Depending on the technical functions, the following main types of furniture fittings are divided into groups.

1. The first group is the mechanisms that are needed to connect and fix the position of parts relative to each other. This group includes furniture fittings for detachable connection, for detachable connection and for movable connection.

Furniture fittings for permanent connection combines screws, screws, nails (including wallpaper), bolts, rod holders, dowels, brackets, ties, hooks, upholstery "buttons" of upholstered furniture, etc. The common name for them is connecting fittings for furniture.

As for the couplers, they are divided into eccentric and connecting. The eccentric screed is made from a material common for all furniture fittings - galvanized steel, which is particularly strong. The “corner” screed has decent strength and is easy to install: it does not require drilling holes in the ends of the furniture.

And with the help of wedge and threaded ties, furniture has been installed for more than one year. Nut with screw - all notable examples threaded ties. So, thanks to the thread of the screw, the nut and the stud, a reliable connection is created. And with the help of wedge ties, you can connect the elements especially quickly. They are based on plates, brackets, wedges. To connect wedge ties, traditional screws are taken.

Furniture fittings for detachable connection- this is doorknobs and devices that replace them, latches, shelf holders, magnetic latches, locks, latches, locking hooks, etc. Here we note that door handles, as well as hinge and lock details visible on cabinet facades, are usually referred to as “front fittings”.

The choice of such a seemingly small detail as handles should be very deliberate. After all, it is important that it is combined with furniture and furnishings not only in style, but also in harmony in color. Fortunately, there are a great many materials and methods for finishing handles now. These are not only wood and metal familiar to us, but also newfangled plastic, glass and ceramics that are always relevant. The most favorite colors here are matt chrome and gold. In addition, the ergonomics of the handle is important, how comfortable it is to grab it with your hand. Now most often handles are mounted with screws or self-tapping screws.

To sliding fittings include hinges, guiding devices for sliding doors, drawers, microlifts, etc.

Devices such as elevators (lifting mechanisms) are used in various furniture, one of the most frequent places is in kitchen cabinets, the doors of which lean up. In addition, there are elevators in such furniture fittings, the mechanisms of which push the corner elements. Then part of the furniture moves smoothly along an arc or in several steps, while several lifting mechanisms take part in the process. Thanks to the lifting mechanisms, even very heavy drawers can be easily pulled out. And for more comfortable movement, they can be mounted: pneumatic mechanisms, as well as various guides, including ball bearings. So we smoothly move on to the following types of furniture fittings.

2. The second group - the mechanisms that are needed to change the operational properties of furniture during its use without correcting the structure of the fittings itself. These are rotary mechanisms (for example, "carousel"), mechanisms for sliding tables, guide devices, swing devices, etc.

A considerable part of the furniture can no longer be imagined without such furniture fittings as guides necessary for sliding elements. Depending on the method of extension, guides of full and partial roll-out are distinguished. When they are fully extended, therefore, the drawer also fully extends, to the contents of which excellent access opens. By what parameters are these furniture accessories evaluated? Fittings "guides" should be easy and silent in operation. Tandemboxes are especially distinguished. They necessarily contain such furniture fittings as rollers, which are supplied with recessed bearings. The material of the guides depends on their level: it can be steel, fluoroplastic or even non-ferrous metal, for example, duralumin (the roller is made Teflon). In prestigious systems, the rollers are equipped with brushes that clean the space between the grooves.

3. The third group - means that transfer the product during its operation from one functional state to another using the spatial transformation of mechanisms. Such furniture accessories are mechanisms for changing the working height of furniture, as well as mechanisms for transformation (for example, sofa beds, wardrobe beds, etc.), etc.

4. In addition to those listed, the furniture fittings market also represents the fourth group of furniture fittings - overhead moldings necessary for decorating structural furniture parts that have a relatively pronounced volume. They can be of three types:

- strip (in particular, and composite),

- badge,

- cord.

Materials are taken for them: wood, plastic, metal, glass, braid, ceramics, etc.

Strip parts have a straight or curved shape. In addition, there are flat, ornamental and profile strip details. They are generally suitable for contouring door edges, cabinet walls, seat bases, table tops, etc.

Details by type of plaque can have a variety of shapes. Previously, disks, rosettes, medallions, stylized images of a person, plants and animals, etc. were popular.

The cord (in most cases, filament) is used to finish the seats and backs of upholstered furniture and sometimes its sides.

In addition to functional features, there are various types of furniture fittings, depending on the material from which it is made. So, if a hundred years ago most furniture handles and supports were made of natural wood, now metal and plastic occupy the leading positions. Of course, the metal must have a special anti-corrosion treatment, and the plastic must meet hygienic and operational requirements. For elite models, accessories can be covered with gold or silver or imitate these coatings. Crystal, rhinestones and even natural stones. If wood is chosen as the material, then it must undergo high-quality processing in order to withstand moisture, light and temperature changes for a long time.

We note a very important thing: no matter how complex the furniture fasteners, fittings and their supplier must be chosen very carefully. After all, the functioning of all furniture directly depends on this. Figures illustrate the importance of furniture fittings: out of the total cost of cabinet furniture, the share of fittings is from 10 to 15 percent. For kitchen furniture, this figure can be 25%. And the highest figure is for upholstered furniture with frame transformation mechanisms: it is from 30 to 40%.

As for the furniture fittings market as a whole, the main suppliers to Russia are Germany, Italy, China, the Czech Republic, Poland and the USA. And so far it has to be noted that foreign suppliers of furniture fittings are now valued more than domestic ones. The fact is that the experience of foreigners exceeds ours by several decades.

Stained glass is a special kind of monumental and decorative art. Interesting in itself, it acquires great expressiveness in combination with other species. fine arts especially with architecture. His past is rich, his prospects are boundless, his creative possibilities are inexhaustible. Stained-glass windows are called transparent paintings, drawings, patterns made of glass or on glass. They are usually installed in the light openings of windows, doors, lanterns. In our time, in connection with the improvement of the artistic processing of glass, the concept of stained glass has also been expanded. stained glass windows name any decorative glass filling of window and door openings, lanterns, plafonds, vaults, domes, solid wall planes and even special decorations of art products. Stained-glass windows in the form of ornamental compositions, patterns or paintings are made of colorless or colored glass, with painting of individual details or the entire plane of the glass with ceramic paints or without painting. Stained-glass windows made of individual glass parts are reinforced with lead tape; monolithic glass does not require reinforcement. The purpose of stained-glass windows is varied: they are a rich decorative decoration of buildings and individual rooms, they replace window panes and door panels, let in light and make it possible to isolate the premises of the first floors from prying eyes. Reflecting in their images the nature and purpose of the building and complementing its artistic image, stained glass plays a significant role in interior design. Stained glass art originates in the distant past. Stained-glass windows, which previously represented a set of colored glasses, often served as an accidental decoration of the room; over time, their composition, drawing, artistic glass processing and performance technique were improved. Stained-glass windows became genuine works of art, an integral part of the strictly thought-out monumental and decorative decoration of buildings. Stained-glass windows, which were used mainly in the decoration of churches and monasteries, gradually penetrate into residential and public buildings . The religious themes of stained-glass windows are replaced by secular ones, reflecting the modern trend in art, following the aesthetic requirements and the spirit of the era. Many stained-glass windows created by outstanding painters and skilled craftsmen have been preserved in the world. The name of the author or master often tells us the artistic value of a particular work of art. However, many wonderful stained-glass windows were created by the hands of masters whose names remain unknown to us. The artist belongs to his era, but works of art often outgrow their era, become eternal. Similar stained glass masterpieces have been preserved in France, Germany, Italy, Switzerland, England, the Netherlands, Czechoslovakia and other countries. Worthy of attention are the stained-glass windows stored in the State Hermitage Museum in St. Petersburg. Stained glass windows benefit not only from bright sunlight, but also from the soft tones of the sunset and sparkling evening lights. As for the artificial lighting of stained-glass windows, even with fluorescent lamps, it has been established that such lighting gives the stained-glass windows a kind of frozen expression, it cannot cause that play of light and shadows, those light and color effects that natural lighting creates, endlessly changing to throughout the day and throughout the year. It is possible, of course, in some cases, the use of special installations with synchronously changing artificial lighting, but this already belongs to the field of expensive equipment and hardly justified effects. Stained glass - a glass picture, mosaic or carpet, whose colors never fade, do not fade. It is difficult to say when the first stained-glass windows were created. In any case, there is no reason to assert that they appeared soon after the invention of glass. It is only known that a mosaic of small plates of colored glass was discovered in ancient Rome during the empire (first century BC, beginning of AD) and in the temples of the first Christians. The windows of the Sophia Cathedral in Constantinople, which became the capital of Byzantium in 330 AD. e., were glazed with colored glass, apparently soon after the construction of the cathedral. According to some literary sources, it is known that during the excavations of the cities of ancient Italy, Pompeii and Herculaneum, who died in 79 AD. e. during the eruption of Vesuvius, colored glass mosaic floors, wall paintings and fragments of stained glass were found. According to other sources, only a glass mosaic of floors and walls was found in Pompeii, since there were few windows in the houses, and then mostly without glass. But the use of window glass is confirmed by pieces of frosted or, perhaps, opaque glass found during excavations. The colored glazing of the windows was originally a glass mosaic inserted into the stone and wooden openings of the openwork windows. Then came a mosaic of colored glass, cut and assembled in a lead frame in the form of a pattern, geometric or floral ornament. Such mosaics were assembled in a metal frame and installed in window openings. It is very likely that intense and bright colors were used in large windows, while pale and calm ones were used in small windows. Colored glazing gradually formed a special branch of decorative art and became equal among other branches and art forms. Over time, the requirements for glass mosaic patterns have increased. We tried to shade colored glass by overlaying darker colors. The results were positive. The technique of painting glass using firing was discovered in the 9th century. This new technique has found wide acceptance. Thus, painting on glass arose and developed at the end of the 10th century. With the development of painting on glass, glass mosaic began to fade into the background, but it was not completely supplanted, but continued to exist in combination with painting on glass. Lead and black paint were used to make a stained-glass window with human figures.Kitchen furniture needs the most carefully thought-out functional filling, since it is here that households spend most of their free time, which means that it is subjected to the most severe exploitation.

In order for the new kitchen furniture to serve for a long time, it is necessary to provide it not only with bright, beautiful facades, but also Special attention should be given to the selection of high-quality and reliable fittings.

Types and classification of kitchen fittings

Furniture hinges

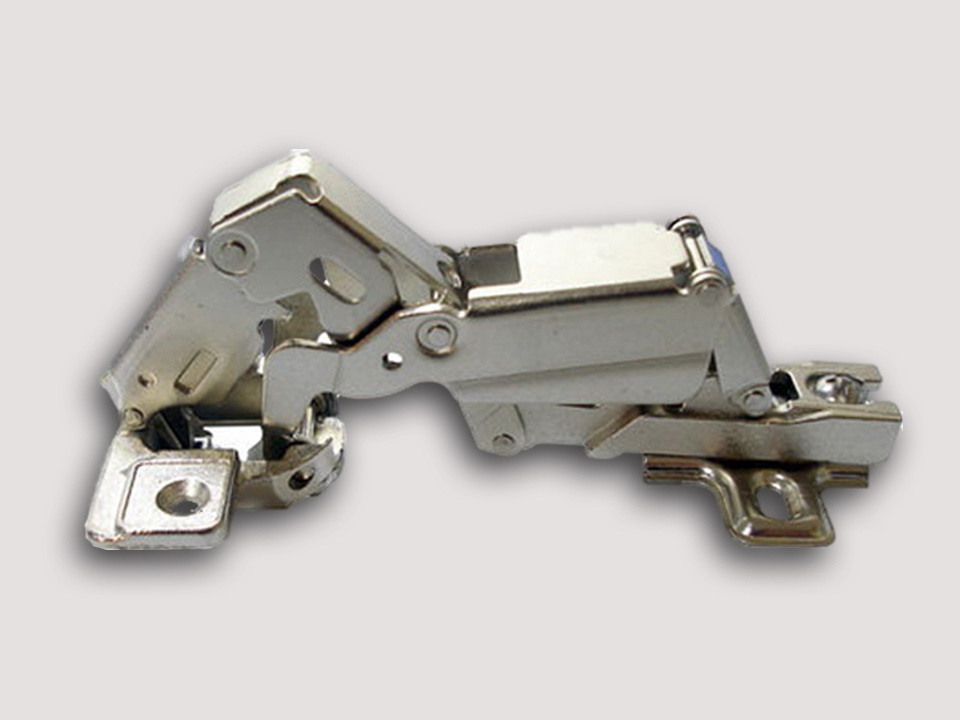

For each type of facade and for a variety of kitchen cabinet configurations, there is a different type of hinge with a different opening angle, ranging from 30⁰ to 270⁰. Each hinge can be additionally equipped with a closer, which allows you to quietly and smoothly close the facade.

1 slip loop

It is used for ordinary hinged facades, which are superimposed over the sides of the cabinet. Such a loop allows the door to swing open by 110⁰.

2 Half overlay loop

It is necessary in cases where it is technically impossible to cover the entire side of the cabinet with a facade. A semi-overlay (middle) hinge is used in cabinets where two doors are mounted on one side and open in opposite directions. Opening angle - 110⁰

3 Inner loop

The facades are located between the two sides, opening at an angle of 100⁰.

4 Angle hinge

Installed in corner boxes, opening angle - 90⁰.

5 Shtolnaya (deaf, straight) loop

It is attached to the overlay bar, which is located flush with the facade. Opens at 90⁰.

6 Complex (medium, carousel) loop

Applicable in corner boxes with a box resembling the letter "G". Allows you to fasten two facades in the middle for further synchronous opening.

7 Loop-transformer

Installed in tandem with complex. It is she who holds the weight of the two facades and is equipped with a good opening angle. You can also use it if you plan to install a drawer inside the cabinet, behind the door.

Naturally, this list is far from complete, there are many more furniture hinges, but those listed above are the most popular in the production of kitchen sets.

Retractable fittings (sled)

The main types of guides for drawers

1 Ball (telescopic) guides

The method of action lies in the movement of the sled with the help of miniature balls inside the metal case. The undoubted advantage is the full extension of the drawer, smooth running and the ability to install a door closer. Telescopic guides are equipped with innovative tandemboxes and some functional baskets;

Budget option with incomplete opening (1/3 of the internal space of the case is closed from view). With roller slides, inexpensive retractable nets are made, applicable to optimize the interior space of the kitchen and metaboxes (drawers with metal sides).

Fittings for kitchen corner cabinets

The most inaccessible place in the kitchen is the inside of the corner drawers. Despite the impressive size of the empty space of the cabinet, usually nothing is stored there, since the objects placed inside are quite difficult to get out.

It was for the maximum optimization of the corner space that pull-out baskets were invented with complex mechanisms that pull the shelves attached to it when the facade is opened; mesh carousels used to store large kitchen utensils, where the shelves rotate around their axis; guides for corner drawers and much more.

Lifting mechanisms

Furniture fittings for hanging drawers with horizontal facades are quite diverse.

1

Two shock absorbers are installed on one facade in tandem with hinges. The principle of operation is a piston mechanism. They differ in the lifting force, which must be calculated based on the overall dimensions of the facade and the material from which the furniture door is made.

2 lifting mechanism(lift) with door closer for opening the facade vertically

The principle of operation - the door smoothly rises, providing full access to the interior. Minus - the distance from the roof of the box should be greater than the height of the door.

3 Folding mechanism with a closer for simultaneous opening of two horizontal facades at once

In this case, the doors fold like a screen relative to a horizontal plane. Ideal for small people.

4 Lifting mechanism that allows the furniture facade to “drive in” on the roof of the hinged box

In this case, the door, as it were, lies on top of the cabinet. Convenient opening for tall top cabinets that are close to the ceiling. The mechanism is equipped with a closer.

It doesn't matter what fittings are chosen for kitchen furniture - with or without closers, retractable or hinged, with a vertical or folding lift - the main thing is that it is made by a trusted manufacturer.

The quality of assembly of furniture and the reliability of its operation are largely influenced by fasteners designed to connect individual elements to each other and used for mounting products. Of course, the type and design features of fasteners depend on the category of furniture and its operating conditions.

The modern industry offers a sufficient number of new fastening accessories that greatly facilitate the assembly of furniture and increase the durability of its use in the most adverse conditions. For example, kitchen designs made from cheap particle board are more likely to fail by delamination of the panel or peeling of the decorative coating than to fail due to poor quality or reliability of fasteners.

Today, with industrial and self-manufacturing furniture products, quite a lot of types of fasteners are used, which differ in functionality, method of fixation, size and protective coating.

Categories of fasteners

If half a century ago the main elements for assembly constituent parts furniture were wooden dowels, and the installation of various specimens at the place of operation was carried out using nails or screws, today the range of accessories for connecting individual parts and furniture elements has expanded significantly.

Modern fastening and connecting parts can be divided into several categories, including both highly specialized products and universal fittings:

The most common types of furniture fasteners

Consider the most common groups of connecting and fixing fittings for furniture, the features of its installation and operation.

Button head or ornamental head screws and bolts with a fixing mustache or square neck are the main examples used to tie individual panels of frame furniture. Thanks to the fixing mustache or square head, the bolt (screw) is fixed in the hole of the chipboard, which prevents it from turning. By virtue of this design feature the assembler has the ability to tighten the nut without additional fixation of the screw.

Universal screws with countersunk or semi countersunk head have slots of various shapes (cross, with an internal hexagon, a straight slot, and others) and are designed for fastening individual assembly parts inside furniture structures. They are used for:

On a note!

When using universal screws, either screwdrivers with interchangeable bits or screwdriver sets with interchangeable tips are used.

Confirmates (Euroscrews) in modern furniture production are the most popular type of fastening and fixing devices. This type is used for fastening any parts made of chipboard or MDF panels.

Before screwing the euro screws, holes are pre-drilled in the parts using a special confirmation drill, the diameter of which depends on the diameter of the fixing element. To screw this type of fastener, it is used either with special bits or screwdrivers with seed nozzles. The type of bit or nozzle depends on the type of slot.

Eccentrics other fittings, bearing the somewhat exotic name of rastexes and minifixes, allows you to connect and pull panels located at right angles to each other. Despite the obvious advantages of this category of fasteners, their main disadvantages are:

- the need for additional milling of furniture panels, for the installation of individual fastener parts;

- relatively high cost.

- high accuracy of marking and the complexity of installing individual fasteners;

On a note!

To install the individual parts of the minifix, you will need three different kind woodworking tools - one end mill and two drills of different diameters.

Furniture corners proved to be a reliable, easy-to-install element. Today they can be made either from metal or from special, high-strength plastic. In industrial production, the color of the plastic corner is matched to the color of the furniture.

Modern furniture dowels made of wood, plastic or metal. Their main advantages are low cost and ease of connecting furniture parts to each other. To increase the reliability of the connection, there is a corrugation on the surface of the dowels.

Special types of fasteners

Today, furniture, the individual parts of which are made of glass sheets or in the form of mirrors, is becoming increasingly popular. If ten years ago glass was mainly used as doors for furniture cabinets and showcases or doors for shelving and shelves, today you will not surprise anyone with a glass top for a coffee or dining table.

To interconnect glass parts and furniture elements made of other materials, special types of fittings are used, which are attached to glass surfaces with the help of special adhesives, by wrinkling clamps with rubber gaskets or by drilling holes in the glass. When choosing this category of fittings, it is necessary to pay attention to the weight that it can withstand, which is especially stipulated in the instructions for its use.

The review will focus on the latest furniture fittings.