The protective screen for the stove in the steam room is a shield that covers the sides of the stove and wall cladding, made of non-combustible materials. It reduces the effect of heat rays. Screens are built of brick or made of metal. In most cases, they are used to ensure the protection of metal furnaces.

What is a protective screen for?

Metal stoves for a bath have both advantages and disadvantages, and these disadvantages will help level the protective screen:

- During the heating process, the metal furnace is very hot, so the likelihood of getting burned increases. Also, during the heating process, intense infrared radiation comes from the metal, the effect of which affects the skin - spots appear on it. Therefore, the first function of a brick screen is protection, thanks to which you can enjoy the soft warmth of the bath.

- Very often self made metal ovens have an ugly look. And the brickwork of the screen makes the oven attractive, that is next function- decorative.

- Since it is impossible to control the release of convection heat flows of hot air in metal furnaces, the screen will regulate this convection heat transfer. Dome-shaped screens with holes made in their upper and lower parts will ensure the regulation of heat transfer.

- The screen laid out of brick is able to accumulate heat. During the heating process, it heats up intensively, and at the end of the bath procedures it will give off heat, speeding up the drying of the bath.

- And one more main function of the screen is fire protection, it will not allow the walls to heat up to critical temperature indicators.

When you don't need a screen protector

However, not in all cases there is a need to install a protective screen or make a protective sheathing. If the stove is installed at a fireproof distance from the walls (that is, at the distance at which the IR rays are scattered and their number becomes safe for the walls), then there is no need to make additional protection.

The safe distance to the wall for a brick kiln is 32 cm, for a metal unlined kiln - at least 1 m, for a metal kiln lined with brick from the inside - 70 cm.

Therefore, if the bath room is small, it is almost impossible to adhere to these rules. In such cases, a protective screen and sheathing will just be the solution to this problem.

Metal protective screen for furnace

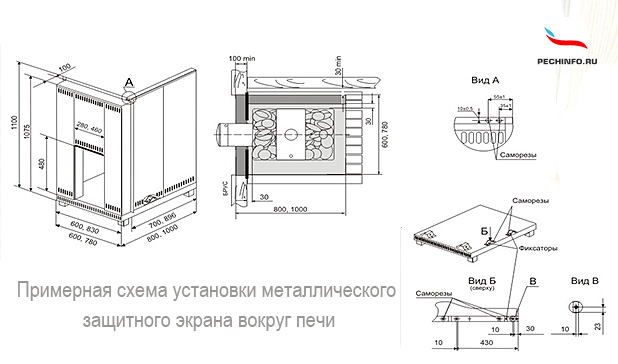

Very often, a protective screen is used, made of sheets of steel or cast iron, which can be purchased from a specialized store. Its installation is carried out along the perimeter of the furnace with a distance of 1-5 cm from the walls of the firebox. Depending on which side of the furnace needs to be screened, front or side screens are selected. On sale you can also find furnaces already equipped with a casing that acts as a screen.

Thanks to the metal screen, it is possible to reduce the temperature of the furnace walls to 80-100 ° C, reducing the fire safety distance to 50 cm.

Accordingly, the distance from the wall to the firebox, taking into account the mounting gap, will be 51-55 cm. The installation of the screen is simple. As a rule, it has legs that are simply attached to the floor with bolts.

The brick protective screen makes it possible to close the side parts of the furnace, creating an outer skin for it, that is, a brick casing. You can also make a brick screen that will separate the fire hazard surface and the furnace.

As a rule, fireclay bricks are used for laying a protective screen. Cement or clay is used as the basis for the solution. Experts recommend building a screen in 1/2 bricks, i.e. the wall thickness will be 12 cm, but thinner masonry can also be made - 1/4 brick (6 cm). However, such masonry reduces the thermal insulation performance of the protective screen by half. This must be taken into account when calculating the safety distance.

In the lower part of the wall, you need to leave holes that will be closed by furnace doors. This is necessary to ensure air exchange between the furnace and the screen.

The screen should be 20 cm higher than the stove. Sometimes it is erected to the ceiling of the steam room.

Protective screens for sauna stoves should be erected at a distance of 5-15 cm from the stove and from the walls.

Now it is enough to make a simple calculation to calculate how far from the wall the stove should be located: from 5 to 15 cm + 12 cm + from 5 to 15 cm = from 22 to 42 cm.

Materials and tools for building a brick screen:

- fireclay brick;

- cement (clay);

- sand;

- Master OK;

- construction mixer;

- level;

- fishing line;

- container for preparing the solution.

Sheathing walls with protective non-combustible materials

To prevent overheating and spontaneous combustion of the walls, special sheathing is made of fire-resistant materials.

Covering with reflective materials

As such sheathing, fire-resistant heat-insulating materials and metal sheets are used. A heat-insulating material is attached to the wooden wall of the steam room, on top of which a metal sheet is mounted. Experts recommend using stainless steel.

It is important to use well-polished metal for work. This will increase the efficiency of the cladding, since the mirrored surface reflects heat rays from the wooden walls and prevents them from heating up. Also, the metal sheet will redirect hard IR rays back into the steam room, making them softer to perceive.

Thermal insulation material can serve:

- basalt wool with increased hygroscopicity, good thermal insulation performance and fire safety (it does not burn);

- basalt cardboard, which is basalt fibers, formed into thin sheets, and is distinguished by its sound-heat-insulating and fire-resistant qualities;

- asbestos cardboard - a high-strength sheet refractory and heat-insulating material, characterized by long service life and the ability to protect walls from fire;

- minerite, which is a refractory plate made specifically for the construction of screens for stoves and fireplaces.

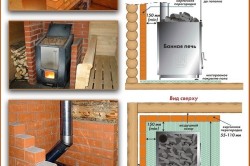

This plating is done like this:

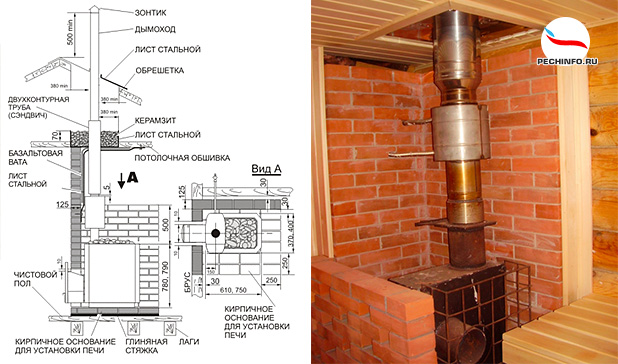

- Scheme: wall - ventilation gap (2-3 cm) - insulation (2-3 cm) - metal sheet. Such protection provides a safe distance from the oven to the wall of 38 cm or more.

- Sheathing fastening is carried out with the help of ceramic bushings, which are not exposed to heat and create an additional gap between the thermal insulation and the wall.

- If for your steam room the safe distance is still large, you can make such a sheathing with two layers of thermal insulation. Then the sheets are fixed with the help of bushings with a gap of 2-3 cm, and after that the top sheet is closed with a metal sheet.

Sheathing with refractory material

There are several types refractory materials, the most common of which are:

- fire-resistant gypsum plasterboard (GKLO), which contains fiberglass, does not deform under the influence of high temperatures;

- minerite is a cement-fiber refractory board, characterized by resistance to moisture and decay;

- glass-magnesium sheet (GML), which is a slab of fiberglass and magnesite binder and has excellent heat, sound, and moisture insulation characteristics and resistance to temperature changes.

Subject to all the installation rules for such protection and the proper organization of ventilation gaps, it will have low heat absorption rates and the wall under it will practically not heat up. protective layer can be masked with facing heat-resistant tiles.

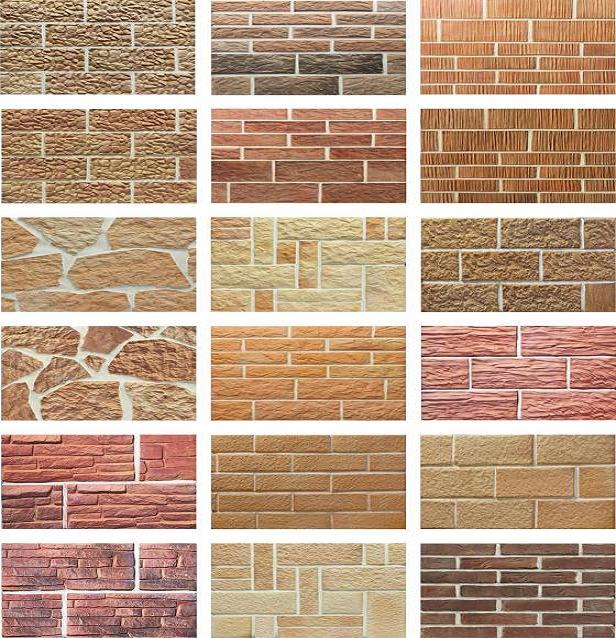

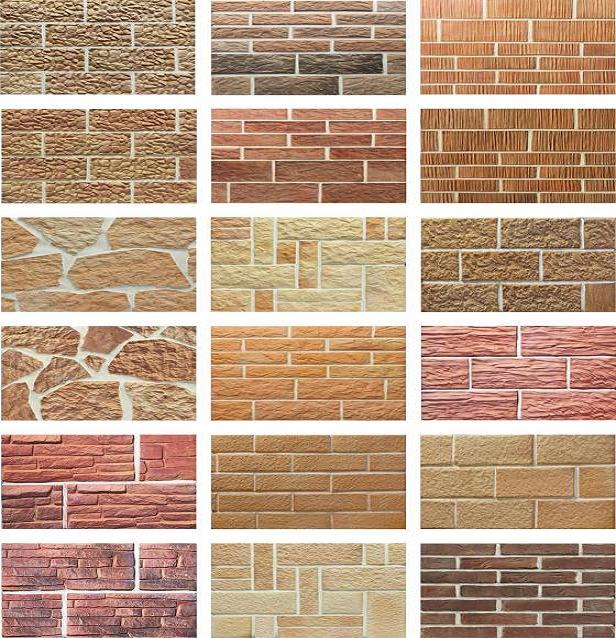

Sheathing with facing heat-resistant tiles

As mentioned above, sheathing with reflective materials is an excellent way to insulate wooden walls from excessive heat and fire. However, it will not be appropriate in all cases from a decorative point of view. For such cases, there is a heat-resistant tile. It will perfectly decorate the skin and will not violate the design and style of the steam room. Such a tile is placed on a special heat-resistant glue.

There are several types of heat-resistant tiles:

- Terracotta tiles, made from fired clay, have excellent strength, heat resistance and durability. It can be matte or glazed, in different shades: from light yellow to brick red.

- Clinker tiles, which are made of clay and look like facing bricks. It has a denser structure than terracotta tiles. Colors can be completely different.

- Tiles, which are a type of ceramic tile, feature which is an embossing on the front side in the form of an ornament or pattern.

- Porcelain stoneware with increased thermal stability and strength. Its front part can be processed different ways. It can be with imitation of stone, brick and even wood. Its colors can be completely different.

- Talcochlorite is a material made from natural mountain stone that has a gray or green tint. Its properties are fire-moisture resistance and strength.

Flame retardant tiling will not provide adequate thermal insulation. The walls will get hot. Therefore, it is only one part of the protective sheathing, which has the following scheme: wall - ventilation gap (2-3 cm) - fire-resistant sheet material - heat-resistant facing tiles. With this scheme, the oven should be at a distance of at least 15-20 cm from the tile.

The bath is a structure that is simply indispensable for any suburban area. Construction can take place according to the most simplified scheme - by contacting a specialized organization. Despite all the advantages of this method, it should be said about its main drawback. It lies in the relatively high cost of solving the tasks. If the task is to optimize costs and spend a much smaller budget, you should talk about doing the work yourself.

In the steam room, the stove plays the most important role, since it is it that ensures the creation of the required temperature. At the same time, the metal parts of the product are heated up to several hundred degrees. Thermal radiation can not only pose a danger to humans, but also cause a fire, and this is a serious problem.

Installation of heat-resistant screens

You need to think about how to create a reliable fence. It won't allow sauna stove cause no damage during operation. To achieve the objectives, it is recommended to use heat-resistant screens.

They are installed in those places where there is contact between walls or interior items with the stove. Installation of protection is required in all cases where there are flammable materials nearby. In the steam room, where everything is finished with natural wood, this moment is especially important.

The screen for the oven is compulsory subject. Features of the product should depend on the material of manufacture of the heating device, its thickness, temperature, power and many other parameters.

The screen should be made in the form of a partition, since it will allow more efficient transfer of heat to the room and not lose it to heat the walls.

The screen can be made by hand, but to complete the task, you will need to take such an event responsibly.

Materials and requirements for the manufacture of the screen

Furnace screens must meet several key requirements, which should be mentioned in more detail. First of all, this includes heat resistance. Insulation implies the impossibility of transferring heat to certain directions. It is impossible to completely exclude such a factor, but there is a real opportunity to significantly reduce thermal radiation.

Furnace screens must meet several key requirements, which should be mentioned in more detail. First of all, this includes heat resistance. Insulation implies the impossibility of transferring heat to certain directions. It is impossible to completely exclude such a factor, but there is a real opportunity to significantly reduce thermal radiation.

It should be said about other requirements that deserve attention:

- Ease of installation. Not all people have the skills and experience to carry out complex installation work. It is for this reason that it is better to consider simpler options.

- High resource of work. Operation will take place in conditions of significant temperatures, humid air and frequent heating and cooling. This implies an accelerated failure if the working resource is small.

- Price. Of course, it's better not to save on screen material, but it's not always possible to buy only the best. It is necessary to take into account the cost of the product.

The modern market can offer the buyer several solutions. The insulation of each of them is different and the screen of the furnace must be chosen taking this into account. Basalt cardboard is quite popular. Sheets with a thickness of about 10 millimeters are optimally suited. Such screens are quite reliable and practical. Mounting must take place at an angle to the oven.

Heat-resistant brick screens

Another option is to create brickwork. Insulation, in this case, is one of the most effective. Heat-resistant brick screens in the steam room should be provided at the construction stage.

Another option is to create brickwork. Insulation, in this case, is one of the most effective. Heat-resistant brick screens in the steam room should be provided at the construction stage.

Masonry involves a significant mass and a foundation must be created under it. If it is made only for the furnace, a different type of insulation is required. If this is not foreseen, the most likely outcome will be the occurrence of deformation of the floor. The base for a brick wall for a furnace can also be made after construction work, but such activities involve high labor intensity. In all other respects, this option provides high quality result.

When brick is used, insulation only involves protection from heat. It is important to consider that the material is able to absorb moisture, and this is considered a big problem. A heavily wet brick loses its qualities. The use of silicate types of products to protect against the heat of the oven in the bath is prohibited. For these purposes, red brick is more suitable. To improve the aesthetic qualities, a clinker variant can be used.

Furnace cladding to create a screen

The screen involves several ways of its creation and it is not at all necessary that it be a separate structure. Enough original version should be called the creation of the cladding. As practice shows, this approach allows you to achieve an attractive interior inside the bath.

The screen involves several ways of its creation and it is not at all necessary that it be a separate structure. Enough original version should be called the creation of the cladding. As practice shows, this approach allows you to achieve an attractive interior inside the bath.

It is best to use solid kiln materials as they are well suited to the task at hand. Special attention should be paid to the solution, since it will be operated at high temperatures. A standard cement-based mixture is not suitable here. Should create complex solution based on cement / sand / clay with proportions of 1/30/10, respectively.

It is recommended to use the type of masonry with bandaging of rows. It is required to take into account the thermal expansion of sheet steel and leave a three-row section on top for this. An obvious addition is the fact that such a screen for a bath is only suitable for a brick oven. Wrapping a metal product is not allowed, since a strong expansion occurs when heated.

When working, it is required to take into account the weaknesses of the design. AT stone structures weak point are the seams. The screen must completely exclude gaps so that there are no places where the flame or heat comes into contact with the wooden surface. Additionally, it is recommended to comply with the norms of SNiP 2.04.05 of 1991 regarding indents from the design of heating elements.

A metal stove is a great option for a bath. But, one of the most basic advantages of this oven - the ability to quickly heat up - turns into a significant drawback at the same time. Its metal body emits harsh infrared radiation, which can cause heat stroke, and accidental contact can cause burns. This is doubly dangerous if you take children with you to the bathhouse.

Brick screen for a metal furnace: for what, from what and how

To make bathing procedures safe and comfortable, it is necessary to install a protective screen around the furnace body - a fence. Safety fences for the sauna stove must be made of fire-resistant and safe materials that do not emit harmful chemicals when heated. Of course, brick is best suited for these purposes.

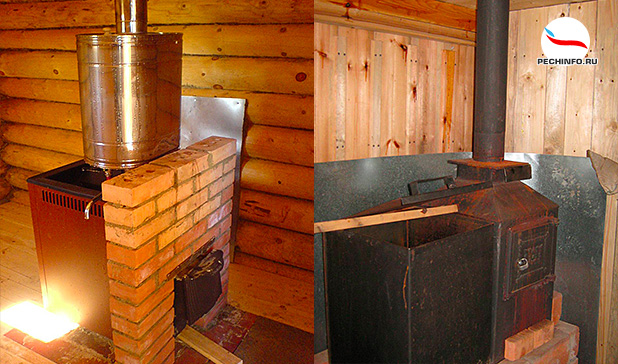

Brick fencing can be easily made by yourself. It can be laid with solid masonry, as in this photo, but this option significantly increases the time required to warm up the steam room and, accordingly, the amount of fuel consumed. This option is considered more acceptable for the atmosphere of a Russian steam room - you can achieve a gentle temperature (up to 70 ° C), and if the stove is closed in the stove, then the steam should be “light”. But for a sauna, this option is somewhat inconvenient from the point of view that it is really necessary to spend more time and firewood on preparing a steam room, but being in a room where the stove heats and does not burn even at high temperatures is much easier and more pleasant than where the oven is not shielded.

Therefore, some attendants, based on operating experience, recommend laying bricks in a quarter, half or in a checkerboard pattern, leaving “windows” between the bricks, as shown in these photos. This way of laying the protective screen will provide both security and will not have a significant effect on reducing the level of heat in the steam room. In this case, it should be taken into account that the distance from the furnace to the brick fence is not critical and can be 3-5 cm.

The brick slowly heats up and gradually accumulates heat, but then gives it to the steam room for a long time, acting as an additional heat accumulator. The brick fencing of the stove converts strong heat into lighter heat, creating comfort in the bath.

For laying a brick protective fence, it is better to use clay-cement mixtures with a cement content of 5–10% - such masonry seams will not be washed away from water and will not crack from high temperature.

Wooden safety fence

To prevent accidental touching of the stove, you can use a wooden fence for the stove. This type of protection is equally applicable both in the bath and in the sauna. It is important to observe fire safety measures and use suitable materials, such as abachi wood, which is highly moisture resistant and has low thermal conductivity and heat capacity: its surface always feels warm to the touch, not hot. But this exotic wood is very expensive. Of our domestic species, alder and linden are perfect for these purposes. It is undesirable to use pine: it contains a large amount of resins, which, when heated, can cause burns.

A wooden fence for a stove in a bath or sauna can be purchased ready-made or you can build it yourself. Here are some installation options for you. If the steam room will be visited by small children, then make a fence in the form of a decorative fence, leaving very small distances between the boards so that even the smallest one cannot stick his hand in and get burned. In the case of visiting the steam room exclusively by adults, you can make a barrier of a simpler design - several longitudinal and transverse guides, as in this photo.

The distance from the stove to the wooden fence is usually indicated in the factory instructions for the stove. According to fire regulations, the distance from the furnace to combustible materials must be at least 500 mm.

Important! Be careful when using wooden fencing. If there is a darkening of the color or other signs of heating, move the guard a little further.

Screens to protect combustible (wooden) walls

It is necessary to protect not only people from the hard radiation of a metal furnace, but also the walls located near it, especially if they are wooden. For this, heat-resistant screens are most often used. Most often, the screens are metal. Moreover, it is desirable that the metal be polished: in this case, heat rays are reflected back into the room. But metal screens cannot be mounted directly on a wooden wall: they have a sufficiently high thermal conductivity and effectively transfer heat to the walls, but we do not need this. Therefore, it is necessary to lay a layer of thermal insulation under a sheet of metal. Most often, mineral or basalt wool of small thickness is used (1-2 cm is enough), cardboard made from the same materials, asbestos sheet could be used earlier, but today it has been concluded that it is harmful. Glass wool was also popular earlier: it is an excellent heat insulator, but it is difficult to work with it - protective suits and gloves are needed, a respirator is required.

Another way to attach a protective metal screen is with a ventilated gap of 2-3 cm. A frame made of a material that tolerates high temperatures, but has poor thermal conductivity, is stuffed onto the wall. You can use small pieces of plastic or metal-plastic pipes for hot water: screw pipe sections with self-tapping screws to a wooden wall (vertically), and there is already a metal sheet on them. In this case, the lower edge of the sheet should be placed a few centimeters above the floor so that an air flow moves between the metal and the wall, cooling both the sheet and the wall.

Another type of protective screen is brick. A second wall is laid out on the floor or in a quarter of a brick. Its height is usually recommended by the oven manufacturers, but it is usually 40-50 cm higher than the top of the oven. Save a wooden wall ceramic tile. It looks great, is durable and easy to care for.

Often manufacturers of metal furnaces offer ready-made screens to protect walls. These are structures made of two sheets of metal with an air gap between them. They are covered with heat-resistant paint, often a decorative pattern is applied to them, so that such a screen serves not only as a protection for the wall, but also as an element of decor.

It can be mounted on a wall or in a place specially left for it (taken into account when planning and building a steam room). Do-it-yourself metal screens cannot be painted: a special heat-resistant paint is required, which is applied in the factory by hot spraying.

Metal sauna stoves (purchased or handmade) are popular due to their low cost and the ability to quickly warm up the room. However, the metal case not only looks far from aesthetically pleasing, but is also a source of infrared radiation and increases the risk of fire (especially if the walls of the bath are wooden). To make the structure safer, it is recommended to fold the brick screen.

Brick or metal: choose the material for protection

Traditionally, there are two main types of stove screens - 1) made of brick, 2) made of metal. Let's take a closer look at the features of each.

brick

Brick screens are the most common option for a metal stove in a bath. Such protection can be done in two ways.

- Firstly, it can be a partition-barrier between the metal structure and the walls of the room, as well as between the building and the steam room, where people wash. Such a partition will protect against infrared radiation and prevent wooden walls from slowly smoldering, creating a fire hazard.

- Secondly, the screen can completely frame the entire furnace with a brick wall. That is, externally, the furnace will look like a brick, not a metal one.

Reflective metallic

Reflective systems made of stainless steel are also often found in baths. But it should be understood that in order to reflect IR rays, the metal must be perfectly polished.

Reflective systems made of stainless steel are also often found in baths. But it should be understood that in order to reflect IR rays, the metal must be perfectly polished.

Metal reflective systems, as a rule, they are mounted on the rear walls directly near the furnace. Their task is to protect the walls from intense heating, as well as to redirect heat inside the steam room. In other words, it helps keep the bath at the right temperature and at the same time cut fuel costs.

It should be taken into account that such a screen is very hot, which means that if it comes into contact with a tree, it can lead to ignition. Therefore, it is recommended to protect the structure on the reverse side with heat-resistant materials or provide at least a small air gap.

On sale there are also metal systems with a matte surface. They are cheaper, but their effectiveness is much less. Moreover, some professional stove-makers claim the complete uselessness of these structures.

Please note that many modern factory-made metal heaters come with their own protective sheathing, which virtually minimizes IR radiation. In this case, it makes no sense to mount an additional partition. It is also not necessary to build it for brick oven structures.

Please note that many modern factory-made metal heaters come with their own protective sheathing, which virtually minimizes IR radiation. In this case, it makes no sense to mount an additional partition. It is also not necessary to build it for brick oven structures.

How to make a brick screen?

For the construction of protective masonry, you will need a solid red ceramic brick, which perfectly withstands temperature extremes and constant exposure to water.

For the construction of protective masonry, you will need a solid red ceramic brick, which perfectly withstands temperature extremes and constant exposure to water.

The basic rules for the construction of brickwork for shielding the furnace are as follows ...

- The heat shield must not be placed close to the body. There should be at least 3-10 cm between the metal furnace and the brickwork.

- At the bottom of the masonry it is worth making holes, through which heat will intensively pass, heating the steam room. If you want to be able to control the temperature in the room, equip these holes with oven doors. You can also put bricks into these "holes", if necessary, remove them, and then insert them again. If you like it to be extremely hot in the bath, increase the number of such windows.

- Masonry is done in half a brick. There are craftsmen who prefer a screen made of brick, which is placed on edge. But such a partition will heat up very quickly. Masonry in a whole brick heats up for a long time, respectively, and the room does not warm up too quickly, but the partition itself will give off heat for a long time.

- For masonry, a solution on clay and sand is used. However, the use of cement mortar is allowed.

- The screen must be at least as high as the top of the firebox. But the higher you build a protective wall, the higher your level of protection from IR rays will be. Often there are structures laid completely up to the ceiling.

We build a metal screen with our own hands

Metal reflective systems are easiest to buy ready-made. They are assembled from small and hollow elements-boxes and framed with sheet metal or stainless steel. But if you wish, you can easily create such a protective structure with your own hands.

Metal reflective systems are easiest to buy ready-made. They are assembled from small and hollow elements-boxes and framed with sheet metal or stainless steel. But if you wish, you can easily create such a protective structure with your own hands.

The easiest way- take a sheet of polished metal with a shiny surface so that the heat, reflected from the screen, returns to the room. As already noted, it is impossible to fasten metal directly to a wooden wall. This means that you will need non-combustible strips with low thermal conductivity and are screwed or nailed to the wall, and the screen is already mounted on them. These non-combustible strips should create a small air gap between the metal and the wall.

Please note that the sheet must be positioned so that it is a few cm from the floor. This is necessary in order for the ascending air currents to blow over the screen and carry away most of the heat.

You can also fix mineral or basalt wool on the wall as thermal insulation, and metal sheets can already be attached to it. However, this method will deprive you of convection. Please note that a crate is needed to mount the roll material.

Be sure to take the time to view the prepared photo and video material, which will help you to better understand the topic of arranging screens for the stove in the bath.

How to overlay a metal (iron) oven with a brick

The traditional stove of the Russian bath was a stove made of stone and brick. It is good because when heated it creates a mild thermal regime in the steam room, then it cools down for a long time. For example, it was convenient that the next day in the bathhouse the hostess usually arranged washing and the water in the boiler was still almost hot, and it was warm to work. However, the stone oven also has obvious disadvantages:

- for a long time, within 4-6 hours, warms up;

- more fuel is required;

- big sizes;

- short service life.

All of the listed negative qualities are absent from a metal furnace. But she has her shortcomings. First of all, it is hard infrared radiation, which comes from a metal heated to a high temperature. Moreover, hot walls, if they are made of ordinary steel, burn out oxygen in the steam room. Such a steam room with insufficient ventilation brings a headache, lethargy and weakness instead of cheerfulness and Have a good mood. Well, the second drawback is the increased risk of burns on contact. And the third is the risk of fire.

If we proceed from the fact that the truth, most often, is in the middle, then the best oven is still a combination of steel and brick. All of the listed negative factors of the metal become less pronounced while maintaining, to one degree or another, the positive features of a brick oven.

How to overlay a metal furnace with a brick

Brick lining a metal bath stove: choice of materials and devices

When the question is being decided how to overlay the stove in the bath, the answer is unambiguous - with a brick, but with what kind of brick - here you need to proceed from the properties of each type. Silicate is not used for this purpose - it is destroyed by temperature. Fireclay is rarely used: the price bites, and it cools down quickly - it has other tasks. It is irrational to use facing - it cracks. Not all, but often from the beautiful appearance not even half left.

Do-it-yourself heat shield for the oven is real

In choosing which red brick to overlay the sauna stove, the owner is free to choose. But it is worth considering that a full-bodied stove brick will take longer to warm up, but it also cools down for a long time, i.e. it dries the steam room well, which is very important for a bath. Well, it's well worth it. Solid or hollow - largely depends on whether you have a foundation for the stove or how powerful the boards and logs are at the screen installation site. Hollow weighs, understandably, less.

In addition to brick for facing the furnace in the bath, you can use porcelain stoneware, a natural stone, tiles, marble ... but these are such rare cases that even a photo of such a bath was quite difficult to find.

How to overlay the stove in the bath? Can be soapstone slabs

Foundation or floor?

The lining of a metal stove with brick begins with an assessment of the bearing capacity of the floor. It is necessary to calculate the weight of the future masonry by multiplying the number of bricks in the rows by the number of these rows and by the weight of one brick. We get the weight of the brick screen. And this weight will be added to the weight of the stove and the water tank! If the mass is less than 700 kg, you can get by with strengthening the log: lay additional ones and fasten them to the main frame. With insufficiently strong lags and high weight, the best option is to make a separate foundation for the furnace.

If the foundation was not prepared at the construction stage of the bath, you will have to disassemble the floor, dig a foundation pit. Its depth is on the same level with the foundation of the building, its dimensions are 15-25 cm wider than the dimensions of the furnace screen.

Before bricking a metal furnace, we prepare the foundation

The foundation of the furnace must be non-cohesive, which means that if the furnace is located close to one of bearing walls, between the foundation of the building and the furnace there must be a gap of at least 5 cm. And the two foundations should not be connected with each other. The distance between them is filled with thermal insulation. This will reduce heat loss and the steam room will warm up faster. The height of the foundation for the furnace is 10-15 cm below the floor level.

After the foundation has dried (at least 30 days), a roofing material, roofing felt or other moisture-proof material is laid on it in two layers, two rows of bricks are placed on top (on a clay-cement mortar), shifting each brick relative to each other so that the seams overlap brick on top. Now the foundation for the furnace and the screen is ready.

Before bricking an iron stove, we prepare the foundation

Even if the logs and the floorboard are powerful enough to support the weight of the entire structure, additional work is indispensable: you need to make a base for installing the stove and for installing a brick screen. Such a non-combustible base can serve:

- a sheet of metal, which is fixed on top of a layer of heat-insulating material;

- two rows of brickwork, which were laid on a wooden floor;

- thick heat-resistant ceramic tiles, natural or fake diamond etc.

Briefly about the solution

When the issue of the foundation is resolved, before bricking the iron stove, the problem with the mortar must be solved. The most acceptable for laying the screen will be simple clay mortar with the addition of sand. This mortar for lining a metal furnace is prepared in exactly the same way as for masonry brick ovens, considering its fat content. Clay from a depth of at least 2 meters is soaked in a trough. So that lumps and foreign inclusions do not come across in the solution, the clay in the soaked state is rubbed through a sieve. The sand is sifted, mixed with pasty clay. The viscosity is selected in such a way that the solution is not squeezed out of the joints during masonry, but is sufficiently plastic.

The screen masonry mortar should not spill out or “float”

Another option is to add 5-10% cement to the clay mortar. Then he will keep well and will not crumble. Some owners of sauna stoves laid brick screens on the cement. They stand well.

Ready-made compounds can be used for masonry, but not those that are used when laying the firebox and refractory bricks: in order for them to normally hold the masonry, a temperature in the region of 1000 ° C is required. Then all these compounds are sintered with refractory bricks into a monolith. If there is no such temperature (and where can it be taken on the screen), the solution gradually crumbles and spills out of the seams.

Thickness and type of brick screen, masonry technology

Connoisseurs say that the stove should be lined with half a brick. This is the best variant. You can make a screen in a brick, but it will warm up for a very long time. And under such a wall, a foundation is required. You can make a quarter of a brick, and even in discharge - leaving "windows". In this case, the steam room will warm up quickly, but the radiation will be quite hard. Here everyone chooses what suits him best, but in any case, the distance between the masonry and the walls of the metal furnace should be within 3 - 10 cm.

Even with a solid screen, you can speed up the heating of the steam room. To do this, special windows are left in the masonry, into which they either insert oven doors or simply close them with bricks. If you need to heat the steam room faster, open the doors or remove the bricks. Hot air actively passes into the steam room. After the temperature becomes acceptable for you, close the doors. Now the steam room will hardly heat up, the temperature will be stable.

Another option, in which hard radiation decreases and the air heats up quickly: you can leave the front part open (this is if the stove is entirely in the steam room).

Brick lining of a metal furnace in a row

If the screen is solid, in the first or second row you need to leave two holes on each side for accelerated convection and heating. Then these holes are repeated in the upper rows. Warm air will come out of the upper holes and quickly warm up the bath. If the stove is very powerful (for example, Teklar stoves are used only with a brick screen), these holes can be equipped with standard cast stove doors and use them to regulate the temperature in the steam room. About how to overlay metal furnaces "Teklar" even removed material.

From practical recommendations, we add that through a row or in each one it is necessary to lay a reinforcing mesh in order for the screen to be durable. Arrange the bricks so that the seam of the previous row is closed by the brick in the next (laying with an offset or with a dressing). Everything will be more clear if you look at the photo.

A brick screen with numerous windows is more suitable for a sauna

The top of the oven is often left open. If the heater is of an open type, then the stones soften the radiation. If you are still too hot, you can lay a metal mesh made of thick wire with a small cell on the finished screen, and put stones for the bath on top. But this option is somewhat inconvenient for servicing the furnace: every time you have to remove everything. Therefore, more often, either the top is left open, or only part of the furnace is covered with a grid with stones.

brick lining iron oven and chimney

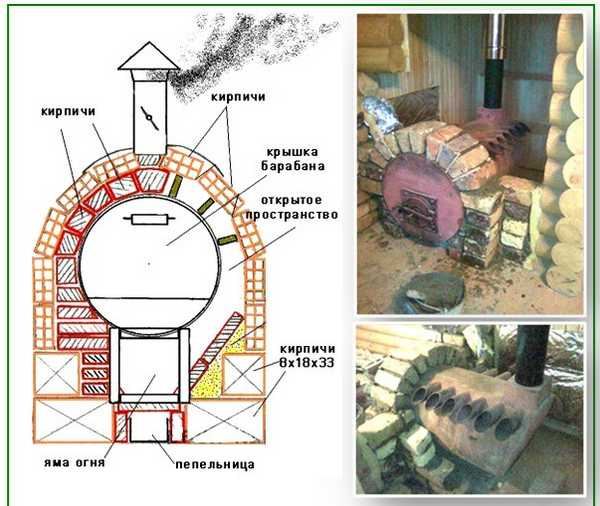

If you have to decide how to overlay a round iron stove with bricks, then there will be no special structural changes. It’s just that with circular masonry, the ventilation holes will have to be placed symmetrically and at about the same distance from one another, as would happen when laying a rectangular oven. And strictly observe the distance between the brick and the oven!

Overlaying a round iron stove with bricks is somewhat more difficult, but the principle is the same. Here, by the way, the top is closed with a net, and stones are laid on it

When bricking potbelly stoves, the same rules apply. Only the moment of making openings in the masonry for the furnace and blower doors is added. The overlap of these openings is made by two segments of steel corners located outside and inside the masonry.

How to overlay a round iron stove with bricks. Scheme

In conclusion, I would like to add that all the described actions can be performed and not necessarily by a professional. high class. Usually the owner does everything with his own hands. After all, the volume of masonry is minimal, and the requirements for the quality of masonry are not the highest.

http://teplowood.ru