Each owner country house wants to see his home beautiful not only from the inside, but also from the outside. A porch, a beautiful roof, neat windows and doors, a facade are the main components that are responsible for the aesthetics of any building. That is why the material with which the outer walls of the house will be finished must be chosen carefully. After all, not only durability and strength are important here, but also appearance.

Most often, the walls of houses are lined with facing bricks. It is a reliable and time-tested material. In this article, we will talk about various types such facing bricks and variants of its laying.

The modern construction industry offers buyers huge assortment facing brick. You can easily choose the right material for your case. Products differ both in their colors and dimensions.

But perhaps the most important difference can be considered the raw materials and technologies used in the production of the material. According to these principles, facing bricks are divided into:

The choice of one or another variant of facing brick will depend from your financial possibilities. If funds allow, you can buy clinker products and “forget” about the facade of the house for many years. If financial opportunities are small, then it is better to give preference to ceramic or silicate brickwork.

Color palette

When choosing products for facing the facade of your house, it is important to choose the right colors. Here everything will depend on the area of \u200b\u200bthe walls, the colors of the roof, windows and doors. The color of brickwork will largely depend on the material used in the manufacture.

When choosing products for facing the facade of your house, it is important to choose the right colors. Here everything will depend on the area of \u200b\u200bthe walls, the colors of the roof, windows and doors. The color of brickwork will largely depend on the material used in the manufacture.

Quite a wide variety of palettes differ ceramic and clinker products. Just look at the photo from the Internet or from the manufacturer's catalog. This is due to the addition of dyes during their production.

But here you should be careful. When choosing a facing brick, it is important to buy products from the same batch. If the silicate material does not differ much in color, then the shades of ceramic and clinker bricks in different batches can differ significantly. Therefore, it is better to purchase "in reserve", otherwise the appearance of the brick facade of your house can be significantly affected.

Hyper pressed brick not subject to firing, so its color is uniform over the entire surface. The palette is determined by the pigments added during pressing. Also, the tone of each part rarely differs from each other. That's why desired color can be easily selected. In addition, due to the special processing, the color of the hyper-pressed bricks is more similar to natural stone, which significantly adds aesthetic value to the products.

If we talk about silicate brick, then the coloring occurs during the mixing of the ingredients. Quite often, too many dyes are added, this makes the products brighter, but less durable. On sale you can find silicate bricks, painted only on the front side, this is done to reduce the cost.

surface texture

In addition to the color palette, when choosing a facing brick, you should pay attention to the surface texture. Manufacturers have also come a long way here. Bricks that are fired may differ large selection of patterns on its surface. Just look at the photo from the catalogs of manufacturers.

In addition to the color palette, when choosing a facing brick, you should pay attention to the surface texture. Manufacturers have also come a long way here. Bricks that are fired may differ large selection of patterns on its surface. Just look at the photo from the catalogs of manufacturers.

Drawing a pattern for fired products is a fairly simple matter. It is enough to attach the desired stencil while shaping, even to a wet surface. After firing, the pattern remains, while the properties of the brick do not deteriorate at all.

In addition to this method, there are several methods for creating an original texture:

- Torqueting. This method involves the application of fine mineral chips to the surface of the brick before it is fired. When exposed to high temperatures, the inclusions melt and are firmly connected to the base material. The result is a beautiful texture with color contrasts. But there are also disadvantages. For example, such a surface collects a lot of dirt;

- Engobing is the coating of a surface with a thin layer of ceramic. A special mass is applied to the dried, but unfired brick. After that, the product is sent to the oven. Such material does not differ in its characteristics from the usual one. The only thing to consider is accuracy when facing. The ceramic layer is quite thin (only one millimeter), so it can easily break off;

- Glazing. The principle of this method is close to the previous one, only here not ceramics are used, but a special glaze. Such products have an improved appearance. Brickwork will resemble a glass surface.

Hyper-pressed brick is not fired, so the above methods cannot be applied here. Manufacturers use a method called "cleavage". As a result, the surface of the brickwork will be more like a wall of natural stone.

Varieties of masonry facing bricks

Masonry during cladding and during the construction of walls can differ significantly. In the first case, appearance is at the forefront, while in the second, strength and reliability are important. According to many builders, there are the following types of masonry facing brick photos of which can be easily found on the Internet:

If you are doing the cladding yourself, then it is better to apply normal straight laying. This method is considered the easiest to perform, but despite its simplicity, direct brickwork looks great. Well, you can get acquainted with the methods and patterns of artistic or decorative masonry by viewing photos from numerous construction forums and sites.

As a conclusion

When building a house, take into account many parameters and factors. The main thing is that the structure turned out to be reliable and durable. But you should not forget about the appearance. And here such material as a facing brick comes to the rescue. Manufacturers offer a large selection of similar products that differ both in their characteristics and in appearance. Therefore, there is always something to choose from. And if it is still correct, with artistic taste, to choose a masonry method, then the appearance of your house will delight not only its owners, but also neighbors and guests.

Silicate brick has long been known as "white". But in fact, it can be of a variety of colors: blue, yellow, orange, red, brown, etc. Due to this, this material is widely used for the construction and decoration of houses. The photo shows how beautiful and original buildings made of colored bricks look. It is worth considering in more detail its properties.

Production

Silicate bricks, regardless of color, are produced using the same technology. Mix quartz sand and lime in a ratio of 9 to 1. If you want to get colored bricks, for example, red or blue, then add a coloring pigment. Without this substance, the product will have a grayish-white color. The mixture is pressed into the desired size and shape, and then treated with hot steam (up to 200°C) and subjected to high pressure (8 to 12 atmospheres). This manufacturing method is called autoclave synthesis.

Strength and others specifications products depend on how correctly and accurately the manufacturing technology was observed. To improve the quality of bricks, special additives-modifiers allow. So, with their help, you can increase the level of frost resistance or strength.

Types of colored silicate bricks

There are many varieties of silicate bricks. It is divided into colors (red, black, green), structure, shape, size and application.

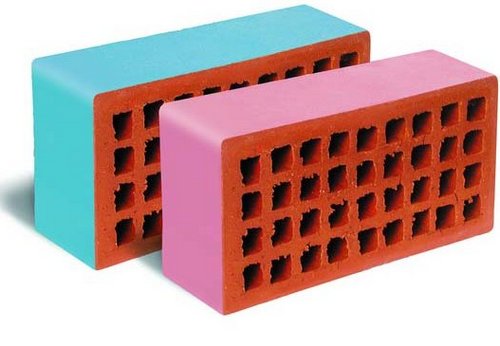

According to the structure, two types of bricks are distinguished: corpulent and hollow. In the first case, the product does not have internal voids, in the second - they are present.

According to the field of application, they are divided into ordinary, that is, the one from which the masonry is performed, and the front one. The latter is used for facing houses, buildings.

Divided by size:

- Single (dimensions 250x120x65 mm);

- One and a half (parameters 250x120x88 mm);

- Double (250x120x138 mm), bricks of this size are often called silicate stone.

As you can see, the length and width do not change, only the thickness of the products increases.

Bricks, as a rule, have the shape of a parallelepiped.

In construction, smooth products and with a chipped texture are used. The latter are used in facing works. Embossed brick makes the architectural appearance of houses more diverse, creates the feeling that the masonry is made of natural stone.

Currently, materials of various colors are produced, not only white, but also yellow, red, black, blue, green, etc. The use of already painted products expands the possibilities of construction and decoration. After laying the facing colored brick, no additional work is required to improve the facade. From colored material, you can lay out a specific pattern or pattern. The photo shows various options for decorating houses in yellow and red colors. Thanks to the use of colored silicate bricks, interior and exterior walls are decorative without additional finishing.

Characteristics

The properties and qualities of a brick determine its technical characteristics: strength, frost resistance, thermal conductivity, density, etc. The durability of the material and the conditions under which and for what purposes it can be used also depend on them.

Strength indicates how much load a product can withstand. Measured in kg per cm 2. It is designated by the letter M, followed by a number indicating the permissible load. Now in production silicate brick different levels of strength from M-75 to M-300. Products of the M100 brand are in the greatest demand. It can be considered basic, because bricks of this level of strength can be used to build buildings up to 5 floors high. It is he who is most often used in individual housing construction in the construction of private houses and cottages, in the construction of various social institutions, etc. For the construction of buildings with a higher number of storeys, it is necessary to use materials of greater strength.

Frost resistance level is the next parameter. It is denoted by the letter F and shows how many freeze-thaw cycles the product can withstand. The higher this indicator, the more durable the material.

Density can vary from 1300 to 2100 kg/m 3 . The levels of thermal conductivity and sound insulation directly depend on this parameter.

Thermal conductivity shows how quickly heat will be transferred to colder areas. The higher this figure, the faster the brick will freeze in winter. The thermal conductivity of silicate products can be in the range of 0.35-0.7 W/m°C.

Moisture absorption rate for silicate brick can not exceed 12%.

Heat resistance level silicate bricks are not the highest. They should not be used where they will be heated up to 550°C. At high temperatures they start to crack and crumble. Therefore, it is not recommended to use this material for laying furnaces and pipes.

Weight is the final parameter. It can vary greatly depending on the type of product. So, a single hollow brick will weigh about 3.5 kg, and a solid one - up to 5 kg.

Advantages and disadvantages

Sand-lime brick, like any other building material, has a number of advantages and disadvantages. Of the positive qualities of the material can be noted:

- High level of sound insulation. In a house built from this material, sounds from the street are practically inaudible;

- There are products with a low level of thermal conductivity, which helps maintain a good indoor climate;

- High level of strength;

- A wide range of colors (from yellow and red to blue and black);

- The presence of products with different textures, which opens up scope for design solutions;

- Heat resistance, withstands heating up to 500 ° C without compromising its qualities;

- It can be used for laying internal partitions, load-bearing and external walls, for facing houses;

- The ability to use colored material for decorative finishes;

- Eco-friendly, consists only of natural components, does not emit harmful substances into the air during operation, therefore it can be used for the construction of buildings for any purpose, including for kindergartens, schools and hospitals;

- Colored material can be used to decorate facades;

- It is not combustible, is a fire-resistant material, is absolutely fireproof and does not burn;

- One of the most affordable building materials, both in terms of price and prevalence, it is not difficult to find sand-lime brick in any city.

However, this material has a number of significant drawbacks, which limits the scope of its use. Of the minuses note:

- Large weight, especially for solid blocks, sand-lime brick is considered one of the heaviest building materials;

- High-rise buildings require additional strengthening of the foundation due to the high weight of the structure;

- Most of the silicate products have a high level of thermal conductivity, which leads to rapid freezing of the walls in winter, buildings often need additional insulation;

- Absorbs moisture from the environment;

- Low level of chemical resistance;

- Decomposes quickly in conditions of high humidity;

- May be deformed;

- Does not tolerate heating above 600 ° C;

- Poor adhesion to cement mortars.

Such disadvantages impose serious restrictions on the scope building material. For example, due to high level moisture absorption and instability to moisture, silicate brick cannot be used when building a foundation. Also, it can not be used in the arrangement of furnaces, pipes, chimneys. Silicate stones are not used in the construction of baths and hot shops. On the other hand, due to the ability to maintain a microclimate in the room, decorative and environmental friendliness, this is one of the best options for housing construction. The most important thing is to choose the right material.

By themselves, the facades of buildings made of brick look majestic and noble, especially when red brick is involved in the masonry. However, if earlier only two types of this material were used in construction: red and white, then the modern construction industry allows you to paint it in any, even the most unimaginable color. How they manage to do this and, in fact, what opportunities colored bricks open up in architecture - we will talk about this today at Dream House, and also see what varieties of this building material exist.

Types of brick staining

Everyone who is at least a little familiar with the construction business knows that brick staining can be voluminous and superficial.

- In the first case, coloring pigments are added to the composition from which the brick is made, and after firing it acquires its permanent color. If such a brick is broken into pieces, then inside and outside it will be the same color. The color range of three-dimensionally painted bricks is not limited to reddish hues; blue and green dyes are used with equal success in their production, which give the facades more lightness and weightlessness. Such a brick is used not only for decoration country houses and cottages, the colored face brick will bring some originality to the architecture of the city, painting commercial buildings, shops and cafes in sky blue or light green color. As mentioned earlier, such unnatural colors for a brick are achieved by adding a coloring pigment during its production, but to make, for example, a light brick of the color “Cream” or “Ivory”, clarifiers will help, which are also added to the composition and give the material yellowish tints .

- Speaking of surface coloring, it means that only the outer layer will be colored, which, as a rule, does not exceed 2-3 mm. With the help of powdered paints or special impregnations, the finished brick is painted in one color or another. With such tinting, absolutely any color can be given to a brick, and the manufacturer gives a guarantee for color fastness for more than 20-30 years.

Colored brick types

If we talk about the classification of colored bricks according to the method of production and the material from which it is made, then the following types should be distinguished:

- silicate brick- made of environmentally friendly material, which consists of almost one sand. If we add a coloring pigment to this composition, pour it into a mold and then send it to the oven, we will get a silicate colored brick of any color, even pink, even green. Such bricks are used for facing low-rise and high-rise buildings for both commercial and non-commercial purposes.

- ceramic brick- obtained from clay by firing in a kiln at high temperature. After such a temperature shake, most of the clays at the exit have a red color. However, there is also a colored ceramic brick, its coloring is achieved by any of the above methods, i.e. can be superficial and voluminous. Such a brick is used in one-story and high-rise housing construction, and can also be successfully used in restoration work.

- Hyper pressed brick- made from various limestone rocks, but its peculiarity lies in the fact that it does not go through the process of drying and firing. The raw material is simply pressed under high pressure, as a result of which its super-density and strength are achieved. To make a colored hyper-pressed brick, iron-oxidized pigments are added, which make it possible to obtain a finished product of white, yellow, greenish, gray,. This brick is used for facing facades, decorating individual elements of structures under construction, as well as for erecting fences.

Another type of colored facing bricks is the glazed look. Its peculiarity lies in the rich colors and smooth surface that is inherent in any glaze. Such a brick is made in two ways:

1) the first method is that the glaze is applied to a fully finished and fired brick, and then it is placed in a kiln, where, at a temperature of up to 750 ° C, re-firing occurs for two hours;

2) in the second method, the glaze is applied to the formed, but still raw brick, and then they are all fired together for 1.5 days in a kiln at temperatures above 1000 ° C - with this manufacturing method, the adhesion of the decorative glaze and the brick surface is the strongest.

Despite the method of production, this brick is distinguished by excellent performance, strength, high resistance to weather conditions (frost and moisture resistance), scratches, and fire resistance. The main feature of glazed brick is its decorative properties, among which it is necessary to note the rich color and gloss of the surface. However, it is important to note here that glazed brick can have not only a glossy surface, but also a matte one, and the glaze itself can be transparent and opaque and even have a pattern (for example, imitation of natural stone). Such facing material used for exterior finish buildings and for internal works- erection of partitions, and furnaces.

Possibilities of colored bricks in facade cladding

Colored bricks are widely used in building cladding, creating unpretentious drawings or mosaic panels on.

And for this it is not at all necessary to use glazed brick with a bright pattern, it is enough to be smart and use not ordinary masonry, but, for example, Bavarian. Its essence lies in combining bricks of the same color, but in different shades (and some craftsmen even connect adjacent or contrasting colors). As a result of such masonry, the building acquires a deeper meaning, and the fantasy of the drawing adds originality and peculiarity to the structure, which competes with similar buildings of the same type.

Bavarian masonry - facade cladding

Thinner and more elegant lines are obtained when using glazed bricks, especially if a pattern is applied to it. Houses made of colored bricks of this class are classified as elite, they breathe comfort and give visual pleasure, what can we say about positive emotions from living in such a house. Therefore, it is not surprising that in recent times Glazed bricks are increasingly being used in one-story housing construction and suburban construction. And quite advanced owners of suburban real estate order decoration from fluorescent glazed brick, which is able to glow at night.

Finishing with German clinker is one of the most effective and modern ways facade cladding for residential and commercial buildings. Presented in a large number of color shades (the available palette includes more than 100 colors), the facade brick allows you to give any building an aesthetic, beautiful, bright, original and even extraordinary appearance.

Construction companies in Germany and other European countries using clinker in building design and construction are gradually moving away from using a small amount of traditional brick colors and have already begun to introduce bolder and more unusual colors into cladding and renovation projects. color solutions. Together with the creation of peculiar dimensional combinations, the development of unique color compositions brings fantastic appeal to the overall value of the structure.

Color features of facade clinker "AVS-Klinkergruppe":

- The variety of colors of ABC-Klinkergruppe clinker is achieved only by natural methods. The formation of a particular color of a brick is influenced by:

Shade of applied clay or loam,

Baking coal and sandstone into a semi-finished clay product at high temperature firing to obtain a “burnt” shade and different textures,

- use of "reduced firing" technology.

- The most important characteristic of natural facade brick- so-called " color game". During the firing process, bricks located at different locations in the tunnel kiln may have slight differences in tone. Therefore, in one batch, the presence of products that are slightly different from each other is acceptable. In order to obtain a surface with beautiful color tints, there is no need to additionally mix the bricks on the construction site - they are already mixed.

- Features of facade clinker production technology make it possible to use natural coal to achieve a greater variety of colors and shades. In contact with a molded product at high temperatures, dark blotches form on the surface of the brick. These spots, being an integral part of the facing brick, give it a very interesting shade and create a special color scheme for facades.

What color solutions does FacadeKeramika offer?

Depending on the mineral composition of the types of clay and loam used, the ABC-Klinkergruppe facade clinker has a wide range of colors from yellow, through red, to brown. In addition to standard colors used in Russian construction, we offer:- standard clinker colors widely used in Europe;

- unusual colors"mix", created from several shades;

- original, non-stamped colors and their combinations.

At the warehouse of our company in Moscow, there are always at least 7 commonly used colors of facing bricks in stock. The entire color range of facade clinker is more than 100 shades of color and surface textures. You can see the full collection of colors we offer here.