gives you a wide choice. You can purchase and install a ready-made oven, or you can create it yourself. But, in any case, you can’t do without installing a heat shield. And often there are several screens:

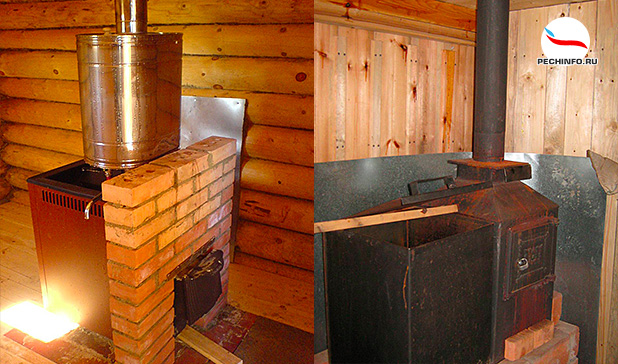

- One closes the body of the metal furnace itself. This shield softens heat radiation from the case. Most often it is made of brick.

- There are screens to protect combustible walls. They are made from any refractory materials and cover adjacent walls.

- And one more kind - non-combustible material on the floor. It can be either a brick “podium” for a metal furnace, or a tile laid on a layer of glue, porcelain stoneware, artificial or natural stone, a sheet of metal, under which a layer of heat insulator is placed.

There are several reasons for making a protective screen for the furnace. And they all deserve attention:

- During the furnace, the metal furnace heats up quite strongly, respectively, there is a high risk of getting burned. It is clear that the constructed protective wall will be a salvation. In addition, if you do not protect the walls of combustible materials near the stove, you can also expect a fire.

- In some situations, when a metal furnace is made by hand, brick screen around the stove also performs a decorative function.

- A metal oven of any type does not allow you to regulate the heat flow of air in the bath. A well-made brick screen is able to fix this and create an adjustable heat exchange.

Everyone knows about the dangers of hard infrared radiation, but from incandescent iron oven there is such a heat that there is no need to lean against - even at a distance you can get burned. will save the inhabitants of the steam room and allow you to feel the full comfort of bath procedures.

Any metal furnace is a source of danger

How to install a brick screen

It is not difficult to make a heat shield for the oven with your own hands. The most popular type is brickwork. Any brick can be used, but solid ceramic is best. It is used for laying brick ovens (about). It is worth knowing only a few basic principles. You need to remember this:

How to protect the walls of a wooden bath

If your bath is brick, then the risk of fire is reduced to a minimum and any stove can be installed right next to the wall. But many people prefer to build wooden baths: it is more useful, more comfortable and more economical. But now it is already impossible to put the stove right next to the wall, since the probability of spontaneous combustion of wood is high.

A good protection for the walls of the bath from the stove is the creation of a protective screen. Unlike complex options with replacing part of the outer wall or laying out the stove in the middle of the steam room, this is easier and more convenient. Consider a heat-resistant screen for a convection-type sauna stove.

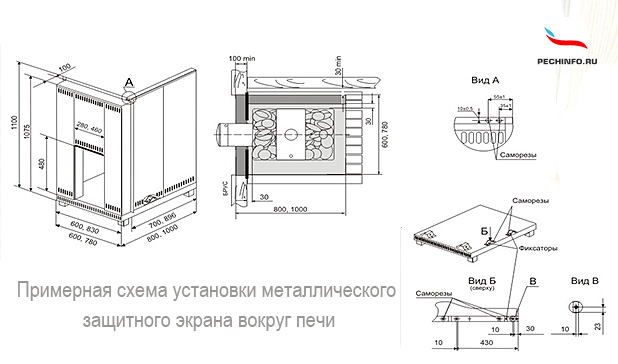

Metal screens for the furnace are assembled from small hollow elements inside, such as boxes. They are framed with stainless steel or sheet metal painted with heat-resistant paint. It turns out that between the two sheets of metal there is an air gap, which provides excellent thermal insulation, protecting the wooden walls from extreme heat. The temperature that is set in such cases between the screen and bearing wall, is no longer sufficient for spontaneous combustion. There are holes at the bottom of the screen, the task of which is to create the necessary air circulation and prevent overheating of the steel sheets.

Create protective screens for sauna stoves do it yourself very easy. The easiest option is to take a sheet of metal. It is better if it is polished - shiny surfaces reflect heat rays well, i.e. it turns out that part of the thermal radiation will be “deployed” into the room, and not absorbed by the metal.

It is impossible to fasten metal directly to a wooden wall: it heats up strongly, and due to its high thermal conductivity, it transfers heat well to wood. Therefore, they take non-combustible strips of their material with low thermal conductivity, nail / screw them onto the wall, and metal is already attached to them. As a result, an air gap remains between the screen and the wooden wall. And one more nuance: the sheet is positioned so that there are several centimeters from the beginning of the metal to the floor. Then the ascending air currents will blow over the screen and carry away most of the heat with them.

You can do it differently: lay a layer of thermal insulation on the wall (mineral, basalt wool, glass wool, etc.), and attach metal to it. There will be no convection in this case, but the wall will be protected from overheating. The thickness of the material depends on the characteristics of the selected heat insulator. They fix it again, depending on the type. If it is a rolled material, a crate is made, the distance between the planks of which is slightly less than the width of the material. A heater is inserted between the planks. In principle, it should hold well without additional fasteners, but you can additionally fix it with the help of special dowels with a large cap. You can put a piece of something dense, but not metal or plastic, under an ordinary nail. If the heat insulator is mineral wool cardboard or asbestos sheet, it can be fixed directly to the wall, and there is already a metal sheet on top.

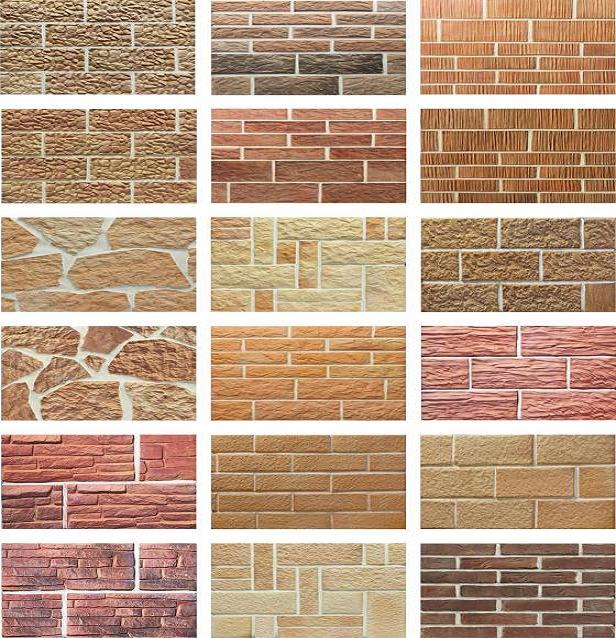

What else can you make a heat-resistant screen for the oven? Looks good and easy to care for ceramic tile, looks great artificial or natural stone. You can lay out a brick wall along a wooden wall. It is advisable then to take the same brick as for the screen (if you did it). Then the overall design will be in the same style. The lining of soapstone slabs or any other looks very nice. natural stone especially in combination with a similar oven lining. But such screens in baths are rather an exception - the material is very expensive to decorate a bath with them.

Metal sauna stoves (purchased or handmade) are popular due to their low cost and the ability to quickly warm up the room. However, the metal case not only looks far from aesthetically pleasing, but is also a source of infrared radiation and increases the risk of fire (especially if the walls of the bath are wooden). To make the structure safer, it is recommended to fold the brick screen.

Brick or metal: choose the material for protection

Traditionally, there are two main types of stove screens - 1) made of brick, 2) made of metal. Let's take a closer look at the features of each.

brick

Brick screens are the most common option for a metal stove in a bath. Such protection can be done in two ways.

- Firstly, it can be a partition-barrier between the metal structure and the walls of the room, as well as between the building and the steam room, where people wash. Such a partition will protect against infrared radiation and prevent wooden walls from slowly smoldering, creating a fire hazard.

- Secondly, the screen can completely frame the entire furnace with a brick wall. That is, externally, the furnace will look like a brick, not a metal one.

Reflective metallic

Reflective systems made of stainless steel are also often found in baths. But it should be understood that in order to reflect IR rays, the metal must be perfectly polished.

Reflective systems made of stainless steel are also often found in baths. But it should be understood that in order to reflect IR rays, the metal must be perfectly polished.

Metal reflective systems, as a rule, they are mounted on the rear walls directly near the furnace. Their task is to protect the walls from intense heating, as well as to redirect heat inside the steam room. In other words, it helps keep the bath at the right temperature and at the same time cut fuel costs.

It should be taken into account that such a screen is very hot, which means that if it comes into contact with a tree, it can lead to ignition. Therefore, it is recommended to protect the structure on the reverse side with heat-resistant materials or provide at least a small air gap.

On sale there are also metal systems with a matte surface. They are cheaper, but their effectiveness is much less. Moreover, some professional stove-makers claim the complete uselessness of these structures.

Please note that many modern factory-made metal heaters come with their own protective sheathing, which virtually minimizes IR radiation. In this case, it makes no sense to mount an additional partition. It is also not necessary to build it for brick oven structures.

Please note that many modern factory-made metal heaters come with their own protective sheathing, which virtually minimizes IR radiation. In this case, it makes no sense to mount an additional partition. It is also not necessary to build it for brick oven structures.

How to make a brick screen?

For the construction of protective masonry, you will need a solid red ceramic brick, which perfectly withstands temperature extremes and constant exposure to water.

For the construction of protective masonry, you will need a solid red ceramic brick, which perfectly withstands temperature extremes and constant exposure to water.

The basic rules for the construction of brickwork for shielding the furnace are as follows ...

- The heat shield must not be placed close to the body. There should be at least 3-10 cm between the metal furnace and the brickwork.

- At the bottom of the masonry it is worth making holes, through which heat will intensively pass, heating the steam room. If you want to be able to control the temperature in the room, equip these holes with oven doors. You can also put bricks into these "holes", if necessary, remove them, and then insert them again. If you like it to be extremely hot in the bath, increase the number of such windows.

- Masonry is done in half a brick. There are craftsmen who prefer a screen made of brick, which is placed on edge. But such a partition will heat up very quickly. Masonry in a whole brick heats up for a long time, respectively, and the room does not warm up too quickly, but the partition itself will give off heat for a long time.

- For masonry, a solution on clay and sand is used. However, the use of cement mortar is allowed.

- The screen must be at least as high as the top of the firebox. But the higher you build a protective wall, the higher your level of protection from IR rays will be. Often there are structures laid completely up to the ceiling.

We build a metal screen with our own hands

Metal reflective systems are easiest to buy ready-made. They are assembled from small and hollow elements-boxes and framed with sheet metal or stainless steel. But if you wish, you can easily create such a protective structure with your own hands.

Metal reflective systems are easiest to buy ready-made. They are assembled from small and hollow elements-boxes and framed with sheet metal or stainless steel. But if you wish, you can easily create such a protective structure with your own hands.

The easiest way- take a sheet of polished metal with a shiny surface so that the heat, reflected from the screen, returns to the room. As already noted, it is impossible to fasten metal directly to a wooden wall. This means that you will need non-combustible strips with low thermal conductivity and are screwed or nailed to the wall, and the screen is already mounted on them. These non-combustible strips should create a small air gap between the metal and the wall.

Please note that the sheet must be positioned so that it is a few cm from the floor. This is necessary in order for the ascending air currents to blow over the screen and carry away most of the heat.

You can also fix mineral or basalt wool on the wall as thermal insulation, and metal sheets can already be attached to it. However, this method will deprive you of convection. Please note that a crate is needed to mount the roll material.

Be sure to take the time to view the prepared photo and video material, which will help you to better understand the topic of arranging screens for the stove in the bath.

The bath is a structure that is simply indispensable for any suburban area. Construction can take place according to the most simplified scheme - by contacting a specialized organization. Despite all the advantages of this method, it should be said about its main drawback. It lies in the relatively high cost of solving the tasks. If the task is to optimize costs and spend a much smaller budget, you should talk about doing the work yourself.

In the steam room, the stove plays the most important role, since it is it that ensures the creation of the required temperature. At the same time, the metal parts of the product are heated up to several hundred degrees. Thermal radiation can not only pose a danger to humans, but also cause a fire, and this is a serious problem.

Installation of heat-resistant screens

You need to think about how to create a reliable fence. It will not allow the sauna stove to cause any damage during operation. To achieve the objectives, it is recommended to use heat-resistant screens.

They are installed in those places where there is contact between walls or interior items with the stove. Installation of protection is required in all cases where there are flammable materials nearby. In the steam room, where everything is finished with natural wood, this moment is especially important.

The screen for the oven is compulsory subject. Features of the product should depend on the material of manufacture of the heating device, its thickness, temperature, power and many other parameters.

The screen should be made in the form of a partition, since it will allow more efficient transfer of heat to the room and not lose it to heat the walls.

The screen can be made by hand, but to complete the task, you will need to take such an event responsibly.

Materials and requirements for the manufacture of the screen

Furnace screens must meet several key requirements, which should be mentioned in more detail. First of all, this includes heat resistance. Insulation implies the impossibility of transferring heat to certain directions. It is impossible to completely exclude such a factor, but there is a real opportunity to significantly reduce thermal radiation.

Furnace screens must meet several key requirements, which should be mentioned in more detail. First of all, this includes heat resistance. Insulation implies the impossibility of transferring heat to certain directions. It is impossible to completely exclude such a factor, but there is a real opportunity to significantly reduce thermal radiation.

It should be said about other requirements that deserve attention:

- Ease of installation. Not all people have the skills and experience to carry out complex installation work. It is for this reason that it is better to consider simpler options.

- High resource of work. Operation will take place in conditions of significant temperatures, humid air and frequent heating and cooling. This implies an accelerated failure if the working resource is small.

- Price. Of course, it's better not to save on screen material, but it's not always possible to buy only the best. It is necessary to take into account the cost of the product.

The modern market can offer the buyer several solutions. The insulation of each of them is different and the screen of the furnace must be chosen taking this into account. Basalt cardboard is quite popular. Sheets with a thickness of about 10 millimeters are optimally suited. Such screens are quite reliable and practical. Mounting must take place at an angle to the oven.

Heat-resistant brick screens

Another option involves the creation of brickwork. Insulation, in this case, is one of the most effective. Heat-resistant brick screens in the steam room should be provided at the construction stage.

Another option involves the creation of brickwork. Insulation, in this case, is one of the most effective. Heat-resistant brick screens in the steam room should be provided at the construction stage.

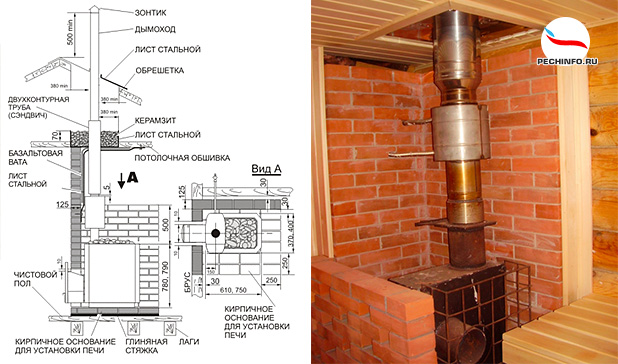

Masonry involves a significant mass and a foundation must be created under it. If it is made only for the furnace, a different type of insulation is required. If this is not foreseen, the most likely outcome will be the occurrence of deformation of the floor. The base for a brick wall for a furnace can also be made after construction work, but such activities involve high labor intensity. In all other respects, this option provides high quality result.

When brick is used, insulation only involves protection from heat. It is important to consider that the material is able to absorb moisture, and this is considered a big problem. A heavily wet brick loses its qualities. The use of silicate types of products to protect against the heat of the oven in the bath is prohibited. For these purposes, red brick is more suitable. To improve the aesthetic qualities, a clinker variant can be used.

Furnace cladding to create a screen

The screen involves several ways of its creation and it is not at all necessary that it be a separate structure. Enough original version should be called the creation of the cladding. As practice shows, this approach allows you to achieve an attractive interior inside the bath.

The screen involves several ways of its creation and it is not at all necessary that it be a separate structure. Enough original version should be called the creation of the cladding. As practice shows, this approach allows you to achieve an attractive interior inside the bath.

It is best to use solid kiln materials as they are well suited to the task at hand. Special attention should be paid to the solution, since it will be operated under high temperatures Oh. A standard cement-based mixture is not suitable here. Should create complex solution based on cement / sand / clay with proportions of 1/30/10, respectively.

It is recommended to use the type of masonry with bandaging of rows. It is required to take into account the thermal expansion of sheet steel and leave a three-row section on top for this. An obvious addition is the fact that such a screen for a bath is only suitable for a brick oven. Wrapping a metal product is not allowed, since a strong expansion occurs when heated.

When working, it is required to take into account the weaknesses of the design. AT stone structures weak point are the seams. The screen must completely exclude gaps so that there are no places where the flame or heat comes into contact with the wooden surface. Additionally, it is recommended to comply with the norms of SNiP 2.04.05 of 1991 regarding indents from the design of heating elements.

The steam room in the bath is a room with an elevated temperature, which is created and maintained by the stove. Wherein this device in addition to heat, it emits a large amount of infrared radiation, which also contributes to an increase in heating. That is why it is necessary to choose the right screen for the stove in the bath in order to get reliable protection from this influence and at the same time do not reduce the intensity of air heating.

Types of structures

To begin with, it must be said that there are two types of such structures that have a similar purpose and at the same time can perform various additional functions. Modern protective screens for sauna stoves quite often combine several different materials and are made in accordance with the design of the stove.

Given these features, the masters try to combine all the properties of such products in order to achieve maximum results.

Brick walls and decoration

- Very often, creating stoves with their own hands, craftsmen resort to creating brick screens.

- Usually this is a partition that separates the metal product from the walls. It prevents the spread of infrared radiation to wooden surfaces and protects them from high temperatures, which can lead to fire.

- Also, the installation instructions advise installing such structures and the place where people will be. So intense radiation will heat the partition, which will play the role of an additional heater. However, it is worth remembering that when using a simple wall, a small air space should be left.

- Some masters offer to immediately frame the whole or stone so that it can perform both tasks at the same time. So the design will protect the walls of the room and prevent intense radiation from getting outside.

- It is worth noting that the screen for the sauna stove can not be used if the structure already has its own skin. This also applies to brick ovens, which in fact themselves represent a firebox with thermal protection.

- For the manufacture of such structures, only red ceramic bricks or other materials with similar properties are suitable. The fact is that it perfectly tolerates moisture and can withstand large temperature changes. Some craftsmen use special stones for this, which have low thermal conductivity and at the same time retain heat well.

Advice! When choosing a material for creating such structures, it is necessary to take into account the fact that it must perfectly tolerate high humidity and even direct contact with water. It should also be remembered that the product will be exposed to high temperatures and it is desirable that it be able to hold it for a long time.

Reflective surfaces

- Quite often, masters recommend using a stainless steel screen for a bath. It should be noted that this metal must be perfectly polished and reflect infrared radiation.

- Similar systems are usually used on the back walls near the stoves. They protect the surface from intense heat and at the same time redirect heat into the room. This allows you to reduce the cost of kindling and maintaining the regime.

- Such heat-resistant screens for sauna stoves work very effectively even with brick ovens or when combined with stone partitions.

- Some manufacturers, making structures for heating baths, actively use them to raise specifications its products. At the same time, professional craftsmen prefer to additionally mount stone or brick bath screens so that they take on all the radiation, converting it into normal heating.

- Special attention deserves the fact that the metal also heats up very much and, in contact with wooden surfaces, can lead to a fire. That is why it is best to protect such a screen for a bath from the back with a heat-resistant material or make a small air gap.

- Quite often on sale you can see screens made of metal with a matte surface. Their price may be several times less, but they are less effective, and professional attendants claim that such screens are generally useless and only take up extra space.

- It is worth noting that such structures require periodic maintenance, since over time plaque and stains appear on them. To do this, they can be wiped with a special detergent or lemon juice.

Advice! AT recent times in stores you can buy ready-made products with a reflective surface. They are immediately placed in a heat-resistant frame and do not need additional processing. That is why it is much easier to use them.

![]()

Conclusion

In the proposed video in this article, you will receive detailed information on this topic. At the same time, on its basis, it can be concluded that the screen is a necessary element of the bath, especially if metal furnaces are used in it. The choice of a specific type of such a design depends only on the personal preferences of the master, although experts say that it is the combined products that give the maximum result ().

To build a protective screen for the furnace, a little brick is required. Another thing is whether it is necessary to build it and how to do it correctly. In this case, we are talking about a bath, or rather, a steam room. To heat it, the owners usually limit themselves to installing a metal wood-burning stove, since a brick one is much more expensive. Here it is important to understand when it is necessary to provide a heat shield, and in what situations it is not needed.

The heat shield enhances the heat transfer of the furnace and ensures compliance with fire safety.

The answer to this question lies in the way heat is distributed from furnaces of any type. There are 2 such ways:

- Direct air heating in the steam room.

- Heat transfer to surfaces using infrared radiation.

For a bath, the first method is preferable, when in the process of heating the steam room, the air is first heated, and wooden shelves, walls and floors receive heat from it. If necessary, hot dry air in the steam room is humidified, this is called "letting steam".

Infrared radiation is emitted by all heated surfaces, including the red-hot walls of the sauna stove. Given that the combustion temperature of firewood reaches +600°C, the outer surface of the metal walls warms up to +300°C. It emits such a powerful stream of infrared radiation that people taking bath procedures can get skin burns.

Sauna stoves of the middle price category are equipped with a steel convection casing, which simultaneously plays the role of a protective screen. More expensive cast iron products are finished with slabs of natural stone: mineralite, soapstone and other rocks. But budget and home-made steel stoves do not have such a screen.

A screen for a sauna stove is required in the following situations:

- when the hot body of the furnace is not closed from the outside with a steel convection casing, and the stove is located in an open place;

- if the oven is equipped with a casing, but stands close to wooden cladding walls;

- if the factory screen is made of thin metal and does not protect well from radiant heat.

It is necessary to protect not only people from hard radiation, but also wooden walls, as the fire safety rules say. Therefore, a heater installed close to a wooden wall must be protected from it by a fireproof barrier. Brick is best suited for this purpose.

What kind of stone is better to protect the stove?

A brick screen is the best solution for a metal sauna stove, and here's why:

- the material completely shields the flow of infrared radiation;

- taking radiation on itself, brickwork accumulates heat, and then gives it to the room for a long time;

- a brick partition is fire resistant and will protect wooden structures;

- construction will not require large investments;

- overlay a homemade steel stove - good way wrap it up nicely.

The best properties for the construction of a protective screen are ceramic solid bricks. It features high heat capacity, flame retardant and attractive appearance, especially if you use facing varieties.

Red hollow stone can also be used for the screen, but you need to understand that it does not accumulate heat so well, is sensitive to temperature changes and will last less.

Putting a fireclay brick screen in the bath will be expensive, and it’s also pointless. Fireclay is not so heat-capacitive, and there are no too high temperatures in this zone.

Types of partitions

Depending on the functional purpose and configuration, the screens are conditionally divided into the following types:

- Protective barriers. Protect people from direct exposure to radiant heat.

- Fire screens. They are built between a wooden wall and a stove in accordance with the requirements of regulatory documents.

- Decorative. They are made in the form of a semicircle or in the form of arched vaults over steel furnaces made of pipes.

In any case, a fire screen is necessary for fencing wooden structures, even when the sauna stove is equipped with a metal casing. The rules allow the use of ordinary sheet metal for this purpose, but a brick partition will look much more aesthetically pleasing.

Cover homemade heaters different designs brick - this is a way to successfully veneer them, since such products do not shine with beauty. If the heat source is welded from a vertical pipe, a round screen can be built around it. A brick arch is built above the horizontal pipe.

Rules for laying a protective partition

The main rule is that a metal furnace and a brick screen must stand on a common foundation that is sufficiently reliable.

If the stove is very small and the fence is low, then it can be built on wooden floor, having previously strengthened the lags. In other cases, it is necessary to arrange a concrete foundation in the form of a slab with a reinforcing mesh inside, since the brickwork has a significant weight.

When constructing a foundation, installing a stove in a bathhouse and laying a brick screen, you must follow these rules:

- From the inner plane of the partition to the walls of the stove, you need to retreat 8-10 cm so that heated air circulates in this space. If you build a screen close to the heater, then the bath will be heated for too long, because the masonry will take the first part of the heat.

- When erecting a brick fire screen, it must be taken at least 5 cm from the wooden wall, so it will be better to give off heat to the steam room. If the wall is external, and the partition is attached close to it, then in winter condensation and mold will appear at the junction of brick and wood.

- To ensure air circulation, it is necessary to provide several openings in the lower rows of bricks, where the cooled air flow will penetrate.

- It is better to prepare a masonry mortar from clay and sand with a small addition of cement for strength. The ratio is as follows: 1 part of clay is mixed with 2 parts of sand, after which 10 to 20% of M400 cement is added to the solution.

To build an ordinary partition out of brick, it is enough to add 10% cement to the mortar, for arched vaults you can add a little more. In addition, for the laying of arches, it is necessary to prepare wooden templates - circles, allowing you to make a gap between the arch and the steel pipe.