There are many options and opportunities for building a garage. There are also many different materials from which it can be built. But before proceeding with the construction, or the choice of building materials, it is worth considering everything from the very beginning - from the moment of design.

preliminary planning

Initially, as soon as the idea of \u200b\u200bbuilding came up, you should not think about what it is better to build a garage from, first you should consider its design, layout, dimensions, etc.

You should be aware that garages can be divided into many types and subspecies. They can be:

- Freestanding, temporary structure;

- Detached, capital construction;

- Adjoining directly to the house;

- Temporary building adjacent to the house.

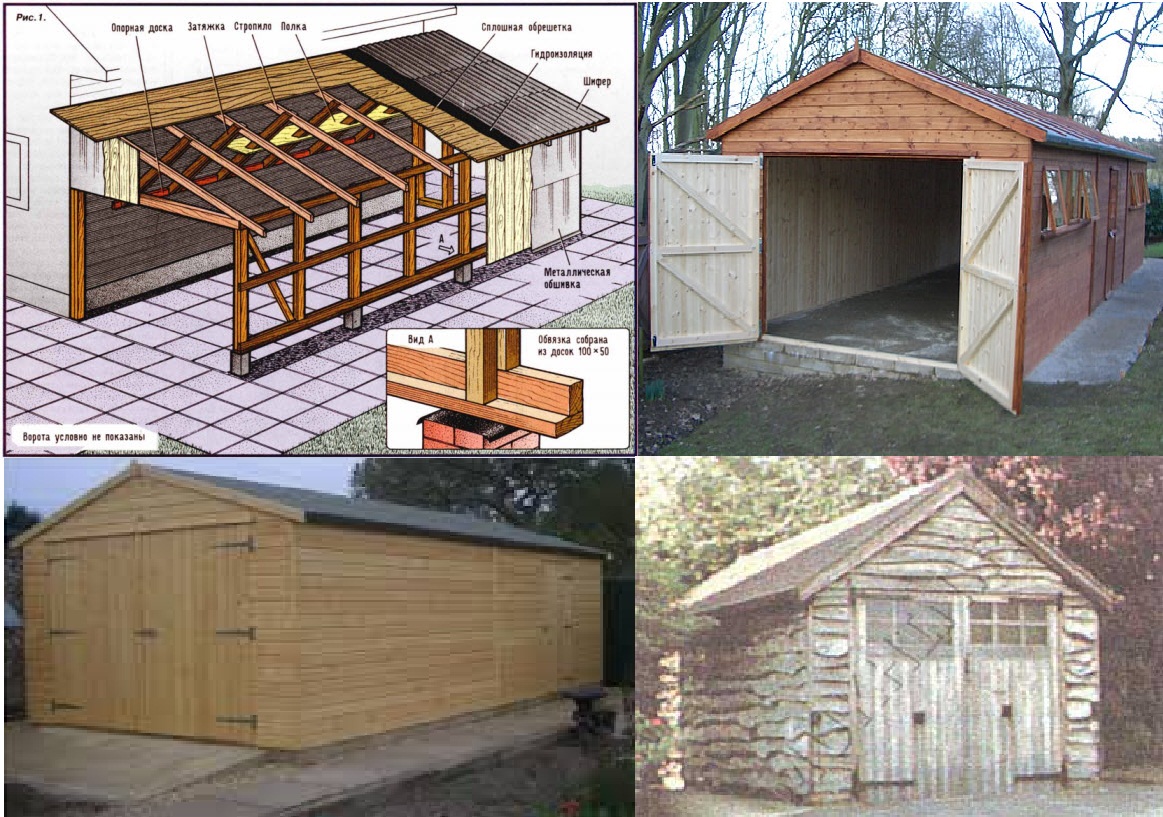

How free-standing temporary and capital garages look like can be seen in fig. 1 below.

On the left, you can see a capital brick building, and on the right, a metal building. You have probably seen such garages more than once. It is about them that we will talk.

As an example for the article, we will take a garage that stands separately.

Garage building plan

If you are going to build a garage, you should initially carefully consider its dimensions - height, width and length. Again, if you plan to put a car in the garage and no longer use the garage space for any purpose, it’s worth dissuading you - make a small margin - it will certainly be very useful for you in the future. It will be possible to put, say, winter tires, spare parts, tools, etc. there. There will never be extra free space.

Again, there are no specific standards for building a garage, but you can consider them. On fig. 2 you can see several sizes for the garage, each of which will allow you to save money, get the most usable area and convenience, or find a middle ground.

Now that you have decided on the dimensions, it is worth starting to choose the materials from which we will build the garage.

Materials from which you can build a garage

Like the types of garages, there are many different materials from which you can easily build your garage. The main options include:

- Brickwork;

- Wood, boards, beams, etc.;

- metal sheets;

- You can use slag concrete;

- Reinforced concrete structure.

All of these options are acceptable for building a garage, however, you should consider all these options separately, as each of them has its own advantages and disadvantages.

For example, brickwork has always been relevant. If you want to build a garage, then it is this material that is publicly available, it does not have a high price, such a garage, after taking care of the foundation, can be built with your own hands, without resorting to the help of professional builders. Such a design, of course, depending on the quality of work, will be able to serve for a long time, will not require constant repairs, etc. Brick buildings are reliable and practical.

In the figure below you can see a variant of the garage, built purely of bricks.

If this option does not suit you, you should start considering others.

For example, you can take cinder blocks as a material for a garage. In this case, you can save a lot. Slag concrete will cost you much less than brick, but you will also face a number of difficulties. For example, cinder blocks are much more difficult to work with than bricks, you will spend much more time and effort than in the case of bricks. Again, with regard to the safety and reliability of such a building, it will be significantly lower than when building a brick garage.

Wood, boards and similar materials

Unfortunately, this material is not entirely suitable for building a garage. Despite its cheapness, this material is very whimsical. In particular, in the future, you will have to update the design very often:

- Change rotten boards;

- Paint the walls of the garage;

- To patch holes that will invariably appear;

- Such a design will be very unreliable in terms of hacking.

However, such a design will be optimal if you have enough wood from which to make a garage. You do not need to buy other building materials. Again, if the garage is located next to the house, on the site, then this option is quite acceptable. The garage will always be in front of your eyes. Then this option can be accepted and proceed with the construction. If the garage is far from home, out of line of sight, then other materials of manufacture should be preferred. How the garage from the boards will look can be seen below.

Here are the options for creating a garage from boards, bars, an option adjacent to the house, detached.

Despite the obvious impracticality of this option, it is preferred by many, due to the primary cheapness. But, in the future, after a few months, new stocks of boards will be required, new investments in the construction, restoration of the garage.

Metal sheets and reinforced concrete

Many, in the distant 90s, preferred to build free-standing garages from sheets of metal. There are several production options here:

- It is possible to make a one-piece structure, with the possibility of quick dismantling;

- You can make a preliminary frame on which the sheets will be installed.

Whichever option you prefer, you should know that the sheets need to be fitted very tightly, even when overlapping. If one of the edges of your sheets starts to rust, you can get a hole that will have to be repaired with something. In this case, you will have to buy a new sheet of metal and attach it to an existing structure. Also, take care to purchase quality metal sheets that can withstand weather conditions, humidity, frost, heat, etc.

The optimality of this option will also be high due to the fact that you do not need to invest large sums, building a garage from this material will not hit your budget. Another plus is the ability to build a garage very quickly. Perhaps metal garages are much faster and easier to build than any other materials.

An example of such a garage can be found below, in the figure. Surely you have often seen such garages in your area, in the city. Such designs were once very popular in garage cooperatives.

In the case of reinforced concrete, you will get a reliable structure that can be easily and easily disassembled and dismantled. Such materials also cost relatively modestly, but the reliability of such a design is very high. In the figure below, you can see a reinforced concrete building.

When choosing materials for building a garage, you should not forget about what the foundation of your garage will be like. An important point and a useful clarification would be the layout of the garage under the gate. Do not be too lazy to make metal loot in the gate of your garage. In the future, you will be grateful to yourself, because it will be much easier to install any type of gate, both to weld ordinary, swing, and to install sliding, lifting, sectional, etc., depending on your preferences.

An example of the foundation and preparation of the gate in the figure below.

Useful video - what is better to build a garage from

The garage is an important building object that performs a considerable number of functions. In addition to the direct appointment, i.e. places where you can leave the car behind reliable walls, the garage can be a kind of storage for various supplies and products from the dacha: products, building materials, winter supplies. Therefore, it is worth thinking about its construction not only for car owners, which is acceptable, but also for other people.

In addition to its obvious economic benefits, building a garage will also be beneficial from a financial point of view. The fact is that it is difficult to constantly pay for paid parking, and these expenses themselves are incomparable with the price that you pay for building a garage.

What to build a garage from?

Today, it is justified to build from the following types of material:

- brick;

- foam block structures;

- cinder blocks;

- wood;

- sandwich panels.

It should be noted that these materials can be of a different nature, i.e. be temporary and permanent. This difference lies in the ability to easily disassemble the structure to move it to another place.

The common similarity is that a foundation is needed for their construction, but it performs a different function. In the case of a permanent building, the foundation is needed to transfer the load from the walls to the ground, and in temporary buildings, to level the ground so that technical modules can be installed on it.

Pros and cons of different types of materials

- Brick. When building a garage, not only the financial component is important, but also the purpose of this building. If you use the garage only in the warm season, then it is not advisable to insulate the walls. With year-round use, it is necessary to make a selection of material that meets these requirements. Brick garages, if they are not previously insulated, will not be the best option for using a garage all year round. In addition, it is worth installing a brick garage in cooperatives, which will protect against the possible penetration of intruders. Brick garages are also erected in free territory, but, in this case, you will have to take care of sufficiently thick walls of the building (at least one brick wide). Building a brick garage is a difficult task, because at least minimal knowledge of masonry methods is needed.

- Foam concrete. This type of material is quite popular, gradually replacing the usual brick buildings. This is achieved due to a simple and convenient way of building these objects, deep energy saving and masonry speed. Blocks of foam concrete or aerated concrete of large size, while having a light weight which makes building a garage a breeze. Upon completion of construction, the outer surface of the blocks is treated with a primer (modular, acrylic). This is necessary to protect the garage from moisture and other aggressive environments.

- Wooden bar. A little time ago, this type of material was unsuitable for the construction of garage structures, in view of the fact that wood was considered a fire hazardous material. Today, thanks to the emergence of effective refractory impregnations, wooden garages have become commonplace and commonplace. The main advantage of this material is considered appearance, thanks to which you can easily make all the buildings on your site in the same style. Apart from outdoor processing timber, inside they use lining with basalt wool slabs, which will improve the fire resistance and integrity of the building. When installing the floor, you need to think about insulation in advance. To do this, we use expanded clay screed, which we upholster the floor. This procedure is necessary for a comfortable stay in the garage, and to save the vehicle body.

- Sandwich panels. This material belongs to the category of prefabricated, which makes the material attractive for purchase. The basis is a metal frame, which is further sheathed with corrugated board. For the construction of an insulated structure, a certain gap is left between the racks of the frame, in which a mineral wool slab is placed. Sandwich panels are divided into 2 types:

- an ordinary sandwich with a different insulation (foam, mineral wool, etc.);

- OSB sheets with foam.

For the construction, you will need skills in working with a welding machine and a screwdriver, so self-assembly is a difficult task. When buying, they also order the installation of the structure, so there will be no problems with this. When erecting a structure, the main point is considered to be a correctly poured concrete floor. Errors in this work lead to difficulties in installing the walls of the garage, so you need to be careful.

What is cheaper to build a garage

Materials have advantages over competitors. Some are cheap, like cinder blocks, others are reliable, like foam concrete or brick structures. But it is important to remember that the choice of material should not be based on momentary calculations of the cost of building a garage, but on a relatively large time period equal to months.

Wooden garages for the consumer will be an economical option, but there is one caveat.

Boards tend to rot over time, so repairing and laying new boards can be very costly. Based on this, the most preferred option, taking into account an affordable price and quality, is a foam concrete garage. In addition to the low cost of purchasing the material, the construction of this garage is considered the least difficult than when working with other materials.

Cost calculation

If we consider foam blocks as a material option suitable for building a garage, then it is easy to calculate the necessary cost estimate required for the construction of this structure.

The first stage of costs is the purchase of foam blocks:

- Wall blocks - the average cost is about 3 thousand rubles per m3 (block dimensions - 60/30/20cm). The price for one block is 100 rubles.

- Partition blocks - the average cost is within 2800 rubles per 1 m3.

In addition to purchasing blocks, for construction you will need a standard set of building materials:

- Cement. The price for 50 kg (M300) is within 250 rubles.

- Sand. price for one cubic meter- within 200 rubles.

- Crushed stone - 1700 rubles per 1 m3.

- Gravel - 1200 rubles per 1 m3.

- Insulation - within 1300 per 1 m2.

- Waterproofing - from 40 rubles per 1 m2.

As we can see, the construction of a garage, even considering the low cost of foam blocks, will cost a sum of money. There are ways to help save on construction costs:

- The floor in the garage is covered with gravel, and they do not make a monolithic layer of cement. It is only necessary to pre-compact the soil before backfilling.

- Making a foundation on pillars, which will help save on cement mortar.

- Buying materials can be cheaper if you buy them in the winter.

Watch a video on how to build a garage from foam blocks with your own hands

Outcome

Building a garage is justified for car owners. Initially, the cost estimate for this building can be intimidating, but considering that a car left in the open will be the goal of every car thief, these costs will seem like a trifle to you.

The construction of a garage begins with its design. The type of garage base will depend on the type of soil. When designing, the number of cars, an inspection pit, a working area for tools, and an entrance door are taken into account.

You can build a garage from foam blocks without a heavy base with your own hands. Foam blocks are inexpensive, warm and easy to install material. Prices for foam blocks are about 50% lower than for bricks, and in terms of their construction characteristics, they are in no way inferior to the latter. It’s really cheap to build a garage with your own hands from foam blocks: foundation costs will be minimal. When building a garage, you can save on pouring the floor, limit yourself to plastering the walls and not equip a viewing hole.

Foam block garage: construction and wall installation

The cost of a foam block garage will depend on the material, its size and installation method. To simplify installation, they buy corner blocks, then you do not have to spend time aligning the corners. The blocks are reinforced with a cementing mixture or a special adhesive solution.

The construction of a garage begins with a foundation; it does not require capital if you do not equip a viewing hole. Installation of blocks begins with setting the corners. A cord is stretched to the finished corners, along which the walls are later leveled. Foam block masonry must be reinforced every few rows. The most technologically difficult moment in the installation of a foam block garage will be the installation of a lintel above the door: a metal corner is welded or purchased for it and installed from the inside.

Foam blocks are a material that does not allow air to pass through. Condensation will accumulate inside the garage, so it is recommended to install ventilation systems in such garages.

Garages from corrugated board

It is not difficult to build a garage from a metal profile with your own hands: it does not impose great requirements on the foundation, it is built in a few days, it is inexpensive. If a viewing hole or a cellar will be built in the garage, then it is necessary to make a strip foundation. The corrugated board is attached to a frame made of galvanized corners or square pipes. Additional supports must be attached to the frame. Do-it-yourself garage from corrugated board can be built entirely from a metal profile or lined with foam blocks or cinder blocks.

Metal profile sheets are attached to the frame with self-tapping screws with additional sealing washers. The roof of the garage can be made single or gable. A separate frame is equipped for the roof; the same materials can be used for it as for the main structure of the garage. The crate is made in increments equal to the width of the corrugated sheet. Previously, heat-insulating materials are attached to the roof of the garage. The joints between the sheets are treated with sealant. For the floor in the garage, you can use lumber. First, expanded clay is poured onto the base, and flooring from boards is laid on top of it. A more preferable option is to fill the floor in the garage with concrete, this is a practical and reliable way.

How to quickly build a garage with your own hands

The fastest and easiest way to build a garage from corrugated board. Such a garage can be built in a couple of days. Fixing the walls does not present any difficulties, the service life of such garages is several decades, it is easy to move it to another place. But corrugated garages need to be insulated, they are easy enough to break into. Another cheap option is building a cinder block garage. Such a garage is easy to build, it will last a long time, heat will be stored in such a garage much longer than in a metal profile garage. The creation of a project and its implementation is within the power of everyone, and a capital garage can be erected in a short time with savings on contacting a construction company. The garage needs to be finished from the inside. You can carry out the necessary communications: electricity and even sewerage. Heating and ventilation of the garage is very important.

Other materials for building garages

Building a wooden garage is most often required in areas with country houses also made of wood. For a wooden garage, strip foundations are preferred. The floor of the garage can be laid on the bottom trim. Previously, a layer of waterproofing is placed on the foundation, for example, roofing material. For the construction of a wooden garage, a frame structure is now increasingly being chosen.

Building a garage from a cinder block will cost less than from a foam block. Cinder blocks have a shorter service life, they can begin to crumble after a few years. The foam block is made of porous concrete, and the cinder block is made of slag cemented with mortar. Cinder blocks are laid on a cement mortar. The entire subsequent construction will depend on the first row of masonry. Cinder block walls are not built too high.

If the car owner lives for a significant part of the year in a country house or in country house, he inevitably wonders what to build a garage from? It is far from always necessary to park a car in a solid room made of brick and concrete. In most cases, you can get by with a more economical building that will serve the owner flawlessly for decades.

The market offers a wide range of materials of different price categories. Thinking about what to make a garage from, you first need to decide on the functions of this room. It can be used not only for parking a car, but also as a workshop and warehouse for household equipment. After that, you need to solve the issue with the dimensions of the building and the possibilities of the budget.

Those who first encountered the issue are advised to familiarize themselves with the list of the main stages of work that will require both monetary investments and labor efforts.

- building a foundation;

- the device of the lower and upper floors;

- roof installation;

- installation of doors and windows;

- wall insulation;

- Finishing work.

Choose the type of garage

If the main selection criterion is an inexpensive garage, it makes sense to pay attention to budget frame-panel buildings. They are good because they allow the entire list necessary work do it by hand. This will significantly reduce construction costs. There is another way to save money: choose an economical type of foundation and frame sheathing.

Light shield construction does not require a powerful foundation.

If the type of soil and the relief of the site allow, it can be erected on column foundation. Optimal choice — screw piles. But this type of supports cannot be classified as economical. Metal screw piles are very expensive.

What material is more profitable to build a foundation? There are two options: pillars of concrete-filled asbestos-cement pipes and MZL (shallow strip foundation). The latter can be built from used bricks, which will significantly reduce the cost of the process.

There is another extraordinary way to build a foundation: use car tires filled with compacted sand. For the construction of walls and roofs, the choice is small: you can use either metal or wooden materials.

About prefabricated metal structures

Manufacturers offer a wide range of models of prefabricated structures made of steel and corrugated board. These kits are easy and quick to install. If necessary, the owner can easily insulate the room. Of the minuses of metal garages, the following parameters can be noted:

- low resistance to breaking;

- the possibility of quick loading and transportation by intruders;

- low level of fire safety;

- lack of ability to retain heat.

Construction materials

Having opted for a frame, the car owner can be sure that this room will serve him for a long time, will be warm and outwardly attractive. To build a garage, inexpensive and widely available materials will be required.

For erection strip foundation:

- cement grade not lower than M400;

- brick;

- sand;

- gravel or crushed stone;

- lumber for the construction of formwork;

- roofing felt and bitumen for waterproofing brick or concrete.

To build a frame:

- timber with a section of 10/10 or 15/15 cm;

- metal brackets and corners;

- screws and nails;

- flame retardant composition for wood processing.

For building walls and roofs:

- boards with a section of 4/15, 5/15, 5/20 cm;

- screws and nails;

- window;

- doors;

- roofing material: ondulin, metal tile, slate.

For cladding and wall insulation:

- sandwich panels or OSB boards 9 mm thick, moisture resistant plywood;

- insulation: mineral wool or polystyrene;

- for interior decoration premises, you can use wood, plasterboard, plastic.

It is necessary to decide what is better to build a garage from, based on the specific situation with finances and the availability of materials. In some cases, you should not rush and strive for the maximum reduction in the cost of construction. The garage should serve its owner for more than one year. Therefore, the choice of the type of building and its size must be approached seriously and thoroughly.

Today, in the age of the economic crisis in our country, not all motorists can afford to build a capital garage. But how to build a garage inexpensively?

The construction market and Russian prowess for invention will help build a garage that will last for a long time, and will look like aesthetically pleasing.

In the article we will talk about what material cheaper to build a garage and how to build budget garage with your own hands.

In contact with

Brick is expensive, but recent times he is not in demand, and not only because of the high cost. Yes, the brick looks beautiful, has excellent characteristics, but construction takes too much time. Another thing - alternative materials:

Here are the three main building materials used economical builders. Let's explore the details technology building a garage cheaply and reliably.

from wood

Perhaps, wood- this is the best option, because here, like in no other option, external aesthetics, environmental friendliness, economy and ease of construction are successfully combined. But working with wood has its own nuances.

Please note that there are two ways to build: from round logs and frame technology. The first is more reliable, the second is cheaper. Choose the most suitable option for you.

Technology

How to build a garage cheaply with your own hands from wood? Preparatory stage consists in choosing the location of the future structure and its model. Garages are free standing or attached to the building. The types of gate opening are also multivariate. All of these points must be in advance.

After drawing up a plan and layout, the construction site is leveled, cleaned, and rammed. The site must be perfectly flat so that after that there are no kinks and distortions.

The site is ready, it's time to start the most important part of our construction - pouring the foundation. Along the perimeter of the future development, a trench is dug, on which formwork is installed. Definitely a must do pillow from several layers of sand and gravel, which is carefully compacted.

The base is reinforced with metal rods and poured with concrete. Now you need to let the foundation stand at least three weeks. When the foundation is ready, we proceed to the lower strapping, which is carried out from the board 50x100 mm.

ATTENTION: Be aware of the wood's tendency to absorb moisture and rot. Therefore, pre-treat the building boards antiseptic.

For corner posts and gate leaves, it is best to take timber, while other frame elements are made of boards 50x100 mm. When performing the lower strapping, maintain an interval of no more than 120 cm.

Also, if you want your garage to be as durable, strong, solid and last as long as possible, install braces at the corners. This will give the structure more stability.

The hardest part of the job is foundation pouring and frame erection. For the frame, stronger, thicker boards are needed, while for the arrangement you can already use a 25x100 mm board, even a simple lining will do here. The board is then sheathed with any finishing material, after which it is necessary to carry out hydro- and vapor barriers by laying several layers of polyethylene or polypropylene film.

As you can see, the garage itself is cheap wood not that hard to build.

Garage photo wooden:

cinder block

Second most popular building material for the garage is cinder block. To date, cinder blocks are of several types:

- from blast-furnace slag, which is famous for its excellent performance and durability;

- shell rock;

- brick fight.

To improve performance, some manufacturers add more perlite, polystyrene and other materials.

The cinder block is good for everyone, but there is one in it flaw: like a tree, he absorbs moisture, which is rapidly destroyed. With dry soil, this quality of the material will not be problematic, and with proper construction it will last up to fifty years, but in places where ground water, it is better to choose another material, because, if the tree can still be varnished, carry out such manipulations with a cinder block it is forbidden.

ATTENTION: You need to know that cinder blocks are divided into types not only by composition, but also by configuration into hollow ones, which are used for walls, and solid ones, intended for the foundation. Ignoring this feature can lead to the rapid destruction of the entire structure.

Technology

In the construction of a garage cinder block, we also carry out preparatory work, clearing and leveling the site, developing a plan for the future structure.

A flood foundation is ideal for a tree, but cinder blocks do not need such a powerful support, it will do here. The strip foundation is made as follows: the top layer of soil is removed and a trench is dug about 45-50 cm deep and 40-45 cm wide. Then a pillow is made of sand and broken brick, which is then poured with cement.

You can also do it differently: the trench is covered with sand, and then filled with water. The combination of water and sand gives the construction strength and makes it resistant to time and changes in temperature and humidity. After that, reinforcement is laid on the bottom and the entire structure is concreted.

In a month, you can start building walls. The third way to build a strip foundation even easier: rubble stone is poured into the trench instead of sand and the entire structure is poured with cement raster, not lower than 150 marks.

After the foundation has been erected, the basement is equipped with heat and vapor barrier materials. The most versatile option for hydro, heat and vapor barrier is a simple ruberoid.

- walling;

- floor screed;

- roofing;

- hanging gate.

cinder block masonry identical with bricklaying, only here this work is carried out several times faster. Laying can be carried out in the stone floor (spoon method) or in one stone (poke method).

Masonry in 2 and 1.5 stones is also practiced. You choose the option that suits you, remembering that the thickness of the walls directly affects the durability of the garage and its ability to withstand sudden changes in temperature. A one-stone garage will freeze in winter, even if several heaters are installed in it, while one and a half and two stones will be warm and cozy.

When building walls, you should initially lay out the corners, and only then, stretching the building cords between them, start laying blocks using the brick method, that is, blocking the seam of the previous row.

When constructing the floor, remember that the screed must be at least 10 cm. Concrete is good for screed M200, which is poured in several layers, and then, after drying, rubbed.

The final stage - electrification and interior decoration.

Garage photo from cinder blocks:

Decking

How easy is it to build a garage? For this, a universal material is suitable. corrugated board. It is perfect for fences, for sheds, it also makes good garages. But here the most important condition is the competent choice of corrugated board: only cheaper is suitable for building a garage brand PS or FROM.

Decking is marked with a letter and a number. Letter "FROM" stands for "purpose for walls", number - sheet stiffness. The higher the number, the stronger the sheet. S-20- the best option for construction.

Sometimes sellers, due to their illiteracy or when there is no twenty in stock, advise ten or eight for construction, but! Never fall for this sales trick! A garage made of such a sheet, although it will cost much less, will not last long, besides, it will be icy in winter, and it will be impossible to warm it up. And the walls will shake from the wind. You need it? We think not, therefore, we stop at the standard twenty.

Ideal deck thickness half a millimeter.

Technology

How to build a cheap garage with your own hands from corrugated board? We will need:

- reinforcement and concrete for the foundation;

- elements for the frame: corner, bars, metal rods;

- metal elements for gates;

- self-tapping screws.

Arm yourself next tool:

- screwdriver;

- welding machine;

- Bulgarian;

- metal scissors;

- jigsaw.

Garage photo from corrugated board:

Let's get to work. First of all, we fill. Having cut off the soil by half a meter, the resulting trench is covered with sand and poured with water. Under the frame racks, wells are made, which will simultaneously become foundation racks.

This work will help to make the foundation stronger and more resistant to ground movement. Wells are driven to a depth of at least half a meter.

Further, everything is standard: a wooden formwork is erected, on which the bars of the reinforcing structure are installed. For strength, the rods are attached with wire. Now the main thing is not to forget to install frame structure racks in the wells.

IMPORTANT: Before installing racks, it is necessary to process bitumen underground part of the building.

To prevent the racks from warping, they are carefully aligned with level. The last stage of work is pouring reinforcement with concrete. Use mark 300, for this case, this is an ideal option.

Some builders claim that it is possible to build within two or three days after pouring concrete, but professionals advise to wait for the required three weeks, otherwise the foundation may crack, and then it will no longer be possible to correct the error. Patience and again patience is the key to success.

When the foundation is ready, erect metal carcass . Here, welding, and a grinder with an electric jigsaw for cutting metal pipes of the right size, and some more welding skills are useful. With the basic skills of a welder, the frame is cooked in a day or two. The newcomer is transported for a week. In order to make a frame, you need to carefully study the drawing several times and cut the material according to its data.

Using welding, we cook horizontal metal rods to the racks. Welding in progress at three points. If the frame is made of timber, then in addition to everything, special fasteners for wooden beams are welded to the racks. The bars are attached with self-tapping screws.

Now the corrugated board is attached self-tapping screws. You can adjust the sheets to size using a jigsaw. This work is best done team out of three or four people, it is almost impossible to cope with it alone.

When the frame is completed, the installation phase of the gate begins. Here you also need to show patience and maximum attention in order to avoid mistakes. The frame of the gate is made of metal corners and sheathed with a profiled sheet. This job can be done in a day or two.

As a rule, it is performed in a single-sided version. The roof frame is made of crossbeams (wooden or metal), on which a crate from a lining is attached. It is important to take into account the climatic features of your region.

In the southern regions, a lightweight construction of the crate can be used. In the north, where the winter period with blizzards and snow drifts is long enough, it is better to make a stronger, more solid structure that can withstand the load of snow.