In the field of heating equipment, a huge number of fairly well-known companies compete in the market. There are so many manufacturers alone that if we were to list them, it would take a fair amount of time.

However, in this article we will pay attention to the Italian Concern, which is engaged in the production of gas boilers, and also consider their main line of equipment. This refers, of course, to Baksi wall-mounted gas heating boilers.

1 Features and device

The Baxi wall-mounted gas boiler is a unit designed for heating medium-sized residential premises. The Italians themselves specialize in domestic heating systems. They produce a range of boilers with a wide variety of characteristics.

The most popular option is the Baxi wall-mounted gas boiler. they are convenient because they take up little space and are very compact, which, however, does not affect their effectiveness in any way.

In some cases, wall-mounted models are even more productive than stationary ones, especially when it comes to heating relatively small areas.

In addition, gas wall boilers Baxi is equipped with the latest developments of the company. They are fully automated, run by program management and are able to issue regular reports to the owner on the built-in display.

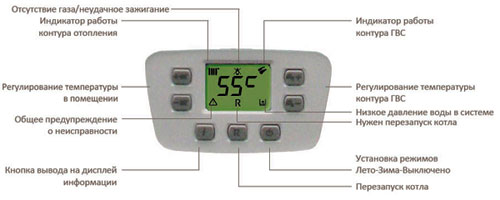

The control of the unit is carried out at the expense of the instrument button or even the touch panel. All elements are intuitive and quite easy to use. The display shows the current system status:

- Temperature;

- heating level;

- The amount of gas consumed;

- Heat supply, etc.

And this is only a small part of the indicators. In fact, it all depends on specific model boiler, and there are a lot of them.

Baxi wall-mounted gas heating boilers, as the name implies, are powered by gas. This is the most convenient and acceptable option, especially when it comes to heating apartments or medium-sized cottages.

Gas is moderately cheap, it is supplied to almost every home, and its main advantage is a constant supply. That is, the boiler, in fact, due to electronics, is able to function independently.

All that is required of you is to monitor its condition and set up the equipment itself before starting work.

The very principle of its work is quite simple. As we noted above, a gas boiler works by heating the liquid with gas, or rather, by releasing temperature from its combustion, and then transferring it to the liquid itself. Water enters its chamber through a system of pipes, where it is heated by a jet of fire. Heating occurs almost instantly, as the water is distributed evenly through the tubes.

After passing through the chamber, the heated liquid is distributed along the working circuits. The number of circuits depends on the model of the device and its purpose.

2 Types of Baksi boilers and their differences

There are a fairly large number of models of gas boilers, especially if we are talking about products from the Baksi company.

They differ depending on the model. Moreover, there are separate rulers that differ in the type of design, purpose and many other points.

We will now consider the main varieties of the above products. So, according to the type of device, boilers are divided into:

- Single-circuit;

- Double-circuit;

- Condensing.

In fact, there are many more options, but Baksi is concentrating its efforts on the development of these particular samples.

The gas single-circuit wall-mounted boiler Baxi is a unit that is intended exclusively for heating residential areas. The term single-circuit itself means that the boiler heats and supplies liquid through only one pipe, which is intended to heat the apartment.

Accordingly, it has only one outlet and one fluid inlet. Passing a full cycle through the system in an apartment or house, the water returns to the boiler, is tested on a thermometer and, if necessary, is heated up a little.

If you have installed something like a mixer with temperature control in your apartment, then the system can be closed in one of the sections, and hot water from the boiler can be mixed through automation. This is a more expensive option, but it is much more productive and reliable. Yes, and the savings in the end will be quite impressive.

Baksi single-circuit wall-mounted gas boilers are quite popular, one might even say that they occupy a dominant position in the market, due to the combination of efficiency, reasonable price and compactness.

But let's not forget about dual-circuit models. They are more complicated by an order of magnitude, but they provide more functions.

The double-circuit heating equipment means that it is capable of supplying heated water in several directions, or to be more precise, in two. The first direction is traditional - directly the heating system of the apartment. But the owner chooses the second one according to his taste. However, in the vast majority of cases, we are talking about heating water for domestic services.

In many homes, even now, hot water is not supplied centrally and people have to deal with the arrangement of their homes on their own.

This is where these models come in handy. The most popular example of double-circuit models is the Baxi-Main wall-mounted gas boiler. It is quite compact, productive, but at the same time extremely reliable.

The Baxi wall-mounted condensing gas boiler differs from previous models due to an interesting heating system and maintaining the carrier temperature.

Reviews of the Baxi gas wall-mounted boiler indicate that this equipment is extremely reliable and extremely economical. What is possible thanks to its principle of operation.

When choosing a specific model of the boiler, first of all, be guided by the personal needs and features of your particular home. So, single-circuit boilers it makes sense to buy for those who already have a supply system hot water for domestic needs, and it remains to solve the problem only with heating.

They are quite comfortable and reliable, and they are cheaper. Although a single-circuit boiler, as a rule, is weaker than a double-circuit one.

Pay attention to temperatures. The more of them, the better for you. Some models have the ability to adjust the temperature depending on the heating system used.

![]()

It makes sense to buy dual-circuit models for those who want to organize both heating and hot water supply to the bathroom or kitchen. This will be a good option, since you do not have to spend additional funds to buy a boiler.

Condensation models are good for owners of country houses. They are fully revealed when the heating system is quite voluminous. In an apartment, they will be less useful.

Malfunctions of the Baksi wall-mounted gas boiler should not scare you, as the product is extremely reliable. But still, we recommend checking the equipment upon purchase, and if any are found, immediately contact service centres. It is better not to joke with gas, and not to take independent actions.

__________________________________________________________________________

The device and connection of the boiler Baxi main four

The Baxi main four gas boiler is a double-circuit one, and therefore it is suitable both for heating a room and for preparing burning water for domestic purposes.

This wall mounted unit has small size, which does not prevent him from having sufficient power (up to 24 kW).

Distinctive feature Baxi main 5 is a bimetallic heat exchanger. This allows this double-circuit, wall-mounted device to operate for a long time.

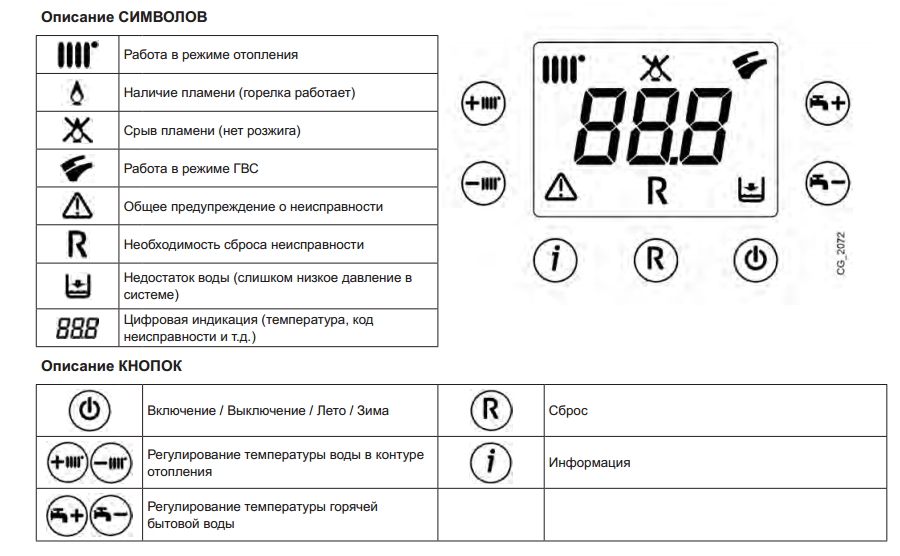

Fig.1. Double-circuit wall-mounted boiler Baxi Mine For with an open combustion chamber and a bithermic (double) heat exchanger

Gas system:1. Gas cock; 2. Fan; 3. Ignition electrode (flame control for boilers of the Main Four and Eco Four series); 4. Burner; 5. Gas valve. Hydraulic system: 6. Shut-off valves of the heating system; 7. Faucet cold water with filter; 8. Three way valve; 8a. Three-way valve motor; 9. Drain tap; 10. Expansion tank; 11a. Primary heat exchanger; 11b. Bithermic (double) heat exchanger; 12. Secondary plate heat exchanger; 13. Automatic air vent; 14. Pump; 15. Pressure gauge; 16. Automatic bypass; 17. Fill valve; 17a. DHW flow sensor; 17b. Flow sensor with filter and water pressure limiter. Temperature control: 18. Heating circuit temperature sensor; 19. DHW circuit temperature sensor. Control and safety devices: 20. Heating system pressure switch; 21. Overheating thermostat; 22a. Thrust sensor - pneumatic relay; 22b. Draft sensor - thermostat; 23. Flame control electrode; 24. Safety valve.

Technical parameters of gas boilers Baxi main four 240 F / 24

The greatest useful thermal power, kW - 24/24

The smallest useful thermal power, kW - 9.3

Maximum power consumption, kW - 25.8 / 26.3

Minimum power consumption, kW - 10.6

The highest consumption of natural / liquefied gas, m3 / h (kg / h) - 2.73 (2.00) / 2.78 (2.04)

Maximum performance (efficiency),% - 92.9 / 90.6

Performance (efficiency) at 30% power,% - 87.7 / 88

Capacity / filling pressure of the expansion tank, l / bar - 6 / 0.8

Productivity of hot water at t=25°C, l/min - 13.7

Hot water capacity at t=35°C, l/min - 9.8

The smallest water consumption in the DHW circuit, l / min - 2

Max/min pressure in the DHW circuit, bar - 8/0.15

Chimney diameter, mm - 120

Nominal inlet pressure of natural gas, mbar - 13-20

Electrical power/voltage, W/V - 130/230 / 80/230

The double-circuit gas boiler Baxi main four 240 F / 24 is equipped with a cast-iron firebox, atmospheric two-stage gas burner with full pre-mixing and electronic ignition system with pilot flame.

The unit is available in 4 versions with a power range from 66 to 116 kW and is supplied with a control panel on which the control module is located.

When starting, the first flap of the main gas valve opens and the igniter automatically ignites the pilot burner (pilot flame), the flame of which is controlled by an ionization sensor.

This burner continues to operate all the time until the main burner is ignited. The system is controlled by a control device that issues a command to open the main and additional valves (for 7 and 8 sections).

During the adjustment process, a self-check is carried out before each ignition of the main burner by briefly stopping and restarting the pilot burner.

Operating principle:

The main valve has two stages: the 1st stage (reduced) is adjusted at the factory to 60% of the second stage (nominal).

The boiler thermostat also has two stages (1st stage - 60% performance and 2nd stage - 100% performance).

When the boiler temperature reaches the value set for the second stage, the main valve switches to the lower stage. If the temperature reaches the 1st stage, the thermostat switches off the burner.

The temperature difference between the 1st and 2nd stage settings is 10°.

Installation works of double-circuit gas boilers Baxi main four 240 F / 24

Boiler installation Baxi Mine For 240 F / 24

If the floor of the boiler room is even, dry, not loose and made of non-combustible material, the boiler can be installed directly on the floor without a foundation.

The legs of the boiler must never be permanently attached (free expansion).

During installation, it is necessary to observe the distances to ensure the connection of water and gas pipelines and to carry out maintenance of the boiler.

Hydraulic connection

The heating circuit is connected from the back of the boiler. The connection of the boiler to the city water supply network is carried out in accordance with the accepted rules and established standards.

This uses a CB type switch to fill the heating circuit. If the water hardness in the water supply network exceeds 20 on the TH scale (where 1 unit = 10 mg CaCO3 per 1 liter of water), it is recommended to install a water treatment system.

The double-circuit wall-mounted boiler Baxi main four 240 F / 24 has a slight inertia, which makes it easy to adapt to the specified adjustment parameters.

In the event of a sudden interruption of the water supply, the safety thermostat is activated, which leads to a complete shutdown of the boiler and the need to restart. Thus, when calculating the installation, it is necessary to ensure smooth adjustment, taking into account the response time of thermostats.

Works on connecting the combustion products removal system:

The system connection unit consists of a vertical outlet into which a chimney adapter is inserted.

When calculating the chimney, it is necessary to follow the current regulations.

The boiler in the boiler room is installed in such a way that the path of gases from the boiler to the chimney is as short as possible. The vertical chimney pipe from the connection point to the first bend must be as long as possible. The measured draft must be within 0.8 mm - 3 mm of the water column (during the measurements, the boiler must work).

The chimney must be securely fastened and must not rest on the boiler. It is recommended to install collapsible chimneys.

The Baksi Mine For boiler is installed in a well-ventilated room separate from the residential area. Ventilation openings must be maintained in good condition and provide the minimum allowable ventilation.

Electrical connection

The electrical connection of the Baxi main four 240 F / 24 boiler, in particular, must be accompanied by the installation of an insulating device on each of the switches having a contact gap of at least 3mm.

Access to the terminal block is achieved by removing the top panel. It is located in the upper left corner of the bracket (opposite the boiler).

The phase wire is connected to the L terminal of the block. The line must be rated for 6.3A at 230V, 50Hz and grounded (check that the pumps are compatible with these power supplies).

Complete electrical connections according to wiring diagram given in the instructions. The earth wire must be 50 mm longer than the neutral and phase wires to ensure safety in the event of a break.

The burner switch installed on the control module eliminates the need for a wall switch. Grounding is installed on the terminal block in accordance with existing codes and regulations.

In case of insufficient ionization current, due to improperly installed ground and zero, it is recommended to install a power circuit isolation transformer of at least 600VA.

Operations for connecting to the control module of the working equipment of the Baxi main four boiler:

Ignition transformer and gas pressure switch (6-pin connector).

Main two-stage valve (9-pin connector).

Optional two-stage valve (3-pin connector).

Connect the ignition cable (left electrode) and the ionization cable (right electrode) to the igniter.

Install the thermostat and thermometer sensors (as well as the adjustment sensor as an option) in the technical holes as shown in the diagram.

The gas pipeline-burner unit is initially adjusted to the nominal and reduced gas flow. If the pressure on the injectors needs to be changed, then unscrew the pressure adjustment screw located on the gas train on the injectors and set the desired pressure using a pressure gauge.

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

OPERATION AND REPAIR OF BOILERSThe heating system is the most important part country house, without which comfortable living in it is impossible. The heating system is based on a boiler. In real life, gas boilers are more efficient and economical ways of heating a room. One of the important factors affecting the availability of such heating equipment is fairly cheap fuel. In addition, these gas boilers are not difficult to operate and repair. Read the Proterm Panther gas boiler installation instructions.

Technical characteristics of the Baxi gas boiler

The entire range of Baksi heating gas boilers meets the following technical specifications:

- Power consumption 135/165 W

- Temperature regulation range 35-65 °C

- The combustion chambers in the entire line are closed, only the Luna-3 Comfort 240i gas boiler has an open combustion chamber.

- Efficiency of heating gas boilers 88.7 / 90.8%

- The volume of the expansion tank is from 8 to 10 liters.

Types of gas boilers Baksi

The Baksi Ecofor 24 gas boiler deserves special attention - the most popular model on the Russian heating equipment market. It can not only heat the room, but also heat water using an external boiler.

Device and installation of a gas boiler Baxi

Absolutely any residential and industrial space in which people are supposed to be located requires a comfortable temperature regime. Before running to the store for elements of the heating system (boiler, filters, pipes, radiators, etc.), it is necessary to calculate the norm of the heating boiler. Of course, the calculation will be 100% correct only when the process is supervised by a technical specialist. Only people with such an education have the necessary set of knowledge. The calculation of the required heat energy per room area is practically the most important document that contributes to solving the problem with the heating system.

The next steps should be preparatory work: installation and connection. The issue of connecting a heating gas boiler must be approached with special care and responsibility.

You can connect a gas boiler in several stages:

- Installation of a heating device;

- Heating system connection;

- Water connections;

- Connection to the gas pipeline;

- Setting up a gas boiler Baksi.

It should be taken into account that the boiler should be installed in a well-ventilated non-residential area.

You should also think about security measures. For example, on the wall where the heating boiler will be mounted, a refractory sheet should be fixed, which will be slightly larger than the heating device itself.

If the boiler is installed on the floor, then the floor surface must be as flat as possible. Recommendations for installing the boiler Proterm Medved.

Connecting and starting a gas boiler Baxi

Almost the entire range of Baxi gas boilers has the same location of pipes. The branch pipe, which is located in the middle of the body, is intended for gas supply. On both sides of it there are fittings necessary for supplying water. All the rest are intended for summing up the heating circuit.

talking in simple terms, they are needed to cut the boiler into the heating system of the building. Moreover, the right side is designed to drain the cooled coolant, and the left side is necessary to supply hot coolant to the radiators.

Quite often, debris accumulates in radiators, which is typical for heavy water. In order to prevent debris from entering the heating boiler, a filter is attached to the right branch pipe, designed to drain the cooled coolant.

It will also be necessary to embed an “American” (cut-off tap) on each side, these taps will help with possible breakdowns. Cranes will save the owner from cutting pipes and draining the coolant from the entire heating system.

Baxi gas boiler instruction manual

Baksi gas boilers are incredibly easy to use. They are equipped with an LCD display showing pressure and temperature readings. You can control the Baxi gas boiler remotely. However, it does not make sense to paint all the points related to the operation of the heating boiler, because step-by-step instructions are available with each device.

Repair of Baksi gas boilers should be carried out only by a certified specialist who can assess the breakdown and has the right to interfere in the internal structure of the device.

Baksi gas boiler, malfunctions and their elimination

The documentation on the operation of the heating gas boiler indicates information about all possible error codes for Baxi gas boilers. Even in the accompanying instructions, you can get information on how to solve the problem with a non-working Baksi gas heating boiler.

How to deal with error e01 gas boiler baxi? This is one of the most common errors - ignition failure. You can try to solve this problem yourself: re-ignite, check the gas supply. If no visible violation is found, then contact the service department.

Spare parts for Baxi gas boilers

In stores selling plumbing and heating equipment, you can freely buy components that can fail after a while. As such spare parts you can buy:

- room thermostat for gas boiler Baxi;

- coaxial chimney for gas boiler Baxi;

- inverter for gas boiler Baxi;

- voltage stabilizer for gas boiler Baxi;

- ups for gas boilers Baxi;

- Baxi gas boiler draft sensor;

- gasoline generator for the Baksi gas boiler;

- heat exchanger for gas boiler Baxi.

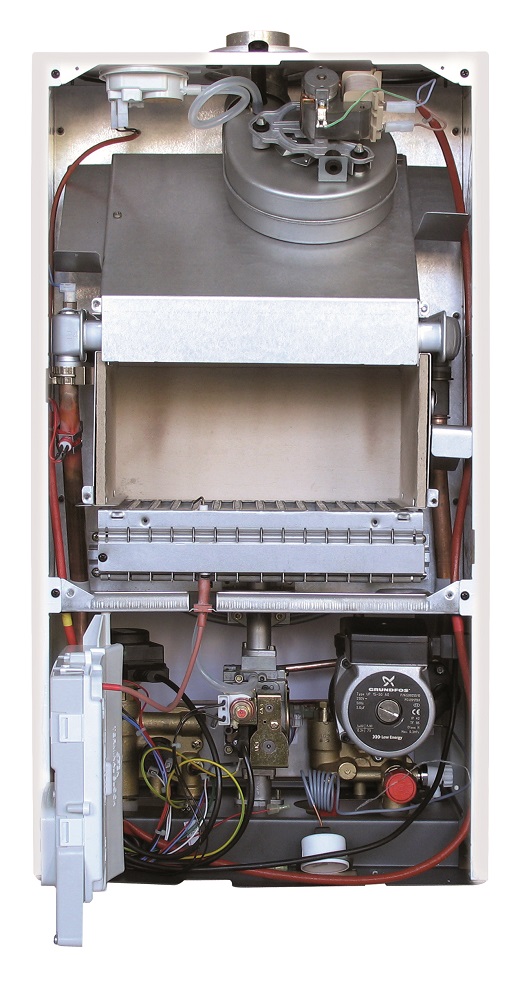

Consider the basic device of the Baxi boiler. The schematic diagram is printed in the instruction manual for each specific model, but the main components will be the same.

At the top is a chimney. Immediately below it is a fan with a Venturi tube and an exhaust hood to remove combustion products. Below is the primary heat exchanger, which looks like a radiator and a coil, a little to the left is a safety thermostat and an NTC heating temperature sensor.

In the center is a combustion chamber, inside which there is a burner and electrodes for ignition and flame ionization. A gas train with nozzles is connected to the modulating burner, into which gas is supplied from the gas valve.

On the right side, a pipe goes down from the heat exchanger, connected to an expansion tank and a circulation pump. The pump is equipped with an automatic air bleed valve. It ends at the bottom with a tap for draining the coolant from the apparatus and a pressure gauge; water from the house heating system enters it.

On the left side, a pipe descends, on which a hydraulic pressure switch is installed and safety valve at the end. Water flows out of it into the heating system. Between themselves, these pipes are connected by an automatic bypass.

In double-circuit models, a secondary plate heat exchanger, a DHW priority sensor and a three-stage valve are additionally installed. The Baksi Luna 3 Combi and Nulova 3 series of models are equipped with an indirect size boiler of small volume.

Main 5 boilers are equipped with a bithermic heat exchanger, which simultaneously heats and running water and heat carrier. This is realized due to the fact that inside the tube through which the liquid from the heating system flows, there is another tube of a smaller diameter through which tap water flows.

An electronic control board is installed in front. The wiring diagram printed in the instruction manual shows where all the elements and sensors of the boiler are connected to. From it you can understand how the electrical part of the equipment works.

A steel casing is installed outside, on which there is an electric control panel with buttons for switching on and selecting an operating mode. In modern models, a display is installed to display technical data and error codes in the event of a malfunction.

Principle of operation

You can find out complete information on the selection, operation and maintenance of gas boilers of all manufacturers if you go.

Let's figure out what is the principle of operation of the Baksi gas boiler. The coolant enters the apparatus system through the right pipe, driven by a circulation pump. Then it enters the heat exchanger.

When the temperature of the liquid drops below the setting in the control panel settings, the gas valve supplies fuel to the burner and the ignition electrode is activated. A flame ignites, which heats the heat exchanger. When heated, the coolant expands and its excess enters the expansion tank.

The coolant exits through the left pipe, passing through the temperature sensor. When the water has heated up to the set level, the gas flow to the burner is shut off. A remote room thermostat can also regulate the operation of the boiler, in which case the operation cycles will be tied to the temperature in the room.

In two-circuit series, a three-stage valve changes the priority of hot water and heating, depending on the needs of the consumer.

Baxi three stage gas valve

Baxi three stage gas valve

The piping of such a boiler is quite simple, since all functional elements are configured and located inside the body. Need to calculate right amount radiators, draw a diagram, and then connect them together and bring all the pipes to the device.

Series and their features

You can find out the whole truth about the conspiracy related to the selection, operation and maintenance of heating boilers of all manufacturers and models.

In order to determine the type of boiler by name, let's deal with the markings. The symbol "F" or "Fi" indicates that the boiler is turbocharged with a closed combustion chamber. Atmospheric vehicles have the letter "i". The word "Comfort" means that the kit comes with a remote control panel, the mark "Air" says that this panel is remote.

The first digit after the name of the series reflects the generation of boilers, and the second - power. For example, the fourth generation Baxi Eco Four 24 F with a closed combustion chamber and a power of 24 kW.

Boiler Baxi Eco Four 24 F

Boiler Baxi Eco Four 24 F

The fifth generation Main 5 series is the next stage in the development of the Baxi Main Four 240 F boilers. It includes three wall-mounted models with a capacity of 14, 18 and 24 kW. All of them are double-circuit due to the installed bithermic heat exchanger, they have electronic protection against scale. Equipped with a closed combustion chamber. The configuration is very adaptive, the boiler operates at a reduced gas pressure of up to 4 bar and power voltage fluctuations from 170 to 270 V.

Boiler panel Baxi Main Four 240

Boiler panel Baxi Main Four 240

The development of the outdated Eco 3 Compact series was the ECO Four (Ecofor), Eco 4s and Eco 5 Compact lines. Baxi Eco Compact devices are small in size due to the optimized internal arrangement of the main components. They include single-circuit and double-circuit devices with a secondary stainless steel plate heat exchanger.

Boiler Baxi Eco Compact 4s

Boiler Baxi Eco Compact 4s

The hydraulic system includes an economical circulation pump with automatic air removal. The range includes 18 models with closed and open combustion chambers with power from 14 to 25 kW. They have a liquid crystal display. Eco 5 Compact devices can be connected to an integrated solar circuit.

The Baxi Four Tech line (Fortech) is a cheaper analogue of the Eco Four series due to plastic inlet water pipes. The Luna 3 and Luna 3 Comfort editions offer single and dual circuit units from 24 to 31 kW. They can run on liquefied gas. The burners have continuous electronic modulation of the flame.

Boiler Baxi Four Tech

Boiler Baxi Four Tech

The electronic board has a self-diagnostic function and the possibility of weekly programming. The Comfort series is equipped with a remote control panel with a built-in room temperature sensor. In the Luna 3 Combi devices, domestic hot water is provided by a built-in 80-liter indirect heating boiler made of Combi 80 stainless steel.

Floor-standing boilers Baxi Slim have very compact dimensions, a stylish gray body with a black control panel and are equipped with a cast-iron heat exchanger. In Slim 2 models, an indirect heating boiler of 50 or 60 liters is installed.

The circulation pump works in three speeds. Power range from 15 to 62 kW. It is possible to connect a programmable timer. Slim EF devices are equipped with gas automatics with a thermocouple, which allows you to work in a non-volatile mode with natural circulation of the coolant.

In conclusion, we offer a video about the device of the BAXI eco four 24 f boiler:

If you want to get complete information on this problem, as well as find out other important nuances about the heating boiler from your manufacturer,.

But, we also have on this problem and not only that, first of all, you will not find it anywhere, because it is asked by specific people who could not get more support and advice anywhere (which they themselves inform us about). And secondly, their problems are so complex that sometimes our expert Alexander Kholodov deals with people for 10 or more days.

And now EVERY question of the user and the answer to it, in order to avoid monetary costs as a result of improper operation or repair of the boiler. And here it doesn’t matter which manufacturer’s device is involved in the issue. What matters is the unique situation that gave rise to this question, because as one good saying goes: "forewarned is forearmed."