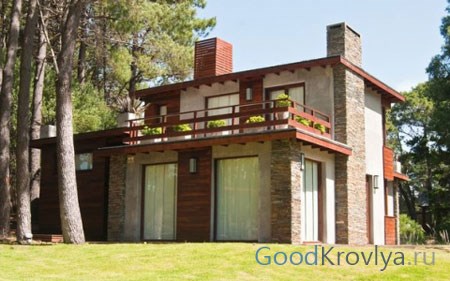

Houses with flat roofs, as in the photo, are mostly multi-storey industrial or residential buildings. It is rare to meet private households with such a roof, their design is exclusive and they look original and stylish. The owners of the house can use their surface at their own discretion. For example, an inverted flat roof even allows you to equip recreation areas with lawns, flower beds, ornamental trees and gazebos.

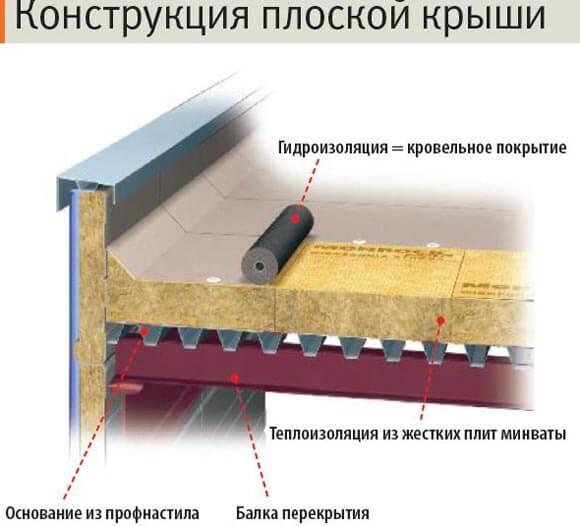

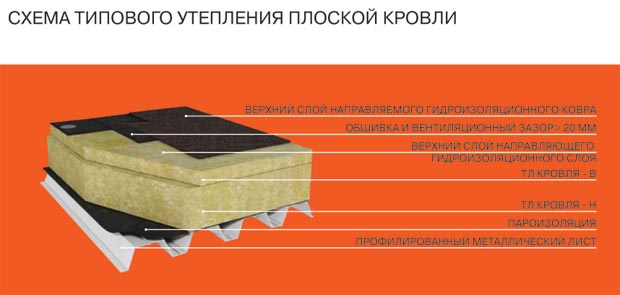

Structural features of the roofing "pie"

Installation of a flat roof involves, which provides protection for the house from the adverse effects of precipitation, high and low temperatures, wind loads and other things. A roofing cake for a flat roof does not allow condensation to form and protects from moisture, icicles will not appear on the roof in winter, and a comfortable temperature will be maintained in the rooms in summer.

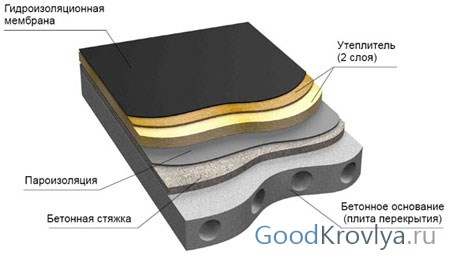

A properly executed flat roof cake is considered to contain the following layers:

- bearing base;

- vapor barrier;

- multilayer insulation;

- waterproofing.

The most important layers that make up a flat roof are insulation and a waterproofing carpet.

Preparation of the base for a flat roof

The installation of the roof begins with the preparation of the foundation for it. It needs to be leveled, clean the places where there are cracks and defects in the concrete, fill them polyurethane sealant, on the basis that 180 grams of material is consumed per linear meter with a seam width of 5 centimeters and a depth of 0.3 centimeters.

Then priming is performed using an epoxy primer. For porous surfaces, it will take 0.2 kilograms per “square” of area, and 0.12 kilograms for non-porous bases. The primer must be prepared: using a low-speed mixer, it is mixed until a homogeneous mass is formed, after which it is diluted with water in a ratio of 1:2. It is applied to the surface with a brush or roller.

Further, when a roofing pie is created for a flat roof, the base surface is reinforced by applying a special mastic (consumption rate of 14 kilograms per 1 cubic meter). Before polymerization is carried out, a construction bandage is laid on it, after completion of work it is again covered with mastic.

Vapor barrier is required for each roof, for which either polyethylene or polypropylene film is used. It is fixed with nails or adhesives are used. Do not forget to maintain a 10 cm ventilation gap to prevent vapors from accumulating under the film.

Roof insulation and thermal insulation materials

Heat preservation in the house provides a heater. As for the heat-insulating material, it is mounted in such a way that it fits snugly against the roof surface and its protruding parts, such as parapets, chimneys, ventilation blocks, etc.

Equally important is the quality of the selected insulation, which provides heating for a flat roof. With properly selected thermal insulation materials for the roof, you can significantly save on heating your home. By doing a competent one. Particular attention should be paid to such indicators: fire safety, low thermal conductivity, vapor permeability, resistance to mechanical stress and moisture.

The material that is chosen as a heater must be resistant to point loads, since in 8 cases out of 10 they cause problems with roofing.

The main ones are:

- violation of waterproofing, as a result of which the flat roof is damaged - which moisture reaches and destroys it;

- causing serious damage to the roof due to freezing of the snow mass in the event of a thaw, an increase in heat loss and the formation of "cold bridges".

One of the most popular heat-shielding materials is stone wool, which can withstand temperatures of about 1000 degrees. In addition, it is easy to work with her. Polyurethane foam, extruded polystyrene foam, foam glass, foam concrete are often used as thermal insulation.

stone wool . Its plates have two degrees of density. The side that has increased density is often marked with a black stripe and should be on top. Plates are laid on the roof surface and glued.

polyurethane foam (abbreviated PPU). This material is high-tech and has excellent waterproofing performance. It has a drawback - polyurethane foam cannot be the final coating, since ultraviolet destroys it, making it brittle, and thereby shortens the life of the insulation. It should be noted the good maintainability of polyurethane foam. One cubic meter will require from 60 to 80 kilograms of this insulation. PPU is prone to burning, but combustible qualities are reduced when used in such a volume. If direct fire hits the polyurethane foam, it begins to melt, but when the source of ignition is eliminated, it fades almost instantly.

foam concrete . High-quality insulation is obtained at a consumption of 250 kilograms of this material per cubic meter. But such an amount of insulation increases the load on the roof.

Extruded polystyrene foam . When a flat combined roof is being built, this material is used in large quantities, since it is easy to install. Thermal insulation boards

They are laid on the entire surface, after which they are glued together.

Foam glass . It is resistant to acids and high temperatures, has a low thermal conductivity, due to which excellent insulation is provided. For its installation, it is required that the surface is flat and dry, it is pre-filled with molten bitumen. Blocks of material are laid at a certain distance from adjacent elements. To fix the position of the plate and extract excess bitumen from under it, press on its middle with your foot. The reason why the material has not been widely used is its rather high price.

Creating waterproofing on a flat roof

The waterproofing that is part of a flat roof can be done in many ways, but bituminous is considered the most common. To create a waterproofing layer, the bituminous mastic is stirred for 5 minutes using a drill with a nozzle. In this case, the first of the applied layers is made more liquid than the rest. Apply mastic at the rate of 90-120 grams per square centimeter of surface area. The next bituminous layer is laid after complete drying, which takes about 10-12 hours. The reliability of waterproofing depends on the number of layers: the more there are, the better the protection.

These include almost all high-rise residential buildings of the Soviet era, as well as industrial construction sites and shopping centers, where, for economic reasons, it is not advisable to have flat roof. This type of roof is divided into two types:

- operated (located on the roofs of summer restaurants, cafes, viewing and walking platforms),

- unexploited, not requiring additional reinforcements.

It is one of the simplest types of roofs. The construction of such a roof does not require large expenditures. Money and scope of work.

To build such a roof, certain conditions must be met:

- bias,

- the entire structure must be waterproofed and have a drain for rain and Wastewater,

- roof insulation.

When arranging a roof terrace, the necessary slope is of great importance, since it serves as a waterproofing.

The necessary devices for the flow of water can be made with the help of gutters. It is best to use a heated inner pipe so that frost does not form inside it in winter.

The base of the roof can be made of concrete. Concrete should be insulated with special materials, then a layer of waterproofing should be laid on the thermal insulation, while Special attention should be given to the most wet areas, for example, the connection of the wall and roof.

As stated above, flat roof has several varieties.

Types of flat roofs

Operated. This type is equipped with such a purpose that people will go to it. For example, to repair and inspect coatings and waterproofing or ventilation systems.

One of the important conditions for creating such a roof is the construction of a fence around the entire perimeter, which must be stable and reliable. The internal and external drainage system is also important.

Unexploited flat roof. Usually it is used on structures that have a small area, for example, it can be a garage, warehouse, bathhouse or gazebo. Since there is no access for people to it, the rigidity of the base does not play a special role.

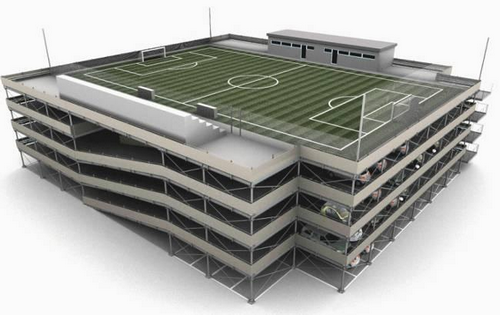

Another type of roof is inverted. It implies active exploitation. For example, on roofs of this type restaurants, cafes, winter gardens or parking lots can be located.

All calculations must be carried out by professional engineers. Only they will be able to calculate the ceilings, thermal insulation and waterproofing.

When building private houses, flat roofs can be made of wood. In this case, waterproofing is also of great importance.

In any type of flat roof, it must have:

- vapor barrier layer

- high quality waterproofing

- insulation layer,

- roofing covering.

Insulation should be selected depending on the type of roof, for example, soft materials can be used on an unused roof, and in the case of an exploited roof, only hard types of insulation coating should be used.

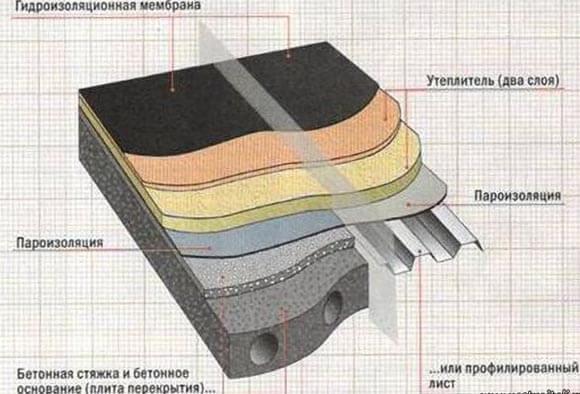

Flat roof consists of several layers:

- grounds,

- vapor barrier,

- insulation,

- waterproofing, which is also a roofing.

Vapor barrier is the protection of the insulation coating from warm air that enters through the ceiling. Various materials can be used as a vapor barrier, for example, a vapor barrier film or fiberglass.

In places where the vapor barrier is connected to vertical surfaces, it is brought to a height that is greater than the thickness of the insulation and roofing. Sealant or hot bitumen is added to the joints.

For houses that are intended for operation, usually the insulation is polystyrene foam, polystyrene foam or other heaters that have a solid structure.

Bulk mixtures can be used as a heater, but not on actively exploited roofs. In this embodiment, a screed of sand and cement is poured over the loose coating.

Choosing flat roof covering, the reference point should be the quality of the waterproofing material, since the effectiveness of the coating and the elimination of leaks depend on it.

Pros and cons of a flat roof.

The main advantage of this type of roofs can be attributed to cost-effectiveness, since during its arrangement the material will be required 1.5-2 times less than when building other types of roofs, for example, pitched. As a result of this, space heating is saved, since a small roof area gives off less heat to the atmosphere.

The disadvantages of such a roof include:

- not very attractive appearance house view,

- it is necessary to have a good drainage system,

- the presence of a strong and reliable waterproofing system is mandatory.

If on flat roof no attic space is provided, then insulation should be carried out both outside and inside the room.

Thermal insulation can be laid in one or several layers. It depends on the temperature conditions of the region.

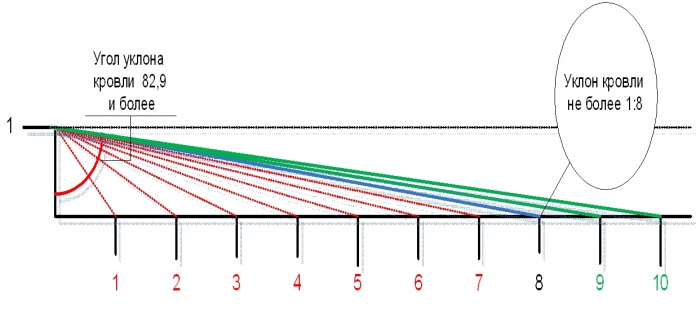

Any roof must have a slope, even if it is called flat. This is done for the unhindered flow of water and their entry into gutters and funnels.

On residential buildings, the slope is 1-5 degrees. If this is not done, then water will accumulate on the surface of the roof, which will further render the coating unusable.

While summer precipitation can evaporate, autumn precipitation goes through a repeated cycle, that is, it freezes, then melts, and so on. As a result of this, the top layer of the roofing is destroyed, and water penetrates into the insulation material.

If the slope on the roof is insufficient, then moisture enters under the waterproofing layer, as a result of which leaks begin. In addition, dust gets into the ever-standing puddles, which settles, and the seeds are brought by the wind. different plants, which later grow, turning the roof into oases. Often you can see a picture where not only grass, but also trees grow on the roof. In order to avoid these undesirable consequences, it is necessary to roll out the roof. This is done at the stage flat roof devices. All related processes are aimed at acquiring the necessary bias.

A flat roof looks like a kind of multi-layer cake, the layers of which are:

- base, represented by an iron floor slab or a metal profile of a certain height,

- vapor barrier materials,

- insulation, having a different structure,

- several layers of rolled waterproofing,

The slope is made directly at the stage of laying the insulating material. In order for the drainage to have sufficient efficiency, the minimum slope of the slope should be from 1 to 4 degrees.

In addition to all other components, there must be drain funnels in the roof structure with an internal drain. If the drainage system is located outside the building, then gutters are installed, which are arranged on the outer wall of the structure or under the roofing.

To achieve the required slope, several methods are used:

- with the use of bulk materials,

- using a mixture of concrete with the same fillers,

- with help concrete mix filled with polymeric material,

- using insulating materials.

At flat roofing bulk materials are not very convenient, because they have high mobility. During the work, the material may move, and, accordingly, the angle of inclination may differ from the specified parameters.

In order for the bulk material to take a stable shape and retain the specified slope parameters, it must be poured with a cement composition and wait some time for the material to seize.

So flat roofs recent times quite popular among the population, as they greatly help to save space. On such a roof, you can install a summer cafe, an observation deck, a restaurant or a parking area.

When constructing such a roof, all its features should be taken into account, the main of which is high-quality and reliable waterproofing. If all calculations are made correctly and all the main nuances of a flat roof device are provided, then it will have a long service life. The system of insulation and ventilation is also an important point.

Flat roof will help save not only on space, but also on materials.

flat roofs- these are roofs with almost no slope. Their slope does not exceed 3-4 degrees. A small slope is betrayed so that the water from the roof can flow by gravity.

This type of roof is widespread in multi-storey buildings. residential construction, in industrial and warehouse buildings, public facilities. Flat roofs can be exploited (terraced roofs) and non-exploited according to their intended purpose.

It is believed that a flat roof is cheaper and more economical than a pitched one. Why? - With the same area of the building, the area of \u200b\u200bthe pitched roof will be more area flat roof. Since the area of a flat roof is smaller, then due to the footage, less is needed for its installation. building materials. Also, the work associated with the installation of a flat roof is less dangerous and much easier to carry out. Also, flat roofs are simpler and more convenient for maintenance, routine inspections, for cleaning storm drains, working with antennas, chimneys, ventilation ducts and the roof itself. Flat roofs do not require special climbing knowledge and skills from workers and maintenance personnel.

A big plus for flat roofs is the possibility of convenient location of a variety of equipment on them: air conditioning units, ventilation equipment, etc. Many flat roofs are operated with the widest range of purposes: from compensating for the insufficient area of land plots adjacent to the building in dense urban development or in budget cottage construction, to revealing the aesthetic advantages of a flat roof (developing winter gardens and gardens on them). open field, playgrounds, swimming pools, etc.)

Large snow loads fall on a flat roof, but unlike pitched roofs, they do not have windage, which is very important for multi-storey construction. Also, the positive factors include the possibility of a phased deployment of the construction of a flat roof.

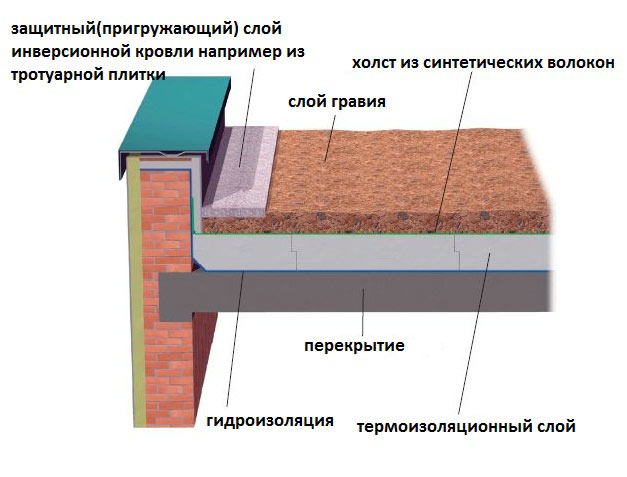

Depending on the roofing materials used and the technologies for their implementation, flat roofs are divided into traditional and inversion. Accordingly, flat roofs can be covered with traditional or inverted roofing.

Traditional flat roof- these are types of roofing for flat roofs that are laid on thermal insulation. In this building technology " weak point"Waterproofing is considered, since it is constantly exposed to atmospheric influences, sudden changes in temperature, and under the conditions of the operating roof, it is also mechanically stressed. A big disadvantage of such roofs is that when leaks occur in the roof, it is difficult to find their place, and the work associated with the repair is laborious and costly.

Inverted flat roof. Unlike a traditional flat roof, the insulation in such a roof is placed above the waterproofing material. At the same time, the waterproofing of the roof itself is protected from temperature changes, exposure to sunlight and mechanical damage. Also, laid under a layer of insulation, it also performs the function of a vapor barrier. At the same time, the inverted roof structure makes special high demands on thermal insulation. Inverted roofs are especially widely used in many countries for multi-level parking lots and allow more efficient use of space in dense urban areas. The use of an inverted roof allows you to place green areas on it, equip multi-level parking lots and sports grounds.

Exploited roofs

Exploited roofs are widespread in megacities, where, with very dense buildings, there are few free plots of land. They arrange green areas, sports grounds, parking lots, cafes, etc. One of the varieties of exploited roofs can be the overlapping of underground premises (the same parking lots, shopping areas, etc.), which from the surface of the earth are perceived as a well-maintained spot in urban development (square, summer cafe, etc.).

The device of the operated roof for underground parking is arranged according to the following scheme: the waterproofing layer is laid directly on the screed made on the concrete floor. Thermal insulation boards are laid on top overlapping each other. On top of the thermal insulation, a special filter layer is laid, on which is a layer of gravel backfill. Paving slabs are laid on gravel. It turns out not a roof, but a yard area, which is used as usual, although it is not recommended to plant trees there. Flowers, grass, small shrubs - please. If the roof of the underground parking is intended for use as a guest parking, then instead of slabs and gravel filling, a continuous reinforced concrete pavement should be used.

Flat roofing is the most inexpensive and affordable option for roof construction. It is widely used in the arrangement of both residential buildings and industrial buildings. Depending on the purpose, it can have an unexploited or exploited surface. The slope of a flat roof (necessary for the removal of precipitation), as a rule, does not exceed three degrees.

Why a flat roof is better than a pitched one: the main advantages

A flat roof is a more economical option for arranging a roof than a pitched one. With an equal building area, the area of \u200b\u200bthe first is less than the area of \u200b\u200bthe second - which means that less materials will be required. A flat roof is being “built” under conditions of “lower extremeness”, therefore, we can talk about reducing labor intensity installation work.

Subsequent maintenance of the surface is also simplified - cleaning drains, inspecting chimneys and ventilation ducts, etc. A specialist working with your building will not need the skill of a climber. It's also nice that the projects of houses with a flat roof allow you to mount climatic equipment (for example, outdoor units of air conditioners) without "touching" the facade.

But there are moments in which a flat roof loses pitched. For example, it “suffers” more due to snow loads.

Types and features of flat roofs

A flat roof can be exploited or non-exploited, traditional or inverted.

Exploited coating

It must necessarily have a rigid base (the goal is to maintain the integrity of the waterproofing) - it can be a corrugated board or a concrete screed. When insulating such a roof, it should be remembered that the heat insulator will be subjected to increased dynamic and static loads - therefore, it must have high compressive strength. If the insulation was purchased not rigid enough and nothing can be done about it, you will have to form an additional layer of cement screed on top of it.

Recently, special attention has been paid to the equipment of such roofs - an additional area for parking or a summer cafe, given the modern rhythm of life, simply cannot be superfluous. A flat exploited roof (terrace type) is a standard structure consisting of:

- reinforced concrete slab;

- vapor barrier;

- heat insulator;

- waterproofing layer;

- finish coating.

The classic version of the device "pie" flat roof

The most common finishing option can be called paving slabs installed on sand cushions or special stands. On areas prepared for intensive use, it is recommended to mount an inverted roof.

The main advantage of an exploited roof, which is not difficult to guess, is the ability to transform an “ordinary” roof into a cozy, quiet corner where you just want to settle down after an exhausting day at work.

![]()

On the exploited roof, you can arrange a terrace with a cozy seating area

Unexploited design

Not demanding on the rigidity of the base and insulation. It is much easier to equip it than to operate it. But this affects the service life of the surface - it is significantly reduced.

traditional roof

Its design includes a layer of vapor barrier laid directly on the base. Vapor barrier films are designed to protect the insulation from moisture "from below" (diffuse). They are laid on top of the screed, at the edge of the roof along a vertical plane they are brought to a height exceeding the height of the insulation. Insulation can be foam or mineral wool. Waterproof the surface with bitumen-based materials.

Thus, the process of installing a heater takes place

Inverted type

Its main difference from the traditional flat roof is the location of the insulation layer not under the waterproofing, but above it. This design protects the waterproofing agent from negative UV exposure, mechanical damage and atmospheric "whims".

As a heater, you should use a material that can retain its properties even when in contact with moisture (for example, extruded polystyrene). The waterproofing carpet must be made of PVC membranes, bituminous mastics or euroroofing material.

The design of the inverted roof makes it possible to use it as an exploited one - you can successfully plant grass on it, equip an area for hiking, set tables and sun loungers.

breathable roof

Most roof coverings lose their properties due to excessive moisture in the thermal insulation layer. This is manifested in the formation of cracks, ruptures and swelling. The most intensively destructive process takes place in summer, when moisture begins to evaporate intensively from the insulation. As a result - the roof detached from the base.

To avoid this phenomenon, you can use a breathable roof that provides high-quality removal of water vapor. To install it, it is not necessary to completely dismantle the outdated coating - the old fused roofing carpet can easily act as an additional waterproofing layer.

green roof

Allows you to solve one of the most important problems of our time - the problem of lack of communication between man and nature. Moreover, it greatly improves appearance buildings. Thanks to modern landscape designers, flat-roofed houses become real works of art with exquisite flower beds, English lawns or even a full-fledged park.

Please note that the decision to install a green roof must be made at the design stage of the building. The fact is that the soil layer creates a considerable additional load on the floors, and this cannot be ignored.

![]()

Green roof - a great place to relax

A green flat roof should consist of the following layers:

- reinforced concrete construction;

- high-quality waterproofing (EPDM membranes, polymer membranes are recommended);

- insulation (extruded materials are suitable);

- geotextile;

- drainage layer (gravel / crushed stone);

- pad;

- priming;

- vegetation cover.

Depending on the type of operation and landscaping, extensive and intensive green roofs are distinguished. The first operation is not expected, the paths are laid solely for the freedom of movement of the attendants: as a rule, only lawn grass is planted on them, while larger plants are placed in pots. The second is a full-fledged garden with shrubs, flowers and trees. The main condition for arranging an intensive roof is reliable structures and the ability to lay a meter-long soil layer.

Only professionals should be entrusted with the installation of a green roof, since it will be quite expensive and problematic to repair it after inept "amateur" work.

Rules for the operation of a flat structure

There are a number of necessary requirements for the device of an operated flat roof:

Typical coating defects and how to eliminate them

Leaks after rain / after a while

Possible reason:

- mechanical damage or marriage made during the laying of the roof;

- the formation of cracks at the junction of the roof to the ventilation shafts, longitudinal and end parapets;

- crack at the junction of floor slabs;

- microcracks in the rolled material.

- installation of patches on defective places. The damaged area must be covered by at least 15 centimeters in each direction.

During heavy snowfalls, a significant amount of snow accumulates on flat roofs, which, when melted, can cause leaks.

Swelling of the roofing carpet - air or water

Possible reason:

- moisture ingress into the layers of the rolled carpet during the installation or operation of the roof;

- vapor barrier punctures;

- wetting of the heater.

- Cutting the swelling with an envelope, drying this area. Cleaning the inner surface of the corners from dirt. Heating the base with a propane torch flame, gluing the corners and rolling them with a roller. Attaching a patch.

- Full opening of the roof covering in the area of blistering. Removal of screed and thermal insulation layer. Drying the damaged area. Correction of the vapor barrier in accordance with the project. Restoration of thermal insulation, screed and finish coating.

Timely implementation of preventive inspection and repair of the roof will prevent roof leaks at the most inopportune moment.

Cracking of the top layer of the roll coating

Possible reason:

- destruction of the material due to solar exposure (due to the lack of a protective layer).

- application of mastic (bitumen-polymer) with a heat resistance of at least 90 degrees to the surface. The optimal number of layers is two, and when applying the second, it is recommended to add aluminum powder to the composition.

The appearance of dampness on the ceiling of the upper floor of the house

Possible reason:

- insulation damage. Probably a layer with gaps, not continuous; damaged during installation or not equipped at all.

- complete removal of the roofing "pie" and competent installation of the vapor barrier layer.

Depressions on the surface of the coating: depth - more than 1 centimeter

Possible reason:

- the base under the roofing carpet has potholes or depressions.

- notching the rolled carpet with an envelope, fixing the base with a c / p solution. Drying the surface, gluing the folded corners in place, installing a two-layer patch.

Minor roof repairs

Peeling of one layer of roofing mat from another or from the base

Possible reason:

- insufficient heating of the first layer of material during the deposition of the second;

- installation was carried out on a damp or uncleaned base;

- concrete or cement-sand screed not previously treated with a primer.

- separation of sheets roofing material in places of delamination, their cleaning and re-gluing. Sealing gaps with strips of rolled material;

- in the case of a defect spreading over a large area, the complete removal of peeled panels and their replacement with new samples.

Turning to professionals is the key to the durability of a flat roof

As you can see, a flat roof is both a very simple and incredibly complex thing. So that she served the house faithfully long years, all work on its installation, maintenance and repair should be entrusted exclusively to specialists. Not forgetting to personally control the correct execution of the technology at all stages of the process.