Hot water in the bath is necessary, at least in order to take a shower. However, it is far from always possible to supply hot water from the house to a separate bathhouse, and it is not advisable to install an additional electric tank in the bathhouse for heating water. In fact, why increase the cost of electricity if the bath already has a very efficient heater - a stove stove? It remains only to install the tank so that the water is heated, and this does not affect the operation of the heater. The most common way to heat water in a bath is a tank.

Sauna and hot water - how to combine?

Hot water in the bath is necessary, at least in order to take a shower. However, it is far from always possible to supply hot water from the house to a separate bathhouse, and it is not advisable to install an additional electric tank in the bathhouse for heating water. In fact, why increase the cost of electricity if the bath already has a very efficient heater - a stove stove? It remains only to install the tank so that the water is heated, and this does not affect the operation of the heater. The most common way to heat water in a bath is a tank (50-60 l), which is simply attached to one side of the sauna stove, and the water will heat up within 1-2 hours.

Another option - the tank is built into the front or rear wall of the furnace. True, in this form, he will not be able to contain more than 30 liters, the water in it will quickly boil and soar all the time. This method of heating water has one big disadvantage: this option is not acceptable for a sauna, because humidity will constantly be felt in the steam room. Even if you close the tank with a lid, you still cannot avoid humidity in the steam room, and the Finnish sauna differs from the Russian bath in that the humidity in it should be almost zero. If you are planning to use your bathhouse both with the effect of a Russian bath and as a Finnish sauna, there is an option for installing a stove with a heat exchanger (coil, register). In this case, you can regulate the humidity level only by pouring water on the stones, and the water in the tank will not affect the humidity in the steam room in any way.

The advantage of such a connection is that the tank can be moved to an adjacent room (and used as a heating battery), or even to the attic (you can arrange a shower there). Quite an interesting scheme for using a "samovar" type tank (in the case of a smoke tube passing through the tank). In this case, there are two options: a tank on the heater and just a "samovar" tank.

The first option has the inconvenience that water can only flow onto the stones from the side, i.e., the side stones will cover the stones inside the heater. The second option has the problem that you have to fill the water high. But many advantages are also pleasing: - the oven comes out much more compact; - decent savings by reducing the number of chimney elbows, because in this case the role of one of the knees is played by the samovar tank itself; - the high location of the tank solves the problem of the fireproof outlet of the chimney turbine through the ceiling (in case part of the tank gets on the ceiling).

However, the problem of taking water into a highly located tank is easy to solve if you bring a cold water supply pipe to the tank. Then you don’t have to draw water manually at all, it will be enough to open the tap. But do not forget to monitor the water level so that the tank does not overflow and the water from it does not start to overflow.

How to competently conduct water supply in the bath

Usually at each summer cottage or in country house bath is under construction. And what is a bath without water? Water is needed both in the steam room and in the shower. Water supply in the bath can be divided into two types: summer and winter.

Bath water supply in summer

If the bath will be used only in summer, then the pipes can be laid directly on the ground. If soft pipes are laid, then in the fall, with the onset of cold weather, they are removed. Water supply from rigid pipes is not removed for the winter. Its installation is carried out with a slope and a drain pipe is installed at the lowest point, near which a crane is mounted. Another tap is placed on the side of the water supply. For the winter, the water from the pipe is drained, and then it is not afraid of any frost.

Part of the pipeline to the supply tap must be insulated, since water will always be there. Of course, water must be drained from all containers located in the bath itself.

Water supply in winter

First of all, you need to choose pipes in order to properly supply water to the bath. For the outer part of the water supply, metal-plastic pipes are the best option: they are easy to install, have a significant service life, and are not subject to corrosion and frost. Plastic pipes are laid inside the bath.

The trench for the water supply must be deeper level freezing of the ground, otherwise in winter the water in the pipes can freeze and damage them. Usually a trench with a depth of 70-100 cm is sufficient. In addition, the pipes must be insulated with any type of insulation.

Water can be supplied from various sources.

If the site has a central water supply, then water, of course, is taken from it.

The well can be sand or artesian. An artesian, self-flowing well provides for deep drilling, since such water lies at a considerable depth. In this case, the cost of drilling will require considerable financial investments. Getting to sandy waters is much easier and more economical.

Quite often, the water supply in the bath is solved using a conventional well, but it must be taken into account that it must have good water content and a clean bottom.

In order to provide the desired water pressure, quite often set deep pumps. When choosing a pump, pay attention to the following points:

Characteristics of pumps for bath water supply

pump power - the pressure of water in the system will depend on it;

safety;

durability;

well diameter;

lifting height.

After installing the pump, an electrical cord is drawn. It is better if a toggle switch is installed rather than an outlet, as hands can be wet and the toggle switch is safer in this case.

The source of hot water for a bath can be:

centralized backbone network;

geyser;

Electric heaters are capacitive and flow. For a bath, flow heaters are considered more convenient. But their operation requires a large electrical power, which requires a three-phase power supply system. In the absence of such a system, hot water supply in the bath can be carried out using a capacitive heater. Such a heater heats water for 3-4 hours, and then maintains the temperature at a given level.

If electricity is used to heat water, then it is first necessary to ensure reliable wiring.

In the cold season, after each use of the bath, the water must be drained so that the pipes do not freeze from frost. For separately located baths, where it is difficult to supply water, heating is provided from a stove-heater, using special containers for hot and cold water.

People with experience in the construction of domestic structures know that the bath arrangement requires no less attention (and understanding) than the design of residential volumes. For good steam an appropriate water supply system is required.

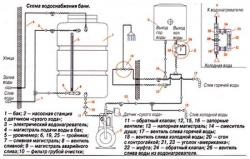

In the absence of a nearby centralized hydrotransmission line, a local water source is being built. Usually this is a well shaft or a borehole pit. If other conditions are equal, the first option is cheaper. But it is advisable to dig a well with a relatively shallow occurrence of the desired hydrolayer (up to 15 m). If a source has already been erected for the house, then you can use it. Then an additional branch of the pressure pipeline simply stretches to the bath house. It should be remembered that the consumption of hydrocontent here is expected to be considerable. Therefore, the water supply scheme of the bath in this case should be in harmony with the overall project of the local water supply system (well / well resource, pumping station performance, etc.).

For the competent formation of the system, it is necessary to find out ahead of time the number and location of water points where the water-heating unit will be located. If, without thinking in advance, then add another pressure branch, then under it it will be necessary to create an additional drain circuit. And this is very difficult to do correctly in an already erected bath building. By the way, the drainage network is built in the project synchronously with the pressure network, taking into account all the proposed places for liquid analysis.

In the case when hydraulic filling is carried out from a source separate from the dwelling, then it will be necessary to take care of the selection of a hydraulic pumping apparatus. Typically, a water supply scheme for a bath is equipped with a submersible deep pump of one modification or another. On a stainless steel cable, such a device descends into the well / well shaft to a previously verified depth. Choice specific model is carried out by a combination of durability, safety and some performance indicators. The latter include the height of the liquid, the diameter of the well, the required pressure in the circuit.

For water heating, a volumetric water-heating electric apparatus is well suited. The displacement of the main tank is selected depending on the number of people who will use the bathhouse. For four people, a tank for 7-8 buckets will be enough.

Drain bends should not be narrower than 50 mm, the slope for them must be maintained at least 2 cm per meter of length. The beginning of each drainage system is completed with a shutter. The drainage collector is deployed no further than 5 m from the building.

Any bath water supply scheme is impossible without pipe bends and connecting fittings. The material for them can be black (simple carbon steel), galvanized, metal-plastic, polymer and even copper. From experience recent years best reviews in terms of price / quality ratio, polypropylene (PPR) elements for plumbing are obtained. With all the lightness and aesthetics, such parts hold water hammer well, work without loss of quality for up to 50 years, and do not collapse at low temperatures. In addition, PPR pipes are indifferent to most chemical active substances. Basically, they can't rust. Solid deposits and colonies of microorganisms do not stick to the inner walls of such pipes.

A polypropylene bath water supply scheme is mounted by heating the mating surfaces of the pipe and fitting with further connection and welding. As a result (after cooling), a homogeneous inseparable continuum emerges, which, in terms of physicochemical properties, does not differ in any way from other sections of the pipe network.

In baths located in the private sector or on summer cottages, metal or brick stoves are usually used to heat water. Such stoves are usually heated with wood and operate periodically, heated by flue gases passing through them. The main disadvantage of such stoves is that you have to wait until the fuel burns out completely so that carbon monoxide does not get into the bath. When the stove stops heating, the soaring time is also limited, as the water and air in the steam room begin to cool.

To avoid this, install a continuous oven made of steel sheets in the bath. Such a stove has a lot of advantages: small dimensions, fuel efficiency, quick heating of a large volume of water and space in the bath, the ability to regulate the temperature of water and air in the bath, complete protection of smoke and combustion channels, which prevents carbon monoxide from entering inside and allows you to heat the stove during bath time.

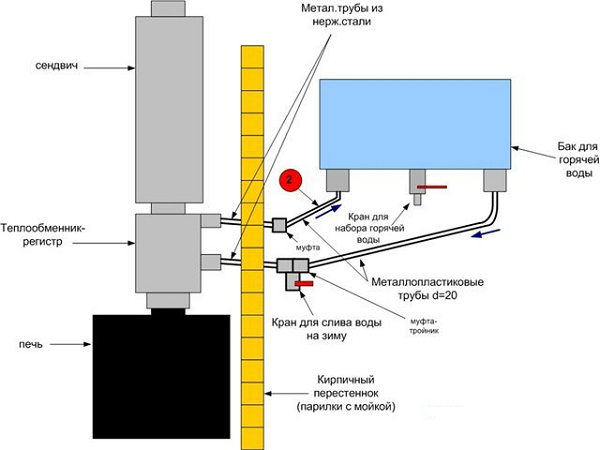

Make a stainless steel hot water tank steel sheet 2 mm thick and is fixed on the wall, and connected to the stove communication with two pipes with a kettle using spurs and nuts. Close the top of the tank with a lid with a hole, through which you can draw water from a hose or fill it with a bucket. Install a drain valve at the bottom of the tank.

Before igniting the stove, fill the tank with water to whatever level is required. Thus, in the process of heating the furnace, the water in the kettle is heated and circulated in the system.

Install such an oven in a bath with a large area with a separate steam room. In this case, the stove can be located in the steam room, and its front wall will be in the washing compartment. Fasten the hot water tank to the wall in the washing room, which provides additional heating. The wall between the steam room and the sink around the stove is made of brick. At any time of the year, the heating of the air in the steam room reaches + 100 ° C for an hour, and about 100 liters of water is heated to boiling water. The ratio of air temperature in the sink and steam room is 1:2. Adjust the heating of water and air by changing the draft in the furnace or the water level in the tank. This can be done by changing the location of the firewood in the firebox: if the firewood is placed closer to the door, the water will heat up faster, and if it is closer to the back wall, the air in the steam room will warm up faster.

The most ideal option would be to make the entire structure of stainless steel. The disadvantage of such a furnace is the low heat capacity, which is compensated by the ability to heat the furnace as much as necessary.

Unconventional way to heat water

Greetings to all bath lovers!

There are many requests in a personal with questions about the method of heating water, which is implemented in my bath (see "Bath Know-How"). Not everyone can find a description of the method, and I decided to put it in a separate topic with recommendations for use.

This method of heating water can be used in metal furnaces, and in brick. It works in several baths (I have about eight years), has justified itself as a reliable way.

What are the advantages of this method:

1. The water tank is not in the steam room, but in the soapy one (for separate baths) - i.e. does not affect the bathing conditions of the steam room;

2. The tank is installed on an ordinary wooden stand at the level of the furnace furnace (excludes hanging on a pipe);

3. The absence of any faucets and, as a result, a quick set of water in the bucket;

4. Quick installation and quick dismantling (no problems with draining water in cold weather);

5. Hot water ready time (for steaming brooms) from 25 to 40 minutes, depending on the volume and initial temperature of the water.

The essence of the method:

1. A tank is made of stainless steel for a volume of 40 to 80 liters of steel with a thickness of about 1 mm (I have 50 liters);

2. A pipe with a diameter of 60 to 80 mm and a length of up to 2.5 m is welded into the side wall of the tank, which has a passage from the side of the tank wall and is welded with a plug at the end. This pipe through the hole in the side wall of the furnace furnace is placed across the width of the furnace at its far end. The length is chosen from considerations: the width of the furnace + the thickness of the wall separating the soap and steam rooms + the distance for free installation of the tank on the pedestal.

How to use it correctly:

1. Install the tank in the furnace;

2. Pour water into the device without leaving bubbles in the pipe (for this, you can tilt the tank by placing a thin rail under it);

3. Fire up the stove by placing wood directly on the water pipe.

Recommendations for use (from personal experience):

1. During the firebox, for the fastest heating of water, coals can be heated directly on the pipe;

2. When the water is heated enough to soak the brooms, drain and add the tank to the top.

3. During washing and parks, if necessary (when approaching boiling water), add cold at your discretion.

Process physics:

1. The water in the pipe boils and goes into the tank being replaced cold water;

2. Since the boiling point is 100 degrees, the iron itself does not heat up more than 100 degrees.

3. No fire hazard (the tank is on a wooden platform)

4. The smoke from the hole in the soap does not go according to the laws of the stove draft.

From experience, we can say that with a tank volume of 50 liters, up to 90 degrees, about 100 liters are heated during the bath (when cold is added).

The method is reliable as a three-ruler. No negative points have been identified.

Hot water is vital for the normal operation of the bath. Many lovers of the steam room are well aware of how problematic the situation is when, in the midst of a steam bath, there is no boiling water. Attempts to heat water on the stove or take it from the stove’s hanging tank usually end in an accident and the owners of the bathhouse are not welcome. Therefore, the source of hot water in the bath must be autonomous.

Providing hot water from an instantaneous water heater

There are several proven methods of flow heating water. These do not include all kinds of electric boilers and heat accumulators. As a rule, such a technique heats water for quite a long time, and at a time it can give out 30-35 liters of hot water. More powerful bulk water heaters cost a lot of money, and for a bath that is visited once or twice a week, it is not advisable to install such a boiler.

It is easier and cheaper to install an instantaneous water heater in a bath. The most convenient options for heating water in a flowing way are several:

- Use a branded flowing water heater for a bath;

- Get boiling water by passing a stream of water through a coil-heat exchanger installed in the bath oven;

- Heat water in a flowing way in a tank welded into the container with a part of the chimney pipe;

- Make a homemade discharge instantaneous water heater.

Important! The first and last options for instantaneous water heaters are convenient in that electrical devices do not depend on the operation of the stove in the bath and provide the most stable volume of water in terms of temperature.

Which instantaneous water heater for a bath is better

The answer is simple - the best would be an instantaneous water heater, which can provide an unlimited amount of hot water, and at the same time provide the most high level security. Most often, the owners or managers of a small bath do not want to complicate their lives by installing “cunning” schemes for flowing water heating, but use simple electric water heaters for a bath, available on the market. But the more people use the bath, the more electricity, and hence the money spent on heating water. Therefore, non-electrical circuits are also widely used, and in some cases there is simply no alternative to them.

Non-electric water heating options

If electricity is not supplied to the bath, there are two ways to heat the water. In the first case, a copper coil or heat exchanger is used for heating, mounted directly into the furnace furnace. At a height of at least three meters, a container with a supply of cold water is installed. A steel pipe supplies a certain amount of water to the flow heater of the furnace, which is regulated by a tap. After heating, due to the difference in pressure, the excess liquid is squeezed into a second container and stored there until used for the needs of a bath, steam room, shower.

To avoid heat loss, the container is wrapped with thermal insulation, as a rule, this mineral wool or felt, and covered with a fiberglass body. Such a system provides heating of water in a constant mode in an unlimited amount. In more modern version Because of the large mass, they try not to lift the tank with cold water in order to avoid pressure on the structure of the bath.

In this case, water is supplied to the water heater of the furnace by creating excess pressure in the cold tank. To avoid local overheating in the water heater heat exchanger in the furnace, it is recommended that one of the pipes, either inlet or outlet, be made entirely of copper, brass or aluminum. In such a system, it is imperative to provide for an emergency valve that would allow superheated hot water to be bled back into a cold container.

The second method involves the use of special containers for running water heating with a part of the chimney pipe welded inward. The built-in fragment of the chimney is made of heat-resistant alloy steel. In this case, the heat of the flue gases moving through the chimney is used for heating. When the furnace is operating even at half power, the gas temperature is at least 400-500 ° C, due to which the water in such a heater is heated to a temperature of 70-80 ° C as quickly as in the previous version.

Unlike a scheme with a tubular coil-heat exchanger, such a water heater is much safer, it is not afraid of failures in the water supply to the flowing part of the water heater. In addition, this method of heating is considered more economical, since it uses the energy of exhaust gases. The disadvantages of the design include the relative complexity and high cost of manufacturing the container - the flow part of the water heater.

Combined designs of instantaneous water heaters

If desired, to provide the steam room and baths with hot water, you can use a combined instantaneous water heater of industrial production. In fact, the device is a boiler with a built-in heater and a small firebox that heats the heat exchanger. The cost of such a heater ranges from 10 to 25 thousand rubles, most often this option is used in permanent baths to provide showers with hot water in continuous mode.

Electric instantaneous water heaters

The most famous version of the instantaneous water heater is the design in which water from the water supply is supplied to a tubular boiler, the surface of which is heated by a hot nichrome spiral. As a rule, the performance of such a water heater is limited to 3-4 liters per minute. The positive aspects include the simplicity and cheapness of the heater, the low weight and compactness of the device, and the relatively low price.

The disadvantages of an electric instantaneous water heater include high sensitivity to the quality of the supplied liquid. At great content calcium and magnesium salts in water, a large amount of scale is deposited on the inner surface of the heating circuit, leading to overheating or even burnout of the water heater heat exchanger.

In addition, the device requires constant pressure in the water supply, otherwise the temperature of the water in the flow path may vary in proportion to the pressure from boiling water to just warm or almost cold. In a bathhouse, the use of such a heater will require the additional installation of a booster water pump and a cold water pressure regulator.

In expensive models of instantaneous water heaters, automation elements are installed that control the heating process and partially compensate for pressure and temperature surges. Instead of nichrome spirals, ceramic elements coated with gold or platinum are installed in the flow part of the water heater, on which scale is not deposited. In operation, such a water heating device turns out to be more economical and convenient than any of the above schemes.

In addition to those listed, there is another category of electric water heaters - electrode heaters. Their principle of operation is different from the previous ones. Heating of water during its movement through the heat exchanger is carried out using two electrodes immersed in the water flow, to which an alternating voltage of the mains is supplied. A feature of such a device is the self-regulation effect: the more liquid flows through the tank, the more heat is released when current passes between the electrodes. In the absence of water supply, heat generation stops without the use of any automation. Thanks to this, the device turned out to be very simple and reliable in operation.

Conclusion

Of these schemes, the most reliable instantaneous water heater can be called a system equipped with automatic operation control. Even with increased power consumption, this option looks more attractive for use in the bath.

Most steam lovers choose a stove, in whose design there is a device for heating and circulating water. It is called a heat exchanger and is made in the form of a flat container with a volume of 3-5 liters with two welded threaded pipes. Such pipes are connected to a remote tank or heating devices.

heat exchanger

Obviously, wooden stoves are used for a bath with a heat exchanger for heating in shower water for heating a rest room or dressing room. Such modern furnace designs can be divided into two categories: with a heat exchanger attached to the chimney or its internal variety. In the second case, these are wooden stoves with a built-in heat exchanger between the firebox and the convector casing, which do not have direct contact with the fire.

The first case is a furnace design having a samovar-type pipe. In this case, the container seems to encircle the entire chimney module, as a result of which the heat received from the combustion of firewood is used as rationally as possible. In wooden sauna stove such a device for hot water supply or heating, built directly into the structure, takes the heat provided for heating the steam room and stones. In a samovar-type device, water is heated due to the heat of the chimney, which is still lost. Installing a heat exchanger on the furnace tube is more efficient, as the water heats up quickly.

The principle of operation of such a design is based on the laws of physics. Before starting the kindling, the container must be filled with water from below in order to prevent the formation of air pockets. The water gradually heats up and passes into the upper part of the pipe. From the lower pipe comes a liquid of lower temperature. As a result of this, not only the circulation of water between the heat exchanger and the heating device occurs, but also an increase in its temperature.

Operation features

As with the installation of any other furnace structures, for this structure, you must also follow the safety rules and established standards. However, in addition to this, there are certain recommendations of experts that are worth listening to.

According to experienced stove builders, the use of water heating from a stove is the most effective option for heating a liquid, if the total length of the connecting pipes between the heater and the heat exchanger is no more than three meters. In this case, natural circulation will be carried out. To do this, it is necessary that the return and direct pipelines be installed at an angle of 2-5 degrees. If a pump is connected to such a system, this will allow you to adjust its length.

In the event that the installation of the furnace in the bath room is carried out without a heat exchanger and there is a need for its further installation, then in this case the power of both units must be taken into account. The removed heat of the device should not take more than 10% of its power from the furnace.

If a remote tank designed specifically for water is connected to the stove, it should be selected in such a way that after two hours of kindling, the temperature of the water in the system is quite high. If this happens earlier than after two hours, then in the future the water will simply boil. At the same time, the steam room itself will be filled with supersaturated steam, harmful to human health. If you use too large a tank, the heated liquid will not soon be at the bathers.