PVC panels for the balcony today are the most popular material for finishing the interior surfaces of glazed premises. PVC material is often referred to simply as plastic. The abbreviation PVC stands for a complex chemical polymer compound called polyvinyl chloride.

Products made from this material have a lot of positive qualities. PVC is not electrified, has sufficient strength, is easy to process, can have any colored surface and causes a pleasant aesthetic perception. appearance. It is very convenient to finish the internal surfaces of glazed balconies and loggias with plastic panels.

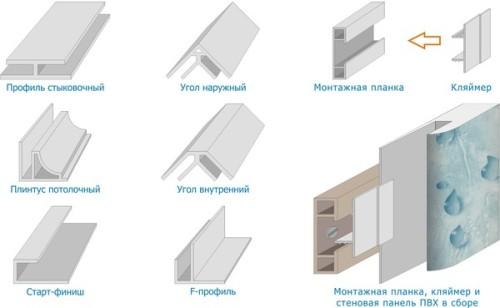

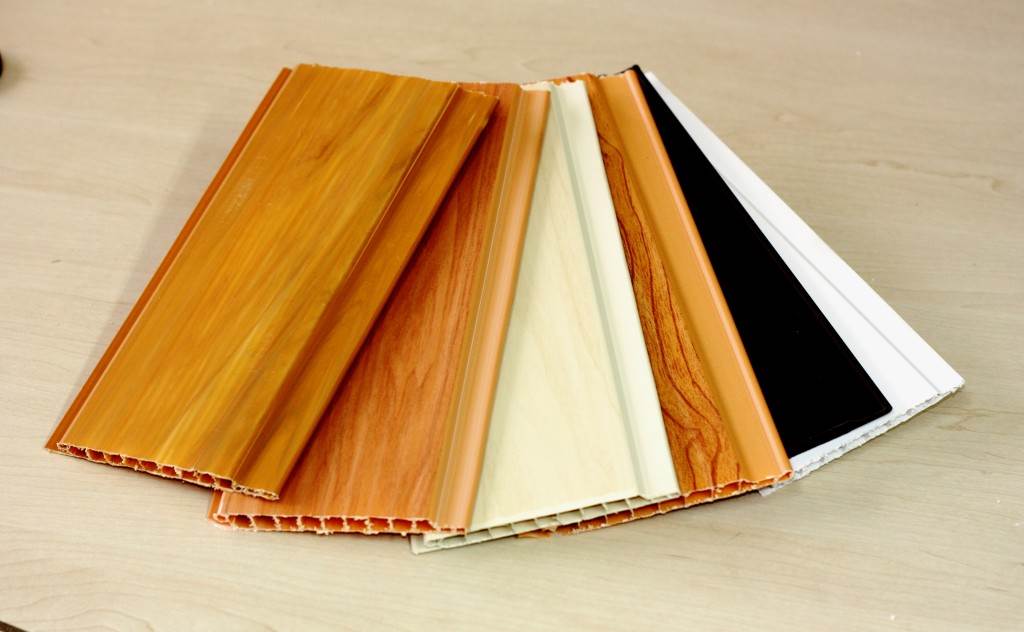

For sheathing, several types of profiles are used.

Adjuvants and additives such as plasticizers, accelerators or retarders, banding agents, coloring pigments, glass fibers, etc. made it possible to play on strength, heat and sound insulation, weight, color, texture and even transparency of the material. Numerous types of concrete panels were born due to differences in materials, shape, proportions and methods. In the commercial literature, the industry has explicitly emphasized the infinity of choices.

The external surface can be made of white concrete with a smooth surface or with visible flint aggregates. These panels had the feature that they could be taken apart and reused: they were usually stacked on top of each other and secured to a steel, concrete or wood frame with reversible galvanized steel hooks. Another option was to move them into profiled columns and fill in the butt joints, but in this case further disassembly is not possible.

PVC panel structure

The plastic panel is a kind of sandwich. Stiffening ribs are placed between the front panel and the back surface.

Thanks to this structure, PVC panels can withstand minor loads, while maintaining the integrity of their surface.

Panel dimensions

Panels are made in lengths from 2.5 to 6 meters. For finishing balconies, plastic is usually purchased 2.5 meters long. If the height of the balcony or loggia is 3 meters, then it is advisable to buy six-meter panels and cut them in half.

Ceiling plastic sheathing

Research has focused on mixing, compacting concrete, shaping, texturing and finishing elements. The architectonic concrete was made from a 150 m long prefabricated plant, which also included equipment for vibrating and dry concrete.

The company has become one of the most important manufacturers concrete concretes in Belgium, and also exported to Holland and France. The production line for architectural concrete was organized according to a 24-hour production cycle. The formwork was filled with an automatic mixer. After being compacted on vibrating tables, the elements were transported in an air conditioning tunnel to harden. At the end of the tunnel, the elements were dismantled and subjected to surface treatment.

For wall surfaces of complex configuration, panels 10 cm wide are used. Usually, panels of the same width - 25 cm are purchased for wall and ceiling cladding. large areas walls.

Types of PVC panel coatings

Three types of technology for applying images and patterns to the surface of panels are known:

Three types of technology for applying images and patterns to the surface of panels are known:

The company has published its own specifications with specific recommendations for precast architectural concrete related to insulation, connections, joints, anchors, surface treatment and prototyping. The prefabricated architectural concrete facade panel consisted of two layers: a decorative layer of at least 10 mm in the first place, followed by a layer of ordinary concrete. It had a thickness of 7 cm and a length of up to 2.5 m; For large panels, grooves or reinforcing edges should be provided.

These signs have been used for the construction of office buildings, residential buildings and public buildings such as schools or community centers. Among his products was quartzolite, a special type of natural quartz concrete that resisted water and frost.

- offset printing;

- laminated film;

Each method of printing on the front surface of the PVC panel is attractive in its own way.

thermal printing

A special thermal film with a certain heating is applied to the front of the plastic. Then the surface of the panel is covered with a layer of varnish. The shiny surface creates a three-dimensional perception of the applied pattern.

Quartzolite has been used, among others, for façade cladding panels, thresholds, door frames and backstones. This brochure, published with the help of several companies, showed that the thickness of the outer layer of decorative concrete should be at least 10 mm, and the concrete layer covering the reinforcement should be at least 15-20 mm.

In the chapter on brickwork and façade, there was a paragraph on prefabricated decorative concrete elements for façade cladding, which mentioned small elements with a special surface or composition Ready-mixed concrete coated with a decorative material is intended to be attached to a supporting structure. In addition, the General Conditions prescribed the use of metal accessories made of galvanized steel, stainless steel, wrought iron, copper or aluminium. These flexible seals can be in the form of bituminous packing, expanded sealant, stainless steel or plastic strip, or a suitable adhesive.

Offset printing

An example of thermal printing on a PVC panel

An example of thermal printing on a PVC panel The drawing is applied to the panel in a typographical way. This method allows you to get the best images. natural stones: onyx, marble, malachite, basalt and granite.

Photographs are good. Panels with offset printing are varnished in the same way as in the previous form.

This paragraph included requirements for form, measures, appearance, structural aspects, joints, transport, assembly, etc. in general, these requirements were more stringent than those for small and unloaded items: the top decorative layer should now have minimum thickness 20mm, and the reinforcement of the cover should not be less than 20-35mm thick. Cracks must be taken into account during the design process as they have been a major problem with facades exposed to wind and rain.

Thus, cracks can be caused, for example, by irregular deformation of prefabricated facade elements and the beams on which they were supported, or due to thermal expansion. The article reporting these studies reviewed six popular compositions. These included several types of aggregates, as well as sand from the Mole area and Rhine sand. The cement commonly used was gray Portland cement, but gray blast-furnace cement or white cement was sometimes used.

Laminated film

A film with a finished pattern is glued onto plastic. The surface of the laminated film does not need to be varnished. The simplicity of the laminated coating technology significantly reduces the cost of PVC panels.

A variety of types of laminate flooring allows you to choose panels that mimic the structure of materials such as wood, stone, bamboo and leather. Finishing a balcony with plastic of this type is especially popular among the population.

Prefabricated facades in Brussels

Precast concrete façade panels are most commonly found in apartment buildings; Less frequent use in single-family homes. Of the one hundred and sixty house descriptions relating to the materials used, about 20 mention the use of precast concrete facade elements. With the exception of the four-story villa in Uccle or private houses with claustics, almost all buildings were medium residential buildings and towers. In these apartment buildings commissioned by public and private owners, precast concrete was used most often for changing rooms, and in the fields for some applications for balconies.

A set of fittings for mounting PVC panels

A set of fittings for mounting PVC panels Mounting profiles

Mounting kits are purchased with PVC panels. plastic profiles:

- end profile.

- Connecting profile.

- Inner corner.

- outer corner.

Upon completion of installation metal frame walls on the balcony (we will discuss this in detail below) in places adjacent to the ceiling, in the corners of external and internal, on window and door slopes, plastic mounting profiles are installed.

Upon completion of installation metal frame walls on the balcony (we will discuss this in detail below) in places adjacent to the ceiling, in the corners of external and internal, on window and door slopes, plastic mounting profiles are installed.

Most residential buildings had a reinforced concrete frame. This structure was either visible or articulated, with prefabricated façade panels between columns or covered like intermediate walls with prefabricated panels. The façade panels were prefabricated from various materials such as quartz, flint, rolled gravel, white stone, porphyry, etc. their surface was washed, polished or smooth. On an aesthetic level, panels allowed architects to play with colors and patterns. In some cases, concrete panels use, for example, the color of the plinth and window shelving, or contrast strongly with the concrete frame.

All profiles have a wider part of one of the sides.

This is made for hidden fastening with self-tapping screws to a metal frame.

How much and what mounting profile is needed for cladding with plastic panels on the balcony is determined in advance. PVC panels are completed with a mounting profile to match the color of the entire plastic.

Technology for installing a frame for cladding with plastic panels

Before installing the frame, you need to prepare essential tool: screwdriver, puncher, screwdriver set, hammer, hacksaw and pliers.

Before installing the frame, you need to prepare essential tool: screwdriver, puncher, screwdriver set, hammer, hacksaw and pliers.

Self-paneled balcony

The linear pattern of the joints was also clearly incorporated into the design of the façade, for example by drawing a rectangular grid or highlighting the horizontal lines of the balconies. The articles contain small details in terms of dimensions, connections, installation technologies, etc. in one case, it was clearly stated that the panels were placed after the completion of the framework; in another case, the panels served as lost formwork for the framework; in another case, the use of prefabricated panels was mentioned to cover the side of balconies drying with open joints.

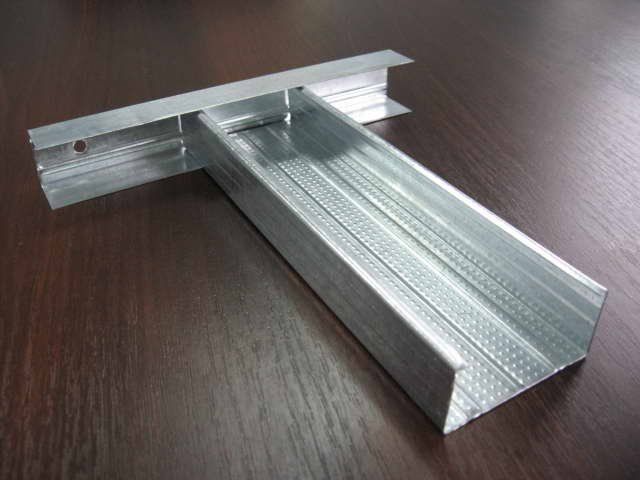

The frame for cladding glazed rooms of balconies and loggias is made of two materials: wooden beams and a metal profile.

Wooden crate

Installing wooden beams and slats on the walls and ceiling of the balcony is a rather difficult operation. But the advantage is that such a frame itself is a heat-insulating material.

A very concrete solution was used by Charles Van Nuten in the Rue Hote social housing complex in Brussels: the facades, separated from the concrete frame, consisted of prefabricated panels and prefabricated posts with special profiles, in which the panels could be moved. These messages generated a mesh pattern on an otherwise flat façade and allowed the panels to expand and thus minimize the risk of cracking. From short descriptions most precast concrete facade panels were used as panels, often leaving a gap between the panels and the supporting structure.

The wooden crate together with the laid insulation eliminates the appearance of cold bridges between the walls and the cladding.

The crate is mounted using mounting plates

The crate is mounted using mounting plates The installation of the bars is carried out using mounting plates. The plates are fastened with screws to the timber.

The use of sandwich panels seems to be quite exceptional. These panels consisted of vitrified bricks on the outside, an insulating core, and a layer of concrete on the inside. The glass panels are attached to aluminum frames that hang from uprights and cross bases.

Aesthetics of clean and straight lines and a thin strip of aluminum is visible on the perimeter. A large sliding glass wall separates the kitchen from the dining area, allowing light to filter through. Indefinite demarcation since the doors are transparent and have panels that allow even partial closing.

Then the second end of the plate is attached to the wall with dowels. Reiki and walls are drilled with a perforator.

Dowels are hammered into the holes obtained. Thus, the crate is installed both on the walls and on the ceiling.

Working with a wooden frame is time-consuming and requires special care and skills in such a matter.

Metal profile frame

AT recent times people prefer to install a frame for facing loggias and balconies from a metal profile. A metal profile, mounting elements and hardware allow you to perform high-quality surface cladding of any configuration. For information on how to install the crate, see this video:

Integrated even in mixed compositions, sliding doors outer wall can be connected to fixed lock panels. Cultural Center Onassis in Geotemwergk in Germany. Perfect for decorating your event or as a gift to your guests, each lantern measures 10cm x 6cm and is made from a solid gold colored metal frame surrounded by glass panels on all four sides, supported by always black metal poles. This helps create a stylish aesthetic combined with functionality and maximum safety.

First, wide profile racks are installed in the corners of the room and in the places of window and door openings. Horizontal frame ties are installed from a narrow profile.

First, wide profile racks are installed in the corners of the room and in the places of window and door openings. Horizontal frame ties are installed from a narrow profile.

For fastening the metal elements of the frame to the walls and between themselves, mounting plates, self-tapping screws and dowel-nails are used.

Let's say right away that the likelihood that this material is obtained is mainly due to the predominance of the advantages obtained in relation to the costs that are supported for its application. In addition, the ease of application, combined with the lack of use of specialized tools and crafts, makes it an ideal material for those who are not familiar with building work.

The northern exposure of the house, which cannot be isolated from the outside, is best used by applying a layer of Depran on brickwork inside, the ceiling of an unheated garage above the house can be thermally insulated using cladding panel.

Mount the ceiling frame separately from the walls

Mount the ceiling frame separately from the walls In areas with a harsh climate, a metal profile on walls and ceilings can become a cold bridge. Then in winter, according to the frost that appears on the balcony lining, you can determine the location of the details of the metal frame.

In case of irregular surfaces, apply the first layer of handkerchief to adjust the flatness. After all the aforementioned preliminary operations have been carried out, it is always necessary to remove dust residues with compressed air in a radical manner.

Technology for installing a frame for cladding with plastic panels

As an adhesive, you can usually use dispersed adhesives, and when you want to cover a tile wall, it is good to use the same adhesive that is used by the tiles. A suitable balcony is an important element for the implementation of facades and influences the personality of the house.

Of course, this cannot be allowed. There can be only one way out of this situation. The frame must be mounted separately from the walls.

A free-standing frame will significantly reduce the internal volume of a glazed room. But the insulation placed between the frame and the walls will reliably keep the heat on the balcony and loggia.

frame false ceiling is formed in such a way that the crate "hangs" on the mounting plates. But along the entire perimeter, the ceiling frame is fixed with dowels to the walls of the loggia or balcony.

It retains its value and requires very little maintenance. Therefore high resistance to weather and life expectancy. Durable surfaces that can withstand almost all types of impact are easy to handle and require very little maintenance.

We provide custom cuts upon request. This breathable pre-blended product is ready to use based on cement, selected aggregates appropriately, specific resins and additives that impart special properties of adhesion, hardness, abrasion resistance, total absence of shrinkage and in such a way as to be able to achieve an easy shave preparation. The product is used internally and externally, it adheres perfectly to any type of wearer, allowing it to breathe.

After the frame of the walls and ceiling is fully assembled, holes are drilled in the walls for sockets and switches. The boxes are installed in the seats and electric wires are pulled to them. For more information on how to drill holes for sockets, see this video:

Insulation is laid and fixed between the frame elements. It could be urethane foam mineral wool or other insulating material.

Facing the walls of the balcony with plastic

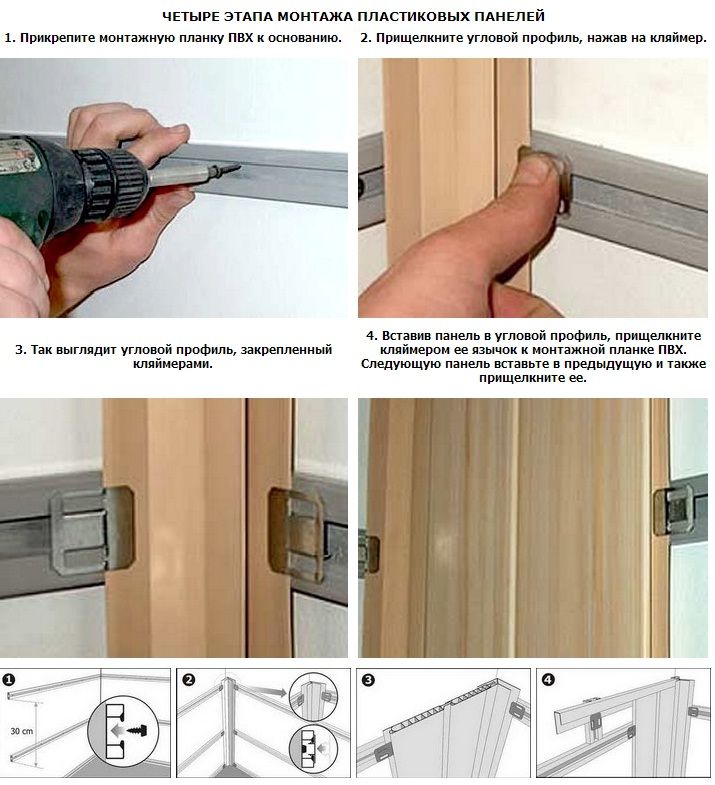

When the frame and fittings are installed, electric wires are stretched and connected, insulation is laid, mounting plastic profiles are fixed, and the walls are faced with PVC panels.

Scheme of installation of plastic panels

Scheme of installation of plastic panels Plastic panels are connected to each other end-to-end. The strip on one side has a thin protruding part - a feather. A groove is arranged on the other side of the strip. Connecting the panels end-to-end, they get an almost seamless solid surface.

Some PVC types panels have an elongated feather. By connecting strips of plastic, small seams are obtained. Such gaps in the surface of the cladding visually increase the height of the walls and at the same time create an original relief surface.

Consider the installation of wall cladding in stages:

PVC paneling of the suspended ceiling frame

Installation of panels on the ceiling starts from the side of the window

Installation of panels on the ceiling starts from the side of the window The installation of panels on the balcony ceiling begins from the side of the external front glazing. Why do you need to do this? When finishing any surface with plastic, the last strip has to be cut along. Therefore, the last strip of ceiling lining will practically be hardly noticeable, since it will be located above the entrance to the balcony. A glance from the room at the ceiling of the balcony will not notice any disproportion in the width of the plastic strips.

Don't forget to drill holes in the ceiling for lights.

Don't forget to drill holes in the ceiling for lights. Fasten the panels to the ceiling frame with self-tapping screws through the pen. Then the places where the suspended ceiling adjoins the walls and windows are covered with a plastic cornice.

At locations spotlights holes are cut out in the panels, the ends of the wires are brought out through them. Fixtures are connected to the ends of the wires, which are then inserted into the holes in the cladding. Thanks to the spring stops, the luminaires are firmly held in the ceiling cladding. For more information on how to fix plastic panels to the ceiling, see this video:

Only after connecting the entire circuit, the entire lighting and power supply system is connected to the electrical network of the apartment.

Maintenance of pvc balcony cladding

Plastic panels on the balcony are easy to clean with soapy water or shampoo. Washing powder can damage the lacquered surface of the plastic, which will lead to the loss of the beautiful appearance of the cladding.

Plastic panels on the balcony are easy to clean with soapy water or shampoo. Washing powder can damage the lacquered surface of the plastic, which will lead to the loss of the beautiful appearance of the cladding.

In the event of mechanical damage, the PVC strip can be easily replaced with a new piece of plastic. To do this, you need to have one or two PVC strips in stock.

Installing plastic on the balcony as a cladding is beneficial and aesthetically beautiful.

When the repair on the balcony comes to its logical conclusion, it remains only to do its interior decoration. If the walls are finished correctly, then the balcony can turn into a separate room. It can also be made a continuation of the living room or kitchen. There are many materials for finishing, so you should figure out which one is best to buy.

Wall panels for interior decoration. Advantages

All Wall panels for balconies have a number of advantages:

- They have a service life of at least 10 years.

- Installation can be easily carried out independently and fairly quickly.

- Since the wall panels are very light, it becomes possible to clad any surface, regardless of what the basis of the material is.

- In addition to the fact that wall panels are used on the balcony, they can also be finished in other rooms.

Wall panels for interior decoration. Material selection

For wall decoration, cork and plastic panels are most often used, as well as plaster, drywall, wooden lining and some other materials.

If the balcony is not insulated, then tiles, plastic lining, cork panels, and so on are quite suitable.

Let's consider each material in more detail.

Cork panels

Cork is the pressed bark of the cork oak. The material from it is made in the form of flexible and thin sheets - panels. They are easy to assemble and cut. Cork panels are suitable for any balcony, not even glazed. They are resistant to moisture and fading and do not absorb various unpleasant odors.

The only drawback, and even controversial, can be called extremely high wall cork panels.

Siding

Siding attracts many people, first of all, with its low price category. In addition, it has fire resistance and is not afraid of low temperatures. It can be fixed with ordinary self-tapping screws, as this material is very light.

Unfortunately, in the sun, it fades quite quickly, so white is the only color that is recommended to buy.

Drywall

This material is non-toxic, so it is used when combining a balcony with other rooms.

When the walls are sheathed with drywall, they will become smooth and even. They can be painted or tiled if desired. Unfortunately, drywall is afraid of severe frosts. Therefore, it is used only on those balconies that are insulated.

PVC panels

Just yesterday, these panels were afraid of extreme cold. But today frost-resistant models have already appeared on the construction market. Although they fade over time in the sun, they tolerate moisture very well. In addition, PVC panels are inexpensive and easy to install. They can be planted on self-tapping screws or regular glue.

MDF panels

Dried and pressed wood fibers - it is from this material that MDF panels are made. They are covered with a laminated color film. Sometimes they are made to match the color of the tree. The material is afraid of strong changes in temperature and moisture. However, it is difficult to install. In addition, it is not expensive and perfectly retains heat.

Wooden lining

If you love the smell of natural wood and do not want to save on decorating your own balcony, then this material will do just fine. Outwardly, wooden lining is similar to siding. With its help, you can create amazing interiors.

Also, wooden lining has other advantages:

- fits for any balcony;

- endures sudden changes in temperature;

- does not change their flowers.

Plastic lining

This material is an excellent conductor of heat and has a low cost. She tolerates both cold and heat equally. Therefore, such material can be placed both on insulated and non-insulated balconies.

Other advantages:

- long service life,

- has sound insulation

- does not burn out

- does not scratch.

Facing stone

The walls, which are finished with facing stones, look spectacular and chic. This stone tolerates all kinds of temperature changes and will last a very long time.

Panels for interior wall decoration. Balcony insulation

If we talk about lighting, then in this regard there will be no problems with the balcony.

If the balcony is equipped as a worker, then you will need to install lamps in different corners.

But the choice of heating system must be taken seriously. Basically, it all depends on the budget allocated to it. For example, if you are willing to spend a large amount, then you can install it in a water version. If there are few funds available, then it is quite possible to put a conventional oil cooler.

As for furniture, it is best to buy it to order.

She must be:

- small size,

- comfortable

- practical.

Design Choice

You also need to decide on the purpose of the balcony and carefully prepare this project. In addition to the fact that it can be used as an office, there are other options.

So the balcony can be:

- rest room,

- game room,

- mini greenhouse.

In addition to the appointment, you need to designate what the style of your small room will be.

If you want to make the most of the free space of the balcony, then it is recommended to apply the following tips:

- You need to make a big window sill. It can be used as a table on which you can put a laptop or flowers.

- Use a variety of decor that will give the room a personality.

As you can see, a loggia or balcony can be turned into a full-fledged living room or study. It all depends on your imagination. The main thing is to find such wall panels for the balcony that will fit perfectly into this small room.

Attention, only TODAY!