only it has sufficient strength. Forged steel is immune to the grinder. It can only be cut with an autogen, but thieves are unlikely to use it.

If you decide to make window grilles yourself, we recommend using the following as a constructive option:

- steel corner;

- fittings.

A frame is assembled from a steel corner to fit the window. Seam welding in progress. Spot is not strong enough.

Further, reinforcement is driven into the end of the window opening in four places - two on the left, two on the right (naturally, at the upper and lower edges of the window opening). Reinforcing bars are welded onto the frame in accordance with the selected sketch.

After the grating itself is completed, it remains to weld it onto the installed reinforcing bars in the wall and paint (to protect the metal from corrosion).

Naturally, you can not do without a welding machine. Depending on which armature you have chosen, you will need either an autogen or a grinder with diamond wheels.

It is quite difficult to perform bending of reinforcement without specialized equipment. A pipe bender is not suitable for this. An induction heater will be of great help.

For bending reinforcement, you can use the old-fashioned method. A pipe is buried in the ground. Next, the reinforcement is heated at the place of bending, then inserted into the pipe and, using muscular force, is bent to the desired configuration.

Remember that if you decide to block the windows with bars in order to maintain security (against thieves), the apartment (or cottage) must be equipped with another exit.

The video will demonstrate the process of creating lattices for windows: