Ramp - a device designed to simplify the movement of prams and wheelchairs.

It is customary to distinguish between two types of such a device: stationary and folding.

The first type of ramps is not suitable for all entrances apartment buildings. Its installation is not possible when the width of the stairs is less than 2.5 meters. A folding ramp is suitable for such stairs.

In accordance with Article 19 of the Constitution of the Russian Federation and Articles 15 and 16 of the Federal Law "On the social protection of persons with disabilities in the Russian Federation", any resident apartment building has the right to request the installation of a ramp in the entrance of his house.

To do this, he must apply to the ZhEK or HOA with a written application addressed to the head. It must indicate in which house, entrance and on which floor you want to install a ramp.

Despite the fact that since 2013 it is not required to collect signatures from neighbors, it is still recommended to enlist their support. The more signatures of neighbors are collected, the more likely it is that the management company will make a positive decision on your application.

Please note: the application must be drawn up in 2 copies, one of which is sent to the Housing Office or HOA, and the second remains in your hands.

It can be submitted in two ways:

- personally;

- mail.

In the case of a personal appeal, the incoming number and date must be affixed to your copy. When sending by mail, use only registered mail with notification. Attach the receipt of delivery of the letter to your copy of the application.

After the home service organization receives your application, they have 30 days to review it, after which they must make a decision on it and give you a written response.

At whose expense is the installation of the ramp?

The installation of a ramp in a multi-storey building, according to the type of work, refers to the reorganization and overhaul. Therefore, payment for its installation is charged from homeowners.

To install the ramp, they can choose any contractor or carry it out on their own in agreement with the management company. Moreover, it must have documents confirming its safety.

In their absence, the ramp can be dismantled, and management company issue a fine of 50,000 rubles.

What to do if the installation of the ramp is denied?

Despite the law, the Criminal Code or the HOA, in some cases, may refuse to install the ramp. Most often, the refusal is argued by the inconsistency of the flight of stairs with the requirements for installing a stationary type of device.

You can file a complaint against a specific official with authorities such as:

- prosecutor's office;

- city administration;

- housing inspection;

- society for the protection of consumer rights.

You can also appeal the denial in court.

How to make a ramp yourself?

In the event that you have expressed a desire to make a ramp with your own hands and have received permission from the management company or the HOA for this, you can proceed to design it.

First, you need to decide what kind of ramp you need. Further, its dimensions should be calculated, taking into account the established standards and norms of SNiP and GOST.

Requirements for ramps

When designing, the following nuances should be taken into account.

- The angle of inclination of the device should not exceed 8% when lifting to a height of more than 20 cm and 10% if the lifting height is less than 20 cm.

- There must be space for the wheelchair before and after lifting, its minimum size must correspond to the size of the wheelchair.

- If the ramp is intended for one-way traffic, its width must be at least 90 cm, and for two-way traffic - at least 180 cm.

- It is mandatory to have handrails on at least one side with a lift height of more than 15 cm or a ramp length of 180 cm.

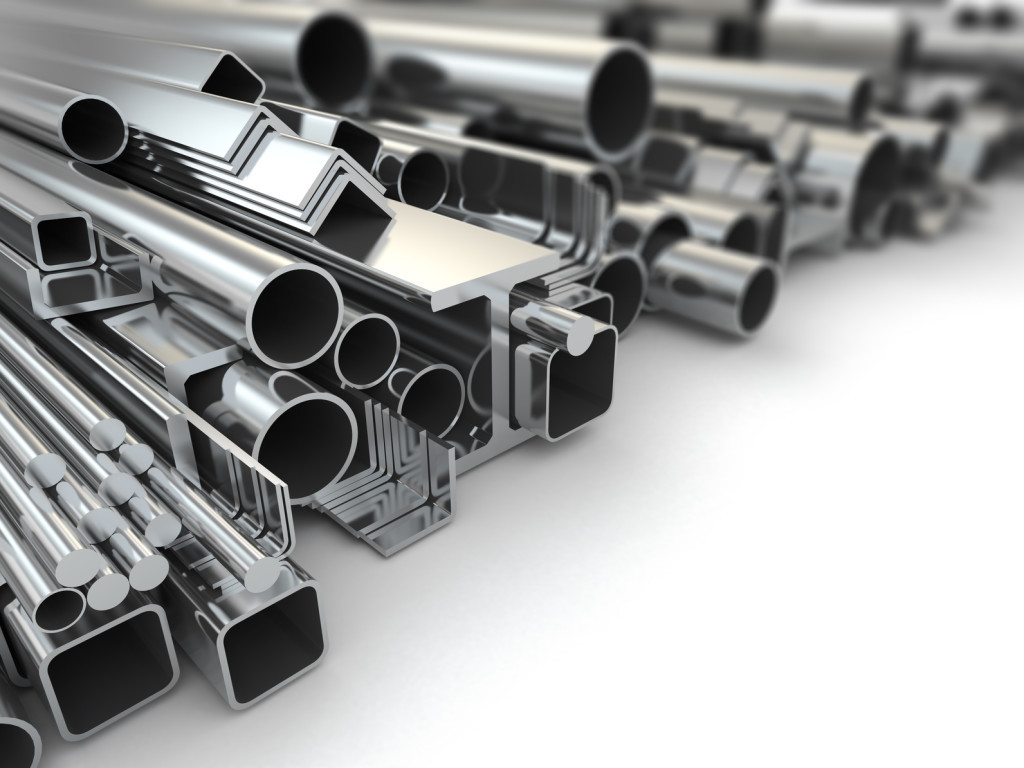

Permission to install a ramp in an apartment building has been received, the device has been designed, now it remains only to choose the material for its manufacture. It can be both metal and wood.

Metal ramp

In a multi-storey building, due to narrow flights of stairs, folding ramps are the most popular.

For its manufacture, the following materials will be required.

- Two channels of the same length, and it must correspond to the length of the flight of stairs. Regarding the thickness, their qualities such as carrying capacity and weight should be taken into account. When choosing a material for channels, you need to give preference to light and, at the same time, durable metals. It is important to understand that a metal device can attract thieves.

- Metal corners or strips of steel, which, in this case, will act as spacers connecting the channels to each other. When choosing corners, you need to pay attention to their width and thickness, which should be no more than 40 and 5 mm, respectively.

- 3 of each of the following: heavy duty door hinges, extension plates and fasteners.

The process of creating a metal folding ramp with your own hands

The process of working on the manufacture of the device can be divided into several stages:

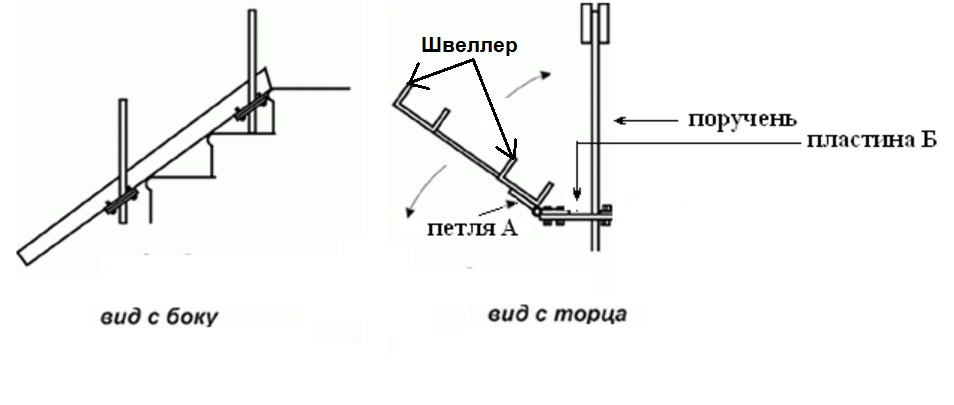

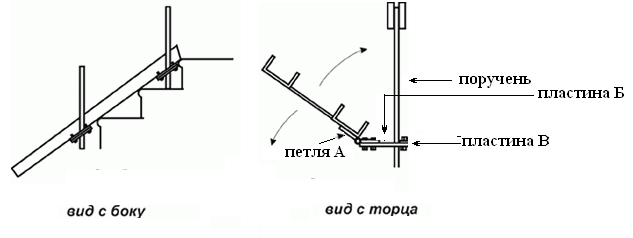

- The first stage boils down to making holes in the channels that completely coincide in size with the holes in the door hinges. Making them is simple with a drill and an appropriate drill. Further, the door hinges are connected to the near channel with bolts. It is extremely important to connect them in such a way that the bolt heads do not peek out of the structure. This can be achieved if you first remove the chamfers from the hinges. Since the extension plate is attached to the hinge on one side, it must be the same width as the hinge. The length of the plate must correspond to the distance between the nearest channel and the handrail, otherwise it will not be possible to assemble the ramp.

- At the second stage, you need to measure the distance between the wheels of the stroller. Based on the data received, ramps are built. Please note that if the spacers do not fit snugly on the steps, a person walking behind the stroller may catch their foot on them and be injured. In this case, the ramp will be subject to dismantling, and the head of the management company may be fined 50,000 rubles for providing services of inadequate quality to the population.

- The final step is to install a loop to fix the device in its assembled form. It is installed on the channel farthest from the wall. If the ramp is connected to the handrail when folding, a chain with a lock can be used for fastening. If there are no railings, you can use a regular latch to fix the device. It is installed on the wall and, when closed, grabs the loop of the ramp, thereby holding it in the folded state.

Wooden folding ramp

To make a ramp with your own hands, you can use not only metal, but also wood, or rather boards from it. The principle of working on a wooden ramp is almost the same as on a metal one. The only difference is in the materials used.

In this case, the channel, metal corners and strips of metal are replaced with wooden boards and strips. Door hinges and bolts are also used to connect them together.

When connecting the spacers to the ramps, you need to pay attention not only to their location, but also to the width, since there should be enough legroom on the steps for the person walking behind the stroller.

Since a tree can quickly become unusable, in order to extend the life of such a device, its working (upper) surface must be carefully planed and covered with drying oil, and the lower one should be varnished. For safety reasons, you can make small bumpers along the edges of the device by stuffing slats on them.

Important: you need to install the ramp at a distance of about 5 cm from the railing or wall, otherwise the descent, as well as the ascent, will be quite difficult.

Conclusion

The ramp is a necessary device for the movement of people with limited mobility and prams. It can be installed in the entrance of your house, both independently (in agreement with the Criminal Code or the HOA), and their employees or employees. The choice of workers and installation of the device is carried out at the expense of the homeowners.

When installing the device on your own, it is important to comply with all the requirements for them. It is forbidden to install the ramp close to the railing or wall.

For self-manufacturing You can use a variety of materials, but be aware that a device made of a metal such as aluminum can attract thieves.

Today we can see a huge number of people on the streets with handicapped. But it often happens that others, and in particular the state, forget about them. civil rights and special needs. One of these needs is a ramp - a structure without which the movement of people in wheelchairs often becomes simply impossible. Without a ramp, you won’t be able to leave your apartment, go to a supermarket or pharmacy, or attend a match of your favorite football team. Among other building structures, the one we mentioned is perhaps the simplest, but not everyone will be able to answer the question, but how to make a ramp with your own hands?

First you need to understand what this design is? A ramp is a platform with a slight slope, with the help of which surfaces located on different levels in relation to each other. Most often, you can observe such platforms made of concrete near the entrances to public institutions, made of metal - at the entrance of any residential building, made of wood - in private suburban housing.

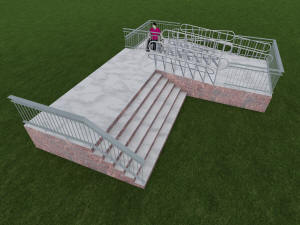

In addition to the fact that the ramps differ in the material of manufacture, they can also be differentiated by the type of construction. For example, the most common is the stationary option. Fixed ramps are, of course, monolithic concrete structures, which are often laid at the design and construction stage of any facility.

However, often non-removable ramps are made of metal or wood. Stationary structures most often located outside the building.

Stationary ramp can be made of metal

![]()

or wood

Idea!

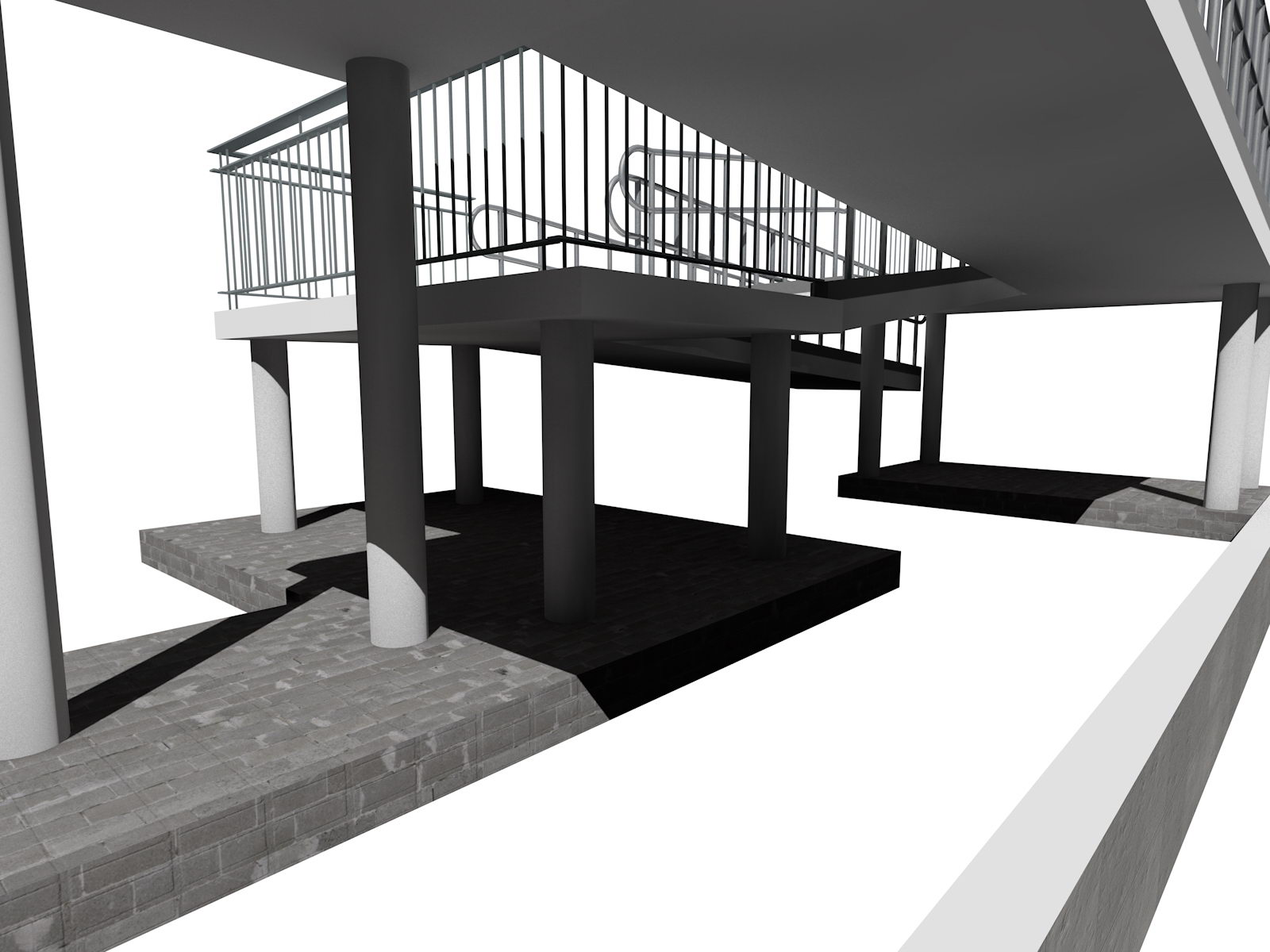

Inside the building, hinged structures are more acceptable, which are installed in the working position only as needed.

The folding structure is somewhat stationary, since it is always in the same place. That's just it can be folded back in order to free the passage on the landing. They are popular in private houses and entrances of multi-storey buildings. Making such structures with your own hands takes a minimum amount of time and effort.

Another type of ramps are removable structures:

- ramps that are installed to cross the threshold;

Ramps are most commonly used for crossing thresholds.

- telescopic structures that can be extended as needed;

![]()

The telescopic ramp consists of several retractable sections

- roll ramps that roll comfortably like a carpet and do not take up much space.

Rollopandus Overview

Advantages of a metal ramp device

It should be noted that the ramp is indispensable not only in those houses where there are wheelchairs. , but also children's transport on four (or three) wheels. Young mothers should not lift the stroller with the baby up the stairs. First, because it's big exercise stress, secondly - because it is very unsafe for both the child and his mother. Therefore, the ramp is appropriate in an apartment building, and in a public institution, and in a private house, where there are only two floors. If you are tired of waiting for the local authorities to equip a ramp near your entrance, give this issue just one day - and you will be able to equip a safe ramp for everyone in need with your own hands.

Making such a ramp does not take much time.

Today we will talk about the simplest, most reliable and convenient design - a metal ramp. This design is suitable for installation both inside and outside the building. It can be fixed in place or can be folded out. If there is an urgent need to install a ramp on the street, and there is no extra metal at hand, make a concrete ramp. Just remember that it will be suitable for operation only after 28 days, when the concrete gains strength.

After you have done the pouring of concrete, you need to wait about a month for the concrete to set. After this period, the ramp will be ready for operation.

This fact once again indirectly indicates that it is better to focus on a metal construct, which will significantly save time spent on the manufacture of an inclined platform.

Initial materials for work performance

So, let's try together to make a metal ramp, which can be removed to the side as unnecessary, that is, with a folding design. Making such a ramp will take a minimum of time.

Advice!

Before you start working on the construction of the ramp, do not be too lazy to read some of the regulatory requirements for the arrangement of these structures.

For work, we need the following consumables:

- Metal channels - 2 pcs. When choosing a rental number, please note that the channel must have a length that spans the span of the march, and its bearing capacity must ensure the perception of the load from the stroller with the person. Do not take heavy channels - keep in mind that the ramp will be folded back by a person manually.

- Struts. They are necessary for connecting channels to each other. When choosing, be guided by pipes or corners and sheet metal up to 5 mm thick and up to 40 mm wide.

Use corners or pipes as spacers

- Door hinges for fastening the ramp to the wall and providing the possibility of reclining.

- Plates. They will be needed to move the ramp to the required distance from the wall.

- Other fasteners (screws, bolts, nuts, etc.). Stock up on three pieces of each of the parts mentioned in this paragraph.

Don't forget to buy fasteners

Sequential execution of construction works

Work on the construction of ramps with your own hands should be performed in the following sequence:

- First, drill a few holes in the channel so that they fit into the holes in the hinges. Attach the hinges to the channel, which will be installed closer to the wall, using bolts. If chamfers are removed from the hinges, then the bolt heads will not be noticeable in the mounted structure.

- Pick up the extension plates so that they match the width of the hinges. Keep in mind that the railing posts will be installed in the plates in the future, so make cuts in them a little larger in diameter than the railing posts.

- Determine the required length of spacers or the distance between the ramp channels. You must proceed from the distance between the wheels of a child or wheelchair. Try to make sure that there are no gaps between the spacer and the concrete step. Otherwise, the person who will follow the stroller has every chance of tripping and falling.

When unfolded, there should be no gaps between the step and the spacer

- Fix the channel with spacers by bolting or hand welding.

Connect channel and spacers with bolts or welding

- Last thing. Provide a device for fastening the ramp to the wall in the non-working (folded) position. It can be a latch mounted on a wall, or a loop attached to a distant channel. The loop on the chain with a lock can be fixed on the handrail.

Attach the ramp to the wall. In this case, a bolt is used

On this, all the work on making a metal ramp with your own hands is completed. Feel free to test your brainchild. If the test was successful, then you did everything right and the device is ready for use.

The problem of disabled people in wheelchairs who cannot go down stairs is known to everyone. They have been talking about this for a long time, but things are still there. Well, if the stroller fits in the elevator, then the problem is solved. But it is simply impossible to go down the stairs alone without the help of strangers. And as they say, the problem of drowning people is the business of drowning people. Therefore, disabled people take the initiative and build ramps, of course, not on their own, but they achieve their goal with the help of assistants.

When it comes to street structures, the problem is not so acute. The biggest difficulty is when it is necessary to install a ramp for the disabled at the entrance of the house. There is not enough space here, and the neighbors may be indignant. Therefore, the first thing to do is to agree with the neighbors on the entrance, but it is better to collect signatures from them that they are not against installing a ramp for the disabled. After that, you can proceed directly to the construction.

The first step is to choose the design of the ramp, what it will be built from, what its shape will be, and so on. Let's look at the types of ramps for the disabled, which can be installed at the entrance of the house with your own hands.

Design options for the ramp at the entrance

The easiest option is to install two channels 200 mm wide along the steps of the stairs in the entrance. It is just enough to get the wheels of the stroller crazy. The distance between them must be strictly equal to the distance between the wheels of the chair.

Attention! The internal surfaces of the channels must be made non-slip, therefore it is recommended to weld the wire across the wire using electric welding or glue special non-slip rubber pads to them.

Now, how can you attach the elements of the ramp for the disabled? In principle, there is only one option, the fastening is made to the horizontal landings of the flight of stairs. To do this, you will have to cut the side shelves of the channels and bend each of them so that their horizontal shelves touch the surface of the sites. The top one curves outward, the bottom one inward. In this case, the undercut of the lower should be made in the form of a triangle.

After that, two or three holes are made in the curved elements with a drill, the diameter of the holes is 8-10 mm. Next is the installation of the ramp at the entrance.

- The channels are installed in place, marks are made through the holes on the plane of the platforms (we use a marker).

- We remove metal profiles, make holes in the concrete plane of the flight of stairs.

- We install the ramp elements in place and screw them through the mounting holes of the anchor. It is important here that the fasteners do not protrude above the surface of the channel shelf. It is possible to strengthen one channel, which is installed against the wall, with fasteners, for which you will have to drill several holes in the side shelf of the profile and fasten it to the wall through them.

In principle, everything, a ramp for the disabled from channels at the entrance of the house is installed. Can be exploited. To prevent this structure from spoiling the interior of the entrance, it is necessary to paint it.

Of course, this is a very simple but effective device. It will be very easy to make it with your own hands. But there is one problem in this project - it is the inconvenience of using the flight of stairs for walking people. The ramp will occupy a decent place, because it has its own specific dimensions. For example: the width of the stairs at the entrance of a residential building is standard - 135 cm, the width of the ramp for the disabled should be 90-100 cm according to GOST. In fact, only 40 cm remains for free passage.

Folding ramp design for the disabled

Therefore, craftsmen offer another option. It differs little from the first one. But changes have been made to its design regarding the ability to remove the device from the stairs.

To do this, it is necessary to connect the channels to each other, that is, to make a single device with your own hands, to which three standard door hinges are attached. True, more powerful loops are needed for the ramp. So how can all this be done.

- First, a single ramp design for the disabled is made. Two channels are interconnected in three or four places with metal strips (width 30-40 mm, thickness 3-5 mm) or squares. Fastening is made by welding.

- In one of the channels (closest to the wall), holes are drilled for the installation of door hinges. Fastening is carried out by bolting.

- In order to strengthen the fastening unit, it is recommended to use a so-called extension plate. The thing is that the height of the side shelf of the channel is greater than the width of the attached part of the door hinge. If you attach the hinges directly to the wall or fence (handrail), then the nearest side shelf will not allow the entire structure to fold to the end. Its edge will definitely rest against the wall. Therefore, it is necessary to increase the distance between the ramp and the wall.

- An extension plate is bolted to the free part of the door hinge. And already her against the wall.

Attention! All bolt fasteners must be countersunk.

To prevent the device from falling from the installed vertical position, it is necessary to attach a conventional latch to the wall. If the wheelchair ramp is installed closer to the railing, then a chain with a metal hook or safety carabiner must be hung on the fence. The chain can be replaced with a cable, spring or strong rope.

There is another option for a folding wheelchair ramp. It is better to make it from lightweight materials, for example, from an aluminum profile. For this, there is no need to fasten two profiles under the wheels tightly. Stretch marks are installed between them, which look like door hinges. That is, when folding the ramp, you can fold the tracks themselves to reduce the height of the folded structure. Look at the photo below and you will immediately understand everything. True, this device has several fairly significant minuses:

- Such a device is very expensive.

- It will not work to make it from aluminum with your own hands, you will have to look for factory options.

- Non-ferrous metal is always in price, so there is a high probability that non-ferrous metal hunters will just steal a ramp one day.

- You can also make such a design from channels or a galvanized or stainless steel sheet. But the weight of the ramp will be very large. A disabled person with such a heavy device cannot cope on his own.

Wooden ramp for wheelchairs

Another ramp device at the entrance of the house for the disabled, made of wooden materials. It is the simplest, because the manufacture does not require the use of any complex tools and equipment (meaning electric welding). Edged boards form the basis of structural elements. Board sizes: thickness 40-50 mm, width 200-250 mm.

Between themselves, the bearing elements are connected by the same boards using metal fasteners and self-tapping screws. In all other respects, this is the same device as the metal version. There are several requirements for a wooden ramp.

- It must be installed in a vertical position so that the planes of the structure do not touch the wall. To do this, it is necessary to install an emphasis on the wall surface from the same board to which the hook, lock, latch or carabiner is attached.

- The lower planes of the ramp for wheelchairs must be trimmed to match the design of the entrance of the house. The best option is to varnish or freeze. In this case, a vertically located ramp will look beautiful and act as an additional railing.

- The crossbars connecting the two tracks should be located so that they fall between the steps of the flight of stairs.

- The work surface will have to be slightly modified. It must not be allowed to be slippery, so varnishing it is not recommended. The best option is to fill or glue non-slip pads (they are sold in hardware stores) or fill rubber strips with small carnations every 20-30 cm across the tracks.

Attention! If a wheelchair user moves independently along the entrance without the help of outsiders, then it is necessary to install latches, hooks and safety carabiners at the edge of the ramp on both sides.

That is, there will be two fasteners. One will open the structure at the exit, the second at the entrance.

Installation of additional railings

Of course, when the ramp is installed closer to the stationary railing, then the disabled do not have problems with independent movement up the stairs. But if the device is located closer to the wall, then the problem is obvious. Therefore, it is necessary to make handrails on the wall with your own hands. They can be wood, metal or finished plastic.

![]()

Here the most important thing is to accurately determine the installation location. What does the state standard say about this (meaning the dimensions of the installation site)?

- For ease of use, the railing is installed at a height of 80 cm from the top surface of the wheelchair ramp. For disabled people with small stature, the installation is carried out at a height of 60 cm.

- For children, the height is 50 cm, but they will not be able to move along steep flights of stairs without the help of adults, therefore, railings are not provided for them in the entrances.

- The railings themselves are not made of sliding materials.

- The distance from the wall to the support is 5 cm.

- The angle of inclination is equal to the angle of inclination of the stairs.

- The railing protrudes 30 cm beyond the flight of stairs on both sides.

How is the railing for the ramp installed? First of all, the installation height is set; for this, the installation height of the railing is set aside along the edges of the stairs. A straight slanted line is drawn through two marks. The railings themselves are applied to it, mounting points are determined, marks are made in which holes are drilled. Anchors or plastic dowels for long self-tapping screws are installed in them through the mounting strips.

Ready-made ramps for the disabled

Of course, making a ramp for wheelchairs and baby carriages with your own hands is saving a lot of money. But it is necessary to argue from the position not of economy, but of the reliability and high safety of the structure. Isn't it better to purchase a ready-made version, made strictly according to GOST in the factory by specialists. There are no options here, it is better in all respects, the dimensions are strictly maintained, so moving along such a ramp will be easy and safe.

But again, everything will rest on the cost of the product. A disabled person with a minimum pension simply cannot afford such a device, and besides, he will also have to pay for the installation. Therefore, a do-it-yourself option is now more common in the entrances of residential buildings. Even of two structures: metal or wooden, the choice most often falls on the latter.

It is good that in new buildings, architects and designers are already laying the installation of ramps for wheelchairs for the disabled. This ensures the possibility of unimpeded overcoming of the steps of the stairs in the entrance of the house. In older houses, this problem remains unresolved. And although street ramps can already be often found, access ramps are a rarity.

Conclusion on the topic

As you can see, you can make a ramp from simple materials with your own hands. Today, these structures have increasingly begun to appear in the entrances of residential buildings, which pleases. This business is not only dealt with by disabled people, their relatives and neighbors. Many charity organisations allocate large finances in order to somehow increase the living comfort of wheelchair users.

But there is not enough money for everyone, so you should not wait. For example, a wooden ramp is a very simple device, making it yourself is a small cash investment and literally a couple of hours for manufacturing and installation. Residents of one entrance can do all this together, without involving anyone. So, maybe it's worth it all to make and mount. After all, this is help not only for the disabled, but also for mothers with small children who are carried in wheelchairs, pensioners who lift a bag of groceries to the upper floors.

Designing ramps for the disabled

Ramp angle for wheelchairs and prams

|

|

|

|

|

|

|

|

|

|

(in this example, the fences are not made in accordance with GOST R 51261-99 "Stationary rehabilitation supporting devices. Types and technical requirements") |

|

|

Ramp option on columnar supports for people with limited mobility |

|

|

Tactile road markings and hotel ramp |

hotel hotel ramp |

|

|

|

The permissible slope of the ramp is regulated by SP 59.13330.2012 “Accessibility of buildings and structures for disabled groups population" - an updated version of SNiP 35-01-2001, the document was put into effect on 01/01/2013.

The standard angle of inclination of the ramp for wheelchairs should be no more than 1:20 (5% or 2.86 degrees) and the length of one ramp march should not exceed 8 m.

In some cases, an increase in the maximum slope of the ramp is allowed:

up to 1:12 (8% or 4.76 degrees) - for temporary structures and infrastructure, provided that the height difference between horizontal platforms is less than 0.5 m and the length of one ramp march is not more than 6.0 m;

up to 1:10 (10% or 5.71 degrees) - with a floor height difference of less than 0.2 m.

The ramp slope is calculated using the formula: ramp slope \u003d H / L, where: H is the height difference that needs to be equipped with a ramp, and L is the length of the horizontal projection of the inclined section of the ramp.

Example

The height of the porch is 0.4 m. In this case, it is necessary to use a ratio of 1:12:

L=12*0.4m=4.8m.

The length of the inclined surface of the ramp \u003d the square root of (4.82 + 0.42) \u003d 4.8 m.

The ramp can be arranged without horizontal platforms, since the length of its inclined surfaces is less than 6 m.

Ramp slope can be expressed in degrees, percentages and as a ratio of height to length:

E ramp slope units

Ramp slope according to SNiP 35-01-2001 and SP 59.13330.2016

In the above documents, there are discrepancies in the standard value of the slope of the ramps: in SNiP 35-01-2001, the permissible slope of the ramp is 1:12 (or 8%), and according to SP 59.13330.2016 - it is 1:20 (or 5%).

SNiP 35-01-2001 is a national standard approved by Decree of the Government of the Russian Federation dated June 21, 2010 No. 1047-r. If the customer does not put forward a requirement to design a ramp according to SP 59.13330.2012, then the design and manufacture of ramps can be according to the standards indicated in SNiP 35-01-2001, i.e.: the allowable slope of the ramp is 1:12 (or 8%, or 4 .76 degrees).

For reference

Order of the Ministry of Construction on amendments to SP 59.13330.2012, new requirements for the slope angle of ramps

On October 21, 2015, the order of the Ministry of Construction of Russia was issued to approve changes to SP 59.13330.2016. In accordance with the changes, the slope angle of the ramp on the reconstructed and adapted structures is allowed in the range from 1:20 to 1:12.

Order of the Ministry of Construction of Russia No. 750/pr dated October 21, 2015 “On approval of amendment No. 1 to SP 59.13330.2016 “Accessibility of buildings and structures for people with limited mobility”. Amendment No. 1 to the set of rules SP 59.13330.2016 "Accessibility of buildings and structures for people with limited mobility".

In accordance with the change

1. "When designing reconstructed, subject to major repairs and adaptable existing buildings and structures, the width entrance doors taken from 0.9 to 1.2 m.

2. "When designing reconstructed, subject to major repairs and adaptable existing buildings and structures, the slope of the ramp is taken in the range from 1:20 (5%) to 1:12 (8%)."

The change went into effect on October 26, 2015.

Minimum ramp length

|

Ramp height, m |

Ramp length, m |

||

|

1:10=10%=5.7° (used when the height difference is less than 0.2 m) |

1:12=8%=4.8° (for temporary structures) |

1:20=5%=2.9° (standard indicator) |

|

|

0,1 |

1 |

1,2 |

|

|

0,2 |

2 |

2,4 |

|

|

0,3 |

3,6 |

||

|

0,4 |

4,8 |

||

|

0,5 |

10 |

||

|

0,6 |

7,2 |

12 |

|

|

0,7 |

8,4 |

14 |

|

|

0,8 |

9,6 |

16 |

|

|

0,9 |

10,8 |

18 |

|

|

10 |

12 |

20 |

|

|

1,1 |

11 |

13,2 |

22 |

|

1,2 |

12 |

14,4 |

24 |

|

1,3 |

13 |

15,6 |

26 |

|

1,4 |

14 |

16,8 |

28 |

|

1,5 |

15 |

18 |

30 |

Conventions

|

Valid values |

|

|

Invalid values |

Maximum dimensions (dimensions) of wheelchairs

GOST 30471-96 (GOST R 50602-93) Wheelchairs. Maximum overall dimensions

excerpts

This International Standard applies to wheelchairs and specifies their maximum overall dimensions, which should be considered by architects, engineers, manufacturers and local authorities for the mobility of the user in buildings, vehicles (buses, steamships, aircraft, elevators) and for general maneuverability.

This International Standard is applied by wheelchair manufacturers in new designs.

4 Maximum overall dimensions

4.1 Overall dimensions are for wheelchairs not occupied by the user.

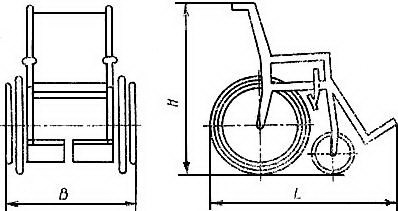

4.2 Overall dimensions are shown in Figure 1.

Picture 1

Overall length L is the horizontal dimension between the most protruding front and rear parts of wheelchairs,

L - 1200 mm

Overall width B - the horizontal dimension between the protruding side parts of the wheelchairs when fully unfolded,

B - 700 mm

Overall height H - vertical dimension from the floor to the highest protruding point of the wheelchairs,

H- 1090 mm

Overall dimensions are measured in accordance with GOST R 50605.

4.3 In the manufacture of wheelchairs for especially overweight users and amputees, the overall dimensions may be increased:

length - up to 1750 mm,

width - up to 810 mm.

4.4 When designing buildings and driveways, to take into account the user's legs, the overall length is increased by 50 mm.

4.5 For manual wheelchairs, clearance to the wall is required to drive the rims of the main wheels; when designing buildings and driveways, the overall width is increased by 100 mm on each side.

GOST R 51261-99 "Stationary rehabilitation support devices. Types and technical requirements")

excerpts

5.1.5 The minimum length of the free section of the support device in any of its positions must be at least 100 mm to capture the entire hand.

5.1.6 The shape and dimensions of the support devices should provide maximum comfort for their grip and stable fixation of the hand for each specific situation during use. At the same time, handrails installed in buildings and structures must be of a round section with a diameter of at least 30 mm (handrails for children) and not more than 50 mm (handrails for adults) or a rectangular section with a thickness of 25 to 30 mm.

5.1.9 Supports used in low ambient temperatures should be made of or lined with materials that have low thermal conductivity.

5.1.13 Support devices should have contrasting colors that allow disabled people, including those with visual impairments, to easily and quickly find support devices and use them.

5.1.14 The support device must remain strong, must not rotate or move relative to the mounting hardware and must withstand a force of at least 500 N applied to any point in any direction without permanent deformation of the components of the support device and the structure to which it is fastened.

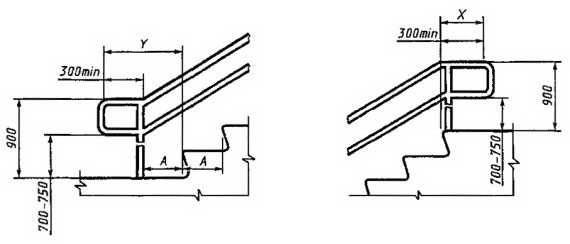

5.2.5 The ends of the handrails of the ramps must be either rounded or firmly attached to the floor, wall or posts, and if they are in pairs, they must be interconnected (Figure B.2).

5.3.4 The height of the covered surface of the stair handrail above the influx of the stair step must be, mm:

- for the upper double handrail - 900;

- for the lower double handrail - not less than 700 and not more than 750.

Figure B.2

Note:

x ≥ 300 mm;

y ≥ 300 mm + tread width (A).

Devices for moving between two planes located at different levels can be very different. These are stairs, elevators, and escalators. But the simplest, perhaps, are ramps, inclined surfaces connecting two horizontal platforms located at different heights. Needless to say, how valuable these structures are in creating a system that has been called a safe urban environment for the disabled.

Depending on the type of lifting trajectory such devices are:

- straight;

- screw.

Screw ones are more often used in warehouse, industrial, transport, commercial and industrial premises, less often - as auxiliary communications in hospitals and hotels. To create conditions for comfortable and safe movement of disabled people in the urban environment, these structures are almost never used and are not considered further in this article.

But straight ramps, in turn, are divided into fixed and removable structures.

Fixed ramps

They are are of the following types:

- stationary wide single-track and consisting of two narrow gauges;

- folding (may also have varieties).

If fixed devices are more common at building entrances and in various in public places(descents to underground passages and the subway), then folding ones are typical for stairs of residential buildings. They, like stationary ones, are rigidly connected to the installation site and cannot be moved, but they can be folded against the wall and secured with a latch after use so as not to interfere with the movement of other people. The same designs can be found in modern public urban transport.

Removable ramps

Unlike stationary and folding ramps, removable stored in a special place. If necessary, they are brought in and set up for use by the wheelchair user. Then they are taken back to the appropriate storage. Such devices can be of the following types:

Unlike stationary and folding ramps, removable stored in a special place. If necessary, they are brought in and set up for use by the wheelchair user. Then they are taken back to the appropriate storage. Such devices can be of the following types:

- sliding telescopic;

- ramps;

- roll ramps.

The first variety is universal and easily adjusts to different lengths.

Ramps are compact designs small sizes, designed to overcome low obstacles, curbs, thresholds. Easily transported.

Roll ramps are well suited for transportation in a car, as they can be rolled up.

Regulations

Since the use of ramps belongs to the field of human safety, their design and use are regulated by the relevant regulatory and technical documents and legislative acts.

SNiP 35-01-2001

Building codes and regulations that determine the accessibility of buildings and structures for people with reduced mobility. According to this document, the permissible longitudinal slope along the route of wheelchair traffic should not exceed 5%, the height difference at the exit from the sidewalk to the pedestrian crossing is permissible up to 0.04 m. There are other requirements, but the main point is that when exceeding the specified parameters, as well as in the presence of descents into underground passages, metro stations, stairs open and located in buildings, it is necessary to arrange ramps or other means of ascent. Floor sections in front of inclined surfaces for a length of 600 mm must have a corrugated surface or a contrasting color.

The material for the manufacture of the ramp must be non-combustible, the lifting height is limited to 0.8 m with a slope of up to 8%. Slope allowed 10% if the height difference does not exceed 0.2 m. If it is impossible to make a straight ramp, a screw version is allowed. The width of the device is at least 1 m for one-way traffic (recommended 1.5 m), it is necessary to have bumpers up to 0.05 mm high at the edges to prevent slipping of the wheels of the stroller.

SP 59.13330.2012

The document regulates the accessibility of buildings and structures for the disabled (and some other categories of the population with disabilities). It is the edition of SNiP 35-01-2001, or its updated version. However, in both recent documents there is a discrepancy in the amount of slope for ramps. So, SP 59.13330.2012 limits the slope to 1:20 or 5% versus 8% according to the requirements of SNiP 35-01-2001. Therefore, if there is no special reference to the requirements of SP59.13330.2012 in the technical order or customer requirements, then the provisions specified in SNiP 35-01-2001 should be followed. Building codes and regulations are a legislative act of wider application and take precedence over other documents.

GOST R 51261-99

This document requires handrails for wheelchair users if the horizontal projection of the ramp exceeds 1800 mm or the lift height is 150 mm or more. Handrails should be continuous along the entire length and go to horizontal platforms adjacent to the inclined part of the ramp. GOST also requires the presence at the beginning and at the end of the inclined surface of horizontal platforms with a length of at least 300 mm each.

Other normative-technical and legal documents

There are other regulatory and legislative acts that should be taken into account when designing ramps or refusing to use them, on the design and parameters of these structures. For example, Decree of the Government of the Russian Federation dated March 17, 2011 No. 175"About the state program Russian Federation"Accessible environment". Each region can have a separate package of documentation on this topic, for example, one decree and two laws, which deal with technical devices for the disabled, are available in the legal base of Moscow and the Moscow region.

In view of the fact that the slopes are given in the requirements for the design and installation of ramps, it makes sense to give some explanations. ramp slopes can be set in various ways. Let's consider them.

In view of the fact that the slopes are given in the requirements for the design and installation of ramps, it makes sense to give some explanations. ramp slopes can be set in various ways. Let's consider them.

- A slope of 1:20 means that the height difference of the object is 20 times less than the length of its horizontal projection. That is, if it is necessary during the design to ensure the lifting of a wheelchair to a height of 0.3 m, then the horizontal length of the ramp should be 0.3 x 20 = 6 m, excluding access areas.

- The slope of the ramp, given as a percentage, shows what part of the horizontal length of the structure is its height difference. For example, a ramp with a slope of 5% has the same parameters as a ramp with a slope of 1:20.

- The slope is given in degrees. This method is rarely used, it is not as convenient for practical use as the first two methods.

Features in the device and the use of ramps

Conclusion

Creating a safe and accessible environment for persons with disabilities, in particular for people with disabilities, is a serious task and requires the attention of both state and public institutions. And one of the directions here should be recognized as the use of ramps that help the disabled overcome height differences on the travel route.

Creating a safe and accessible environment for persons with disabilities, in particular for people with disabilities, is a serious task and requires the attention of both state and public institutions. And one of the directions here should be recognized as the use of ramps that help the disabled overcome height differences on the travel route.

Simple structures can be made by anyone who knows how to handle the tool. But, since here, overcoming one danger or difficulty, a disabled person may encounter, due to the imperfection of the structure, another threat, knowledge and compliance with all the requirements for the design of ramps come to the fore. The disabled person must feel that he is an equal member of society and our living environment is also accessible to him.