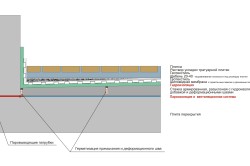

Before starting work on paving the floor, it is important to make sure that the reinforced concrete slab of the terrace is made with a slope of 1-3%. For some materials, this figure is higher. Of course, the descent should be located in the direction from the house, and the floor level of the terrace should be lower than the floor level in the house. You can perform the ramping from mortar, concrete or polystyrene foam wedges.

The material that is supposed to be used for the flooring of the terrace must necessarily meet the following requirements.

- • Frost resistance. This term is understood as a low percentage of moisture absorption (up to 3%), which determines the resistance of the material to repeated freezing and thawing. Information about the characteristic is on the packaging, more often in the form of a snowflake.

• Resistant to abrasion from heavy use and abrasive sand. The indicator determines the aesthetic qualities of the coating, after several years. For stone and wood, this is not the main characteristic, but if we talk about ceramics, then the abrasion class must be at least 4.

• Anti-slip properties ensure safe movement. To indicate this characteristic, the marking "R" is used, for terraces minimum requirement R9.

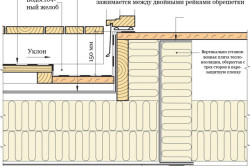

Additional protection must be provided to the wall that is in direct contact with the terraced floor. To do this, it is lined to a height of 15-20 cm from a similar or similar material, and the upper edge of the base is treated with sealant, acrylic or silicone.

Another important point, is the presence of expansion joints. They absorb the difference in expansion coefficients of different materials. The gap of 1-2 cm between the floor of the terrace (including the slope-forming layer) and the wall is filled with any elastic material.

In order to compensate for temperature deformations, such joints should also divide the flooring of the terrace into rectangles and squares and be located every 2-5 m. The higher the thermal effect on the terrace, the smaller the step. The seam is filled with an expansion cord, over which silicone grout is applied.

Terrace ceramic surface

Ceramic products for flooring are characterized by a wide colors, a large number of shapes, sizes and textures, which makes it possible to create original design and makes them the most popular option. For terraces, ceramic and clinker tiles are used.

Porcelain stoneware or gres tiles differ from ordinary ceramics in increased strength and frost resistance. Optimal size such tiles 45*45 mm or 30*60 mm. On sale are presented with a polished and unpolished surface. Unpolished is preferred. It features anti-slip properties and high durability. A uniform cross section allows such a coating to maintain its original appearance even with slight abrasion.

Clinker tiles are ideal for terrace floors due to their resistance to abrasion, moisture absorption coefficient of 0.5-0.7% and durability. It is made from clay, therefore it is presented in brown, red and red shades. If the surface is glazed, then the color range is wider. The anti-slip effect corresponds to the marking. As for the dimensions, the thickness of the tiles is 10-16 mm, the width is 11-31 cm, the length is 24-31 cm.

Features of laying ceramics

If the tile is laid in a pattern, then you need to start work from the most noticeable place. The tile is glued to the base with a special adhesive mixture, which is applied with a notched trowel, both on the base slab and on the tile.

In order to prevent excessive drying of the solution, it is distributed over an area of no more than 1 m2.

The seams are made using crosses (5-10 mm.) And overwritten a few days later, after the adhesive mixture has completely dried. The mass of the grout should be for outdoor use, elastic, with increased adhesion, and quickly set.

To avoid the appearance of persistent stains, all dirt on the tiles and grout that occurs during work is immediately removed with a damp, and then dry, sponge.

Advantages

- • Easy care

• Affordable price

• Constancy of quality characteristics and color.

Flaws

- • Heats up and stores heat.

• Seams require extra care.

• Plaque appears on clinker tiles over time.

Natural stone flooring

Looks most harmonious in a natural environment. However, not every stone is suitable for a terrace. The best option would be a tile made of selenite, basalt or granite. Sandstone, travertine and limestone will be completely inappropriate.

The texture of a stone slab can be: burnt, bush hammered, chipped, polished, polished or sawn.

Styling features

The elements are laid in the same way as ceramic tiles, with the difference that the stone requires a higher surface slope of 3-5%. Stone slabs are glued with special glue for stone made of white cement, on the most even surface. The adhesive mixture is applied to the lower surface of the tile and to the concrete base, with a layer of 4-5 mm. The thickness of the seams is at least 5 mm. After laying, the seams are rubbed. The composition of the grout should include silicone. After the completion of the paving work, the floor covering is covered special preparations, which protect the stone from dirt, reduce the moisture absorption coefficient and make the surface harder.

Advantages

- • Excellent technical qualities.

• High strength and durability.

• In the process of aging becomes even more beautiful.

Flaws

- • The color of the stone often does not match what is expected.

• Heats up quickly in the sun.

• Breakage possible with strong impacts.

• Requires additional care (periodic impregnate treatment).

• Seams get dirty quickly.

Decorative stamped concrete

A special mortar is laid on the reinforced concrete base, sometimes with the addition of coloring pigments and processed with patterned or textured forms.

stamped concrete on the left-bottom imitates granite paving stones, on the right-bottom deck board

As a result of stamping, imitation of stone, sandstone, pebbles, paving stones, boards or bricks is possible. The thickness of such a coating is 10-60 mm. The screed requires a level, stable concrete base, minimum class B25, with a slope of at least 2%.

Styling features

The work begins with the laying and ramming of the fiber-reinforced concrete. The coating is leveled with a hardener, rubbed and stamped with the necessary pattern. An expansion joint separates sections of 3*3 m. After removing the formwork, the coating is covered with acrylic impregnate. A month later, the expansion joints are filled with a highly elastic material. If the layer of stamped concrete is 10-12 mm, then reinforced concrete slabs are pre-coated with an adhesive layer.

Advantages

- • Minimum amount of work.

• Excellent imitation of the selected material.

• Lack of seams.

Flaws

- • Coating may have reflections.

• Every 2-3 years requires treatment with protective compounds.

• Gets very hot in the sun.

Concrete tiles as flooring

Finished products are produced by vibrocasting or vibrocompression. They can be with a smooth or rough surface, imitate natural stone, paving stones, wood, ceramics. The thickness of such tiles is 38*45 mm, the sizes are usually 60*60 cm, 60*45 cm, 30*30 cm and 60*30 cm. In addition to rectangular shapes, decorative elements are made, which allows you to create a complex ornament.

Styling features

Paving concrete tiles, similar to gluing stone slabs. The work uses special adhesive mixtures (not for stone), which are applied pointwise or evenly distributed over the surface of the tile and base. During laying, the tiles must be tapped with a rubber mallet, thus distributing the adhesive mixture. The thickness of the seams is 4-10 mm. For grouting, an elastic mass for stone is used. The finished coating is treated with protective compounds.

Advantages

- • Absolute imitation of the selected material.

• Relatively low cost.

Flaws

- • Plaque may appear over time.

• Additional treatment with impregnation every 1.5-2 years.

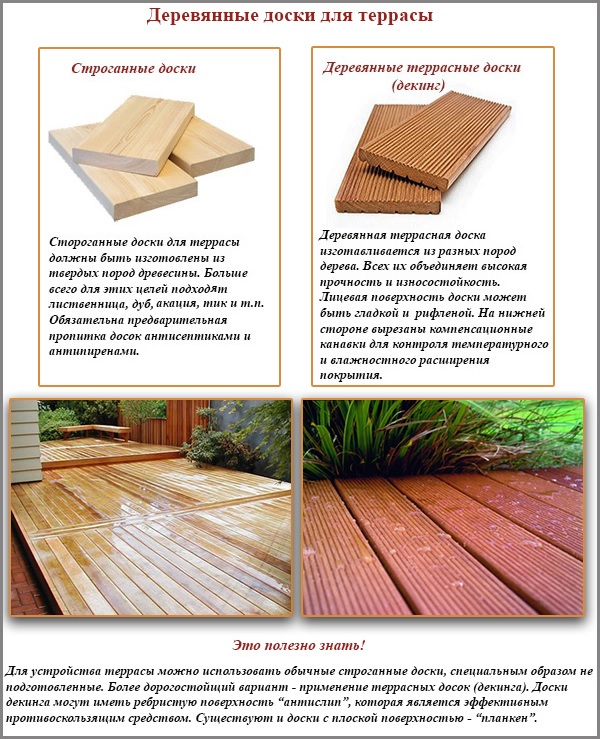

Wood or decking

Durability is determined by the choice of breed, the correct implementation of the supporting structure, installation and reliable protection material. The most suitable wood species are teak, oak, kumaru, bangkirai. They are hard, have high resistance to abrasion and the negative effects of the external environment. And also do not require treatment with impregnation.

Oil or marilka will emphasize the natural color. Sometimes they use spruce or pine, but it is worth considering the fact that these are soft rocks and over time scratches and dents appear on them, they lose appearance and require additional care. To protect wood, it is better to choose impregnations based on natural oils and solvents.

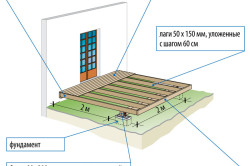

Styling features

Corrugated or smooth boards are used to cover the terrace. Preferably, products with a drip. Board thickness 25-38 mm, length 2.5-5.5 m, width should not exceed 140 mm. Base slope 1.5-2%.

Corrugated or smooth boards are used to cover the terrace. Preferably, products with a drip. Board thickness 25-38 mm, length 2.5-5.5 m, width should not exceed 140 mm. Base slope 1.5-2%.

Logs with a section of 5 * 5 cm are laid on 2 layers of roofing material along the slope line, in increments of 30-60 cm. The boards are nailed at intervals of 8-15 mm, thus maintaining ventilation of the coating. The board is attached to the lags with self-tapping screws or on an adhesive base. Sometimes they use plastic logs, they are more practical.

Another option for wood flooring is the so-called garden parquet. The boards have a parquet lock that easily connects the modules to each other.

Advantages

- • Ease of installation.

• Levels the slope.

• Ideal ethical qualities.

• Optimum floor temperature is maintained even in the sun.

Flaws

- • Burns out quickly.

• Requires special, time-consuming care.

• The frequency of additional protective treatment depends on the degree of exploitation and the type of wood.

• Smooth boards become slippery after rain.

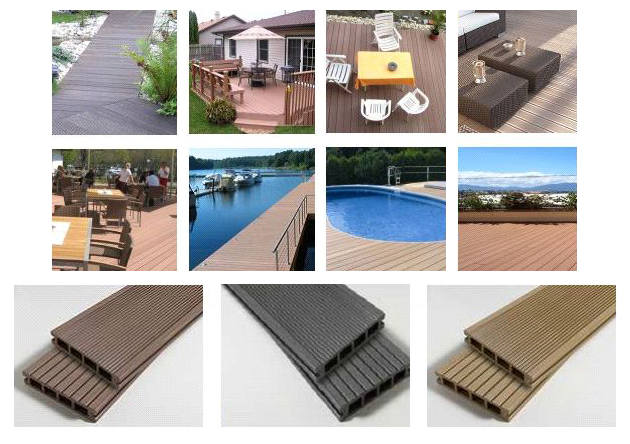

Wood-polymer composite

In appearance it resembles terrace board, but are made by DPS from a mixture of wood flour and plastic. The product is a hollow profile with internal stiffeners. The material is stable, non-slip and frost-resistant, so it is successfully laid on the terrace. Such a board has a thickness of 25 * 30 mm, a length of 2-6 m and a width of 10-15 cm. The warranty period is 10 years, practical 35-40 years.

Features of laying WPC

Special fasteners made of stainless steel are intended for laying DPS: rack frame, screws and clips. Wooden or metal slats are laid in increments of 35-40 cm. Terrace boards are laid across the frame. Steel clips enter the side grooves between the board, they fix the board on the frame and hold it. An expansion joint of 1-1.5 cm is left between the panels and the wall.

Special fasteners made of stainless steel are intended for laying DPS: rack frame, screws and clips. Wooden or metal slats are laid in increments of 35-40 cm. Terrace boards are laid across the frame. Steel clips enter the side grooves between the board, they fix the board on the frame and hold it. An expansion joint of 1-1.5 cm is left between the panels and the wall.

Advantages

• The coating does not require additional processing.

• Easy installation.

• Excellent appearance.

• Does not fade in the sun and maintains optimal temperature.

Disadvantages of WPC

• High price.

Read articles on related topics

The veranda can be called a very unusual place in a private house. It can be both closed and represent some kind of terrace. One thing is obvious - the veranda differs quite significantly from the rest of the premises in the house, primarily by the lack of heating. This, and the often stronger influence of natural factors, makes the choice of flooring for this part of the house special.

In the event that the veranda is positioned as a closed capital premises, it is often done on strip foundation. Often the same is available in the house itself. This design is the most stable and durable. In this case, the floor is usually thermally insulated, but in the case of a closed terrace, they often also conduct a system of underground pipes through which the coolant circulates. The ability to control such heating is an obvious plus.

Often the veranda is an extension with removable windows and walls, or even without them at all - with only one canopy. In this case, piles often become the foundation, and there is a certain distance between the floor and the ground. In this case, lags are mounted on the supporting beams, on which the subfloor is already attached, followed by a finishing layer. Often in this case, the design implies gaps through which water during rain could flow down without flooding the foundation.

What requirements should the floors for gazebos and verandas meet?

- It must be remembered that there people, as a rule, are in shoes. Consequently, the veranda is usually much dirtier than at home. So the floors should be able to be cleaned as simply as possible;

- The floors in a veranda or pergola are usually located in an unheated area, and, in our climate, are subject to strong temperature changes. Therefore, such floors must withstand extreme heat and severe frost without destruction and deterioration of their performance;

- In the case of an open veranda, the floor must withstand precipitation without getting wet or changing its shape. Also, the flooring must be resistant to solar radiation;

- Durability and ability to resist abrasion - you are unlikely to want to change floors in this part of the house often. Therefore, they must withstand the harsh soles of the shoes for the longest possible period of time.

With regard to visual qualities, here you can make a connection with the external or interior decoration at home, or vice versa - play in contrast.

Tiles for the veranda

The tiled flooring on the veranda is ideal in combination with a solid foundation. The most popular is ceramic. However, porcelain stoneware shows itself best in this sense, as it has the best resistance to abrasion.

It is necessary to choose non-slip tiles, especially in the case of open terrace views. For closed options, this parameter may also be important, since when going there in wet shoes from the street, we must be sure to maintain stability.

The disadvantages of tiles include the fact that it is very cold. You can go out without shoes only on a summer day, in all other cases barefoot there will be very uncomfortable.

Important! Separately, it is worth considering rubber tiles, which are highly resistant to natural influences and moisture, environmentally friendly, comfortable and non-slip. At the same time, such tiles are very light, do not require a large-scale foundation, and at the same time can be laid on almost any surface.

Concrete floor

The most durable option for creating a floor in this extension. It is also used only if the floor is combined with a solid foundation, since its mass is very high. In this case, we are not talking about a simple screed, but about much more visually attractive options.

So, concrete at the pouring stage can be diversified with various materials, such as granite, marble, and the like. In this field, we can polish with a special machine, making the floor incredibly attractive. As an option, add additives of various colors to the screed. At the same time, such a floor retains the strength of the stone, is completely resistant to all external influences and is extremely durable.

Important! When polishing the floor, do not be too zealous. A floor that is too smooth can be too slippery.

Wood as a floor for the veranda

In terms of comfort, wooden floors are the ideal solution. This material not only conducts temperature very poorly, thanks to which it is neither hot nor cold on such floors, but it also looks great. However, the tree is very mediocre combined with open verandas and gazebos. But there are a few exceptions:

- Decking is a board created from durable wood and impregnated with special solutions. It is suitable as a floor on the decks of marine vessels, which gave it its name. Resistant to moisture and other natural influences, and also equipped with longitudinal grooves, which makes it non-slip and attractive in appearance. It is best to lay such a board at small intervals so that moisture flows between them;

- Use of moisture resistant paint and varnish. In this case, you can take not decking, but any high-strength wood. At the same time, we advise you to take modern models of a similar paintwork, which maximize resistance to moisture;

- Composite wood. interesting material, obtained using a mixture of wood industry waste with various resins. As a result, a composite material is obtained that completely repeats the appearance of wood, but at the same time devoid of its shortcomings, which are insufficient resistance to natural influences. Of course, such a composite loses to wood in its environmental friendliness, but in the case of an open veranda, all this is not critical.

Self-leveling floors

Another category of flooring, which, due to its polymer structure, is highly durable and is ideal for use in a veranda, terrace or gazebo. However, lovers of everything natural will not be delighted with them, but it is worth recognizing that such floors really look excellent.

They also have disadvantages. In addition to artificiality, this is also a very considerable price, to which it is necessary to add the complexity in preparation and pouring. These processes need to be trusted by professionals, and this also costs money.

Linoleum - the most economical non-slip flooring on the veranda

For people with a limited budget, there is a way out - to use linoleum. Moreover, now a huge number of its types have appeared on the market, among which you can find the perfect option, regardless of requests.

As the undoubted advantages of linoleum can be called cheapness, simple styling as well as ease of use. It must be understood that for the veranda you should choose only the highest quality and dense options that are resistant to abrasion. But even they, unfortunately, eventually begin to rot and rot from high humidity. It saves only that, if necessary, it can be quickly dismantled and a new one laid. In addition, when exposed to direct sunlight, such material begins to smell like plastic, which is not to everyone's liking and can spoil the process of enjoying nature.

Terrace - an open area, which is a "transit point" between the house and the street. The choice of flooring for her is not an easy task. The terrace is open to rain, snow, summer heat and winter frosts. Therefore, the material for its coating must retain its functionality in difficult, almost outdoor conditions. And, of course, to have high aesthetic qualities.

Floor coverings for the terrace should have the following properties:

- High frost resistance. This characteristic is provided by a low rate of water absorption - up to 3%. Materials with this indicator are not impregnated with moisture, it does not freeze in the cold and, accordingly, cannot lead to cracking and damage to the coating.

- Moisture resistance. The floor on the terrace is exposed to atmospheric precipitation. Therefore, the materials used for coating should not absorb moisture, deform from it, or rot.

- Durability. Any coating that "works" in atmospheric conditions must be more durable than home coatings. Otherwise, after 2-3 years it will have to be changed.

- Low abrasion. The durability and appearance of the terrace floor directly depend on this indicator. The minimum abrasion class of materials that are acceptable for terraces is IV.

- Anti-slip properties. They are important for the safety of people, especially when walking on a wet or icy terrace floor.

- UV resistant. If a canopy is not planned to be installed above the terrace, then the sun's rays can reduce the color intensity of the coating. This will not happen if you use materials with a high degree of protection from UV rays.

All these characteristics are inherent in the following materials, which are considered the best for covering terraces:

- decking from WPC;

- ceramics (clinker, porcelain stoneware, ceramic tiles);

- concrete slabs and tiles;

- stamped concrete;

- stone slabs;

- wooden boards.

Let's consider all these options in detail.

Option 1. Composite decking

To cover the terraces, a very convenient material is a specialized decking board. It is made from a wood-polymer composite (WPC), consisting of plastic (20%) and shredded wood (80%). Composite board is a good alternative to natural wood, combining the aesthetics of wood and the hassle of plastic.

WPC boards look almost natural, but are much easier to care for. They are easy to wash, they do not require special care. WPC material is pleasant to the touch, there are no cracks and knots in it, it does not slip - thanks to the longitudinal grooves.

Advantages:

- high moisture resistance;

- heat resistance - withstands temperatures from -45 ° C to + 80 ° C;

- the presence of anti-slip grooves on the surface;

- does not need additional processing and coating;

- simple installation (dismantling);

- simple care.

The disadvantage of composite decking is the visual and tactile difference from natural wood, which, despite the efforts of manufacturers, can still be traced.

On the this moment, decking is the most popular option for terrace flooring. However, we recommend that you purchase such a decking board only in specialized and time-tested stores, for example, deckmayer.ru. This store offers excellent value for money and is well established.

Option #2. Terrace ceramics

The most suitable ceramic products for terrace floor:

- clinker;

- porcelain stoneware;

- ceramic tiles for outdoor use.

Clinker tiles (paving stones) are used for finishing terraces on the ground or on a screed. In fact, clinker is burnt brick, which has absolute frost resistance and does not absorb moisture at all. It happens with a smooth and corrugated surface, different colors: from neutral white to rich red. The shape of the clinker tiles is square or rectangular, with straight or beveled edges.

Porcelain stoneware is a frost-resistant and reliable tile that combines ceramics and granite in its composition. It is distinguished by a variety of design, thanks to the ability to imitate different materials: natural stone (any - from granite to marble), wood, leather. Only unpolished porcelain stoneware with a rough surface is suitable for terraces. Laying is carried out on a prepared concrete slab, on frost-resistant glue.

Ceramic tiles are also used for terraces. But you need to choose it more carefully than clinker and porcelain stoneware. It must be frost-resistant (look for the designation on the packaging!), Specially made for paving on the street. Products with a corrugated, structured surface are suitable. Despite the high decorativeness, it is strictly forbidden to use tiles with a glazed, shiny surface for terraces. A suitable degree of abrasion is IV or V class.

Advantages of ceramic products:

- high frost resistance;

- durability;

- color stability under the influence of precipitation and UV rays;

- variety of textures, shapes, colors;

- simple care;

- easy repair (if necessary, you can replace each tile separately).

Flaws:

- when paving, it is required to observe a slope so that water does not accumulate on the coating;

- moisture can seep into the seams between the tiles, deforming the coating;

- low impact strength;

- porcelain stoneware and ceramic tiles become slippery when iced (this drawback can be circumvented by using special rubber mats with a non-slip effect).

Ceramic tiles are laid on raised terraces, which are reinforced concrete slab with leveling strap. To fix the tiles, use a special adhesive for outdoor use.

Option #3. Concrete slabs and tiles

The terrace area can be formed by paving concrete slabs or tiles on the ground. Laying is carried out on a cement-sand base. If the terrace is a raised concrete platform, then the slabs can be glued to it using adhesive mixtures for outdoor use. However, laying on a cement-sand mortar is preferable, especially when using large concrete slabs.

With the help of large-sized concrete slabs, you can pave a large area, spending very little time on it. The shape of the plates is rectangular or square. Common sizes: 60x60 cm, 50x50 cm, 60x45 cm, 30x30 cm.

Modern concrete slabs imitate hewn natural stone or ceramics. Plates with an unusual, figured surface are especially popular. For example, with stamped lines that visually divide the slab into several bricks - for styling ceramic paving stones.

Concrete or paving slabs smaller sizes offer a greater variety of designs. They can be of any shape: rectangular, square, diamond-shaped, polygonal, complex wavy. On the surface, various embossings are often performed in the form of lines, cracks (craquelure), squeezes (“under the skin”), geometric shapes, colors, etc.

Advantages:

- strength;

- durability (at least 25-30 years);

- variety of sizes, shapes, colors and surface structures;

- the ability to create various patterns and ornaments from tiles;

- simple installation;

- ease of dismantling and restoration (for example, if it is necessary to lay communications under the coating, it is enough to remove a few tiles and then lay them in place again without changing to new ones).

Flaws:

- when paving, it is necessary to observe a slope for water flow;

- in winter, the surface of the tile can be slippery;

- with an improperly prepared base, uneven subsidence of the tile is observed;

- difficult to choose, as high and low quality tiles in the store can look the same.

Thanks to the introduction to concrete mix coloring pigments, the color of the tiles can be amazing. Now it's not just gloomy gray tones! In free sale there are tiles of absolutely any color: from white and yellow to rich red and deep blue.

Option #4. stamped concrete

It is a decorative concrete whose surface can copy natural stone slabs, paving stones, wood parquet, bricks, river pebbles, ceramic tiles. Such a surface can be made on raised terraces, the base is a reinforced concrete slab.

Advantages:

- durability;

- strength;

- the ability to imitate any material;

- solid concrete surface does not allow moisture to seep under the coating;

- ease of care.

Flaws:

- gets very hot in summer;

- when using smooth stamps, the concrete surface may be slippery;

- long installation process.

Stamped concrete is one of the most modern options obtaining a decorative coating on the terrace. To create a stamped surface, a layer of special concrete is applied to the terrace slab, on which a “printing” is performed using polyurethane stamps. After stamping, the concrete surface may look like an old pavement or elite European paving stone. At the same time, all properties of concrete (durability, strength, frost resistance) are fully preserved.

Option #5. Terrace cladding stone slabs

Stone tiles are able to harmoniously combine the terrace with the nature of the backyard. If the terrace is a raised reinforced concrete slab, then for its cladding you can use thin stone tiles, 1-2 cm thick. If you want to decorate the terrace on the ground, large slabs, 3-6 cm thick, will do. In this case, crushed stone or sand pillow.

Advantages:

- high aesthetics;

- durability;

- when abraded, it does not change its appearance, it ages beautifully.

Flaws:

- the stone is very hot in the sun;

- on impact, cracks may appear on the surface;

- seams get dirty easily.

When choosing stone tiles for terraces, pay attention to the moisture resistance and degree of abrasion of the rock. The most stable in open areas are slabs of granite, basalt, shale, syenite. On covered terraces, sandstone, travertine, limestone can be used.

Option #6. wooden boards

Wood is a traditional material for a terrace. Wooden boards create a durable, beautiful and warm to the touch coating. As a rule, he is satisfied by laying boards and wide slats on a frame of logs and girders. It is possible to lay antiseptic thick boards on a crushed stone base.

For outdoor terraces, it is recommended to use boards made of moisture-resistant hardwoods: larch, teak, oak, merbau, kumaru, iroko. They have an increased density, therefore they are not subject to decay, resistant to insects, and retain their original appearance for a long time. Similar properties can be given to the material artificially, through heat treatment. In the process of heating to combustion temperatures, the wood stops absorbing moisture, so it does not rot, crack, or deform. Heat treatment technology is used for spruce, pine, ash, beech, birch.

Advantages of a wooden surface:

- warm surface;

- depreciation properties;

- high decorative effect;

- environmental friendliness;

- a wide range of colors, sizes, structures of boards.

Flaws:

- changes color under the influence of UV rays;

- difficulties in care;

- regularly requires treatment with antifungal coatings.

In the manufacture of the terrace, planed boards (treated with antiseptics and flame retardants) or special terraced (deck) boards are used. The last option is the best. Terrace wooden boards (decking) are made only from hardwoods (otherwise, heat treatment is used). Their edges are rounded, tenon-groove fastening is not provided. Decking elements are laid at a small distance from each other, due to which atmospheric moisture flows freely through the gaps. The surface of the boards can be not only smooth, but also corrugated (with grooves) - this increases the anti-slip properties of wood.

Owners of country cottages have to deal with issues related not only to interior arrangement at home, but also the design of a terrace or a platform in the garden.

Until recently, the choice of floor coverings for such places was very limited, and many of them simply did not have an anti-slip coating, which was very inconvenient in winter. Today the situation has changed radically, in the market building materials there was a wide variety of products.

New modern materials that have all the necessary qualities to be used as a floor covering for a terrace and unheated country houses.

Floor for a summer residence - all about it

The modern market of building products offers a wide range of different options for coverings for terraces. It can be:

- PVC modules

Each of them has its own advantages and disadvantages, which must be taken into account when choosing. The most commonly used materials are vinyl.

PVC tiles: Only best qualities its constituents:

- quartz sand

- Vinyl

The first gave amazing strength, and the second good flexibility. A layer of polyurethane added high wear resistance and the result was modern material, which has a number of advantages.

The first gave amazing strength, and the second good flexibility. A layer of polyurethane added high wear resistance and the result was modern material, which has a number of advantages.

The tile is a multi-layer coating created on the basis of a polymer. It differs in size, shape and structure, which can be matte, glossy, rough.

Advantages: excellent wear resistance, resistance to mechanical stress, environmental friendliness.

Disadvantages: artificial origin.

Decking - two companies shared the palm here:

Decking - two companies shared the palm here:

- Russian - Terradek

Liquid floor - it is produced by a large number of companies. In our market the most popular are:

There are also foreign manufacturers from China and Japan on the market, but their board is more expensive.

Self-leveling floors - these mixtures are produced by a large number of different companies, among them two domestic ones are worth highlighting:

Their mixtures are not inferior in quality to foreign manufacturers, while the price is lower.

When choosing a floor covering for a summer residence, pay attention to various indicators. First of all, it looks like a terraced area. For those located on the ground, PVC tiles are ideal - they practically do not absorb water.

When choosing a floor covering for a summer residence, pay attention to various indicators. First of all, it looks like a terraced area. For those located on the ground, PVC tiles are ideal - they practically do not absorb water.

For raised options - choose porcelain stoneware. It differs in design and structure and will allow you to lay out any pattern on the floor.

The most demanded is a garden board made of natural wood. It can be used for open terraces.

Liquid wood also finds frequent use. It outwardly repeats the natural, but at the same time it is completely unaffected by moisture and wood-boring insects. Its great advantage is the corrugated surface, which prevents slipping in the winter.

Liquid wood also finds frequent use. It outwardly repeats the natural, but at the same time it is completely unaffected by moisture and wood-boring insects. Its great advantage is the corrugated surface, which prevents slipping in the winter.

The modern building materials market offers a large number of different products. Each of them has its own advantages and disadvantages, and is recommended for use in certain conditions.

If you want outdoor flooring for a summer house or terrace to be beautiful and durable, to last for a long time, then follow this advice.

So, when choosing material for open areas in the garden, be guided not only by aesthetic qualities, but also by the operational data of the material. In this case, your floor will not only be beautiful, but will also last a very long time.

- Tools and materials

- Synthetic materials

- natural materials

Before deciding what the flooring on the terrace will be, you should think about the aesthetic component of the project and take into account the functionality of the finishing material.

Raising a terrace suburban area it is best to take care of a canopy over it, so that in rainy weather you can also drink tea on it.

It is necessary that the floor for the terrace has characteristics such as frost resistance and abrasion resistance. The coating must have anti-slip properties.

If the terrace is attached to a house built in conditions of increased permafrost, frost resistance is almost the main requirement for coverage. It provides a low rate of water absorption of the material. The ideal option for a terrace would be a coating that exhibits water absorption not exceeding 3%. With this indicator, moisture will not penetrate into the elements with which the terrace floor was finished.

If the water absorption is higher, the liquid will be absorbed into the thickness of the coating, and in winter it will freeze, which will lead to damage to the coating.

The anti-slip characteristics are in no way able to affect the strength of the terrace floor covering, but the safety of the people who use it will depend on this. Therefore, special attention should be paid to the designation of the level of slipperiness on the package, the higher the number, the better.

With regard to abrasion, the material that is laid on the floor of the terrace is damaged due to exposure to sand. The minimum abrasion class characteristic of products that can be used on terraces is IV. It should be remembered that the strength of the base of the terrace will depend not only on the chosen finishing material, but also on how well the work was done. Thus, the laying of products on the floor of the terrace should be carried out in compliance with the slope, the minimum value of which should be equal to 2 percent in the direction from the wall to the edge. In addition, expansion or expansion joints, the so-called dilatation, must be made, which is especially true for terraces located on the south side of the main building. If the terrace has a small area, it will be enough to make an expansion joint in the place where the structure adjoins the wall, which will prevent the appearance of cracks on the reinforced concrete slab. With a significant width of the veranda, expansion joints should be made at intervals of 5 m.

Tools and materials

- rubber mallet;

- clinker;

- glue;

- putty knife;

- grout for seams.

Back to index

The choice of material for decorating the floor

If you decide to use ceramic tiles for the floor, only frost-resistant material should be used. Easy maintenance will be an advantage, but you need to be prepared for the fact that during the heat such a coating will become excessively hot.

When choosing terracotta, one should prefer a material that has a rough surface and is covered with a matte glaze. It is possible to lay gres on the floor in the terrace, which is characterized by resistance to abrasion, dirt and chemicals. The water absorption capacity of gres is much lower than that of the material described above. But you should avoid glazed and additionally polished gres, as polished porcelain stoneware is rather slippery.

The floor of the terrace can be covered with clinker, which is characterized by extreme hardness, frost resistance, abrasion and impact resistance. high temperatures. The water absorption of such material can vary from 0.5 to 0.7%. In order to glue ceramic tiles on the floor in the terrace, you need to apply adhesive solution, intended for outdoor work, that is, the material must be frost-resistant and characterized by increased elasticity. The adhesive should be applied to the surface of the base and tile with a notched trowel, which will reduce the risk of voids under the base of the tile, which can become a place where moisture will accumulate.

The process of moisture accumulation is dangerous for the terrace in winter, because. freezing of water in the material can cause the destruction of the coating. A few days after the laying is completed, you can rub the seams using a special grout. Contaminants arising from installation or grouting should be removed immediately using a damp sponge, which will help to eliminate the appearance of stains. Seams must be grouted with products that have hydrophobic characteristics and are able to withstand thermal stress.

stone represents natural material that blends in perfectly with the landscape. However, some of its species are characterized by low resistance to the harmful effects of atmospheric factors, which does not allow their use outside.

On the terrace, material based on igneous rocks, among which: syenite, granite, basalt, justifies itself better than others. Granite is more often used, due to its "convenient" characteristics, namely, simple processing, frost resistance, resistance to abrasion and aggressive chemical environments. Syenite has similar parameters. But it is more difficult to process, which did not allow the material to gain high popularity in the decoration of the terrace floor. Slightly worse characteristics are characteristic of metamorphic rocks.

A terrace is a platform raised above ground level, usually near a house, but it can also be a separate structure.

The weakest and in need of more careful care are sedimentary rocks, such as: sandstone, dense limestone, travertine. For the reason that the above-mentioned types of stone are characterized by high abrasion, they should be treated with an impregnation that can strengthen the surface. It is preferable to repeat the procedure annually.

When using marble to decorate the floor of the terrace, laying should be carried out on a stable, even surface, which will help prevent cracking of the material. In this case, an adhesive solution based on white cement should be used. For grouting, you need to use an elastic mass with the addition of silicone. Concrete tiles must be laid after the mortar has been spotted and then spread evenly over the surface of the base and tiles. The laying process should be accompanied by tapping on the tiles, which is done with a rubber mallet, this will allow you to get an even coating.

The floor on the terrace can also be equipped with decorative concrete. This coating can be obtained after pouring a layer of concrete on a reinforced concrete slab, which should have a thickness of 10-12 cm. If the slab was laid on the ground, the layer should have a thickness of 10-12 cm. If such concrete, which is also called stamped, laid on the ceiling, it will be necessary to make an insulating and anti-slip layer before that.

With a concrete layer thickness of 10-12 cm, before the process of laying it on the terrace, an adhesive layer must be poured. Start the application of a 6 cm layer by pouring and compacting the fiber-reinforced concrete. The minimum class of material to be used is B 25. After the surface has been leveled, a hardener must be applied. For dilatation, it is necessary to make anti-shrink cracks, filling them after a month with dilatation mass. Such a seam should also be arranged along the walls. The expansion joints of the slab, as well as the top layer of concrete, must match. In order to prevent the absorption of moisture by the concrete coating, it must be coated with acrylic impregnation.