Anyone who decides to build a private house, wants his future home to be reliable, and long years provided warmth and comfort.

In order for dreams to become a reality, one must first of all seriously approach the choice of material from which the walls will be erected.

To build a house, you can use a wide variety of materials - timber, cinder block, aerated concrete, logs, bricks, sandwich panels, foam concrete. Each of them has its own advantages and disadvantages, so there is no ideal option.

Timber house

Suitable for people who prefer natural and environmental material. Modern construction of houses is made from glued and solid timber.

According to its characteristics, solid timber is more environmentally friendly, but it needs to be treated with special compounds to protect wood from fire, pests and decay.

Glued laminated timber is more resistant to negative external influences and, in addition, has a low coefficient of deformation. But it also has its pitfalls.

An unscrupulous manufacturer may use low quality wood in its manufacture. And, what is most offensive, it is almost impossible to determine this when examining the finished product.

cinder block house

Cinder block is an inexpensive building material that is made from slag, water and a binder. The thermal conductivity coefficient directly depends on the porosity and block size.

If we talk about the merits of the cinder block, then it will be distinguished by its low price, durability and short construction time.

This material also has a lot of disadvantages. It has low frost resistance, has a high water absorption coefficient and low environmental friendliness.

Aerated concrete house

A distinctive feature of aerated concrete is its porous structure, which is achieved by a special production technology.

Aerated concrete has low thermal conductivity and low specific gravity, which makes it possible to build houses from it on lightweight foundations. The presence of a groove and a spike on aerated concrete blocks facilitates the installation of walls during construction.

There are few disadvantages of aerated concrete blocks, but, nevertheless, they are. It has a high water absorption coefficient, so such houses need additional exterior decoration.

You can see the comparative characteristics of aerated concrete with other building materials on the website bgazobeton.ru. If necessary, you can also purchase it there.

Round log house

The log house is modern version classic "chopped" house. The only difference is that the logs have the same diameter and size, which has a positive effect on the construction of the house.

The advantages of a house made of rounded logs are the same as those of the classic material for log cabins. The main disadvantage is that it needs to be treated with special protective compounds from the negative effects of external factors.

brick house

Brick is a versatile building material that has long been a leader in the construction market. He does not lose his popularity at the present time. In the construction of houses, ceramic or silicate bricks are used.

Silicate brick has high strength, density and frost resistance, and when using a hollow option, sound insulation increases and heat loss decreases.

Its cost is lower than that of ceramic bricks. The main disadvantages include low fire resistance, high water absorption coefficient and construction time.

Sandwich panel house

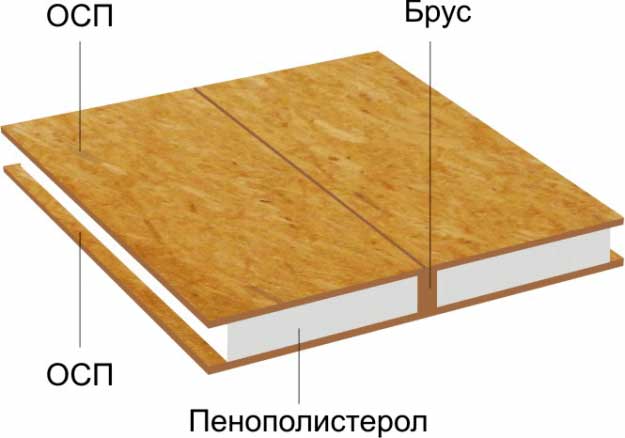

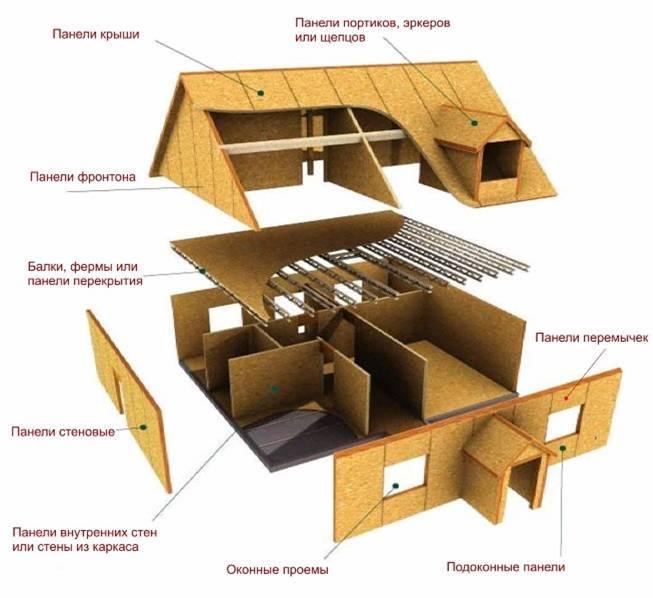

Sandwich panels have found their application in the construction of prefabricated houses. The composition of these panels is insulation and galvanized steel sheets.

This material has a lot of advantages - quick installation of the building, does not require laying a reinforced foundation, has a high coefficient of sound and heat insulation.

And now for the disadvantages. There is a possibility of damage to the outer sheet, in places where the panels are joined, cold bridges can form, a rather short service life compared to other building materials.

Foam concrete house

According to its characteristics, foam concrete is similar to aerated concrete. A significant difference is the fact that houses built of aerated concrete practically do not shrink, as they have the necessary margin of safety.

Foam concrete also needs time to gain strength. It hardens within a month, and the house shrinks for some time.

But unlike aerated concrete, foam concrete has a lower water absorption coefficient. If we talk about the geometry of the blocks, then in aerated concrete it is more accurate.

Even in the tale of the three little pigs, the most important and always relevant idea is raised about the correct choice of building material for the house. A fairy tale is a fairy tale, but many of us, like the heroes of a famous work, want to build a solid, reliable home with minimal effort. However, today it is quite possible to do this thanks to the development of building technologies. However, there are so many different wall materials that the developer has to rack his brains when deciding which material is better to build a house from. Brick, aerated concrete, wood, sandwich panels - which is better, more reliable, more durable and warmer?

The cost of building walls at home is up to 40% of the cost of all work, so it is important to weigh the many pros and cons of each material in order to make the only right decision. It is also necessary to take into account the seasonality of living in the house, the requirements for thermal insulation, the cost of the fuel used for heating, as well as the labor intensity of the work and the budget allocated for construction. Today there are a lot of materials for building a house - finding the one that most accurately meets the needs is not a problem.

No. 1. Wooden house

The most conservative and traditional material for building a house is wood. Its undeniable advantages include:

Minuses:

- high fire hazard, even despite the fact that today special impregnations are used in the production of timber;

- the tree is sensitive to moisture and pests, they are also trying to fight it, but without constant care, the material will be constantly damaged;

- shrinkage;

- high price.

Frame houses repeat many of the advantages of wooden ones, but they are built quickly and are cheap. In terms of quality and durability, they show themselves perfectly, if, of course, high-quality materials were used and the technology was fully observed.

pros:

Minuses:

Low cost and high construction speed made frame houses very popular, so they build entire cottage villages.

No. 5. Houses made of reinforced concrete panels

Another option for quick construction is the technology of building houses from prefabricated factory ones. low-rise house can be built in a few days! The technology resembles that which was so actively used in the Soviet Union for the rapid construction of millions square meters housing.

pros:

Minuses:

- a solid foundation is needed;

- a small number of offers on the market (few companies cast slabs for the created project - elements of typical sizes are usually made);

- such a house "does not breathe";

- Concrete does not hold heat well.

When you need to quickly build a reliable and durable house of decent size, then this is one of the best options, especially since today it is possible to cast panels strictly necessary forms and dimensions to build a building according to.

When choosing a material for building a house, it is important to take into account the climate, the type of soil, the future heating system, and many other factors. But even the highest quality building material can disappoint if the construction technology is violated or the foundation is laid incorrectly, so these points should be given no less importance.

Different materials are used, each of which has its own advantages and characteristics. Which one to choose for your home? Let's try to figure it out.

Brick

One of the oldest materials Thanks to the achievements of modern science, it has not lost its relevance until modern times. - a guarantee that the building will be warm and quiet. The service life of the material is hundreds of years. Modern brick is a light and durable ceramic product. It has a number of advantages:

- Heat and sound insulation. The brick is pierced with numerous holes that help maintain an optimal microclimate. In terms of protection against heat loss and the penetration of extraneous sounds, a brick wall with a thickness of 80 cm is comparable to a wooden one with a thickness of 2 m.

- Durability. If no mistakes were made during construction, the building can stand without overhaul about 150 years old. Products are so securely connected to each other that even a hurricane does not destroy them.

- Immunity to most external influences. The material is not afraid of fire. It does not react in any way to fungi, mold, microorganisms. A brick wall does not rot, but it perfectly passes air. The house from it is ecologically safe.

Blocks

Blocks

Cellular material with good technical specifications. It is used both in private and capital construction. - a fairly simple task, since each element has a small weight (you do not have to spend money on a powerful foundation). The material is quite durable. The blocks are large, which speeds up the construction of the main elements. To work with them, you do not need to have extensive experience and use complex equipment - a novice builder can handle it.

If necessary, the material can be processed, giving it the desired shape. This is useful if you are going to hide wiring and pipes in the wall. The blocks are made from cement, sand and water, so they are environmentally friendly and clean.

The cellular structure increases protection against heat loss, wind penetration and severe frost. At the same time, optimal air exchange rates will be maintained inside the room. The material has excellent sound insulation. However, it is not recommended to use it in places with a very humid climate - a large amount of water degrades performance.

Frame technology

- a relatively new method for our country, but abroad it is actively used. It has a number of advantages:

- You can save on the foundation. The construction will be light, so there is no need for an expensive foundation. Despite the lightness, the frame house turns out to be stable - it is not afraid of the seasonal movements of the foundation due to the movement of soils.

- Construction is underway in a short time. It takes about 8 weeks for a fairly large mansion up to 200 m2. This is one of the fastest results. For example, when building brick house the same area will have to spend about 8 months.

- No shrinkage. You can't start in ordinary houses Finishing work without waiting for about a year. The frame eliminates this problem - you can move in immediately.

- High energy efficiency. The material has a low thermal conductivity, which means that you do not have to spend a lot of energy to heat the premises.

- Ecological purity. The radioactivity index of the material does not exceed 15%. Compare - in concrete it reaches 60%!

bar

The beam is an environmentally friendly material. It will always be easy to breathe from it in the house. But besides this, treated wood has several additional advantages:

- Low cost. This is one of the cheapest construction technologies. Cheaper than it - only the construction of frame houses.

- High speed of work. Four builders can build the walls of a fairly large house in about 3 weeks. does not require complex technology.

- No expensive interior decoration required. If a profiled beam is used, it is not even necessary to use an external finish.

- Good thermal insulation. In most cases, additional insulation is not required. In winter, the building perfectly protects from the cold, in summer - from the heat.

Also, the material does not require a powerful foundation, and the microclimate inside will always be pleasant and healthy.

The growth of individual construction has led to the appearance on the market of various materials, including those that no one had heard of before. The range is so large that even experienced people are often lost, not knowing what is better to choose. Let's try to figure out what modern materials attractive not only in terms of cost, but also the feasibility of using it in the construction of private houses.

As a rule, individual developers are guided by the following indicators:

- the price of materials (including facing);

- the ability to perform all operations with your own hands to the maximum;

- the total weight of the structure, since the type of foundation and the cost of its installation largely depend on this;

- the cost of finishing work;

- durability;

- frequency of current (major) repairs.

Considering some types of new materials, we will focus only on their specific features.

Firstly, exhaustive information on each sample is not a topic for this article. Those who are interested in the details will be able to get acquainted with all the “pluses” and “minuses” on their own on our website in the section “ Construction Materials”, where almost all popular ones are described in detail.

Secondly, many shortcomings are very relative, since the manifestation of defects is often caused not by product quality, but by violations of the work technology and ignorance of elementary things (on waterproofing, thermal expansion, compatibility, and so on). So let's start the review:

Wood

Glued timber

Of all the materials in the "wood" category, professionals recommend giving preference to this particular product.

Of all the materials in the "wood" category, professionals recommend giving preference to this particular product.

- Strict geometry greatly simplifies installation and caulking.

- Finishing is practically not needed.

- A great appearance at home.

- Good microclimate.

Experts note the main drawback of glued laminated timber - additional insulation will be required, otherwise heating costs will be significant. Details about the beam.

rounded log

Possessing the above advantages, this material will require somewhat higher construction costs. Most likely, it will be necessary to involve specialists, at least at the stage of building a log house. Read about round log construction at.

artificial stone

aerated concrete

In every way good stuff. But it absorbs moisture quite intensively. Therefore, when using it, you will need high-quality waterproofing. And this entails the need to produce plastering, which limits the choice of type of cladding.

foam concrete

The specificity of its use is that this artificial stone is quite fragile. And this causes difficulties when attaching attachments and furnishings (lockers, shelves, and so on). You can’t drive a nail into it just like that and you can’t install a self-tapping screw (with a sleeve) - they won’t hold on. Only anchor bolts, and this is not convenient everywhere.

Foam concrete can be built in 1, maximum 2 floors, and then, with reinforcement of the structure. Comparison - perhaps you did not know this yet.

Polystyrene concrete

Of all artificial stones considered the best. In terms of its properties (vapor permeability, environmental safety), it is in many ways reminiscent of wood. Its main advantage is almost zero thermal conductivity. This material itself is an excellent insulation, and additional work in this regard will not have to be carried out.

Another difference from analogues is that fungus or mold will never start in polystyrene concrete. And given the low cost of production (about 1,000 rubles / m³), this stone can be recommended as one of the best building materials. By the way, "bricks" can be made on the spot, without spending money on renting a vehicle to deliver the blocks to the site.

Frame technology

Building with sandwich panels is beneficial in many ways. It is always cozy in such a house, and heating costs will be small (about 26,500 rubles a year). But the service life of products does not exceed 20 years (and this is the maximum). And the repair of such a structure can cost a pretty penny. With many advantages, such a house does not differ in durability. This is rather a variant of a quick solution to the housing problem, but it is not necessary to say that many generations will live in it. In fact, they talk about it

To date, there is a fairly wide choice of materials for building a house, construction technology is progressing, more and more new materials for houses are appearing. The choice of a particular material is determined by its quality, cost, durability of the material, thermal conductivity, and the need for additional finishing.

It also matters how the building will be operated - all year or seasonally. The operating conditions in cold climates must be taken into account. That is why it is so important for the developer to decide on the material from which the house will be built.

All wall structures have their pros and cons. The developer must have an idea of the advantages and disadvantages of the material for the construction of walls, in favor of which he makes a choice.

Before you start building a cottage, you should remember that the cost of the foundation, walls and roof is sometimes more than 50% of the total cost of the house. And the cost of walls in these houses is about 40% of the cost of the house. Therefore, the choice of wall material in low-rise buildings is a strategic issue.

wooden houses

Wooden houses all over the world are considered elite, it is easy to breathe in them, they are always beautiful, cozy and warm. Building a wooden house does not require pouring a heavy foundation; these houses are quite light compared to panel or brick houses.

Houses made of logs are of increasing interest to developers. Logs for such houses are made from pine, spruce, fir, cedar. After proper drying, the log turns into a wonderful building material. Houses are durable and strong. Walls made of thick logs perfectly keep warm in winter, without the need for additional insulation.

At present, rounded logs are produced on modern equipment, carry out high-temperature drying of wood. A house made of logs is warm, "breathes", durable, environmentally friendly.

The house, built of profiled wooden beams, combines good thermal insulation properties and environmental friendliness. Many architects create unique cottages and modern country houses from this material.

A house made of profiled timber has its own advantages:

1) The log house is built relatively quickly, because the logs are made on modern machines with a fairly high accuracy.

2) After the settlement of the supporting structure, it is not necessary to insulate the log house, the consumption of insulation is minimal.

3) With the correct selection of the profile, water does not pass between the logs, this prevents possible decay.

4) Additional finishing is not required, because the house made of profiled timber immediately has an attractive and neat appearance.

During the construction of such houses, the raw material is winter felling wood. The wood is processed on modern machines according to special technology. With the help of drying chambers, the required moisture content of the wood is achieved.

Brick is the most common material for the construction of low-rise buildings. Walls made of this material are durable. Today, there are a lot of structures, masonry methods, a variety of techniques that increase thermal insulation. brick walls lightening their weight. For the construction of a brick house, it is necessary to build the right foundation. After building the box at home, it is recommended to let the walls dry before finishing.

By construction cost brick house, usually, more expensive than houses from other materials. But the undeniable positive properties of this material are obvious. From bricks, you can create wonderful and warm low-rise buildings with a variety of architecture.

Houses made of reinforced concrete panels

Such houses are quite similar in appearance. The advantage is that the construction of a low-rise building box can be completed in a few weeks. Finishing work can begin immediately after the installation of the walls.

If it is necessary to quickly erect a low-rise building, reinforced concrete panels are of great interest to developers.

Sandwich panels have the following design: two planes of wood or plywood (sometimes from boards) are attached to a wooden frame, insulation is placed between the outer and inner walls. Since sandwich panels are produced in factories in accordance with standard designs, house designs are also somewhat monotonous. It can be considered a big plus that, subject to all installation rules and dimensional accuracy, on installation work boxes at home takes a minimum of time and it is not always necessary to involve skilled workers. At the same time, finishing work can begin immediately after the construction of the walls. Walls made of sandwich panels undergo chemical treatment, which protects them from moisture, pests, and fire. A sandwich panel house can be built in a matter of months. Another advantage of such buildings is that they are not inferior to wooden houses in terms of service life.

Lightweight concrete block houses

Today, a large number of structures and materials with improved thermal insulation parameters are used in construction practice. AT low-rise construction such materials are used especially widely. Blocks are made by both individual and industrial methods. The basis of lightweight concrete is made from Portland cement. The type of concrete is named depending on the type of aggregates. If, for example, expanded clay or slag is used for aggregate, then such concretes, respectively, are expanded clay concrete, slag-slag concrete, etc. Walls made of lightweight concrete are small-block and monolithic. Low cost and availability of raw materials, proven construction technology and good qualities often become a decisive condition when choosing in favor of this type of wall.

Foam blocks are perhaps the most inexpensive of the alternative types of such material. Sometimes they can reduce the cost of construction by almost 3 times. Foam blocks are made from cement paste mixed with whipped foam from rosin oil and a special component with a stable structure. Concrete with a cellular structure, formed during the curing of the foam, has all the necessary thermal insulation qualities. The foam concrete blocks that have reached hardness are cut into slabs of the required size.

The main purpose of foam concrete products is the laying of partitions, internal and external walls, thermal insulation of floors and roofs. These blocks are quite light, have good sound and heat insulation properties. Foam concrete products are not inferior to traditional aerated concrete in terms of quality. Thanks to the technology and equipment used, the cost of foam concrete products is 25% less than that of cellular aerated concrete.

Houses from gas blocks

Aerated concrete is made from Portland cement with the addition of silica material and a blowing agent. Often air lime is added to this mixture. After pouring the mixture into molds, it is processed in autoclaves. During construction, large aerated concrete products are cut into individual elements.

The labor intensity in the construction of walls made of aerated concrete is much less compared to the construction of brick walls.

cinder block houses

Slag concrete - light material, which is often used in low-rise construction. Many block and monolithic printed walls of houses are made of cinder concrete. This material is made using metallurgical or fuel slag with a binding agent. The walls of cinder concrete are strong enough, fireproof, low thermal conductivity. The binder for this type of concrete is cement, gypsum, lime or clay. Walls are considered warmer and drier, where cementless cinder concrete is a binder.

Cinder concrete walls are made of separate blocks and stuffed. The walls are laid both solid and with voids, while filling the cavities with heat-insulating material.

Expanded polystyrene (styrofoam) has excellent thermal insulation properties. There are technologies by which in a few months it is possible to build a two-story cottage on a turnkey basis with minimal material and labor costs. Such construction techniques have become possible due to the excellent properties of foam, which is a porous plastic that is obtained by foaming and heat treatment polymers.

The material has uniform distribution pores and is formed during the intensive release of gases that swell the polymer under the influence of temperature. Styrofoam is very light, sufficiently elastic and flexible, not subject to decay. Polystyrene foam is one of the most common types of foam. Expanded polystyrene is a fairly rigid material that is resistant to moisture, many acids and alkalis.

A big disadvantage of expanded polystyrene is its combustibility, so this material is best installed in closed structures with a fire-resistant outer skin. It should be noted that when building walls of a house only from polystyrene foam panels, the walls will have low mechanical strength. However, together with brick cladding, it is possible to obtain wall structures that have not only high mechanical strength, but also excellent thermal insulation properties.