When building absolutely any house, the foundation, first of all, will be the foundation. It is on his shoulders that the whole structure rests, and the quality of further construction and, accordingly, performance characteristics depend on what basis you have prepared for the future home.

Today we want to talk about how to choose the right foundation design and how to properly mount the foundation for the future building.

Types of foundations for building houses

Among building technologies, the engineering construction of the foundation is divided into varieties. As a rule, for certain building structures, different types grounds.

In our case, we want to answer the question of which foundation is better for a brick house.

Let's get acquainted with the full list of available designs and choose the one that suits us.

- Strip foundation, a widely used construction that is ideal for building one-story and even three-story houses. She received her classification due to her device. In practice this monolithic construction mounted in the form of ribbons interconnected.

- foundation pillow, usually a surface that is completely filled with concrete of a certain thickness. Based on engineering calculations, the monolithic pillow then evenly takes the entire load of the future building. It is used both for the construction of private buildings and for the construction of industrial buildings.

- Foundation on piles, such a foundation can be called the most durable. It is this technological approach that makes it possible to build houses on very weak soils. In this case, construction can be carried out on swampy soil or in places where groundwater may be.

- Column Foundation , consists of concrete pillars that take on the entire load. To install them at a certain depth, based on building codes, a special “glass” is installed or poured. In which a concrete pillar is then installed and the entire structure is connected to each other by concrete beams, “crossbars”.

Information! How do you see to build your one-story house it is not necessary to use complex foundations. It is quite possible to use simpler designs that are best suited to your project.

A bit of history

If we turn to history, we can see one interesting thing. In total, some hundred years ago, concrete was not used for the construction of the foundation. To the question of what kind of foundation is needed for a brick house, the answer was unambiguous.

Our ancestors made the foundation for most of the buildings from buta of wild stone, brick, and all these structures still stand and hold the buildings on themselves. Moreover, such buildings can be up to four floors.

Today, such technologies are not used, the modern construction industry is leaning towards more durable materials, and gives its preference concrete structures, which have been used in the construction of houses for more than a decade.

Getting started: what you need to know

Of course, before starting the installation of the foundation of the building, the first thing to do is to conduct research that will answer your question: is it possible to build buildings on this site at all.

There is also a clear instruction that defines the main parameters for preparing the site for the installation of the foundation, and it applies to absolutely all types of foundation structures.

- First of all, it is necessary to examine the soil in the area where construction is planned.

- Clearly know at what depth freezing occurs in the cold season.

- Is there any underwater groundwater on the site that can weaken the strength of the structure.

- What will be the load of the house on the bearing parts of the foundation according to the project of the house.

- Will there be a basement in the house, and for what purpose is it intended?

- Are important underground utilities, a central water conduit or power electric cables passing through the territory of the site.

- Determine the materials from which the foundation device will be mounted.

Important! Very often, land owners start building houses on their own with their own hands, and they don’t even know if important communications pass through their territory. Be sure to check with the relevant authorities, otherwise your building may be destroyed at any stage of construction.

Material for building a house

I would also like to initial stage decide on the choice of material from which the future house will be built. It is at this stage that we can already decide on the type of foundation for our house.

In this example, we will use to build walls building brick. From here it is quite a logical conclusion, the foundation should be made tape. This is the best option for projects of this type.

Firstly, it is financially economical, and secondly, correct calculations will allow you to build a very solid two-story house on such a foundation. Of course, such a foundation can withstand three floors, but based on practice, a two-story building is quite suitable for most homeowners.

Silicate brick and its application in the foundation

In terms of strength and temporary performance, silicate even surpasses concrete structures. At the same time, it has excellent breathability, which is quite good quality for places where there is a lot of dampness.

Such material, if we speak plain language, breathes. In our case, the double silicate brick M 150 can be of great help in building the walls of your house, because it perfectly retains heat, much better than ceramic.

Information! Ordinary silicate brick is not recommended for use in the construction of the foundation of the house and basement structures. If the silicate is saturated with moisture, and it will be affected by negative temperatures, it can simply collapse.

We apply the principle of strip foundation

As we have previously decided, the structure that we will consider will be made of brick and the basis for it will be a simple strip foundation. In the foundation, the main load-bearing structures will be made of brick.

First of all, of course, you need to dig a hole for the foundation, taking into account the plan of the future structure, this is usually the length and width of the building.

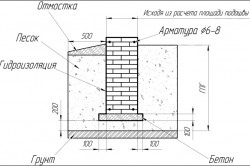

The depth must match acceptable standards soil freezing, which depends on the specific region in which construction work is carried out. In our example, we will take the average value and dig a trench one meter deep.

Pit preparation

Now that the trench has been dug, you need to properly prepare it for the start of bricklaying work. If you used the equipment to prepare the trench, then it is imperative that you manually level the bottom of the pit.

First of all, we fill the bottom of the trench with sand and carefully tamp it down. After the perimeter of our pit, you need to sprinkle it with rubble and compact it in the same quality.

After carrying out work on the installation of the pillow, it is recommended to make a screed at the bottom of the pit, it will serve as the basis for our foundation, as well as a waterproofing layer that will prevent moisture from penetrating into the brick.

Foundation device: proper masonry

After our screed at the bottom of the pit has seized and acquired the necessary strength, you can safely begin laying your foundation. Since we will focus on a multi-storey building, then the device brick foundation will be appropriate.

We lay the foundation and gradually raise the foundation to the desired height in this way:

- The first five rows of masonry cases are four bricks wide. This approach will give us a good wide base for the entire foundation.

- The next five rows must be laid three bricks wide.

- And here is the final touch, the next stage of masonry should be two bricks wide, and the structure should be raised to the calculated height of the base, if any, in the project.

Important! All bricklaying works are carried out using cement-sand mortar. Laying the foundation on clay mortar is unacceptable.

Waterproofing: the final stage

On the final stage work, we need to protect our foundation from unwanted penetration of moisture into the brick, thus maximizing the life of our foundation.

To do this, you must first plaster the entire brick surface. After the plaster has completely dried, the surface must be treated with bitumen. For more reliable waterproofing, a roofing material or waterproofing is installed on top of the bitumen.

After the waterproofing layer has completely dried, the foundation must be covered with earth and carefully compacted.

Finally

In the presented video in this article you will find additional information on this topic.

- A little about the properties of the soil

- The choice of brick for the foundation

- We start construction

- Types of brick foundations and their main properties

- Column Foundation

- Brick strip foundation

The construction of a small country house can be completely done independently. Under such a house, a brick foundation is made. The main thing is to have a general idea of the process itself.

Brick is a familiar, relatively inexpensive, time-tested material. To work with it in the construction of small buildings: houses, utility or work premises, gazebos, etc., you will not have to attract a large number of people and use heavy construction equipment. This is the main advantage of bricks in self-construction. However, in order to obtain a reliable, durable and neat building as a result of such construction, it is necessary to familiarize yourself with some important points to avoid making hard-to-fix mistakes.

A little about the properties of the soil

Before erecting any building: residential or commercial, it is necessary to carefully study the properties of the soil in the selected area. This is an important point in planning. The choice of the main construction technology, the need for additional work and much more depend on the properties of the soil.

The main property of the soil, taken into account when planning construction, is its heaving, i.e., the ability to expand upon freezing due to the formation of ice crystals inside the soil. It depends on the level of groundwater, climate, soil composition.

Back to index

The choice of brick for the foundation

If you are going to make a brick foundation with your own hands, you should remember that for this it is best to use red burnt solid brick. Such a brick has high strength, moisture resistance, durability. Build a foundation of red perforated or silicate brick undesirable, especially on heaving soil. Such bricks are easily saturated with moisture, lose their shape and gradually collapse. To reduce the cost of the foundation, you can use for its construction the brick left after the dismantling of buildings, or burnt brick, which has small shape defects.

Heaving can be high, medium or low. Experts from the soil laboratory will help to accurately determine its level and other properties of the soil on the site, who will conduct a complete analysis of the composition, moisture content and other properties of the soil using special equipment.

Back to index

We start construction

The tools needed to build a brick foundation must be prepared in advance so as not to interrupt work due to the absence of any of them. You will need the following fixtures:

- tape measure or laser rangefinder;

- bubble building level;

- plumb or laser level;

- a hammer;

- pick;

- Master OK;

- cord;

- shovel;

- order;

- tanks for preparation and carrying of solutions from concrete and cement.

From the materials you will need:

- brick;

- sand;

- cement;

- concrete;

- water.

It is better to take all materials with a small margin, which is caused by the presence of errors in the calculations, the thickness of the binder layer and deviations in the geometric dimensions of the brick. It is desirable to use coarse river sand with a low moisture content. Before preparing the mortar, sand and cement must be sifted to prevent foreign objects and debris from entering the cement mortar.

In order for the foundation to be stable and durable, and the construction on it durable, it is necessary to carefully prepare for its construction. The main preparatory steps are:

- Selection of a specific site for construction.

- Determination of soil properties.

- Design.

- Marking the perimeter of the building with pegs and wire.

- Determining the quantity and purchasing the necessary materials.

- Preparation of tools and fixtures for future work.

When drafting a future building, it is necessary to take into account its estimated weight, area, location of load-bearing walls and internal partitions, and some other data.

You can entrust the drafting of the project to a specialist or use the standard option. This will avoid many difficulties and mistakes.

Back to index

Types of brick foundations and their main properties

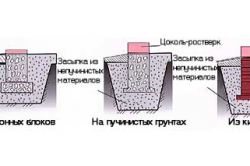

The brick foundation can be made tape or columnar. On dense and dry soil, the foundation can be shallow.

If the soil is medium-heavy, then the depth of laying the foundation should be approximately 0.3 - 0.5 m below the freezing level of the soil. Especially with periodic changes in the groundwater level.

The type and depth of the foundation is also determined taking into account the severity of the future construction. A deep-lying strip foundation made of bricks is necessary for heavy buildings. It is quite possible to erect a light building on a columnar brick foundation.

- Foundation for a brick building

- Examples of mortar recipes

- Choosing a brand of brick

- Waterproofing and insulation

- Building a brick foundation

- Reinforcement of a brick foundation

As a building material, brick has been developed and used for a very long time. Its use in the construction of load-bearing walls, cladding of buildings is not surprising, and now it is used for the construction of foundations. It is difficult to consider it an ideal building material for such a difficult role; it is rarely used in individual construction for this purpose. What characterizes a brick foundation?

A large indicator of rigidity, strength has medium values, low resistance to moisture and low temperatures. Given the above, it is recommended to build a brick foundation in dry, non-rocky, hard soils with low groundwater.

Foundation for a brick building

The brick foundation is mostly used for light one-story buildings. Such a foundation is economical, and if all the technological features of its construction are observed, it can last 28 years or more. Most often, bricks are made of:

- shallow-depth tape foundation - for non-rocky soils;

- strip foundation deepened to the depth of freezing of the soil - for heaving soils;

- columnar foundation - for light buildings on medium-heavy soil.

A strip foundation is an underground support base in the form of a tape under the load-bearing walls of a structure. Its ground part is the base, thanks to which the structure is protected from dirt, dampness, and atmospheric residues. In the underground part of such a foundation, it is possible to arrange a cellar, a basement. The strip foundation is able to withstand a fairly heavy building, not exceeding 2 floors. Perhaps its construction on heterogeneous soil. The strip foundation will effectively withstand a massive house, and also save it from the detrimental effects of instability in the ground caused by rain and snow loads. The desire to add a basement, cellar, underground garage to the building often turns out to be one of the main factors in the construction of such a sole.

With your own hands, a strip foundation can be built from various materials: rubble concrete, reinforced concrete blocks, bricks, reinforced concrete.

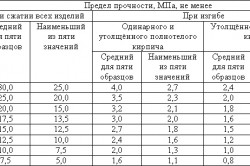

The strip foundation should be made of bricks with high strength and frost resistance (F-35, 50, M-150, 200). For erection strip foundation with my own hands knowledge of cutting brickwork is required. Such work is unthinkable without the use of a specially prepared solution. The mortar recipe is selected according to the type of soil.

Back to indexExamples of mortar recipes

- On dry soil, it is possible to use a solution with the addition of lime: M300 cement / sand / lime - 1/15 / 2.5 (or replace lime with clay: M300 cement / sand / clay - 1/11/1).

- On moist soil, lime or clay is added to the cement mortar in the same proportion: M300 cement / clay or lime / sand - 1 / 0.7 / 8.

- Works on water-saturated soil require only a cement mortar in the ratio: M300 cement / sand - 1/6.

Choosing a brand of brick

To build solid foundation made of brick, it is important not to make a mistake with the brand building material. When choosing a brick, two main characteristics M and F are taken into account. Accordingly, this is a load per 1 sq. cm with frost resistance. Brick of the following grades is considered suitable for laying the foundation: M-300, M-250, M-200, M-175, M-150 with frost resistance F 100-35. Water absorption should also be taken into account. When laying an underground foundation, it should fall within the range of 6-16%.

To build a strip foundation, you can use a single ordinary, thickened, modular or modular thickened brick.

Materials needed to build a brick foundation:

- brick;

- waterproofing;

- insulation;

- cement mortar;

- reinforcement or masonry mesh.

Simple enough to do. Brick is a necessary and main material for this. It should be remembered: the use of various hollow or silicate bricks when creating a foundation is unacceptable.

It is better to lay out the underground part of the foundation with red-colored ceramic solid bricks. It has high-quality firing, greater resistance to compression, less susceptible to moisture. And for the basement, upper floors, the above-ground part of the foundation, silicate white-colored bricks are suitable. But to build an above-ground part of such a brick is permissible only with a deep occurrence of groundwater.

Before starting construction work on the foundation site, it is necessary to calculate its volume, taking into account the planned load (weight of floors, roofs, walls), soil features. In any case, the width of the foundation tape is provided for half a brick wider than the walls of the house being built. So it will be more convenient to arrange the logs when arranging the floors.

Back to indexWaterproofing and insulation

When erecting a brick foundation for a house, the masonry is protected from possible freezing and moisture penetration. For this purpose, various modern insulating materials are used, for example, tiles made of extruded polystyrene foam, rolls based on geotextiles, coatings based on cement or sprayed from bitumen.

Back to indexBuilding a brick foundation

- Excavation work is being carried out, under the strip foundation, digging a trench should provide for the possibility of laying waterproofing masonry on both sides. On complex heaving, clay soils backfilling is done, therefore, the width of the earthen trench is increased by 1 m.

- A sand cushion is being made with a height of about 0.15 m. The sand must be moistened and carefully compacted. You should get a flat surface.

- Perform laying of waterproofing materials. The simplest option is an ordinary roofing material, rolled up in several layers (like a pocket with vertical walls). The best result can be given by the use of more modern polymeric materials for waterproofing.

- The formwork is being installed, the concrete pad is being poured. Its height is about 100 mm. The use of a concrete base increases the bearing capacity of the strip foundation. If desired, concrete can be reinforced with iron bars or wire. This is not mandatory, because the use of such reinforcement will significantly increase the cost of construction.

- Laying is being done. It is carried out after the concrete has completely cured. They start it with the removal of corners, they are produced according to the standards of the rest of the brickwork. If the foundation is not planned to be plastered later, the seam is flush. Otherwise, normal internal seams can be performed. The seams between the bricks of the strip foundation must be filled with mortar. At the base, the external seams perform the function of facing, so they do not need to be filled with mortar to a depth of up to 15 mm. When plastering, this allows you to achieve better adhesion. Such masonry is called wasteland.

- Like any other, a brick strip foundation must be fully cured until the final setting of the mortar. This usually takes 3 weeks.

- If there is a high groundwater approach, preliminary filling is carried out in those places. But apart from a pillow of sand along the bottom of the earthen trench (it is produced around the entire perimeter of the strip foundation). This space is covered with rubble, coarse sand, gravel, just construction waste. The resulting layer helps the rapid departure of water during rapid snowmelt, prolonged rains.

- From atmospheric precipitation there is a way to more effectively protect the base of the house. The surface of the earth along the perimeter of the brick foundation is concreted with a slight slope to the outside, as a result, water flows freely outward.

- Be sure to re-insulate the foundation before erecting walls. This time, treat its upper surface.

In suburban low-rise buildings, for cottages and small houses, a brick foundation is often laid. This is explained primarily by the fact that the device of such a foundation does not require heavy equipment and is quite feasible with your own hands.

What is good and bad brick as a base for a house and how to choose it? How to build a brick foundation with your own hands?

Can brick be used for foundation?

The use of bricks for the installation of load-bearing structures has certain limitations:

- the maximum load on a brick foundation 0.3 meters wide should be at least 14 tons per square;

- such a brick is porous, it absorbs moisture well. In the spring, during the defrosting process, water destroys the material. When constructing a brick foundation, increased attention is paid to waterproofing, protection from soil water;

- on wetlands, in areas with regular floods and in the presence of underground sources / groundwater close to the surface, the installation of a brick foundation is excluded;

- tree roots damage the building. When laying a brick foundation for a house, it is advisable to uproot all the trees nearby, and this is additional labor;

- installation of a brick base is simple, but long. Laying takes more time than pouring concrete or driving piles.

We also note the advantages:

- shrinkage of a brick foundation occurs faster than other foundations;

- subject to all necessary protective measures during the installation process, the brick foundation is strong enough and durable (up to half a century of service);

- it is a breathable material;

- the foundation does not require heavy equipment (as in the case of concrete), high qualification of the stacker is not required;

- relatively small weight;

- ecological cleanliness;

- resistance to mold and rot;

- if there is no near-surface groundwater, laying a brick foundation does not interfere with the construction of an exploitable basement;

- good maintainability: individual sections can be restored without the need to renew the entire masonry and without the risk of collapse of the house.

note

Before deciding to build a brick foundation, you need to collect information about the characteristics of the soil (freezing depth, location of soil water, humidity). First of all, this applies to strip foundations.

What kind of brick is better to use for the foundation?

The composition of the brick is clay and silicate. The first is red, the second is white.

Density (and, accordingly, strength) is different, sizes too. The advantage of red brick is that it is made from fired clay. This feature gives him the best moisture-proof properties.

Red brick is divided into three types: ordinary, special (refractory,), front (facade, decorative).

Private is corpulent and hollow.

![]()

Application possibilities:

- hollow is used for partitions. It is not strong enough for a foundation;

- front (otherwise decorative, facing) is distinguished by good thermal insulation properties and aesthetic qualities. Suitable for cladding, not suitable for foundation either;

- special (aka refractory) is made with the addition of fireclay clay. Suitable for laying stoves and chimneys. For mounting the base, its advantages do not matter;

- ordinary solid, ceramic or clinker - a suitable brick for the foundation and other load-bearing structures.

How to choose a brick for the foundation?

The current retail price for a solid brick is at least 9 rubles per piece (depending on the region of sale). Be suspicious of too low a price. Most often it is a factory defect or a used brick. The second one may look good, but keep in mind that it has probably gone through several freeze/thaw cycles already. Under load, the old brick will not last long.

Distinctive features of quality bricks:

- color. If the material is too bright or faded, the color is uneven - it is likely that the production technology was violated during the manufacture;

- if the brick is uneven, crumbles easily - it is probably used;

- the foundation brick should not easily absorb moisture, this will lead to its rapid destruction;

- the ribbed side ensures good adhesion to the mortar.

The required strength should be - M125 or M200.

Brick foundation technology

Materials and tools that will be required for laying the foundation:

- the brick itself;

- waterproofing materials;

- components of the mounting solution: sand, cement;

- crushed stone;

- shovel;

- solution tank;

- preferably a drill (for mixing);

- level and tape measure;

- Master OK;

- cord and pegs for marking.

Strip foundation

- Dig a ditch around the perimeter of the future structure.

- Fall asleep at the bottom of 10 centimeters from a mixture of crushed stone and sand.

- Install waterproofing.

- Pour the bottom with concrete, wait for solidification.

- The brick is laid with a gap between the joints. Fastening with cement-sand mortar. All cracks are also filled with mortar. The width of the seam is not more than a centimeter.

- Reinforce the masonry with reinforcing mesh.

- After the cement has hardened, a waterproofing material is laid along the walls from the inside and outside.

- Fill the ditch along the walls with soil.

- Features and benefits of a brick foundation

- Columnar brick foundation

- Brick strip foundation

Modern building technologies are based on the use of reinforced concrete load-bearing structures, and this concerns the construction of building foundations in the first place. However, few people know that old houses, built 100-200 years ago and still standing on the streets of many cities, mostly have a brick foundation. This is especially true for two- or three-story wooden houses, preserved in large numbers in middle lane. Despite this, they continue to stand and be used for their intended purpose. Many of them have a plinth at the base, made of the same brick.

Features and benefits of a brick foundation

Brick fully proves its reliability, having passed the test of time, despite many years of exposure to dampness and other adverse conditions. So today, houses built of wood, prefabricated panel structures or even foam concrete, whose walls do not have much weight, may well be based on a brick foundation. It is built much faster, and is incomparably cheaper than reinforced concrete. At the same time, it provides much better thermal insulation and is more affordable for repairs. If necessary, destroyed bricks are much easier to replace than sections of a concrete structure.

For the construction of a brick foundation, it is necessary to purchase consumables and prepare working tools:

- Brick, calculate the flow rate based on standard size 250x120 mm with a thickness of 65 mm. For laying the foundation, you need to take a monolithic, clay, red, well-burnt brick. Silicate is not suitable for this purpose in any case, since, although it can withstand heavy loads, it is not resistant to prolonged exposure to dampness. Facing brick, on the contrary, is quite suitable if it resembles ceramics in composition and is resistant to moisture.

- Cement and sifted fine river sand, which are mixed in a ratio of 1: 3 and diluted with water to the consistency of thick sour cream.

- A trowel or narrow spatula, a shovel and a trough for mixing cement mortar.

- Materials for waterproofing works: roofing felt, bitumen, polystyrene foam or polystyrene.

At the same time, depending on the mass and size of the future house, such a foundation can have both a columnar and a tape structure. These types and their construction have their own characteristics, which must be taken into account.

Back to index

Columnar brick foundation

It is advisable to use it for small summer houses, baths and lightweight summer cottages. First you need to mark its location. Brick pillars should be located at the corners of the structure, in places where they will intersect bearing walls, and also preferably along their perimeter at a distance of about 2 m from each other. To place such a column, you should dig a hole 1x1 m in size and 1 m deep. Sand is poured onto its bottom, which is poured with water and rammed for compaction. It forms a kind of cushion that will not allow the post to go into the heaving soil. Then the remaining volume of the pit is filled with crushed stone or gravel to a depth of 20-30 cm. It must freely pass water so that it does not swell the soil when it freezes. The gravel surface must be leveled with a layer of mortar, on which roofing material will then be laid in several layers, providing waterproofing.

After that, the laying of the brick itself can be carried out. The most common post size is usually 2x2 bricks. The bottom row is simply laid in 2 rows along the axis, the second is 2 bricks across, 4 along and again 2 across, the third is placed 2 along, 4 across and again 2 along, the fourth will be 2 rows across the axis. All seams must be tightly filled with mortar, and then the plaster and waterproofing of the masonry must be made. It is enough to lubricate it with bitumen or wrap it with roofing material, this will protect the brick from moisture and prevent premature destruction of the foundation.

Back to index

Brick strip foundation

If the house is a more solid structure with walls made of foam concrete or other block material, it is best to put a tape foundation under it. For its construction, it is necessary to dig a trench 1 m wide around the entire perimeter of the future building to the depth of possible soil freezing in winter. If the soil is moist and the groundwater is close to the surface, then the trench should be 1 m wider than the width of the future house. This will allow you to equip the drainage system. Coarse sand is poured at the bottom of the trench, watered with water and carefully rammed.

Then, a formwork is constructed from boards at the bottom of the trench, the width of which should be about half a brick wider than the future foundation, and the height should be from 10 to 15 cm. A layer of waterproofing is placed on its bottom with a small margin to prevent moisture from rising to the brick, then a layer of concrete is poured , leveling its surface with the help of a building level. After 2-3 days, it will seize enough, the laying of the foundation itself begins.

Thickness brickwork foundation.

It is desirable to make its base somewhat wider, lifting upwards with ledges and bringing it to the desired width only on the top row. The brick is placed in a dressing, while between the first and second rows of masonry it is necessary to put a layer of reinforcement in the form of bars or mesh and the same layer between the penultimate and upper rows. This will prevent the possibility of destruction of the foundation in the direction of the longitudinal axis.

After the bonding solution of the masonry has hardened, after 1-2 days, its surface should be covered with waterproofing. Then the foundation should be insulated from the outside with foam or polystyrene.

After laying the foundation, it can be surrounded by a trench filled with sand to remove moisture and prevent swelling of the soil. If the humidity is high, then the following system is applied: a ditch is dug 50 cm from the foundation, on the bottom of which a layer of geotextile is placed, covered with rubble from above. A perforated plastic pipe with a slight slope is placed on it, covered with gravel and wrapped in the same geotextile. The pipe leading to the drainage ditch is covered with sand from above. This design will reliably remove excess water from the foundation and extend its life.

The foundation, laid out of brick, if built correctly, will reliably serve several generations of residents of the house.